It may not

exactly fall under the usual automotive news but a BMW Group

employee was honoured for his solution for a cheap, mobile

device for producing drinking water.

On May 26 in

Brussels, an international jury presented the National Energy

Globe Award 2007 to BMW Group designer Stephan Augustin for

his invention of the so called Watercone, a device for

generating clean drinking water.

Guests at the awards

ceremony included Mikhail Gorbachev, Jose Manuel Barroso, and

Kofi Annan.

The Watercone is a solar-powered cone-shaped desalinator that

generates fresh drinking water from salt or brackish water.

With its rigid outer

skin, this plastic cone can be used floating on water or on

damp ground.

The sunrays shining

on the Watercone cause the water to evaporate under the cone

and condense on the inside of the cone. The droplets of water

then accumulate in a collector trough. The water can be poured

out of the opening at the tip of the Watercone into a

container or drunk directly. The water is purified through the

condensation as if it were undergoing a single-stage

distillation process.

Around 1.6 litres of

drinking water a day can be obtained by using this invention.

This means that the Watercone could play a major part in

solving a number of problems.

UNICEF experts

estimate that 5,000 children still die each day from diarrheal

diseases caused by dirty drinking water. Using the Watercone,

people living in coastal regions in Africa, Asia, and South

America can also obtain drinking water from sea water. In

addition, this device also eliminates heavy metals and other

pollutants when used near rivers.

The Watercone is

made from hard-wearing, unbreakable Bayer Makrolon

polycarbonate with an anti-UV coating and has a guaranteed

working life of at least five years.

The Watercone was

even tested in the BMW wind tunnel showing it could cope with

wind speeds of up to 55 km/h without any problems. This means

that it is largely unaffected by weather.

CARE Deutschland

carried out a pilot project in the coastal town of Zinjibar in

Yemen, where it generally rains only three times a year.

Consequently, the

fishermen have to travel into the interior, sometimes up to 15

km, to find clean drinking water even though they live right

by the sea. CARE handed out 100 Watercones to ten fishermen's

families. The water quality produced was analyzed and found to

be perfect. The people in the village went one further: they

said the drinking water from the Watercone tasted better than

bottled water.

Augustin, an

industrial designer, came up with the idea of the Watercone on

holiday on the Canaries. As he looked across the sea, he

brooded about how to convert the rich stocks of sea water in

the oceans into a daily ration of drinking water.

"I wanted to use my

professional knowledge and my experience to offer people who

suffer from water shortage a humanitarian service in the form

of a practical design", says Augustin.

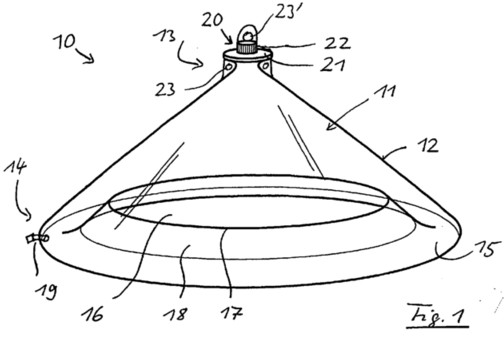

US7534327 -- Device for

Recovering Drinking Water from Condensate..

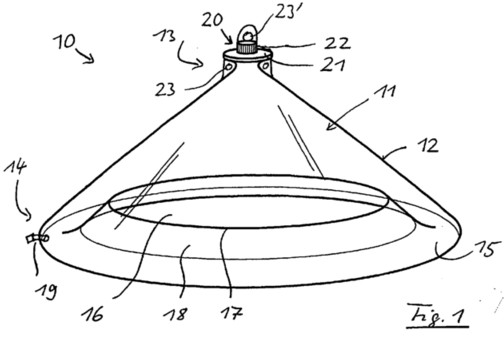

Abstract -- A device for recovering

drinking water from condensate consists of a self-supporting

moulded part 11 consisting of a transparent synthetic resin

such as PET or PC, which is resistant to UV radiation. The

moulded part 11 presents an open bottom area 16 with a

collecting channel 15 on the edge side, with the collecting

channel 15 presenting an inner wall 18 oriented towards the

circumferential surface 12 and serving, at the same time, as

floating aid, and with the moulded part 11 being provided with

a pouring opening in its upper section 13. For the manufacture

of this device, a vacuum is created in a special deep-drawing

tool not only in the region of the circumferential surface to

be produced but also in the region of the collecting channel

to be formed, and the moulded part is separated from a

separated deep-drawing tool element outside the zone of the

collecting channel

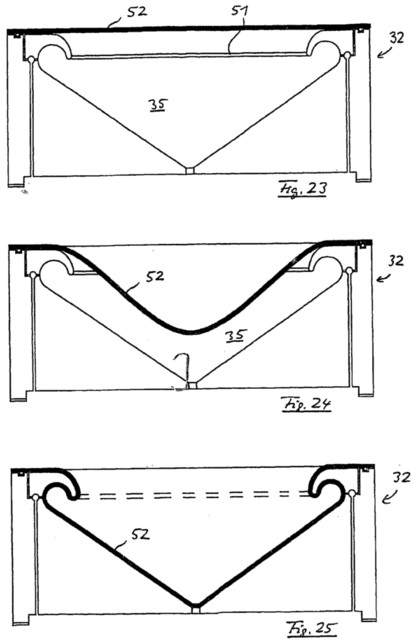

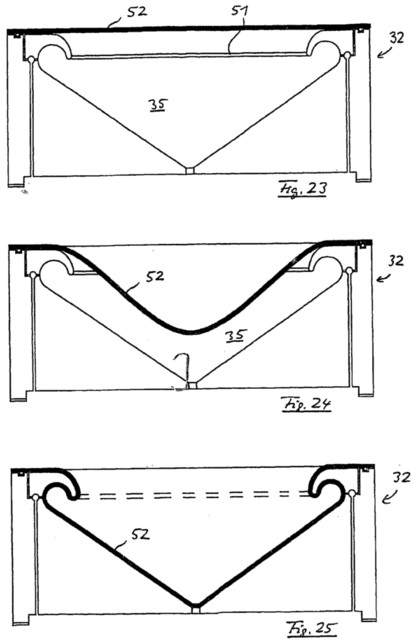

[0027] FIG. 1

is a perspective side view of a first embodiment of an

inventive device;

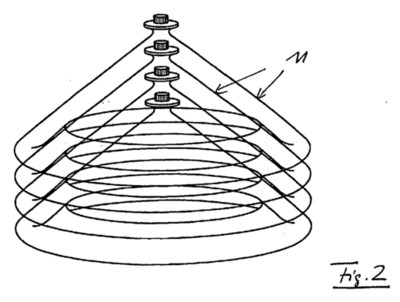

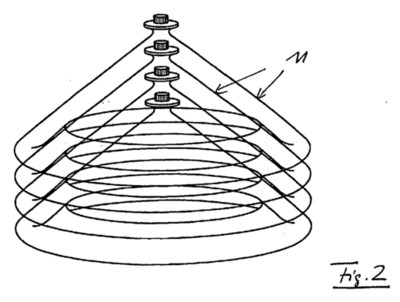

[0028] FIG. 2

is a schematic illustration of 4 devices according to FIG. 1,

which are stacked on top of each other;

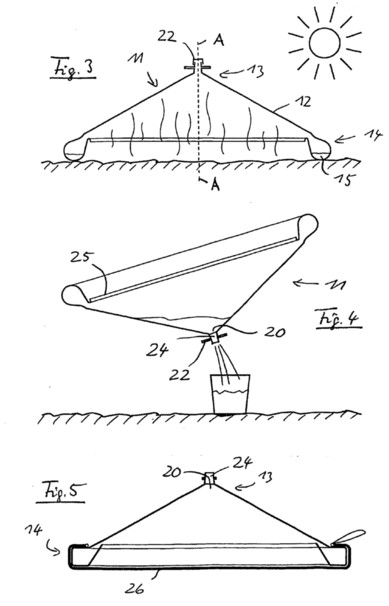

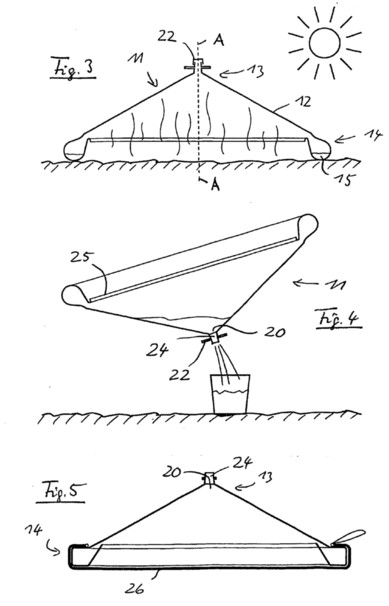

[0029] FIG. 3

shows another embodiment of the invention for explaining the

principle of operation;

[0030] FIG. 4

illustrates the embodiment according to FIG. 3 in a schematic

section in a condition in which the condensate is poured out;

[0031] FIG. 5

is a view of another embodiment of an inventive device in

which a black cloth permeable to water is stretched over the

bottom area to provide protection from the washing of the

waves and for achieving a greater evaporation heat;

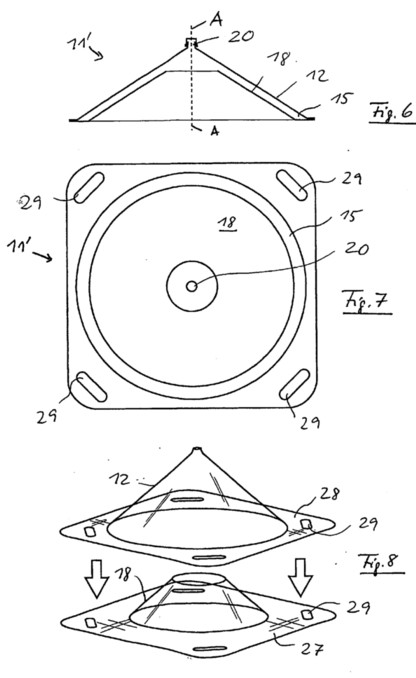

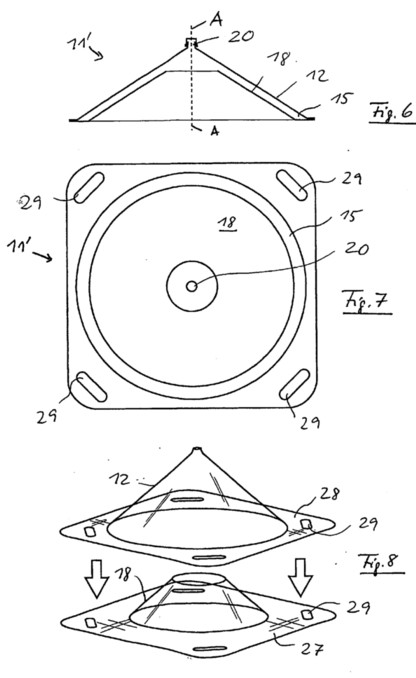

[0032] FIG. 6

shows a schematic view of a further embodiment of the

invention;

[0033] FIG. 7

is a view of the device according to FIG. 6 from below;

[0034] FIG. 8

is an illustration of the assembly of the device according to

FIG. 6;

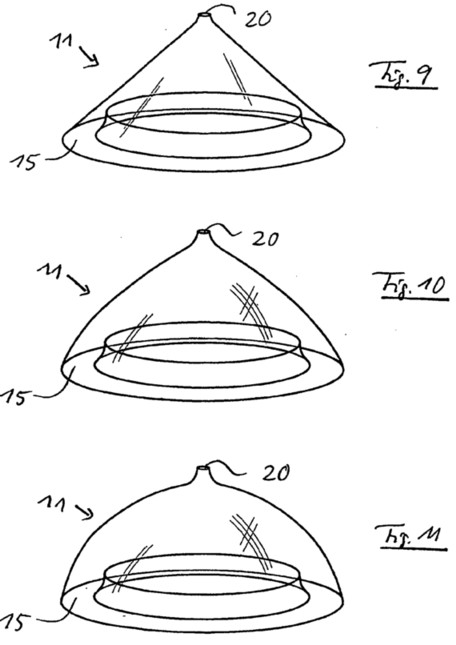

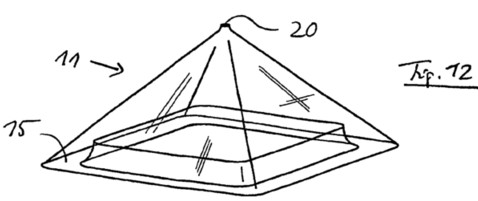

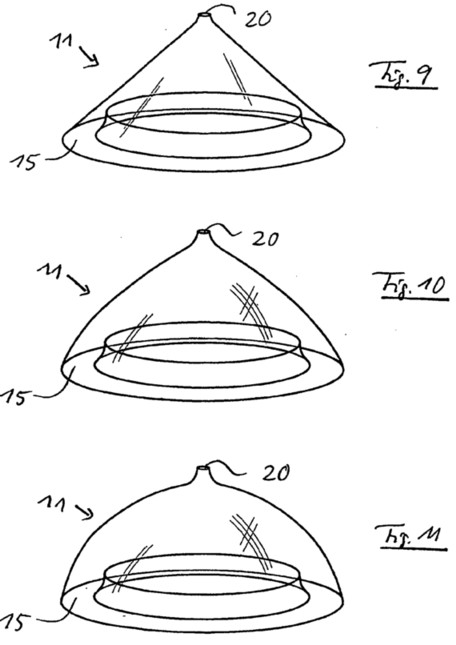

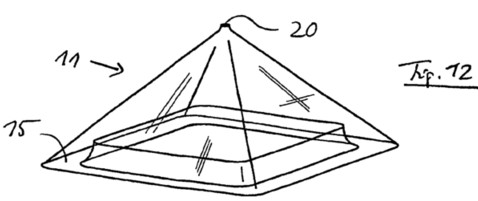

[0035] FIGS. 9

to 12 show various embodiments of devices presenting

different geometries of the outside wall;

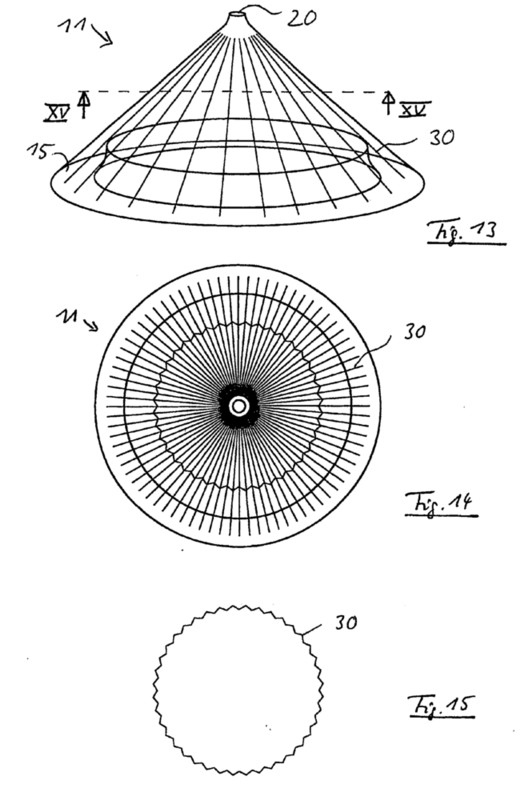

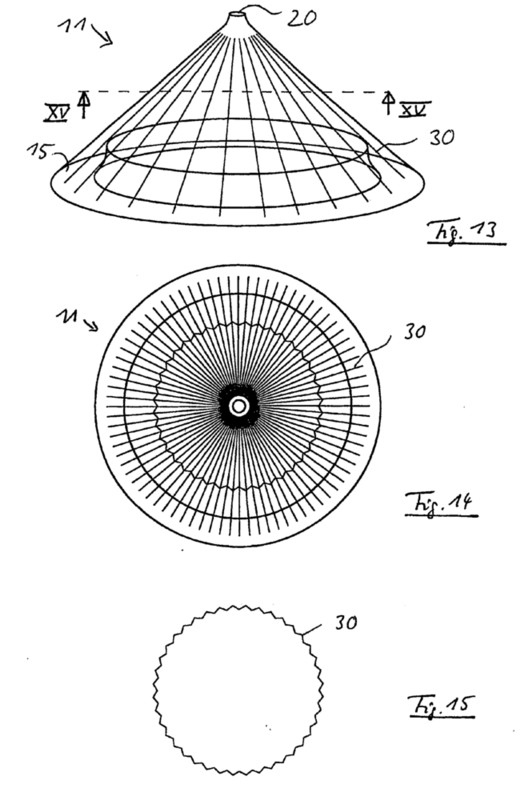

[0036] FIGS. 13

to 15 illustrate a schematic perspective side view, a

view from below and a sectional view along the line XIII-XIII

in FIG. 13;

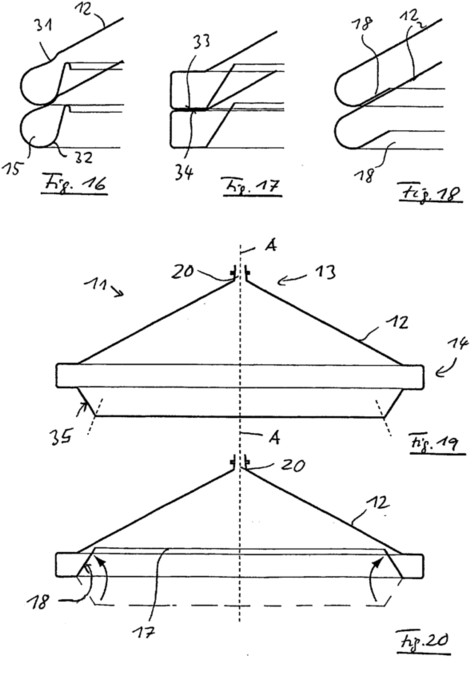

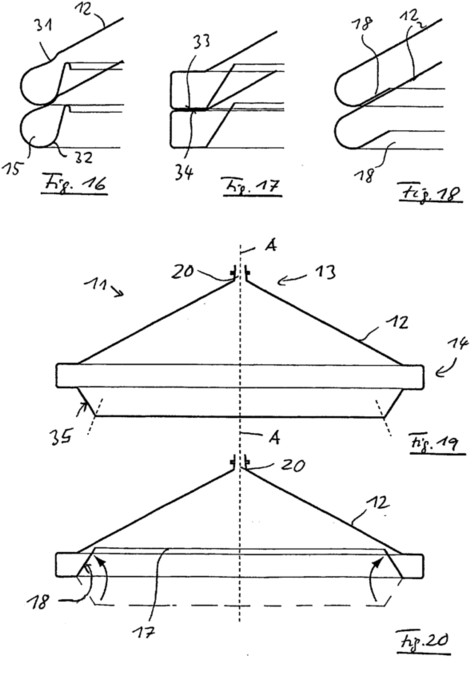

[0037] FIGS. 16

to 18 show various geometries of collecting channels

adapted to be stacked;

[0038] FIGS. 19

and 20 are schematic views of steps for the manufacture

of an embodiment of an inventive device;

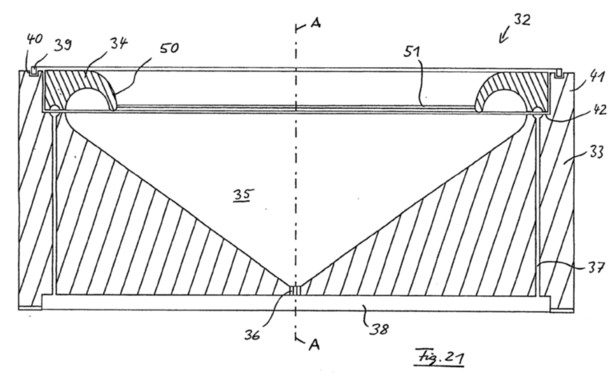

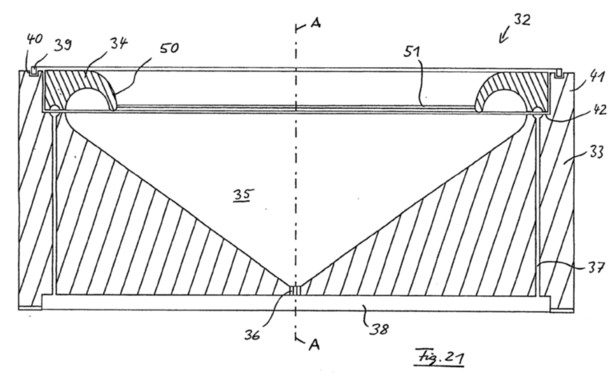

[0039] FIG. 21

shows a schematic sectional view taken through an embodiment

of an inventive deep-drawing tool for the manufacture of a

device presenting rotational symmetry;

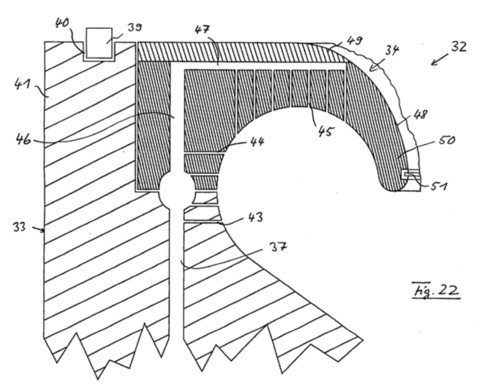

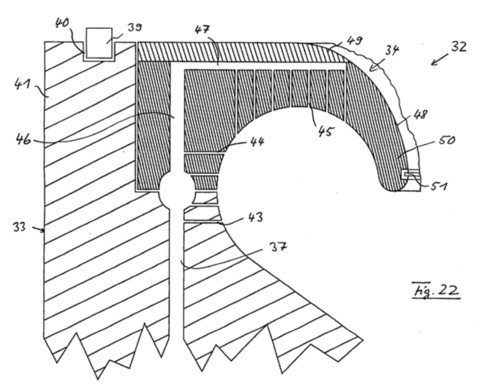

[0040] FIG. 22

is a partial sectional view at an enlarged scale in the upper

left area in FIG. 21 for the illustration of air suction

bores; and

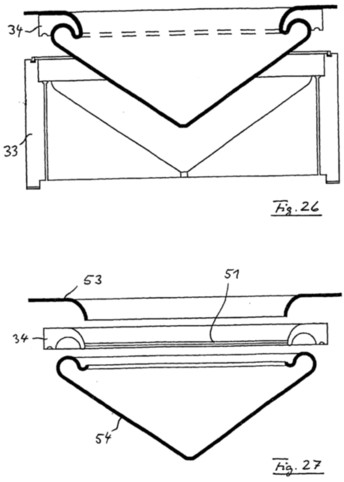

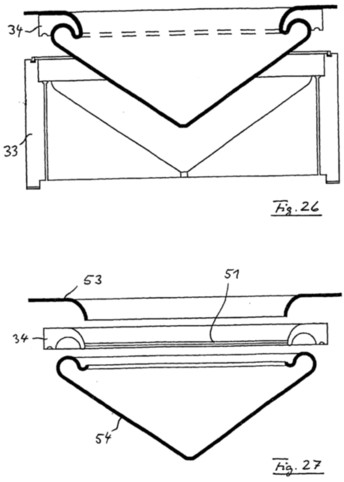

[0041] FIGS. 23

to 27 illustrate individual steps in the manufacture of

one embodiment of the inventive device, using an inventive

deep-drawing tool.