Sheerang CHHATRE, et al.

Fog-Collector

Fog-Collector

Out

of thick air

MIT

graduate student is working to make water available for

the world’s poor by refining the tools and techniques of

fog harvesting.

Peter Dizikes

In the arid Namib Desert on the west coast of Africa, one type of beetle has found a distinctive way of surviving. When the morning fog rolls in, the Stenocara gracilipes species, also known as the Namib Beetle, collects water droplets on its bumpy back, then lets the moisture roll down into its mouth, allowing it to drink in an area devoid of flowing water.

What nature has developed, Shreerang Chhatre wants to refine, to help the world’s poor. Chhatre is an engineer and aspiring entrepreneur at MIT who works on fog harvesting, the deployment of devices that, like the beetle, attract water droplets and corral the runoff. This way, poor villagers could collect clean water near their homes, instead of spending hours carrying water from distant wells or streams. In pursuing the technical and financial sides of his project, Chhatre is simultaneously a doctoral candidate in chemical engineering at MIT; an MBA student at the MIT Sloan School of Management; and a fellow at MIT’s Legatum Center for Development and Entrepreneurship.

Access to water is a pressing global issue: the World Health Organization and UNICEF estimate that nearly 900 million people worldwide live without safe drinking water. The burden of finding and transporting that water falls heavily on women and children. “As a middle-class person, I think it’s terrible that the poor have to spend hours a day walking just to obtain a basic necessity,” Chhatre says.

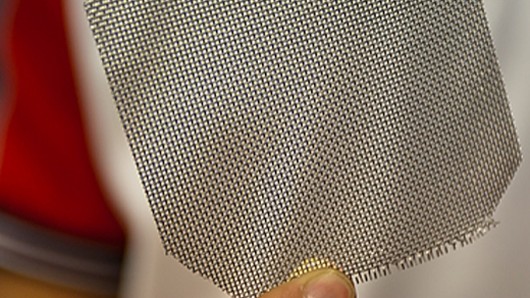

A fog-harvesting device consists of a fence-like mesh panel, which attracts droplets, connected to receptacles into which water drips. Chhatre has co-authored published papers on the materials used in these devices, and believes he has improved their efficacy. “The technical component of my research is done,” Chhatre says. He is pursuing his work at MIT Sloan and the Legatum Center in order to develop a workable business plan for implementing fog-harvesting devices.

Peter Dizikes

In the arid Namib Desert on the west coast of Africa, one type of beetle has found a distinctive way of surviving. When the morning fog rolls in, the Stenocara gracilipes species, also known as the Namib Beetle, collects water droplets on its bumpy back, then lets the moisture roll down into its mouth, allowing it to drink in an area devoid of flowing water.

What nature has developed, Shreerang Chhatre wants to refine, to help the world’s poor. Chhatre is an engineer and aspiring entrepreneur at MIT who works on fog harvesting, the deployment of devices that, like the beetle, attract water droplets and corral the runoff. This way, poor villagers could collect clean water near their homes, instead of spending hours carrying water from distant wells or streams. In pursuing the technical and financial sides of his project, Chhatre is simultaneously a doctoral candidate in chemical engineering at MIT; an MBA student at the MIT Sloan School of Management; and a fellow at MIT’s Legatum Center for Development and Entrepreneurship.

Access to water is a pressing global issue: the World Health Organization and UNICEF estimate that nearly 900 million people worldwide live without safe drinking water. The burden of finding and transporting that water falls heavily on women and children. “As a middle-class person, I think it’s terrible that the poor have to spend hours a day walking just to obtain a basic necessity,” Chhatre says.

A fog-harvesting device consists of a fence-like mesh panel, which attracts droplets, connected to receptacles into which water drips. Chhatre has co-authored published papers on the materials used in these devices, and believes he has improved their efficacy. “The technical component of my research is done,” Chhatre says. He is pursuing his work at MIT Sloan and the Legatum Center in order to develop a workable business plan for implementing fog-harvesting devices.

Beyond beetle juice

Interest in fog harvesting dates to the 1990s, and increased when new research on Stenocara gracilipes made a splash in 2001. A few technologists saw potential in the concept for people. One Canadian charitable organization, FogQuest, has tested projects in Chile and Guatemala.

Chhatre’s training as a chemical engineer has focused on the wettability of materials, their tendency to either absorb or repel liquids (think of a duck’s feathers, which repel water). A number of MIT faculty have made advances in this area, including Robert Cohen of the Department of Chemical Engineering; Gareth McKinley of the Department of Mechanical Engineering; and Michael Rubner of the Department of Materials Science and Engineering. Chhatre, who also received his master's degree in chemical engineering from MIT in 2009, is co-author, with Cohen and McKinley among other researchers, of three published papers on the kinds of fabrics and coatings that affect wettability.

One basic principle of a good fog-harvesting device is that it must have a combination of surfaces that attract and repel water. For instance, the shell of Stenocara gracilipes has bumps that attract water and troughs that repel it; this way, drops collects on the bumps, then run off through the troughs without being absorbed, so that the water reaches the beetle’s mouth.

To build fog-harvesting devices that work on a human scale, Chhatre says, “The idea is to use the design principles we developed and extend them to this problem.”

To build larger fog harvesters, researchers generally use mesh, rather than a solid surface like a beetle’s shell, because a completely impermeable object creates wind currents that will drag water droplets away from it. In this sense, the beetle’s physiology is an inspiration for human fog harvesting, not a template. “We tried to replicate what the beetle has, but found this kind of open permeable surface is better,” Chhatre says. “The beetle only needs to drink a few micro-liters of water. We want to capture as large a quantity as possible.”

In some field tests, fog harvesters have captured one liter of water (roughly a quart) per one square meter of mesh, per day. Chhatre and his colleagues are conducting laboratory tests to improve the water collection ability of existing meshes.

FogQuest workers say there is more to fog harvesting than technology, however. “You have to get the local community to participate from the beginning,” says Melissa Rosato, who served as project manager for a FogQuest program that has installed 36 mesh nets in the mountaintop village of Tojquia, Guatemala, and supplies water for 150 people. “They’re the ones who are going to be managing and maintaining the equipment.” Because women usually collect water for households, Rosato adds, “If women are not involved, chances of a long-term sustainable project are slim.”

Finding financing for fog harvesting

Whatever Chhatre’s success in the laboratory, he agrees it will not be easy to turn fog-harvesting technology into a viable enterprise. “My consumer has little monetary power,” he notes. As part of his Legatum fellowship and Sloan studies, Chhatre is analyzing which groups might use his potential product. Chhatre believes the technology could also work on the rural west coast of India, north of Mumbai, where he grew up.

Another possibility is that environmentally aware communities, schools or businesses in developed countries might try fog harvesting to reduce the amount of energy needed to obtain water. “As the number of people and businesses in the world increases and rainfall stays the same, more people will be looking for alternatives,” says Robert Schemenauer, the executive director of FogQuest.

Indeed, the importance of water-supply issues globally is one reason Chhatre was selected for his Legatum fellowship.

“We welcomed Shreerang as a Legatum fellow because it is an important problem to solve,” notes Iqbal Z. Quadir, director of the Legatum Center. “About one-third of the planet’s water that is not saline happens to be in the air. Collecting water from thin air solves several problems, including transportation. If people do not spend time fetching water, they can be productively employed in other things which gives rise to an ability to pay. Thus, if this technology is sufficiently advanced and a meaningful amount of water can be captured, it could be commercially viable some day.”

Quadir also feels that if Chhatre manages to sell a sufficient number of collection devices in the developed world, it could contribute to a reduction in price, making it more viable in poor countries. “The aviation industry in its infancy struggled with balloons, but eventually became a viable global industry,” Quadir adds. “Shreerang’s project addresses multiple problems at the same time and, after all, the water that fills our rivers and lakes comes from air.”

That said, fog harvesting remains in its infancy, technologically and commercially, as Chhatre readily recognizes. “This is still a very open problem,” he says. “It’s a work in progress.”

http://www.nature.com/nature/journal/v414/n6859/full/414033a0.html

Nature 414, 33-34 (1 November 2001) | doi:10.1038/35102108

Water

capture by a desert beetle

This insect has a tailor-made covering for collecting water from early-morning fog.

Andrew R. Parker & Chris R. Lawrence

This insect has a tailor-made covering for collecting water from early-morning fog.

Andrew R. Parker & Chris R. Lawrence

Abstract -- Some beetles in the Namib Desert collect drinking water from fog-laden wind on their backs1. We show here that these large droplets form by virtue of the insect's bumpy surface, which consists of alternating hydrophobic, wax-coated and hydrophilic, non-waxy regions. The design of this fog-collecting structure can be reproduced cheaply on a commercial scale and may find application in water-trapping tent and building coverings, for example, or in water condensers and engines.

NBD

Nano

Enhanced Condensation Technology

Enhanced Condensation Technology

NBD Nano is developing a novel state of the art hydrophobic coating to address the water energy nexus. By coating condenser tubes, similar to those in power plants and thermal desalination plants, NBD Nano is able to improve the condensation heat transfer up to 200% in pure steam environments.

It is estimated that a 1% system level efficiency improvement in power plants can lead to $10,000,000 in additional revenues for a single power plant per year and can reduce CO2 emissions dramatically. Despite the advancements in improving condensation heat transfer, it has been a significant challenge for researchers to create long lasting coatings to meet the durability requirements in real world applications.

NBD Nano has developed a coating that has demonstrated longer durability and performance than existing hydrophobic coatings due to stronger adhesion properties. The technology was first invented in Dr. Kwang Kim’s lab at the University of Nevada Las Vegas. Dr. Kim is well regarded as one of the leading researchers in the field of dropwise condensation.

Product

Characteristics

150-200% condensation heat transfer improvement in pure steam

150-200% condensation heat transfer improvement in pure steam

Tested up to 500 hours with little to no performance loss

Dip and Spray scalable application techniques

Dip and Spray scalable application techniques

Fog

Capture

Water is one of Earth’s most precious resources.

Unfortunately, we are living in a time where access to fresh

water has become unreliable and disproportionate globally.

The urgency for implementing innovative approaches to

harvest clean water sustainably has become even more

eminent.

NBD Nano is developing a new generation of fog-nets to help provide relief for drought-affected areas both in the US and around the world. Fog harvesting has been used for centuries in places like South America, proving plenty of clean drinking water for remote villages. Unfortunately, the ripe conditions for fog harvesting that are present in South America are not prevalent in most places of the world. Conventional nets simply don’t work.

By coating meshes with NBD Nano’s hydrophobic coating, NBD Nano is able to consistently increase the rate of fog harvesting in coastal areas. Recent data suggest the NBD Nano coating can improve capture rates by 5x in fog events. The company was recently awarded a grant from the US Department of Agriculture to set up pilot sites in coastal regions. NBD Nano’s commercialization efforts are to make this product available to the areas that need it most...

https://www.nbdnano.com/article/dry-run-can-humans-survive-on-water-vapor-alone/

Dry Run: Can Humans Survive on Water Vapor Alone?

Tim Berners-Lee, et al,

THE WORLD IS full of water, flushing down our toilets and flowing from our taps. And yet where I live, in the American Southwest, and quite possibly where you live, the kind of water people need to survive is getting harder to come by. Across the region, temperatures are rising and droughts are getting more severe, and in the coming decades the West will struggle to supply the water its residents and businesses demand. Even in wetter regions like the Gulf Coast, where the storms are getting stronger and the rainfall more persistent, much of that water glut is washing back out to sea, unused, leaving a path of destruction in its wake.

So I worry about the stuff: where it’ll come from, who will own it, when it will dry up. To steady my mind, I’ve turned to technology. More exactly, the emerging innovations that will keep us hydrated in the not-so-distant desertified future. There’s a company called NBD Nanotechnologies, based in Boston, which makes coatings that can be added to plastic and metal surfaces, allowing them to pull water out of thin air. (NBD stands for Namib Beetle Design, referring to an insect that captures moisture on its body from surrounding fog.)

Then I found a company called Zero Mass Water, based in Scottsdale, Arizona, that produces $2,000 “hydropanels” that the company claims can capture water vapor from air. One panel can make up to five liters a day, and two of them together could produce enough for a household’s daily drinking and cooking. In theory, someone—even me—could strap one of these panels to the bed of a truck, drive out to the desert, and live off the grid with water to spare.

The company’s founder and CEO had his doubts. Cody Friesen is a professor of materials science at Arizona State University with a booming, radio-ready voice, and he told me a few times over the phone that, while he appreciated my outside-the-box thinking, his hydropanels weren’t intended for vehicular use. They weigh 275 pounds and are intended for yards and rooftops, not truck beds. The “vibrational activity” involved with desert off-roading concerned him. But I pressed him, and after conferring with his engineering team he eventually said that it could be done or, at least this one time, tried. Once the truck-bound panel was ready, Friesen invited me out. “Will it work?” I asked him when I arrived in Scottsdale.

“Probably,” he said, grinning.

I drove northeast into the high desert in a black Toyota Tundra, past the jagged Superstition Mountains, and worked my way up the escarpment of the Mogollon Rim that borders the Sonoran Desert. Five hours after leaving the city, I pulled over and watched the sky go orange, then pink, then purple, and I felt my throat tighten as my mouth started to dry. Walking toward the strange rig at the truck’s rear, a 5-inch-thick black panel roughly the size and shape of the cab and tilted upward at a 35-degree angle, I found myself asking a question that was both very, very old and (for my purposes, anyway) entirely new: Would I have the water I needed to survive?

I’d put my trust in these panels. Hydrophilic membranes trap water vapor from air that’s blown across them by a solar-powered fan. The vapor-turned-water then drops and pools and flows through a series of mineral cartridges to make it more drinkable. Because both the landscape and the water vapor in the air are changing all the time, the panels connect to HQ back in Scottsdale via a mesh network, and Zero Mass Water staffers upload predictive algorithms that adjust fan speeds and maximize energy efficiency.

As the sky darkened, a chill ran through my body, mostly because it was suddenly quite cold, but also because seeds of doubt were germinating. The fans at the panel’s sides were making a faint whinging sound, still blowing as the last of the solar power worked in the gloaming light. As darkness gathered, I used a flashlight to find the small black nozzle where the water was supposed to flow. Turning it, I held my breath. And after some chugging and wheezing from the pump, water spewed out. I danced a small, silent desert dance, in celebration and to warm me up, then caught myself. Water was pouring out! I was wasting it. And how much did I have? I checked the reservoir. It looked like at least a few liters. More than enough to get me through the night.

NBD Nano is developing a new generation of fog-nets to help provide relief for drought-affected areas both in the US and around the world. Fog harvesting has been used for centuries in places like South America, proving plenty of clean drinking water for remote villages. Unfortunately, the ripe conditions for fog harvesting that are present in South America are not prevalent in most places of the world. Conventional nets simply don’t work.

By coating meshes with NBD Nano’s hydrophobic coating, NBD Nano is able to consistently increase the rate of fog harvesting in coastal areas. Recent data suggest the NBD Nano coating can improve capture rates by 5x in fog events. The company was recently awarded a grant from the US Department of Agriculture to set up pilot sites in coastal regions. NBD Nano’s commercialization efforts are to make this product available to the areas that need it most...

https://www.nbdnano.com/article/dry-run-can-humans-survive-on-water-vapor-alone/

Dry Run: Can Humans Survive on Water Vapor Alone?

Tim Berners-Lee, et al,

THE WORLD IS full of water, flushing down our toilets and flowing from our taps. And yet where I live, in the American Southwest, and quite possibly where you live, the kind of water people need to survive is getting harder to come by. Across the region, temperatures are rising and droughts are getting more severe, and in the coming decades the West will struggle to supply the water its residents and businesses demand. Even in wetter regions like the Gulf Coast, where the storms are getting stronger and the rainfall more persistent, much of that water glut is washing back out to sea, unused, leaving a path of destruction in its wake.

So I worry about the stuff: where it’ll come from, who will own it, when it will dry up. To steady my mind, I’ve turned to technology. More exactly, the emerging innovations that will keep us hydrated in the not-so-distant desertified future. There’s a company called NBD Nanotechnologies, based in Boston, which makes coatings that can be added to plastic and metal surfaces, allowing them to pull water out of thin air. (NBD stands for Namib Beetle Design, referring to an insect that captures moisture on its body from surrounding fog.)

Then I found a company called Zero Mass Water, based in Scottsdale, Arizona, that produces $2,000 “hydropanels” that the company claims can capture water vapor from air. One panel can make up to five liters a day, and two of them together could produce enough for a household’s daily drinking and cooking. In theory, someone—even me—could strap one of these panels to the bed of a truck, drive out to the desert, and live off the grid with water to spare.

The company’s founder and CEO had his doubts. Cody Friesen is a professor of materials science at Arizona State University with a booming, radio-ready voice, and he told me a few times over the phone that, while he appreciated my outside-the-box thinking, his hydropanels weren’t intended for vehicular use. They weigh 275 pounds and are intended for yards and rooftops, not truck beds. The “vibrational activity” involved with desert off-roading concerned him. But I pressed him, and after conferring with his engineering team he eventually said that it could be done or, at least this one time, tried. Once the truck-bound panel was ready, Friesen invited me out. “Will it work?” I asked him when I arrived in Scottsdale.

“Probably,” he said, grinning.

I drove northeast into the high desert in a black Toyota Tundra, past the jagged Superstition Mountains, and worked my way up the escarpment of the Mogollon Rim that borders the Sonoran Desert. Five hours after leaving the city, I pulled over and watched the sky go orange, then pink, then purple, and I felt my throat tighten as my mouth started to dry. Walking toward the strange rig at the truck’s rear, a 5-inch-thick black panel roughly the size and shape of the cab and tilted upward at a 35-degree angle, I found myself asking a question that was both very, very old and (for my purposes, anyway) entirely new: Would I have the water I needed to survive?

I’d put my trust in these panels. Hydrophilic membranes trap water vapor from air that’s blown across them by a solar-powered fan. The vapor-turned-water then drops and pools and flows through a series of mineral cartridges to make it more drinkable. Because both the landscape and the water vapor in the air are changing all the time, the panels connect to HQ back in Scottsdale via a mesh network, and Zero Mass Water staffers upload predictive algorithms that adjust fan speeds and maximize energy efficiency.

As the sky darkened, a chill ran through my body, mostly because it was suddenly quite cold, but also because seeds of doubt were germinating. The fans at the panel’s sides were making a faint whinging sound, still blowing as the last of the solar power worked in the gloaming light. As darkness gathered, I used a flashlight to find the small black nozzle where the water was supposed to flow. Turning it, I held my breath. And after some chugging and wheezing from the pump, water spewed out. I danced a small, silent desert dance, in celebration and to warm me up, then caught myself. Water was pouring out! I was wasting it. And how much did I have? I checked the reservoir. It looked like at least a few liters. More than enough to get me through the night.

https://news.mit.edu/2013/how-to-get-fresh-water-out-of-thin-air-0830

How to get fresh water out of thin air

Fog-harvesting system developed by MIT and Chilean researchers could provide potable water for the world’s driest regions.

...Fog-harvesting systems generally consist of a vertical mesh, sort of like an oversized tennis net. Key to efficient harvesting of the tiny airborne droplets of fog are three basic parameters, the researchers found: the size of the filaments in those nets, the size of the holes between those filaments, and the coating applied to the filaments.

Most existing systems turn out to be far from optimal, Park says. Made of woven polyolefin mesh — a kind of plastic that is easily available and inexpensive — they tend to have filaments and holes that are much too large. As a result, they may extract only about 2 percent of the water available in a mild fog condition, whereas the new research shows that a finer mesh could extract 10 percent or more, Park says. Multiple nets deployed one behind another could then extract even more, if so desired...

The researchers found that controlling the size and structure of the mesh and the physical and chemical composition of this coating was essential to increasing the fog-collecting efficiency. Detailed calculations and laboratory tests indicate that the best performance comes from a mesh made of stainless-steel filaments about three or four times the thickness of a human hair, and with a spacing of about twice that between fibers. In addition, the mesh is dip-coated, using a solution that decreases a characteristic called contact-angle hysteresis. This allows small droplets to more easily slide down into the collecting gutter as soon as they form, before the wind blows them off the surface and back into the fog stream...

...with the MIT-designed system, Park points out, 10 percent of the fog moisture in the air passing through the new fog collector system can potentially be captured...

Langmuir, Vol 29/Issue 43, July 29, 2013

Optimal Design of Permeable Fiber Network Structures for Fog Harvesting

Kyoo-Chul Park, et al.

Abstract -- Fog represents a large untapped source of potable water, especially in arid climates. Numerous plants and animals use textural and chemical features on their surfaces to harvest this precious resource. In this work, we investigate the influence of the surface wettability characteristics, length scale, and weave density on the fog-harvesting capability of woven meshes. We develop a combined hydrodynamic and surface wettability model to predict the overall fog-collection efficiency of the meshes and cast the findings in the form of a design chart. Two limiting surface wettability constraints govern the re-entrainment of collected droplets and clogging of mesh openings. Appropriate tuning of the wetting characteristics of the surfaces, reducing the wire radii, and optimizing the wire spacing all lead to more efficient fog collection. We use a family of coated meshes with a directed stream of fog droplets to simulate a natural foggy environment and demonstrate a five-fold enhancement in the fog-collecting efficiency of a conventional polyolefin mesh. The design rules developed in this work can be applied to select a mesh surface with optimal topography and wetting characteristics to harvest enhanced water fluxes over a wide range of natural convected fog environments.

WO2023230244 -- METHOD AND SYSTEM FOR FOG HARVESTING AND MIST ELIMINATION

[ PDF ]

Abstract -- A system for harvesting fog that includes a core, where the core features a rod-like structure that is configured to direct accumulated fog droplets in a downward direction. The system also includes a plurality of trichomes mounted to the core such that each of the trichomes is configured to accumulate the fog droplets. Interstitial spaces are formed in between trichomes to wick the fog droplets and coalesce them into one or more continuous fluid streams along a length of the core. The system collects the accumulated fog droplets and directs them in a downward direction along the core towards a bulk outflow.

US11680391 -- SURFACES WITH HIGH SURFACE AREAS FOR ENHANCED CONDENSATION AND AIRBORNE LIQUID DROPLET COLLECTION

[ PDF ]

Abstract -- Omniphilic and superomniphilic surfaces for simultaneous vapor condensation and airborne liquid droplet collection are provided. Also provided are methods for using the surfaces to condense liquid vapor and/or capture airborne liquid droplets, such as water droplets found in mist and fog. The surfaces provide enhanced capture and transport efficiency based on preferential capillary condensation on high surface energy surfaces, thin film dynamics, and force convection.

US9352258 -- LIQUID COLLECTING PERMEABLE STRUCTURES

[ PDF ]

Abstract -- A structure for collecting liquid droplets from an aerosol can have a structure and properties that are selected for efficient liquid collection. In particular, the strand radius and spacing of a mesh, and a material for coating the mesh, can be selected to provide efficient collection of water droplets from fog.