Michael ELLSWORTH

Atmospheric Water Generator

A2WH ( Air to Water Harvest )

(AWG)

Atmospheric Water Generator using solar energy

A2WH ( Air to Water

Harvest ) technology extracts the humidity in air and

converts it into liquid water. A2WH is a new generation

of solar powered atmospheric water generator device (AWG)

which are also known as water maker devices (WM) and Water Air

Extraction Devices (WAED). A2WH uses a

revolutionary patent pending solar heat design which does not

require refrigeration. This allows A2WH to operate

cost effectively directly from renewable energy and makes A2WH

ideal for off grid deployment, remote cabins, islands and

other locations where electricity is abnormally expensive.

...

A2WH has designed a patent pending solar thermal powered

system which is fundementally different than common

refrigeration based units. The A2WH design allows allow us to

absorb moisture from relatively dry air with a much lower

energy cost. We use solar heat which keeps the energy

costs low. A major difference is that we can

condense at ambient which eliminates the need for

refrigeration which is the big electricity consumer in most

other WAED units.

This allows A2WH to be

deployed in large scale and to provide much lower operational

costs. These combine to make A2WH scalable from a few liters per

day through millions of gallons.

A2WH requires full sun

exposure. This means it must be installed outside in areas

without significant shade.

With a single acre of land the A2WH A2WH

units can produce in the range 1,000 to 2,500 gallons per day of

water without having any impact on the local water company or

drawing any power from the local utility company...

...The A2WH A2WH units

do not impact the local ground water and they are using a

resource that is completely renewable so there is no risk of

running out in the future...

A2WH Product Overview

The A2WH system produces pure potable water

from air using only solar energy. It operates with a much

lower operating cost than other AWG systems because it does not

require large amounts of electricity.

The A2WH system absorbs moisture at night

when humidity is relatively high and converts what it absorbed

the prior night into liquid water the following day using solar

thermal heat. Well over 90% of the energy used in the system is

solar heat.

In this system all condensing occurs at

near ambient and it does not require any refrigeration. High

quality filters are used to filter the air before the absorption

at night which keeps the interior of the system very

clean.

A HEPPA grade filter is used for the gas

entering the condenser chamber which keeps the water quality

near surgical grade. The system includes an automatic mode where

it sterilizes the condensing area on days when there is

sufficient solar energy to reach pasteurization temperatures.

A small amount of energy is delivered by

Photo Voltaic panels which operate a microcomputer control

system, sensors, blowers, pumps, etc...

How does

A2WH work?

The A2WH system uses a

desiccant to absorb moisture from the air. The

higher the humidity the more water our desiccant can absorb per

pass which increases production.

We use solar heat to

drive both the airflow for the absorption process and to provide

heat during the regeneration process which extracts the moisture

from the desiccant and allows us to capture the water in liquid

form.

A sophisticated micro

controller based sensor system determines when to switch between

absorption and regeneration modes. We use different

types and amounts of desiccants depending on the local

conditions to optimize the performance of the

system. A small Photo Voltaic

solar panel provides power for the micro controller, sensors,

various valves, etc.

We have an optional

enhancement that uses wind energy (wind over 4.5 MPH) to drive

circulation at night when the relative humidity is higher.

To make this work best we increase the weight of the

desiccant used in the system. In some areas with

good nightly wind this allows the unit to work in areas with

daytime humidity as low as 10% We have optional

enhancements which allow electric fans and heaters to augment or

replace the solar heat.

The input air is

filtered before it enters the absorption chamber where the

desiccant absorbs water out of it. The air is re-filtered

when heated for regeneration. A final stage of filtering

is used as the air enters the condensation phase where the H2O

is turned into liquid water. As a result the output water

is very pure. We still recommend treatment

using a NSF 54 grade filter prior to consumption because we do

not have any control over the cleanliness of the storage

tank....

Our difference from common market

units.

Most Air to water

systems use refrigeration to chill air to the dew point that

means that as the dew point drops the more the unit must do more

work to sufficiently chill the air. This

causes them to use large amounts of electricity. It is

fairly common for electric units to consume of 2.2Kwh per gallon

produced which gives them a high variable operating costs which

can exceed 40 cents per gallon.

We designed A2WH units

to operate entirely from solar energy. This is mostly

solar heat with a small amount of solar electricity used to

operate valves, sensors and the electronic control

system. This allows our system to operate much more

efficiently which is especially important in areas where

electricity is expensive such as islands where electricity is

generated using imported fuels.

Most AWG systems are

built around a refrigeration system which is very similar to

that used in small electric air conditioners. The best

units consume 600 to over 3,000 watt hours per gallon of water

they produce. The industry average trends

show consumption over 2,2000 watt hours per gallon which

rise rapidly as humidity drops.

A2WH functions with no

external electricity. This saves 3,000 watts per gallon.

Our novel design and control system allows it to efficiently

extract water in a wide range of conditions including conditions

where electric AWG units become inefficient or do not work at

all.

Our units can reduce

carbon emissions by over 5 pounds of carbon per gallon produced

as compared to grid powered electric systems. (2.2 pounds

carbon per KWh saved * 3000 watts per gallon = 6.4 pounds

of carbon per gallon of water). Even a small 6

gallon per day system this adds up to nearly 11,000 pounds

reduced carbon emissions per year.

Our system uses solar

thermal heat to harvest water from air even when the air has low

humidity. Unlike radiant condensation systems this

system actually produces during the dry months even when there

is no dew and it's production can go up in windy locations which

can prevent radiant chilling systems from working at

all. Our technology can work in conditions where the

dew point is far below the chilling level delivered by radiant

chilling panels.

Our most important

difference is the compatibility of the core design for scaling

efficiently into millions of gallons per day at a reasonable

cost. It's other major benefit is compatibility with

remote areas where grid power is either unavailable or

expensive. In some areas our units can be installed

in mountains outside of towns and provide both water pressure

and electricity for the town. Rather than exaggerate

summer power shortages our system can actually help reduce these

shortages.

Absorption/regeneration

non-conventional system for water extraction from

atmospheric air

Ahmed Sultan, et al.

Abstract -- The present work

suggests a non-conventional method of water production from

atmospheric air, on a 24-h basis using a compact system. The

operation of the system is described and its efficiency is

defined. The system performs under forced convection absorption

and regeneration through a packed tower. The packed tower

consists of two identical columns, each of them is packed with

an identical bed. Each bed consists of vertical multi-layers of

cloth material impregnated with calcium chloride solution of

different concentrations. A numerical model, based on the

experimental results, has been developed to predict the

performance of the system under various operating conditions.

The system efficiency is found to have peak values at certain

cycle times, desiccant final concentration, regeneration

temperature and absorption air stream velocity. It is also found

that the maximum efficiency increases with initial concentration

and decreases with the increase of the regeneration air stream

velocity and absorption temperature.

US6490874 -- Recuperative Environmental Conditioning Unit

Abstract -- A method and

apparatus for removing moisture from within an electronics

enclosure is provided. In particular, dehumidification is

accomplished by removing air from the enclosure, cooling the

air thereby causing condensation of water vapor from the air,

then heating the dehumidified air and returning the heated and

dehumidified air to the enclosure. A single heat pump provides

cooling and heating functions, effectively recouping heat

extracted from the air to be cooled, and transferring the

extracted heat to the air prior to its return to the

enclosure. In this manner, electronics within the enclosure

may be operated at temperatures below the dew point of ambient

air surrounding the enclosure, without requiring a thermally

insulated enclosure. Devices are provided to collect and purge

condensate from the system, either in a continuous or periodic

manner.; Embodiments employing conventional vapor compression

cycle heat pumps and thermoelectric heat pumps are described.

A defrost cycle is provided to eliminate frost that may

accumulate on the heat exchanger associated with the heat pump

normally cold element. Defrost is accomplished by reversing

heat pump polarity, heating the normally cold element. Control

mechanisms and logic are provided to automate system

operation. In preferred embodiments, dehumidification and

defrost modes are activated by a controller monitoring the dew

point within the enclosure, and the air pressure at the

normally cold element. Dehumidification is performed

intermittently, when the enclosure dew point exceeds a set

point. Substantially sealing the enclosure against ingress of

ambient air reduces the system's operational duty cycle.

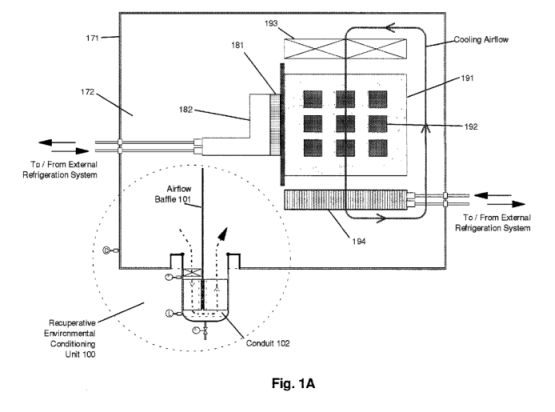

FIG. 1A shows a side

view of an electronics enclosure with an external

recuperative environmental conditioning unit (RECU)

according to one embodiment of the present invention;

FIG. 1B shows a side

detail view of the RECU of FIG. 1A in normal operation;

FIG. 1C shows a side

detail view of the RECU of FIG. 1A, in defrost mode;

FIG. 2A shows a plan

view of the thermoelectric heat pump and heat exchangers

according to one embodiment of the present invention;

FIG. 2B shows a cutaway

view of the thermoelectric device depicted in FIG. 2A, taken

along lines B--B;

FIG. 2C shows a cutaway

view of the thermoelectric device depicted in FIG. 2A, taken

along lines C--C;

FIG. 3A shows a side

view of an electronics enclosure with an external RECU,

according to an alternative embodiment of the present

invention;

FIG. 3B shows a side

detail view of the RECU of FIG. 3A in normal operation;

FIG. 3C shows a side

detail view of the RECU of FIG. 3A, in defrost mode;

FIG. 3D shows a side

detail view of an RECU employing an extended outlet port;

FIG. 4A shows a side

view of an electronics enclosure with an internal RECU

according to one embodiment of the present invention;

FIG. 4B shows a side

detail view of the RECU of FIG. 4A in normal operation;

FIG. 4C shows a side

detail view of the RECU of FIG. 4A, in defrost mode;

FIG. 5 shows a schematic

view of the control devices of one embodiment of the present

invention;

FIG. 6 shows a flow

diagram depicting the RECU control flow, for both the

dehumidification and the defrost operations according to one

embodiment of the present invention;

FIG. 7 shows the RECU of

FIG. 3A, using a wick to remove condensate.

FIG. 8A shows an RECU

using a vapor compression cycle heat pump according to one

embodiment of the present invention;

FIG. 8B shows the

operation of the embodiment of FIG. 8A during normal

operation;

FIG. 8C shows the

operation of the embodiment of FIG. 8A during defrost mode;

FIG. 8D shows a control

schematic for the embodiment of FIGS. 8A through 8C.

US6144013 -- Local humidity control system for low temperature

electronic module

Abstract -- A local humidity control system and

method are provided for a low temperature electronic device

assembly wherein a surface of the low temperature electronic

device assembly is maintained above an ambient dew point.

The local humidity control system includes a first layer of

thermal insulation at least partially surrounding and

contacting the cooled electronic device, and a second layer

of thermal insulation surrounding the first layer of thermal

insulation and the cooled electronic device in which a

volume is defined between the first and second layers of

insulation. A heater assembly interfaces with the volume to

heat the volume to a temperature sufficient to maintain the

surface of the cooled electronic device above the ambient

dew point. The heater assembly includes a thin film heater

attached to the first layer of thermal insulation to

maintain temperature of the surface above the ambient dew

point, and a wire mesh heater suspended within the volume to

lower relative humidity in the volume and inhibit the

ingress of water vapor.