rexresearch

rexresearch1

David RICHARDS, et al.

AquaMagic Water Generator

AquaMagic Water Generator

http://www.keelynet.com/news/033115o.html { 3/31/15 )

http://tesla3.com/human/e_water_from_air.html

Need

water? With AquaMagic, you just add air

HENDERSON — Images of the suffering victims of Hurricane Katrina surrounded by fouled water they couldn’t drink will remain in America’s collective memory for some time. But a company with Longmont ties is hoping its invention will prevent such a scenario from happening in the future. Utah-based AquaMagic is in the midst of its “Hurricane Zone” tour, during which it is showing off its new HP120-DRU, a portable water generator able to make pure drinking water out of air. The tour started June 1 in Houston and is slated to visit 183 Atlantic Coast cities by the time it wraps up in Washington, D.C., at the end of the summer. The official U.S. hurricane season is 183 days long. On hiatus from the tour, representatives from AquaMagic brought the HP120 on Thursday to Cummins Rocky Mountain, a company contracted to supply the 10-kilowatt diesel generators that power the HP120.

AquaMagic has been developing the technology for some time, “but we focused on this (portable) size when we saw what was happening to the victims of Hurricanes Katrina and Rita,” said David Richards, in charge of marketing and innovation for AquaMagic. The mobile unit is being pitched as more efficient and cost-effective than traditional methods of supplying water in the wake of a disaster, such as trucking in bottled water.

Using condensation techniques and its patent-pending AquaFlash technology, the HP120 can get 10 gallons of water for every gallon of diesel fuel it uses, according to John Tompkins, an engineer who works with Richards in Longmont. “You can pull in 10 truckloads of water, or you can bring in one truckload of fuel and get 10 truckloads worth of water,” Tompkins said.

AquaMagic was founded in Ogden, Utah, and Richards was a part of the original core team. He came to Longmont to take a job with Maxtor and continued to work with AquaMagic in his spare time. Richards then met Tompkins, another Maxtor engineer who began to work with AquaMagic in his spare time. The two have since left their jobs at the hard-drive company to work full time at AquaMagic.

The two will be back on the road soon, taking the machine to New Orleans and along the Florida coast. “The intent is to have this go in and support first responders and evacuees,” Richards said. “If you need two gallons a day to stay hydrated in a hot, humid environment, this can serve 60 personnel a day.” Richards said the reactions of those to whom he has made presentations has been “first, disbelief. They say, ‘What? You’ve got to be kidding me.’ “That’s why we have to physically take it there and show it to them and let them taste (the water).”

Local biologist Brent Cannell, who works with Richards and Tompkins as a consultant, has been key to making the water that comes out of the HP120 more pure than bottled water, Richards said. Longmont is “where the (research and development) will be done and will continue to be done” for AquaMagic’s products, Richards said. As big as the potential market for the HP120 is in this country’s hurricane-prone regions, Richards said he expects the international market could be even bigger.

http://usatoday30.usatoday.com/tech/news/techinnovations/2006-09-29-air-water-machines_x.htm

9/29/2006

Air alchemy: Can humidity solve post hurricane drinking water problem?

David

Royse, The Associated Press

Until something like a hurricane makes clean drinking water hard to find.

But the Southeast's climate provides something besides hurricanes in summer. Humidity.

As emergency officials ponder how to better help their residents after disasters, some companies are pushing machines that pull the humidity from the air and turn it into drinking water. A few are also touting the machines as a potential solution to the clean water shortages that plague the Third World, pushing aside concerns that the machines are inefficient and require fuel that also might be scarce.

The biggest machines can make up to 5,000 liters of water a day, enough to provide about a gallon to 1,250 people. Small units cost several hundred dollars, while the biggest, most elaborate cost half a million.

Anyone who's ever looked at an air conditioner or put a cold bottle of water in the sun and watched water bead up on it knows air can be condensed into water when it's cooled. The only questions are how efficient it is on a large scale, and whether it's clean enough to drink.

A few companies are marketing portable condensers they say can make clean, drinkable water out of nothing but the air outside. At least one is marketing it as a tool for emergency responders.

"Tap water systems get knocked out, bottled water often disappears even before the storm shows up ... so this becomes a way to get drinking water that you can count on no matter what," said Jonathan Wright, president of Ogden, Utah-based AquaMagic, one of the companies selling the machines.

The company recently towed a portable unit around the Southeast, visiting fire departments, rescue workers and city officials, trying to drum up interest.

AquaMagic's unit is too small to provide water for a whole city, but could at least provide water for rescue and cleanup workers so they wouldn't have to cart in truckloads of water, Wright said.

One potential buyer is David Roberts, who as fire chief in Biloxi, Miss., oversaw crews working in the aftermath of Hurricane Katrina, which leveled much of his city.

"You don't realize how bad you need water until you don't have it," Roberts said. "In August, the humidity's 95% and its 95 degrees, you can drink a quart of water and it goes right out of you in about 30 minutes."

He called the AquaMagic machine "a great piece of equipment. The water tasted good, too."

Most of the companies making the machines aren't focused on the U.S. market. Some are selling machines where clean drinking water is always hard to find — villages in the developing world.

"Right now at any given time, there's about 1.2 billion people that are drinking contaminated water," said Ron Colletta, vice president of sales for the Island Sky in Hollywood, Fla.

Scientists who study water shortages say that while the technology works simply and could be part of the solution, there are cheaper and easier ways to provide large-scale water purification if cleanliness is the issue.

The simplest is boiling it to remove microbes, or treating it with chemicals like chlorine, said Dr. Mark Sobsey, a professor of environmental sciences and engineering at the University of North Carolina School of Public Health's Drinking Water Research Center.

But boiling has a problem in some poor areas.

"You've got to have fuel and to be able to pay for it," Sobsey notes.

But the biggest obstacle to the machines' wider use is making them cost effective to fuel. Most are powered by diesel fuel. Some run on solar energy, but the panels require a costly initial investment.

Michael Zwebner, the president of Miami Beach-based Air Water Corp., admits the power question is a big problem, but he says the machines can be useful where there isn't enough water to begin with — or where people can't afford to pump it from the ground and treat it.

"In many parts of Africa, there is no water," Zwebner said.

Until recently, there's been little interest in the technology because water is generally easy to get from streams or underground wells and, even in poor countries, it's cheap.

"It's been really only in the last 10 years that water scarcity has been appearing in a lot of places, mainly due to the growth of the human population ... and pollution," explained Roland Wahlgren, a physical geographer who studies water supply and is working to develop air-to-water systems with a Canadian company called Wataire Industries. "Groundwater and surface water supplies have decreased in quality."

Aquamagic's envisioned niche notwithstanding, the systems still aren't generally economically feasible on a large scale in developed countries with plentiful clean water like the United States.

And emergency managers ask: If you're going to truck diesel fuel into a storm-hit area to run the machines, why not just truck in water?

The answer, AquaMagic's Wright says, is that for one gallon of diesel, you can make 10 gallons of water. So one small truck of fuel would provide the amount of water you'd need 10 trucks to bring in.

Air Water's machine was used after the 2004 Asian tsunami, and the military in India has recently signed on to send it into the field with troops.

"In some countries in Africa they actually see this machine as an act of God," Zwebner said.

US7402241 -- Water

purification device and method

A water purification device including a water inlet that receives water generated by a condenser. The water purification device has a water heating apparatus that receives water from the water inlet. The water heating device has a thermal energy source that can pasteurize or flash pasteurize the water by heating the water to a predetermined temperature for a predetermined length of time. The water heating device expels the water at the end of the predetermined length of time.

BACKGROUND

[0001] Many municipal water systems struggle with the ever increasing demand on available potable water supplies. Additionally, natural inventories of water available for treatment are diminishing and require more treatment than ever before. Indeed, many areas of the world currently do not have adequate water treatment systems, water utility systems, or basic access to potable water.

[0002] For example, even though approximately 75% of the earth's surface is water, ninety-seven percent of this water is in saline oceans, and is therefore undrinkable and unsuitable for most uses. Of the remaining three percent that is considered fresh water, two-thirds is suspended in glaciers and the polar ice caps, and one-sixth is trapped beneath the earth's surface. Of the final one-half of one percent of the earth's water, a substantial amount has been chemically or biologically contaminated by industrialization and development. This contamination has made significant inroads into underground water sources in the latter half of the twentieth century, and has made drinking water contamination one of the highest ranking environmental risks. Clean and pure drinking water is, consequently, in great demand throughout the world, and has rapidly become one of the earth's most prized resources. Yet, billions of people lack a reliable water supply.

[0003] Nearly all fresh water on the earth is created and sustained through the hydrologic cycle. In the hydrologic cycle, heat from the sun evaporates ocean water, which falls back to earth as precipitation. Because of the hydrologic cycle, there is a continuous exchange of moisture between the oceans, the atmosphere, and the land. In the atmospheric stage of the cycle there are continually many billions of gallons of water in the air available for harvesting.

SUMMARY

[0004] The present invention provides a water purification device including a water inlet that receives water generated by a condenser. The water purification device also has a water heating apparatus that receives water from the water inlet. The water heating device has a thermal energy source that can flash pasteurize the water by heating the water to a predetermined temperature for a predetermined length of time. The water heating device expels the water at the end of the predetermined length of time. A water outlet releases water from the water heating apparatus after the water has been elevated to the predetermined temperature for the predetermined time.

BRIEF DESCRIPTION OF THE DRAWINGS

[0005] Additional features and advantages of the invention will be apparent from the detailed description which follows, taken in conjunction with the accompanying drawings, which together illustrate, by way of example, features of the invention; and, wherein:

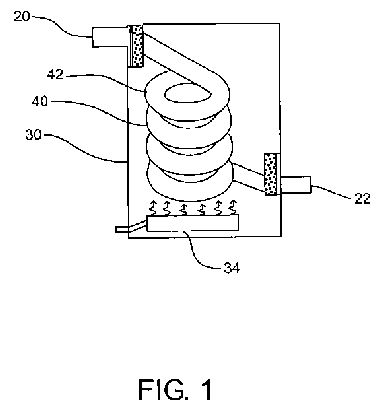

[0006] FIG. 1 is a side view of a water purification device in accordance with an embodiment of the present invention;

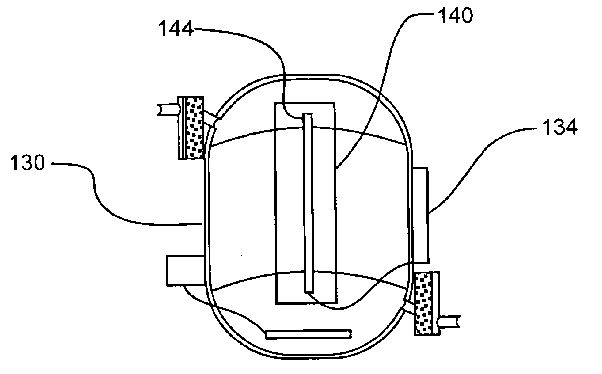

[0007] FIG. 2 is a cross section view of a water purification device in accordance with another embodiment of the present invention;

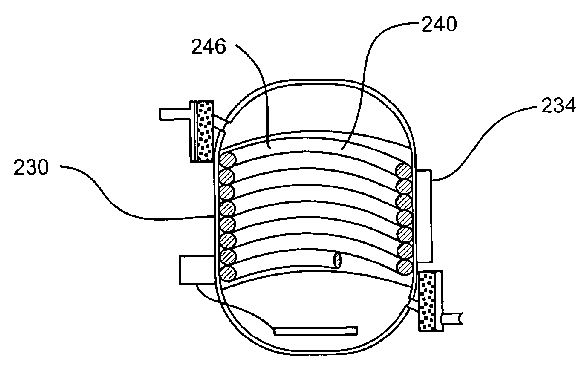

[0008] FIG. 3 is a cross section view of a water purification device in accordance with another embodiment of the present invention;

[0009] FIG. 4 is a schematic view of a water purification system in accordance with an embodiment of the present invention with the water purification device of FIG. 1 coupled to a condenser;

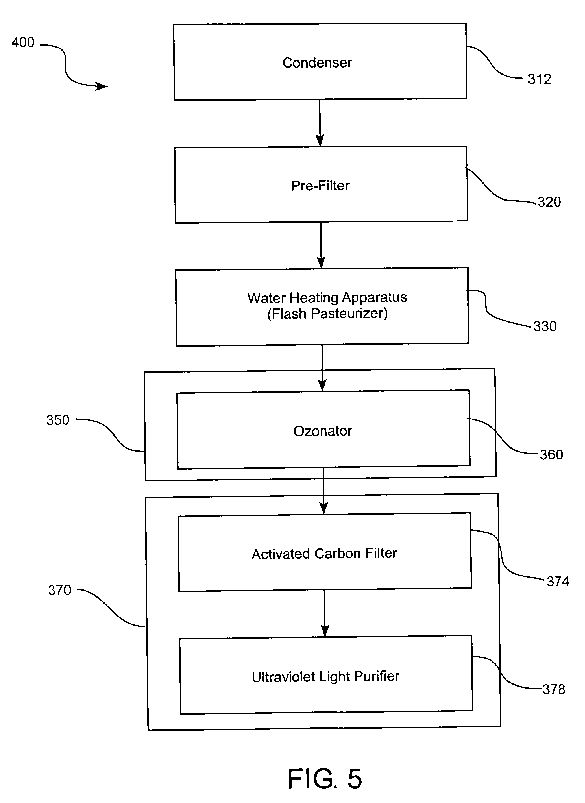

[0010] FIG. 5 is a block diagram of a water flow path in accordance with the water purification device of FIG. 1;

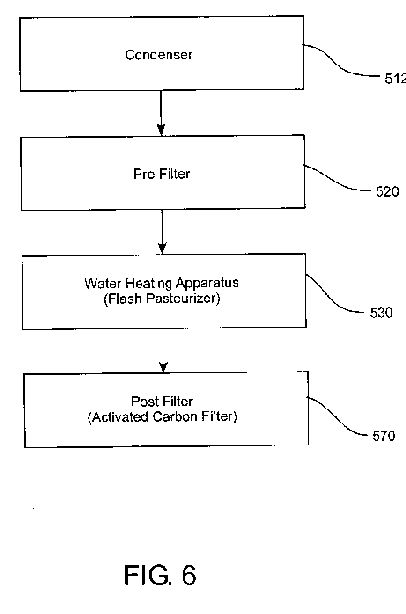

[0011] FIG. 6 is a block diagram of another water flow path in accordance with an embodiment of the present invention; and

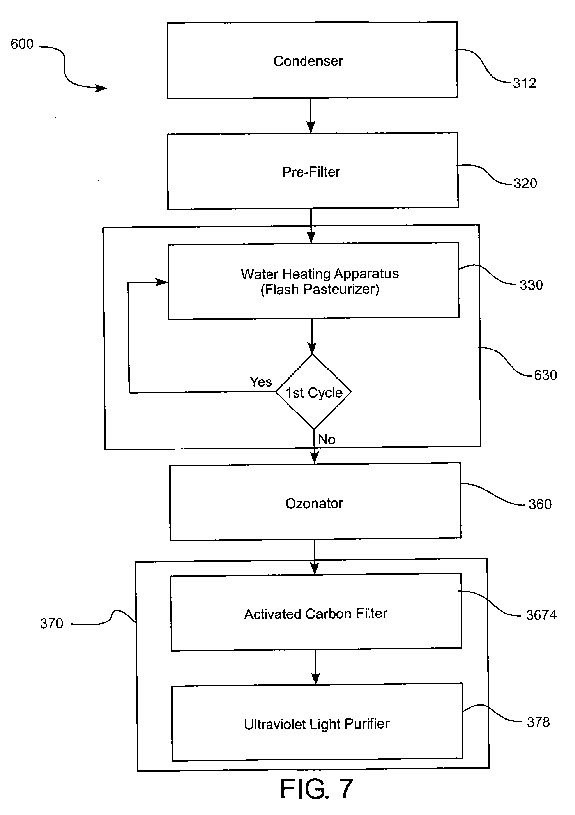

[0012] FIG. 7 is a block diagram of another water flow path in accordance with an embodiment of the present invention.

[0013] Reference will now be made to the exemplary embodiments illustrated, and specific language will be used herein to describe the same. It will nevertheless be understood that no limitation of the scope of the invention is thereby intended.

DETAILED DESCRIPTION OF EXEMPLARY EMBODIMENT(S)

[0014] Reference will now be made to the exemplary embodiments illustrated in the drawings, and specific language will be used herein to describe the same. It will nevertheless be understood that no limitation of the scope of the invention is thereby intended. Alterations and further modifications of the inventive features illustrated herein, and additional applications of the principles of the inventions as illustrated herein, which would occur to one skilled in the relevant art and having possession of this disclosure, are to be considered within the scope of the invention. The following detailed description and exemplary embodiments of the invention will be best understood by reference to the accompanying drawings, wherein the elements and features of the invention are designated by numerals throughout.

[0015] The present invention is generally directed to a water purification system that purifies water generated by equipment that uses a condenser such as dehumidifiers, air conditioners, freezers, refrigerators, and the like. The water purification device receives water that is generated and discharged by the condenser containing equipment and may filter the water with a pre-filter to remove large contamination, such as dust, pollen, mold, spores, bacteria and the like, from the water. The water purification device can heat, or pasteurize the water in a flash pasteurization process to destroy living contaminants not extracted by the sediment filter. The flash pasteurization process may elevate the temperature of the water to a predetermined temperature for a predetermined time in order to kill, or render inactive, living contaminants. The predetermined time of the flash pasteurization process may be a relatively short time and varies depending on the predetermined temperature. An ozonator may be used to generate ozone that may be injected or vacuumed into the pasteurized water to further purify the water. An activated carbon filter may remove organic and inorganic contaminants and other chemicals from the water before sending the water to a storage tank. Ultraviolet light or ozone can then be used periodically to maintain the purity of the water in the storage tank.

[0016] As illustrated in FIG. 1, a water purification device, indicated generally at 10, in accordance with the present embodiment is shown for use in purifying water generated by a condenser. The water purification device 10 has a water inlet 20 to receive water generated by a condenser.

[0017] For purposes of the present embodiments, a condenser can be any type of equipment that generates or condenses water during its operation. It will be appreciated that a condenser can be a part of a larger piece of equipment such as an air conditioner, a dehumidifier, a refrigerator, or a freezer. For example, dehumidifiers use condensers to extract water vapor or moisture from the air, thereby reducing the humidity of the air. Moreover, air conditioners, refrigerators and freezers use condensers to control temperature in a closed environment by extracting water vapor from the air in order to lower the dew point of the closed environment. Other condenser using equipment, as known in the art, can also generate water that is receivable by the water inlet 20 of the water purification device 10. In any case, condensers typically remove water vapor from the surrounding air by condensation and discharge the water in a liquid state.

[0018] It will also be appreciated that millions of industrial sized air conditioners and dehumidifiers are in use throughout the world every day for the purpose of creating more comfortable environments in which to live, work, shop, and play. As described above, these air conditioners and dehumidifiers lower humidity levels indoors by drawing air across a condensing apparatus that extracts water vapor from the air and condenses the vapor into liquid water. Unfortunately, the liquid water generated by these air conditioners and dehumidifiers is not safe for human consumption and is referred to as gray water. Typically, this gray water is sent down drains contributing yet more water to over-burdened water treatment facilities. Advantageously, the water purification device 10 can receive and purify liquid water discharged from a condenser or condenser containing equipment, in order to make the water potable, or suitable for human consumption.

[0019] While much research has been conducted in the areas of dehumidification, gray water purification and water filtration; little, if any research has been focused on retrofitting dehumidifiers or aftermarket mechanisms designed to purify the gray water discharge from dehumidifiers. While some technologists have developed and patented equipment for capturing water vapor, like a dehumidifier, and then purifying the captured water into drinking water, these machines have been custom built for the purpose, and hence often only the financially elite who can afford the benefit of this technology.

[0020] Additionally, the purification of gray water in such systems is typically accomplished by means of a carbon filtration apparatus, a UV light source, or a combination of these processes to kill any germicidal organisms. However, both activated carbon filtration and UV light purification have limitations. For example, activated carbon filters become burdened with time and need to be replaced in order to maintain their effectiveness. UV lamps can become dull with age, as well as from particulate buildup. With time both devices may loose their effectiveness unbeknownst to their operator. Consequently, water could pass by these systems untreated. Furthermore, the effectiveness of UV light purification is subject to the wavelength and intensity of the UV light source, the clarity of the water, as well as the distance of the light source to the microorganisms being treated. Even under normal operating conditions, organisms furthest from the UV source may receive minimal or no effects from the irradiation.

[0021] Therefore, it is a particular advantage of the present invention that the water purification device 10 can be retrofitted or added after-market, to a piece of condenser containing equipment. Thus the present invention can take advantage of the millions of condensers already in the market place and can be used to purify the water generated by already existing condensers. Additionally, the water purification device 10 can be manufactured with new condenser containing equipment.

[0022] Regardless of whether the water purification device 10 is retrofit to a condenser or manufactured along with a condenser, the water can be delivered from the condenser to the water purification device by either a pump or gravity fed plumbing.

[0023] The water purification device 10 can also have a water heating apparatus 30. The water heating apparatus 30 can receive water from the water inlet 20. The water heating apparatus 30 can also have a thermal energy source 34 to pasteurize or flash pasteurize the water by heating the water to a predetermined temperature for a predetermined length of time.

[0024] The water heating apparatus 30 can flash pasteurize discharged liquid water from a condenser. Generally, pasteurization is a purification process that uses heat to kill microorganisms by destroying the cytoplasmic membranes, or inner cell structures of the microorganisms. Pasteurization also kills microorganisms by denaturing proteins essential to microorganism survival. Flash pasteurization, or high-temperature short-time pasteurization, rapidly elevates the temperature of the water and maintains the temperature for a predetermined relatively short duration in order to kill or render undesirable microorganisms inactive. Thus, by heating the condenser discharge water to a predetermined temperature for a predetermined time, the water heating apparatus can eliminate pathogens from the water.

[0025] The water heating apparatus 30 provides several advantages over other types of purification devices and processes. For example, the water heating apparatus 30 can uniformly distribute heat throughout the condenser generated water in order to destroy microorganisms regardless of where the microorganism is positioned within the water mass. Consequently, purification of water by other more traditional filtering mechanisms.

[0026] The water heating apparatus 30 of the water purification device 10 can flash pasteurize discharged liquid water from a condenser. In one example, the predetermined temperature can be at least 161 degrees F. (72 degrees C.) and the predetermined length of time can be at least 15 seconds. In another example, the predetermined temperature can be at least 212 degrees F. and the predetermined time can be 0.01 seconds. The heated water can be expelled from the water heating apparatus 30 through a water outlet 22. It will be appreciated that other time and temperature combinations can be used, but generally the higher the temperature, the less time is needed to complete the pasteurization. Additionally, it has been found that temperatures below 161 degrees F. are not effective at neutralizing undesirable microorganisms.

[0027] The water heating apparatus 30 provides several advantages over other types of purification devices and processes. For example, the water heating apparatus 30 can uniformly distribute heat throughout the condenser generated water in order to destroy microorganisms regardless of where the microorganism is positioned within the water mass. Consequently, water purification of the present invention is not dependent on penetration of light as in an ultraviolet purifier.

[0028] Additionally, the water heating apparatus 30 of the present invention uses readily available thermal energy to purify the condenser discharge water, and so the water heating apparatus 30 does not require any specialized non-renewable equipment such as an ultraviolet light source or activated carbon filters. Furthermore, the heat transfer process of the water heating apparatus is not adversely affected by particulate buildup as is ultraviolet purification and activated carbon filter processes. Consequently, cleaning and maintenance of the apparatus can be minimized.

[0029] It will be appreciated that the thermal energy source 34 can be a conductive heat source such as an electrical heating element, a hot water jacket, a steam jacket, a fire, or a combination of these various heat sources. Additionally, the thermal energy source can be an emissive thermal heat source such as an electrical heating element, a flame, a chemical reaction, or a combination of these various heat sources. Other thermal energy sources, as known in the art, can also be used to heat the water in the water heating apparatus 30.

[0030] The water heating apparatus 30 can also include a heat exchanger 40 that can transfer thermal energy from the thermal energy source 34 to the water received from the water inlet 20. As shown in FIG. 1, the heat exchanger 40 can include a tube 42 heated by the thermal energy source 34. In use, water can pass through the tube 42 and heat can be transferred from the tube 42 to the water. In this way, the water can continue to increase in temperature as the water travels through the tube 42 until a point near the end of the tube 42 where the water temperature is at the predetermined temperature. The temperature can be maintained at the predetermined temperature for the predetermined time, at which point the water can be discharged from the tube 42 and to a water outlet 22.

[0031] Referring to FIG. 2, a water purification device, indicated generally at 100, is shown that is similar in many respects to the device described above. The water heating apparatus 130 can have a heat exchanger 140 that can include a plate 144, or a plurality of plates (not shown) that are heated by the thermal energy source 134. In use, the water surrounds the plate 144 and the temperature of the plate 144 is raised. The plate 144 can radiate or conduct the heat to the water to elevate the temperature of the water to the predetermined temperature for the predetermined time.

[0032] Referring to FIG. 3, a water purification device, indicated generally at 200, is shown that is similar in many respects to the devices described above. The water heating apparatus 230 can have a heat exchanger 240 with a coil 246 that is heated by the thermal energy source 234. The coil 246 can transfer heat to the water to elevate the temperature of the water to the predetermined temperature for the predetermined time. Other types of heat exchangers, as known in the art, can also be used to transfer thermal energy in the form of heat from the thermal energy source 34 to the water.

[0033] Illustrated in FIG. 4, a water purification system, indicated generally at 300, in accordance with the present invention is shown for use in purifying water generated by a condenser 312. The water purification system 300 includes a filtration chain, shown generally at 310. Water from a condenser 312 can be directed through the filtration chain 310 in order to make the water potable. As noted above, the condenser 312 can be a part of another piece of equipment such as an air conditioner, a dehumidifier, a refrigerator, and a freezer.

[0034] The filtration chain 310 can have a pre-filter 320 that can receive water generated by a condenser 312. The pre-filter 320 can filter relatively larger contaminants from the water. The pre-filter 320 can include a particulate screen 324 for removing particles larger than a predetermined size from water passing through the pre-filter 320. The pre-filter 320 can also include an activated carbon filter 328 for reducing environmental and biological contaminants in the condenser discharge water.

[0035] The filtration chain 310 can also have a water heating apparatus 330 that is similar in many respects to the water heating apparatus described above. The water heating apparatus 330 can have a thermal energy source 334 to pasteurize, or flash pasteurize, the water by heating the water to a predetermined temperature for a predetermined length of time. Thus, the water heating apparatus 330 can receive water from the pre-filter 320, and can flash pasteurize the water by heating the water to a predetermined temperature for a predetermined length of time. In one embodiment, the predetermined temperature can be at least 161 degrees F. (72 degrees C.) and the predetermined length of time can be at least 15 seconds. In another aspect, the predetermined temperature can be at least 212 degrees F. and the predetermined time can be 0.01 seconds. The heated water can be expelled from the water heating apparatus 30 through a water outlet 22. It will be appreciated that other time and temperature combinations can be used, but generally the higher the temperature, the less time is needed to complete the pasteurization. Additionally, it has been found that temperatures below 161 degrees F. are not effective at neutralizing undesirable microorganisms unless longer treatment times are permitted.

[0036] The water heating apparatus 330 can receive water from the pre-filter 320. The water heating apparatus 330 can include a heat exchanger 340 that can transfer thermal energy from the thermal energy source 334 to the water received from the pre-filter 320. The heat exchanger 340 can transfer heat from the heat exchanger 340 to the water. In this way, the water can continue to increase in temperature as the water travels through, or about the heat exchanger 340 until the temperature throughout the water, or throughout a cross section of the water mass, is at least at the predetermined temperature. It will be appreciated that water nearer the heat exchanger 340 can have a higher temperature than the predetermined temperature when water farther from the heat exchanger 340 is at the predetermined temperature. Thus, the temperature throughout the water mass can be maintained at least at the predetermined temperature for the predetermined time.

[0037] The water heating apparatus 330 can expel the water at the end of the predetermined length of time into a cooling unit 350. The cooling unit 350 can reduce the temperature of the water.

[0038] Biofilms (colonized layers of microorganisms) can form when bacteria, and other microorganisms adhere to each other and to the surfaces to which they come into contact with. Biofouling (acid production, equipment corrosion, toxin production, etc.) can result within the water purification system 300 if these biofilms are allowed to grow. Under normal equipment operation, it is anticipated that biofilms will develop within the water collection system, water purification train, and water storage container. Thus, from time to time, as the water purification device operates, it will need to be flushed and sanitized to eliminate these biofilms to safe levels.

[0039] Ozone (O3) is lethal to microbes, viruses, parasites, pesticides and the like. Ozone is also a very effective disinfectant. Ozone is highly reactive and once it comes into contact with organic or inorganic matter ozone reacts with the matter and reduces the unstable triatomic oxygen (O3) back to diatomic oxygen (O2). In the presence of bacteria, ozone attaches to the cell wall of the organism causing the cell to lyse (rupture). It has been shown that ozone can be more than 3000 times more effective at destroying undesirable water contamination than chlorine sanitizers. Additionally, ozone can also be produced readily in remote locations with the use of ambient air and is very cost effective.

[0040] Thus, an ozonator 360 can be used to further purify the water in the water purification system 300 by releasing ozone into the water. It will be appreciated that the ozonator 360 can be placed in the cooling unit 350 as shown in FIG. 4, as well as in a variety of other locations along the filtration chain 310. Additionally, ozone can be injected into multiple locations in the filtration chain. Ozone can also be used to periodically re-purify stored water as well as periodic sanitization of the water purification system 300.

[0041] The filtration chain 310 can also have a post cooling purifier 370 that can receive water from the cooling unit 350 and reduce remaining contamination from the water. The post cooling purifier 370 can include an activated carbon filter 374 that can further reduce environmental contaminants from the water. The post cooling purifier 370 can also include an Ultraviolet (UV) light source 378 for further purification of the water. The UV light source purifier 378 can reduce biological contaminants from water from the carbon filter.

[0042] Referring to FIG. 5, a block diagram illustrates the flow path, indicated generally at 400, of water from a condenser through the water purification filtration chain 310 of the water purification system 300 discussed above. Water can be discharged from the condenser 312 and received by the pre-filter 320 which filters larger contaminants such as dust, pollen, spores, and the like from the water. The water then flows to the water heating apparatus 330 where the water is heated to a predetermined temperature and maintained at the predetermined temperature for a predetermined time so that the water is pasteurized or flash pasteurized. The water then flows to a cooling unit 350 or tank where an ozonator 360 can inject ozone into the water to further purify the water. The water then flows through post cooling purifier 370 that can have an activated carbon filter 374 for further filtering environmental contaminants and an ultraviolet light purifier 378 that can reduce biological contaminants. The water can then be used in potable water applications or the water can be stored for future use.

[0043] In the case where the water is stored for future use, additional purifying processes can be used periodically to maintain the purity of the stored water. For example, an Ultraviolet light source 378 can be used to periodically irradiate the stored water to reduce development of contamination in the stored water.

[0044] It will be appreciated that some of the elements of the flow path described above can be eliminated or duplicated as circumstances may require. Additionally, the sequence of the elements of the flow path can be rearranged in a variety of orders to accommodate particular purification needs. For example, referring to FIG. 6, a block diagram illustrating a water flow path 500 in accordance with another embodiment of a water purification system is shown that is similar in many respects to the water purification system described above. In this flow path, water flows into a prefilter 520 from the condenser 512 and from the prefilter 520 to the water heating apparatus 530. Water then flows from the water heating apparatus 530 to a post filter 570 that has only an activated carbon filter. As another example, the water could be sent through the water heating apparatus 630 twice to ensure thorough pasteurization, as shown in the water flow path 600 of FIG. 7. Thus, the filtration train can be tailored to meet the needs of a particular filtration application.

[0045] The present invention also provides for a method for purifying water, including obtaining water from a condenser and filtering the water with a pre-filter to remove larger contaminants from the water. The water can be heated with a water heating apparatus to a predetermined temperature for a predetermined length of time to reduce active biological contaminants in the water. The water heating apparatus can include a thermal energy source and a heat exchanger for transferring heat from the thermal energy source to the water. The water can be cooled in a cooling unit. The water can also be filtered with an activated carbon filter to decrease contaminants in the water.

[0046] The method of purifying water or sanitizing the unit can also include ozonating the water by injecting ozone from an ozone source into the water or unit.

[0047] The step of obtaining water from a water source can also include extracting water from surrounding air with a condenser in an air conditioner or dehumidifier. Additionally, the step of filtering the water from the cooling unit can also include passing the water through an activated carbon filter to decrease contaminants in the water. Moreover, the step of filtering the water from the cooling unit can also include exposing the water from the activated carbon filter to an ultraviolet light source to reduce active biological contaminants in the water.