rexresearch.com

rexresearch.comBob AMARASINGHAM

Hydraulic Motor

Hydraulic Motor

https://www.facebook.com/Boboats

https://wells.nub.news/x/bobby-premarajan-amarasingham-rip

Bobby Premarajan Amarasingham

Bobby died on the 16th June 2021 at Musgrove Park Hospital after being ill over the last six months.

https://seeedcollege.org/bobby-amarasinghams-water-propulsion-technology/

Bobby Amarasingham’s Water Propulsion Technology

This video features one that could be great for water propulsion, making it safer, for swimming pools and for fish.

It uses three cone shapes on a rod, the middle one of which moves forward and backward. As it moves forward the water is “reflected” against the forward cone to push water backwards; and as the middle cone moves backward, it pushes water back with it then as well. So the “forward-backward” action of the middle cone results in pushing the unit forward in the water.

The advantage is that it is much safer than a propeller, and it may be more efficient than a propeller. Bobby says it is around 60% more efficient than propellers.

The prototype toy he built (photos shown in the video) was so popular, all the

ar, all the kids wanted to play with it at the beach. “Can I have a try?” “Can I have a turn?”

He would like to see this patent-protected technology move forward.

Alexander FROLOV : New Sources of Energy

( 2021 )

The English inventor Bob Amarasingham started producing his electricity generators back in 2009. He planned to set up production facilities in China because there are optimal prices for components. His 3-kilowatt autonomous power generator should be priced at around $750, and it could hit the market in 2012. This technology is very simple. Some small electric motor turns a rotor with weights - eccentrics that work on the cardioid trajectory in the vertical plane. As a result, due to the forces of inertia, additional momentum torque appears in the system (at half the cycle of rotation of the weights) and the output power of the electric generator is many times greater than the power consumed by the drive. We'll take a closer look at the Amarasingam generators some later. Unfortunately, there are no great achievements in organizing the mass production and commercialization of this technology in 2021.

The GDS Technologies Group can be named as an interesting example of free energy innovations. These power generators are already on sale, power to order, from 5 kW to 50 kW. The author is looking for partners for the development of the production. We discussed a license agreement for Russia with him in 2014. The acquisition costs for generators of this type are around 500US dollars per kilowatt of installed capacity...

Inventor Bobby Amarasingham successfully tested his AOGFG 12 kW generator in December 2010. This device includes rotating weights and electric drives that produce constant torque. When starting, the drives consume about 500 watts (acceleration) and then only 50 watts, while the generator delivers 12 kilowatts to the useful electrical load. Rolls-Royce engineers have tested this device and prepared contracts with manufacturers in China. The estimated market price for a 12 kW drive (excluding the price of an electric generator) was US $ 5,000. The dimensions will not be more than 1,5 cubic meters. The weight of a 6 kW machine is approximately 120 kg, for a 12 kW machine the weight is about 200 kg.

Note that this principle takes advantage of inertial (gyroscopic) effects resulting from the rotation of eccentrics, so such machines can be much more compact than simple unbalanced wheels. For example, Dmitriev’s and Amarasingam's generators are similar, but for Dmitriev’s device the weight of a 5 kW machine will be about 1,000 kg. The advantages of Amaragingam technology are obvious.

Fig. 18. One of the first Amarasingam Generators

The Amarasingam’s generator is quiet and rustles like a conventional air conditioning system. The plan was to produce around 100 thousand generators per year, initially machines with an output of 3 kilowatts, 6 kilowatts and 12 kilowatts. A small generator (3 kilowatts) can cost around $ 750 in mass production. This generator was supposed to be on the market in 2012 but we never saw it.

Fig. 19. Bobby Amarasingam and his 12 kW Generator

I am a representative of Amarasingam in Russia, but for many years I have not found a serious partner in Russia for the development of this technology. Nobody is interested to start mass production of this generator. In 2012 Amarasingama's marketing strategy was changed. He stopped selling licenses and looked for partners to build power plants to get profit from the sales of electricity. You can find the contacts of this author on Facebook https://www.facebook.com/Boboats

I will briefly explain the principles of operation of this machine at the level of my understanding. A small electric motor turns the rotor with weights - eccentrics that describe the trajectory of the cardioid in the vertical plane. An analogy is the inertial propulsion drive by author Thornson, but the rotor of Amarasingam does not turn in the horizontal, but in the vertical plane of rotation. Fig. 20 shows that the rotor on the left is heavier and the rotor on the right is lighter. In such a situation an additional torque is exerted on the rotor axis due to the force of gravity.

Much more additional torque, however, is provided here by the centrifugal force, which generates strong kinetic momentum in the part of the eccentric trajectory. Therefore, Amarasingam generators can be called inertial gravitational machines. The freewheel on axis periodically provides the generator with additional torque when the eccentric change the radius of its rotation.

Fig. 20. Trajectory of eccentrics.

In 2011, Bob Amarasingham told a reporter for an English newspaper about supporters \of Fusion Energy: "They spent $ 500 billion trying to find a solution when the solution was so simple that even a child can figure it out."

The English inventor Bob Amarasingham started producing his electricity generators back in 2009. He planned to set up production facilities in China because there are optimal prices for components. His 3-kilowatt autonomous power generator should be priced at around $750, and it could hit the market in 2012. This technology is very simple. Some small electric motor turns a rotor with weights - eccentrics that work on the cardioid trajectory in the vertical plane. As a result, due to the forces of inertia, additional momentum torque appears in the system (at half the cycle of rotation of the weights) and the output power of the electric generator is many times greater than the power consumed by the drive. We'll take a closer look at the Amarasingam generators some later. Unfortunately, there are no great achievements in organizing the mass production and commercialization of this technology in 2021.

The GDS Technologies Group can be named as an interesting example of free energy innovations. These power generators are already on sale, power to order, from 5 kW to 50 kW. The author is looking for partners for the development of the production. We discussed a license agreement for Russia with him in 2014. The acquisition costs for generators of this type are around 500US dollars per kilowatt of installed capacity...

Inventor Bobby Amarasingham successfully tested his AOGFG 12 kW generator in December 2010. This device includes rotating weights and electric drives that produce constant torque. When starting, the drives consume about 500 watts (acceleration) and then only 50 watts, while the generator delivers 12 kilowatts to the useful electrical load. Rolls-Royce engineers have tested this device and prepared contracts with manufacturers in China. The estimated market price for a 12 kW drive (excluding the price of an electric generator) was US $ 5,000. The dimensions will not be more than 1,5 cubic meters. The weight of a 6 kW machine is approximately 120 kg, for a 12 kW machine the weight is about 200 kg.

Note that this principle takes advantage of inertial (gyroscopic) effects resulting from the rotation of eccentrics, so such machines can be much more compact than simple unbalanced wheels. For example, Dmitriev’s and Amarasingam's generators are similar, but for Dmitriev’s device the weight of a 5 kW machine will be about 1,000 kg. The advantages of Amaragingam technology are obvious.

Fig. 18. One of the first Amarasingam Generators

The Amarasingam’s generator is quiet and rustles like a conventional air conditioning system. The plan was to produce around 100 thousand generators per year, initially machines with an output of 3 kilowatts, 6 kilowatts and 12 kilowatts. A small generator (3 kilowatts) can cost around $ 750 in mass production. This generator was supposed to be on the market in 2012 but we never saw it.

Fig. 19. Bobby Amarasingam and his 12 kW Generator

I am a representative of Amarasingam in Russia, but for many years I have not found a serious partner in Russia for the development of this technology. Nobody is interested to start mass production of this generator. In 2012 Amarasingama's marketing strategy was changed. He stopped selling licenses and looked for partners to build power plants to get profit from the sales of electricity. You can find the contacts of this author on Facebook https://www.facebook.com/Boboats

I will briefly explain the principles of operation of this machine at the level of my understanding. A small electric motor turns the rotor with weights - eccentrics that describe the trajectory of the cardioid in the vertical plane. An analogy is the inertial propulsion drive by author Thornson, but the rotor of Amarasingam does not turn in the horizontal, but in the vertical plane of rotation. Fig. 20 shows that the rotor on the left is heavier and the rotor on the right is lighter. In such a situation an additional torque is exerted on the rotor axis due to the force of gravity.

Much more additional torque, however, is provided here by the centrifugal force, which generates strong kinetic momentum in the part of the eccentric trajectory. Therefore, Amarasingam generators can be called inertial gravitational machines. The freewheel on axis periodically provides the generator with additional torque when the eccentric change the radius of its rotation.

Fig. 20. Trajectory of eccentrics.

In 2011, Bob Amarasingham told a reporter for an English newspaper about supporters \of Fusion Energy: "They spent $ 500 billion trying to find a solution when the solution was so simple that even a child can figure it out."

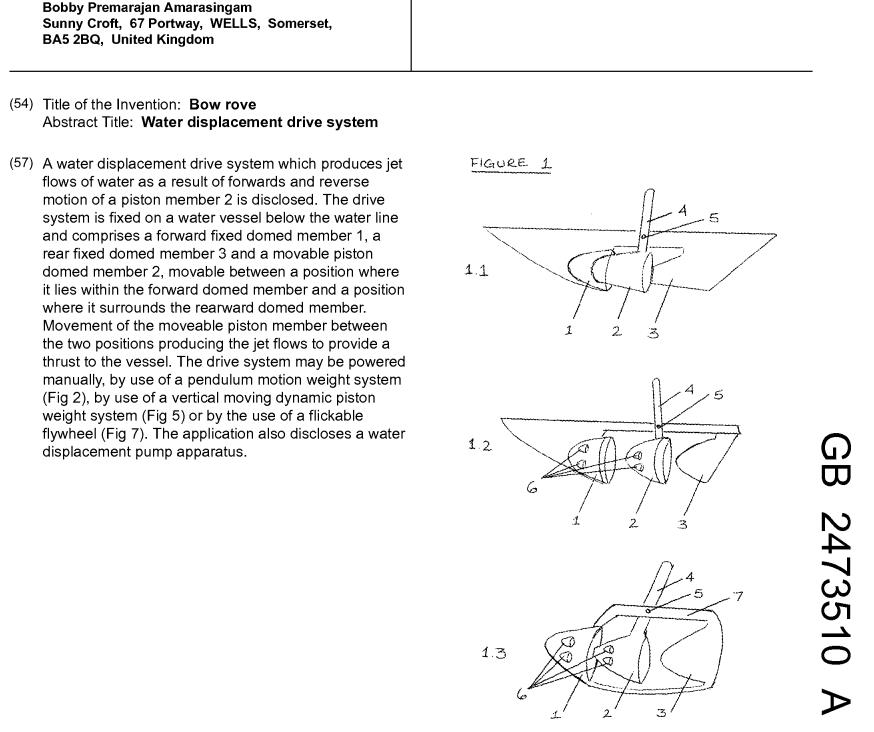

A water displacement drive system which produces jet flows of water as a result of forwards and reverse motion of a piston member 2 is disclosed. The drive system is fixed on a water vessel below the water line and comprises a forward fixed domed member 1, a rear fixed domed member 3 and a movable piston domed member 2, movable between a position where it lies within the forward domed member and a position where it surrounds the rearward domed member. Movement of the moveable piston member between the two positions producing the jet flows to provide a thrust to the vessel. The drive system may be powered manually, by use of a pendulum motion weight system (Fig 2), by use of a vertical moving dynamic piston weight system (Fig 5) or by the use of a flickable flywheel (Fig 7). The application also discloses a water displacement pump apparatus.

A Hydraulic Motor

GB2334763A [ PDF ]

GB2334763A [ PDF ]

A hydraulic motor, powered, for example, by a head of water from a river, comprises a pair of pistons - each reciprocating in a cylinder - and linked together...