rexresearch.com

Roland PLOCHER

Water Treatment

Water Treatment

http://www.wallenstein.pt/english/technology.htm

Roland Plocher Energy Systems

Torenstrasse 26 - D-88709 Meersburg - Germany.

The Plocher System

In the last decades there has been a growing awareness of the existence of energy forms other than the known ones of electricity, magnetism, radioactivity, chemical and thermal energy.

It is one of these "other" forms of energy which is utilized by Roland Plocher in his Energy System. It appears to be omnipresent in Nature. Presently it rather belongs in the faculty of theoretical physics or philosophy than in the exact sciences.

The energy itself is assumed to have a minute wavelength and can therefore not be measured by instruments currently available to science, but the results derived from its practical application can be measured, quantified and replicated.

The Plocher Apparatus

In the Plocher System this fine energy is concentrated by an apparatus and used to copy or imprint the attributes of one or more substances onto other substances. It works much like a photo copier or a laser printer where the energy of the laser beam is replaced by the focused energy of the Plocher apparatus.

RESULTS:

http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.561.1598&rep=rep1&type=pdf

Treatment of American Farm

School lagoons using a novel system

By David Willis and Nikolas Nikolaidis

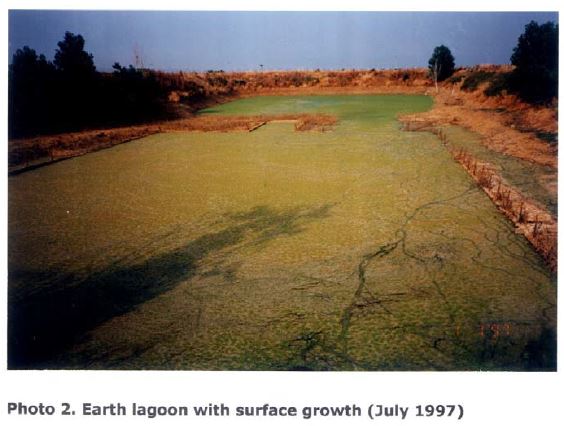

BEFORE:

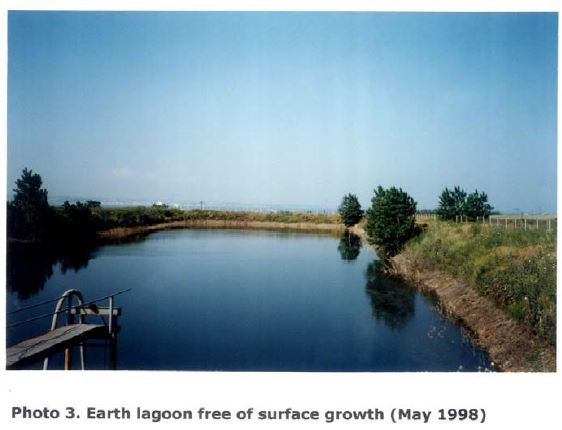

AFTER:

By David Willis and Nikolas Nikolaidis

BEFORE:

AFTER:

DE10140652

Apparatus for purifying liquids

Apparatus for purifying liquids

Inventor: PLOCHER ROLAND

A swimming pool water filter has a housing (1) with an inlet (4) and an outlet (10) with a base panel (3) and cover (2). The housing is sub-divided into several co-axial chambers (6.1-6.3) arranged in the direction of water flow from the core outwards. <??>The chambers are packed with bulk solid filter materials e.g. gravel, basalt, zeolite, evacite, active carbon granules etc.. The packing materials are inserted in different mixtures, ratios and grain sizes. The outer chambers are preferably of larger cross-sectional area than the inner chambers. The feed(10) pipe (4) enters through the base (3) and discharges against the cover inner face. Having descended through the first chamber water passes radially under a curtain wall (5) to the second chamber through which it rises to overflow at the top into the outermost chamber.

The present invention relates to a device for cleaning, treating, filtering, pollutant reduction and oxygen enrichment of liquids, in particular of water with a container, which is associated with at least one inlet and at least one outlet.

Such devices are known for example as a carbon filter, as they can be used in a conventional circuit, for example a swimming pool or the like. They serve u. a. also to free conventional hot water from unpleasant and unwanted odors and germs.

The disadvantage, however, is that previous and conventional devices are not suitable, for example, soiled water, especially soiled water of a swimming pool to reprocess so that it is germ-free, clean and free of contamination.

The present invention has for its object to provide a device of the type mentioned, which eliminates the disadvantages mentioned and in which liquid, especially water to be enriched with oxygen.

In addition, impurities and heavy metals are to be absorbed and germs reduced. Furthermore, the life in such a device should be increased considerably.

To achieve this object, that the container is divided into several durchströmmbare chambers.

In the present invention, a device is provided in which individual chambers are arranged coaxially to one another, which can be traversed individually in succession by a liquid to be cleaned.

In this case, the individual chambers, which are arranged coaxially from the inside to the outside, flows through from the inside to the outside in succession. The individual chambers are filled with Stützkies, basalt, zeolite, Evazit, activated carbon, etc. in different grains and compositions.

In the preferred embodiment, the coaxial outer chambers are formed cross-sectionally, larger than the inner chambers, so that a flow rate decreases from the inside to the outside. As a result, the liquid flowing through the container has a larger wettable surface, so that the cleaning effect, the reduction of germs and the absorption of heavy metals is substantially improved.

Furthermore, in the third chamber, an outer lateral surface is permeable to liquid, preferably designed as a perforated plate, so that the liquid entering the third chamber flows through it partially and penetrates partially through the lateral surface and outside on the perforated plate, additionally oxygen enrichment takes place.

The inventive device can be used for example in a hot water cycle of a swimming pool.

The resulting germs in the process water are degraded or reduced, the absorption of heavy metals optimized, so that at the same time by the optimal cleaning effect, the chlorine concentration of the water can be reduced to zero, which significantly contributes to water quality. It can even be dispensed with a chlorination or ozonization or other conventional treatment of process water to achieve an even better cleaning effect than conventional cleaning methods.

In addition, it is also advantageous if the materials which are arranged in the individual chambers, such as basalt, zeolite, gravel, activated carbon, are treated, in particular treated. As a result, their effectiveness and mode of operation can be significantly improved. This should also be within the scope of the present invention.

Further advantages, features and details of the invention will become apparent from the following description of preferred embodiments and from the drawing; this shows in

FIG 1 shows a schematically represented cross section through an inventive device for cleaning, treating, filtering, pollutant reduction and oxygenation of liquid, especially water;

FIG. 2 shows a schematically illustrated plan view of the device according to FIG. 1;

FIG.3 is a plan view of a further embodiment of the device according to FIG. 1.

According to FIG. 1, an apparatus R1 according to the invention for cleaning, treatment, filtering, for pollutant reduction and for oxygen enrichment comprises a container 1, which is formed from a cover element 2 with a bottom element 3.

In approximately the middle, an inlet 4 opens into the bottom element 3, which rises almost inwardly against the cover element 2.

Through the inlet 4, which may, however, also be arranged in the region of the cover element 2, the liquid to be purified or the water to be purified is pumped into the container 1.

Coaxially around the inlet 4 is formed between the cover element 2 and the bottom element 3 via a wall 5, a first chamber 6.1 coaxially surrounds the inlet 4.

For example, a connection 7, for example, is formed as an opening between the wall 5 and the base element 3, wherein a further wall element 8coaxially and at a distance surrounds the wall 5, so that a second chamber 6.2 is formed.

The chamber 6.2 is, as is apparent from Fig. 2, formed in a circular cross-section and completely surrounds the wall 5 and the first chamber 6.1.

The wall element 8 is preferably connected to the bottom element 3 in a manner impermeable to liquids, wherein a liquid-permeable connection 7 is likewise formed on the end side between the cover element 2 and the wall element 8.

The wall element 8 is surrounded by a lateral surface 9, which allows the liquid to pass.

Cover element 2 and bottom element 3 respectively adjoin front side of jacket surface 9, wherein bottom element 3 overlaps shell surface 9 and simultaneously serves as a collecting container for the cleaned liquid, wherein bottom outlet 3 is assigned an outlet 10.

The chamber 6.3 formed between the lateral surface 9 and the wall element 8, which is also of an annular cross-section, allows liquid to flow outward through the lateral surface 9. This then trickles along the perforated plate down into the bottom element. 3

Thus, during cleaning, treatment, filtering, in the reduction of pollutants at the same time an oxygen enrichment of liquids, especially water to improve hygiene, to reduce sulfur, to reduce nucleation is optimized, the first chamber 6.1 with a filter element 17, in particular as a filter cotton , possibly formed as a filter cartridge used and filled an underlying area with support gravel 11. The water to be purified, which flows in via the inlet 4, enters the first chamber 6.1 and flows completely through the filter element 17 and then through the support gravel 11. The filter element is preferably washable and / or used as an exchangeable filter cartridge or as an exchangeable filter cotton in the chamber 6.1. Subsequently, the water in the frontal region of the wall 5, near the bottom element 3 in the second chamber 6.2, and there must flow through the introduced basalt 12, then the Evazit 13 and the overlying gravel 14 and zeolite 15.

Subsequent to the second chamber 6.2 flows from the second to the third chamber 6.3 in the region of the connection 7 frontally between the wall element 8 and cover element 2, the water in the third chamber 6.3, which is completely filled with zeolite 16. A part of the liquid or of the water passes through the water-permeable lateral surface 9 to the outside and trickles along this lateral surface 9 into the bottom element 3, is collected there and discharged via the outlet 10. The other part of the water flow flows through the chamber 6.3 completely and is collected at the bottom element 3.

In this way, for example, contaminated water of a swimming pool, which is interspersed with germs, treat almost completely germ-free or clean. As a result, for example, in the water treatment of swimming pools on chlorine or other treatments of water with bspw. Ozone or UCV light are dispensed with, which contributes significantly to the water quality.

Position Number List

Important in the present invention is also that in different areas in the individual chambers 6.1 to 6.3 support gravel, basalt, evacite and zeolite can be arranged in different grain sizes and grain sizes. This should also be within the scope of the present invention. It should also be within the scope of the present invention, as shown in a device R2, that the individual chambers 6.1 to 6.3 may be square-shaped, preferably hexagonal, honeycomb, polygonal and / or even rectangular in cross-section. The invention is not limited thereto. 1 Container2 Cover element3 Floor element4 Inlet5 Wall6 Chamber7 Connection8 Wall element9 Outer surface10 Outlet11 Support gravel12 Basalt13 Evacite14 Support gravel15 Zeolite16 Zeolite17 Filter element R1 Device R2 Device