rexresearch.com

Anatoly AKIMOV

Torsion Field Generators

Torsion Field Generators

YouTube : Akimov Lecture

Inst. of Quantum Genetics : Rejuvenation

RU2008111912 : The method of the uncontacted control of the ripple effects on the body's age characteristics...

Akimov, et al. : Models of polarized states of the physical vacuum and torsion fields

Inoan, et al. : Influence of torsion field on arabidopsis thaliana seeds germination

Akimov Torsion Field Generator

US6549805 : Torsion Diagnostic System...

RU2151204 : Steel Structural Characteristics Correction Method

RU2107105 : Method of Correction of Microstructure of metal Casting Alloys

SU1748662 : Method of Correction of Structural Characteristics of material and Device Thereof

US20070287881 : Destressing system, apparatus, and method therefor

Inst. of Quantum Genetics : Rejuvenation

RU2008111912 : The method of the uncontacted control of the ripple effects on the body's age characteristics...

Akimov, et al. : Models of polarized states of the physical vacuum and torsion fields

Inoan, et al. : Influence of torsion field on arabidopsis thaliana seeds germination

Akimov Torsion Field Generator

US6549805 : Torsion Diagnostic System...

RU2151204 : Steel Structural Characteristics Correction Method

RU2107105 : Method of Correction of Microstructure of metal Casting Alloys

SU1748662 : Method of Correction of Structural Characteristics of material and Device Thereof

US20070287881 : Destressing system, apparatus, and method therefor

https://www.youtube.com/watch?v=7LYsVXLRLJY

Lecture of brilliant Russian scholar, academician of the ACADEMY of NATURAL SCIENCES, Akimova A.e., in which he talks about the torsion fields.

Akimov A. E. studied models of physical vacuum, applied problems of torsion fields and technologies on new physical principles.

http://wavegenetics.org/en/portfolio-view/akimov-torsionnyie-polya/

INSTITUTE OF QUANTUM GENETICS

+7 (925) 022-67-37Rejuvenation

All want to quickly become young. But do not forget, the process of rejuvenation, running the programme us the spectra of the placenta, the cord blood of

newborns and children's photo,

THERE CAN BE NO FASTER AGEING PROCESS.

Although this phenomenon is not linear, and there are exceptions ...

So, We've had three patients about 60 and for the 70 years. They returned the menstrual cycle after a year of use-matrices by their children's photo. A month is a clear marker for the young State of the organism.

Another important point: I often write, for example — listening to already 10 days, and there is no effect. ». Answer. Our methods are not the magic wand magic wand and not apples from children's fairy tales-waved, ate and order. Was young and beautiful. No, This long work with faith and positive attitude.

Lying on the couch, nothing will. Quick positive effects are. Rare, but there are also. In extreme conditions of patients. In the final stages of cancer 4th degree. Or a hemorrhage in the brain, coupled with paralysis.

Our research and practice of the application of the principles of Lingvistiko-wave Genetics are in line with the priority work of molecular biology and genetics, Russian Academy of Sciences. See. video: Meeting of the Council for science and education, 20.12.2013.. Moreover, our results in this area substantially ahead of all the, that is received in the "classical" Genetics so far. No one in the world is not yet able to program stem cells, Since the methods used are based on an understanding of genes as a purely physical structures. And this is the error. Genes can function at a level of physical fields, as the quantum equivalent of ourselves. It predicted at the beginning of the last century our scientist A.g. Gurvich. We have confirmed this hypothesis and use wave genes in practice, treatment, inhibition of aging and rejuvenate people.

All matrices are unique because you are individual order.

RU2008111912

The method of the uncontacted control of the ripple effects on the body's age characteristics (halting aging and longevity) and the device for its enjoyment

[ PDF ]

The method of the uncontacted control of the ripple effects on the body's age characteristics (halting aging and longevity) and the device for its enjoyment

[ PDF ]

The method of contactless control of the wave action on the inhibition of aging and prolongation of the life of the organism, regeneration of organs and tissues by modulation by the donor of laser electromagnetic radiation and SHEI carrying metabolic information with the subsequent introduction of this information into the body, leading to corrective changes in its metabolism. !! 2. Method according to claim 1, characterized in that the acceptor (s) is placed at different distances both on the beam axis and outside it for receiving the control genetic-metabolic information from the donor (s). 3. The method according to claim 1, characterized in that the exposure of the scavenger (s) is performed by the SHEI, which is modulated by the donor (s) to alter the acceptor (s) metabolism, resulting in organ regeneration and inhibition of aging. 4. A device including a donor (s) on the optical axis of the laser radiation, characterized in that the electromagnetic radiation of the laser is modulated by the wave information program of the donor (s) when radiation is directed through it to the perceived organism or its organ.

5. The device according to claim 4, characterized in that the wave information program of the donor (s) is automatically formed by complex modulated electromagnetic signals - carriers of genetic-metabolic information of laser and information-related SHEI. 6. The device of claim 4, characterized in that a donor (s) is placed on the axis of laser radiation from a helium-neon laser between two plane-parallel glasses. 7. The device according to claim 4, characterized in that it reflects a portion of the laser beam that has passed through the donor and is modulated in a complicated manner, is returned back to the laser cavity.

https://link.springer.com/article/10.1007/BF00895770

DOI: 10.1007/BF00895770

Russian Physics Journal, March 1992, Volume 35, Issue 3, pp 214–222

Models of polarized states of the physical

vacuum and torsion fields

A. E. AkimovV. Ya. Tarasenko

AbstractA. E. AkimovV. Ya. Tarasenko

A model is proposed of the physical vacuum, taking into account the existence of fields generated by classical spins or angular momenta of rotation.

http://journals.usamvcluj.ro/index.php/agricultura/article/download/10248/8664

Agricultura – Stiinta si practica no. 1- 2(89-90)/2014 Agriculture - Science and Practice

Influence of torsion field

on arabidopsis thaliana seeds germination

University of Agricultural Sciences and Veterinary Medicine, Faculty of Horticulture

400372, 3-5 Manastur Street, Cluj-Napoca, Romania; laurainoan@yahoo.com

Abstract.

Arabidopsis thaliana seeds were exposed to left and right torsion field for 30, 60 and 90 minutes. The field was generated using the Comfort-7, a device that besides axial and radial components of axion field has also an azimuth component. After exposure the seeds were evaluated for energy and capacity of germination. Comparing the results obtained for seeds exposed to left and right torsion field and unexposed seeds, the influence of torsion fields improved the energy of germination by an overall difference of 36.6% and 39.33%. For the seeds exposed to left torsion field, the higher the time of exposure, the greater results were obtained; the energy of germination increased by 14% at 60 minutes and 28.33% for 90 minutes exposure comparing to the 30 minutes variant.

INTRODUCTION

Torsion field theory is rooted in the discoveries and ideas formulated by Einstein's colleague, Eli Cartan, who in 1913 first used the term torsion force referring to its twisting motion, at the same time establishing clearly the momentum density spin angular fields generated concept (Akimov A.E., 1997). As the electromagnetic field is produced by electric charge and the gravitational field by mass, rotation or spin of a mass generates torsion field. All these fields have effects on long distances. The term torsion may be defined as a variable which describes the rotation. Torsion field theory supporters scientists confirms that the interaction of spin - spin can be transmitted by, or through space like electromagnetic waves, except, however, that this does not possess energy and mass but only information. There are generators of torsion fields, electrical installations, the use of which allows us to modify the properties of material objects, such as liquids, metals and alloys. Explaining the nature of the torsion field, scientists have concluded that depending on the direction of rotation the torsion fields can be right or left. They have shown also that the right fields are beneficial to humans because they improve the fluidity of all environments, increase the conductivity of cell membranes and by increasing the fluidity they reduce the chance of blood clots, there is an improvement of metabolic processes, an improvement of human overall homeostasis (www.torser.com). In turn, the left fields have deleterious influence on humans. What is interesting is that just left torsion fields predominate if not all, then most electronic devices around us. Starting from this point, the main purpose of the carried out research was to check if torsion field action can affect the germination of Arabidopsis thaliana seeds.

Arabidopsis thaliana is an annual plant belonging to Brassicaceae family and a very common plant used for research in plant biology and genetics. The small genome, completely sequenced, makes it a model organism and generated a series of large scale Agricultura – Stiinta si practica no. 1- 2(89-90)/2014 Agriculture - Science and Practice projects aimed at discovering the functions of the 25.000 genes identified in Arabidopsis thaliana (Bevan and Walsh, 2005).

MATERIAL AND METHOD

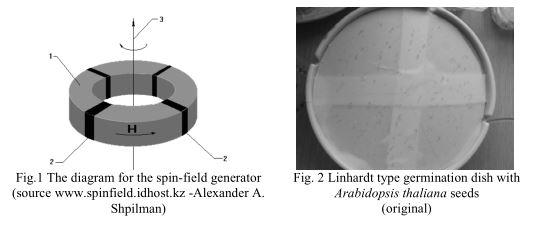

The research was carried out on Col-0 line Arabidopsis thaliana seeds received from the Institute for Plant Biology Szeged, Hungary. To generate torsion field, Comfort-7 was used, a device that has both axial and radial components of the axion field and an azimuth component. The device consists of four sections: the power supply, where a variable alternating current voltage is applied, two stator sections and a pulsed relay section (www.ussdiscovery.com). Spin field generator is shown in Fig.1 and consists of a rotating ferrite hollow cylinder (1) whose axis of rotation (3) coincides with the main axis of symmetry of the cylinder. In the cylinder are inserted, in the form of an oblique comb, four permanent magnets (2). The cylinder can be in the form of either a flat ring or a tube. Seeds were arranged in variants, each variant with three replications of 100 seeds.

The variants were exposed to left and right torsion field action and another one remained unexposed representing the control variant. For each torsion field three exposure times were studied, T1 = 30 minutes, T2 = 60 minutes and T3 = 90 minutes, in order to determine whether the duration of exposure to the torsion field action has an influence on seeds germination and on the future plant growth. After the Arabidopsis thaliana seeds were exposed to the torsion filed produced by Comfort-7 generator, they were placed in Linhardt type germination dishes to determine the germination capacity and energy of germination (Fig. 2).

During the entire germination process conditions of humidity, light intensity and temperature were stable and favorable to the process, with 30% relative humidity and 23 0 C.

RESULTS AND DISCUSSION

The first seeds began to germinate at two days after their placing into germination dishes and until the sixth day the maximum percentage of seeds were germinated for all variants. The energy of germination (%) varied from one variant to another based on the Fig. 2 Linhardt type germination dish with

Arabidopsis thaliana seeds (original)

Fig.1 The diagram for the spin-field generator (source www.spinfield.idhost.kz -Alexander A. Shpilman)

Science and Practice torsion field type action on which they have been subjected to and depending of the time of exposure (Table 1).

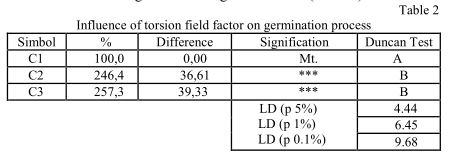

Table 1

Torsion field effect on the average energy of germination (%) of Arabidopsis thaliana seeds

Using analysis of variance for the processing and interpretation of statistical data obtained after germination, the following results were drawn relevant:

To highlight the differences regarding the speed of germination, between seeds exposed to the torsion field action and witness seeds, comparison of the results of the three variants was performed. The influence of torsion field factor on the start of seeds germination was one positively stimulating. Between variants represented by the seeds that were not exposed to torsion field (C1), considered the control version, and seeds subjected to the action of left torsion field (C2) and right torsion field (C3), there were extremely significant difference according to Duncan significance test (Table 2).

Table 2

Influence of torsion field factor on germination process

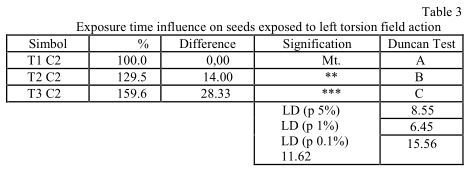

In the case of left torsion field, exposure time has a direct effect on the speed of germination. The difference between the first exposure time T1 = 30 minutes considered as witness in this comparison, and exposure time T2 = 60 minutes, the difference is highly significant. Extremely significant difference was observed between T1 and T3 = 90 minutes (Table 3).

Table 3

Exposure time influence on seeds exposed to left torsion field action

CONCLUSIONS

The effect of torsion fields proved to be stimulating for the germination process of Arabidopsis thaliana seeds and can be successfully used in the future to improve this process.

The seeds under the influence of torsion fields, both left and right, had an increased energy of germination comparing to the unexposed seeds, the improved germination ranged between 29 and 55% based on time of exposure.

For the seeds exposed to left torsion field, the time of exposure was an effective factor to the improvement of germination the differences increased along with time exposure and they were very significant, according to the results of statistical calculations performed.

REFERENCES

1. Akimov, A.E., G.I. Shipov. (1997). Torsion Fields and Their Experimental Manifestation. New Energy News, pp.11-14.

2. Bevan, M., Walsh, S. (2005). The Arabidopsis Genome: A foundation for plant research. Cold Spring Harbor Laboratory Press, New York.

3. http://www.torser.com/en/scientific_base/torsion_fields/torsion_fields_base_Univers/default.aspx, Accessed April 25, 2014.

4. http://www.ussdiscovery.com/torsion_field_generator.htm Accesed April 30, 2014;

5. http://spinfield.idhost.kz/ALMANACH/N3_95/S4_1a.htm, Accessed April 30, 2014.

Inoan Simona Laura, H. Criveanu

University of Agricultural Sciences and Veterinary Medicine, Faculty of Horticulture

400372, 3-5 Manastur Street, Cluj-Napoca, Romania; laurainoan@yahoo.com

Abstract.

Arabidopsis thaliana seeds were exposed to left and right torsion field for 30, 60 and 90 minutes. The field was generated using the Comfort-7, a device that besides axial and radial components of axion field has also an azimuth component. After exposure the seeds were evaluated for energy and capacity of germination. Comparing the results obtained for seeds exposed to left and right torsion field and unexposed seeds, the influence of torsion fields improved the energy of germination by an overall difference of 36.6% and 39.33%. For the seeds exposed to left torsion field, the higher the time of exposure, the greater results were obtained; the energy of germination increased by 14% at 60 minutes and 28.33% for 90 minutes exposure comparing to the 30 minutes variant.

INTRODUCTION

Torsion field theory is rooted in the discoveries and ideas formulated by Einstein's colleague, Eli Cartan, who in 1913 first used the term torsion force referring to its twisting motion, at the same time establishing clearly the momentum density spin angular fields generated concept (Akimov A.E., 1997). As the electromagnetic field is produced by electric charge and the gravitational field by mass, rotation or spin of a mass generates torsion field. All these fields have effects on long distances. The term torsion may be defined as a variable which describes the rotation. Torsion field theory supporters scientists confirms that the interaction of spin - spin can be transmitted by, or through space like electromagnetic waves, except, however, that this does not possess energy and mass but only information. There are generators of torsion fields, electrical installations, the use of which allows us to modify the properties of material objects, such as liquids, metals and alloys. Explaining the nature of the torsion field, scientists have concluded that depending on the direction of rotation the torsion fields can be right or left. They have shown also that the right fields are beneficial to humans because they improve the fluidity of all environments, increase the conductivity of cell membranes and by increasing the fluidity they reduce the chance of blood clots, there is an improvement of metabolic processes, an improvement of human overall homeostasis (www.torser.com). In turn, the left fields have deleterious influence on humans. What is interesting is that just left torsion fields predominate if not all, then most electronic devices around us. Starting from this point, the main purpose of the carried out research was to check if torsion field action can affect the germination of Arabidopsis thaliana seeds.

Arabidopsis thaliana is an annual plant belonging to Brassicaceae family and a very common plant used for research in plant biology and genetics. The small genome, completely sequenced, makes it a model organism and generated a series of large scale Agricultura – Stiinta si practica no. 1- 2(89-90)/2014 Agriculture - Science and Practice projects aimed at discovering the functions of the 25.000 genes identified in Arabidopsis thaliana (Bevan and Walsh, 2005).

MATERIAL AND METHOD

The research was carried out on Col-0 line Arabidopsis thaliana seeds received from the Institute for Plant Biology Szeged, Hungary. To generate torsion field, Comfort-7 was used, a device that has both axial and radial components of the axion field and an azimuth component. The device consists of four sections: the power supply, where a variable alternating current voltage is applied, two stator sections and a pulsed relay section (www.ussdiscovery.com). Spin field generator is shown in Fig.1 and consists of a rotating ferrite hollow cylinder (1) whose axis of rotation (3) coincides with the main axis of symmetry of the cylinder. In the cylinder are inserted, in the form of an oblique comb, four permanent magnets (2). The cylinder can be in the form of either a flat ring or a tube. Seeds were arranged in variants, each variant with three replications of 100 seeds.

The variants were exposed to left and right torsion field action and another one remained unexposed representing the control variant. For each torsion field three exposure times were studied, T1 = 30 minutes, T2 = 60 minutes and T3 = 90 minutes, in order to determine whether the duration of exposure to the torsion field action has an influence on seeds germination and on the future plant growth. After the Arabidopsis thaliana seeds were exposed to the torsion filed produced by Comfort-7 generator, they were placed in Linhardt type germination dishes to determine the germination capacity and energy of germination (Fig. 2).

During the entire germination process conditions of humidity, light intensity and temperature were stable and favorable to the process, with 30% relative humidity and 23 0 C.

RESULTS AND DISCUSSION

The first seeds began to germinate at two days after their placing into germination dishes and until the sixth day the maximum percentage of seeds were germinated for all variants. The energy of germination (%) varied from one variant to another based on the Fig. 2 Linhardt type germination dish with

Arabidopsis thaliana seeds (original)

Fig.1 The diagram for the spin-field generator (source www.spinfield.idhost.kz -Alexander A. Shpilman)

Science and Practice torsion field type action on which they have been subjected to and depending of the time of exposure (Table 1).

Table 1

Torsion field effect on the average energy of germination (%) of Arabidopsis thaliana seeds

Using analysis of variance for the processing and interpretation of statistical data obtained after germination, the following results were drawn relevant:

To highlight the differences regarding the speed of germination, between seeds exposed to the torsion field action and witness seeds, comparison of the results of the three variants was performed. The influence of torsion field factor on the start of seeds germination was one positively stimulating. Between variants represented by the seeds that were not exposed to torsion field (C1), considered the control version, and seeds subjected to the action of left torsion field (C2) and right torsion field (C3), there were extremely significant difference according to Duncan significance test (Table 2).

Table 2

Influence of torsion field factor on germination process

In the case of left torsion field, exposure time has a direct effect on the speed of germination. The difference between the first exposure time T1 = 30 minutes considered as witness in this comparison, and exposure time T2 = 60 minutes, the difference is highly significant. Extremely significant difference was observed between T1 and T3 = 90 minutes (Table 3).

Table 3

Exposure time influence on seeds exposed to left torsion field action

CONCLUSIONS

The effect of torsion fields proved to be stimulating for the germination process of Arabidopsis thaliana seeds and can be successfully used in the future to improve this process.

The seeds under the influence of torsion fields, both left and right, had an increased energy of germination comparing to the unexposed seeds, the improved germination ranged between 29 and 55% based on time of exposure.

For the seeds exposed to left torsion field, the time of exposure was an effective factor to the improvement of germination the differences increased along with time exposure and they were very significant, according to the results of statistical calculations performed.

REFERENCES

1. Akimov, A.E., G.I. Shipov. (1997). Torsion Fields and Their Experimental Manifestation. New Energy News, pp.11-14.

2. Bevan, M., Walsh, S. (2005). The Arabidopsis Genome: A foundation for plant research. Cold Spring Harbor Laboratory Press, New York.

3. http://www.torser.com/en/scientific_base/torsion_fields/torsion_fields_base_Univers/default.aspx, Accessed April 25, 2014.

4. http://www.ussdiscovery.com/torsion_field_generator.htm Accesed April 30, 2014;

5. http://spinfield.idhost.kz/ALMANACH/N3_95/S4_1a.htm, Accessed April 30, 2014.

http://www.hologrammatrix.com

The Akimov generator using own radiator removes the membrane between parallel worlds and opens the portals to the parallel worlds. The portal remains active for several days after turning off the generator. The portal parameters depend on the frequency spectrum supplied to the radiator. If two Akimov generators with the same spectra are switched on in various places this has to make a teleportation tunnel through which radio waves can pass in both directions.

The Akimov torsion generator generates left or right torsion field, modulated by various signals. It is possible to use this generator in various spheres such as information transfer, room cleaning, the changes of metals properties, charging of water and others.

Maintenance manual (extract).

The generator has two connectors. One of them is used for operating voltage (12V DC) supplied from power supply or battery. The second one is for the signal input from the signal generator or mp3 player with the sound recorded.

The Akimov generator begins to receive the signal started about 1 V range. The sound signal supplied to the circuit of the torsion generator amplifies up to the supply voltage and then transfers to the radiation source. The radiator is made as a conical condenser which is made using a copper conductor, wound in a spiral. This construction allows turning of the magnetic field of the coil perpendicularly to the magnetic field of the magnet which is located in front of the radiator.

There are two switches of the generator.

The first is for switching on and switching on the generator. The second one is for changing of the polarity of the torsion field, so the generator creates right or left torsion field.

Applications: water charging, influence upon plants, mineral products searching, the torsion field connection investigations.

After using the generator it is necessary to make a depolarization of the environment where it is located.

A phantom remains for a long time after operating of the generator so it is necessary to switch on the device into the opposite polarity mode to deactivate the phantom presence.

The supply of the generator must be positive in the center of the plug; the negative part of supply must be located on the cabinet of the generator.

US6549805

THE TORSION DIAGNOSTIC SYSTEM UTILIZING NONINVASIVE BIOFEEDBACK SIGNALS BETWEEN THE OPERATOR, THE PATIENT AND THE CENTRAL PROCESSING AND TELEMETRY UNIT

THE TORSION DIAGNOSTIC SYSTEM UTILIZING NONINVASIVE BIOFEEDBACK SIGNALS BETWEEN THE OPERATOR, THE PATIENT AND THE CENTRAL PROCESSING AND TELEMETRY UNIT

A biofeedback diagnostic system includes a central processing and telemetry unit and a triggering sensor. The central processing unit in turn includes a situation-generating block for producing a series of stimuli and transmitting them in parallel to both a patient and an operator of the system via a dual peripheral device. The stimuli can be of magnetic, audio, visual, or other nature. The triggering sensor is designed to remotely acquire the patient's feedback to the transmitted stimuli and send a digital signal back to the central unit. Two biofeedback loops are formed: between the central unit, the patient, and the triggering sensor; and between the central unit, the patient, and the operator, who is interpreting the test results without involving the conscious reaction of the patient.; The triggering sensor includes a noise generator to detect the patient's brainwaves and a detector channel equipped with a logoperiodic multi-turn spiral antenna to further enhance its sensitivity. To improve the patient's intuitive response, an optoelectronic element is placed of the patient's forehead and illuminated with a laser light at a frequency equal to that of the patient's brainwaves theta-rhythm. To isolate the torsion component of the laser light, a cavity resonator is employed with a volumetric chamber having a size being some multiple of the transmission frequency of about 1.45 GHz.

[0028] FIG. 1 is a general block-diagram of the diagnostic system of the present invention, and

[0029] FIG. 2 is a general block-diagram of the triggering sensor of the diagnostic system.

Interruptions

1 1.66 Dark Maroon DO

2 2.49 Red RE

3 3.32 Orange MI

4 4.15 Yellow FA

5 4.56 Green FA-Dies

6 4.98 Light Blue SOL

7 5.81 Blue LA

8 6.64 Violet SI

9 7.47 Dark Violet DO

[0047] Table 1 presents one example of various stimuli to be generated by the CPT unit 10 of the diagnostic system of the present invention. The moments in time when each stimuli sequence begins are all coordinated with each other and with the initiation of the triggering sensor and cadistor so that the operator and the patient receive the stimuli and both loops of biofeedback are formed.

SUBSTANCE: method involves treating steel melt till solid crystallization phase by torsion radiation of spectrum of at least three characteristic frequencies. Such method may be used for manufacture of cast parts, as well as for production of billets which may be used for further conversions. EFFECT: wider range of changes in physico-mechanical characteristics and improved structure of steel.

The invention relates to the field of metallurgy, in particular to the production of steels (ferrous alloys based on iron with a carbon content of not more than 2.14%), as well as alloy steels, and can be used for the manufacture of both cast parts and for casting blanks for Use in subsequent metallurgical operations.

There are known the possibilities of correcting the structural characteristics of various materials by exposing them to torsional radiation at the characteristic frequency.

Thus, a method is known for correcting the structural characteristics of materials, including metals, including metal treatment with torsion radiation at the characteristic frequency.

The method allows to change the properties of metals in order to obtain their given physicomechanical characteristics.

In this method, the treatment of chemically pure non-ferrous metals, such as, for example, tin or copper, is described as examples. The treatment is performed by torsion radiation at one separate characteristic frequency. For example, for copper after treatment with torsion radiation with frequencies of 6 and 100 Hz, the structure of the ingot shows an orderly microporosity, the size of which varies with the characteristic frequency of the torsion radiation source. It is not known from the indicated technical solution about the possibility of changing the structural characteristics of steel by the torsion field, as well as the possibility of changing the physicomechanical characteristics of materials due to the effect of torsion radiation with several characteristic frequencies at the same time. The design of the device intended for carrying out the method, although it is capable of generating torsion radiation with several frequencies, but this torsion source serves both for the direct determination of the values ??of the characteristic frequencies by their search, and for studying the structural changes introduced into the materials under the action of the torsion field on Identified individual characteristic frequencies.

The closest technical solution is a method for correcting the structural characteristics of steel, including processing the steel melt until the formation of its solid crystallization phase by torsion.

In this method, a structural reorganization of the steel taken in an amount of up to 200 kg was detected when it was exposed to torsion radiation from a torsion generator consuming 10 mW of electricity. However, the limitation of this method is the insufficiently high range of changes in the physicomechanical properties of steel.

The problem solved by the invention is an increase in the range of changes in the physico-mechanical properties of steel, and an improvement in the structure of steel.

The technical result that can be obtained by carrying out the invention is to increase the strength, yield strength, elongation, relative contraction, impact toughness by decreasing the relative content of ferrite, increasing the dispersity and uniform distribution of non-metallic inclusions, reducing the average grain size and obtaining equilibrium Forms.

In order to achieve the above-mentioned object with the attainment of said technical result, in a known method for correcting the structural characteristics of steel, including treating the steel melt prior to the formation of its solid torsion-phase crystallization phase, the melt processing of the steel is performed by torsion radiation with a spectrum of at least three Characteristic frequencies.

Additional embodiments of the method are possible in which it is expedient that: each of said characteristic frequencies be suitably selected in one of the intervals: 1 Hz to 20 MHz and / or 20.1 MHz to 200 MHz and / or 200.1 MHz to 2 GHz And / or 2.1 GHz - 200 GHz; - at least two of these characteristic frequencies were simultaneously selected in one of the intervals: 1 Hz-20 MHz or 20.1 MHz-200 MHz or 200.1 MHz-2 GHz or 2.1 GHz-200 GHz.

Due to the effect of torsion radiation on the melt, which simultaneously includes several characteristic frequencies in its spectrum, it is possible to form a homogeneous structure and certain grain sizes, which results in an improvement in the complex of physicomechanical properties (strength, yield stress, elongation, relative narrowing, Viscosity) of cast steel parts and blanks used for further metallurgical operations.

These advantages, as well as the features of the present invention, are explained by the best embodiments of the method for various steel grades.

The figure shows the functional diagram of the stand for torsion treatment of steel melt.

As a result of the action of external torsion radiation on the melt, the spin state of a system of free atoms in the melt changes. In this state, atoms experience mutual attraction through spin-torsion interactions. Due to this mutual attraction, the melt, as a spin system, becomes internally stable. As a result, the structure of the casting grains for steel after crystallization becomes more uniform, the shape of the grains is more balanced, and the non-metallic inclusions are evenly distributed throughout the casting volume. Internal stability of the ingot after crystallization leads to minimization or complete absence of macrodefects (cracks, pores, etc.). All these results combine to improve the mechanical properties of the steel, which can be illustrated by the examples below.

As studies have shown, in the case of steel processing, the use of a mono-frequency in the torsion generator as a signal does not lead to significant satisfactory results, since only one of any melt components has a change in structure. Under the action of mono-frequency or strengthen the influence on the overall structure of the ingot of this component, or weaken. In addition, in the melt there is a spread in the values ??of the natural frequencies of the oscillations of atoms of one chemical element or of the same type of molecules of chemical compounds, which is associated with an uneven distribution of the energy of thermal motion. As a result of the experiments it was established that the achievement of a more efficient structure change during torsion treatment of a melt is feasible in the case of applying a spectrum of certain characteristic frequencies for a torsion generator.

For the experiments, an induction melting unit UPI-0.5-3.0-440 produced by "Reltec", Ekaterinburg, consisting of an induction melting furnace IPP-0.5 and a semiconductor frequency converter PVG-3-440.

Technical characteristics of the furnace IPP-0.5: Capacity of the furnace 0,5 kg Power of the feeding converter 3 kW Power of the furnace 2,7 kW Number of phases of the supply network 1 Number of phases of the loop circuit 1 Frequency of the mains current 50 Hz Current frequency of the loop 440 kHz Nominal voltage Power supply 220 V Rated voltage on the inductor 900 V For each steel grade, 10 control and prototypes weighing 0.15 kg were manufactured. Castings after melting were heat treated (normalization at 920oC and tempering). The chemical composition of steels 35 L, 45 L, 20 GFL and 20 GL is given in Table. 1.

Mechanical tests were carried out on cylindrical samples, carved from castings, obtained as a result of experimental and control melting. The average values from the results of mechanical tests of control and prototypes are given in the tables for each grade of steel. In all experiments, the torsion beam device (source) was located 1 m from the crucible of the induction furnace. The effect of torsion radiation on the melt was carried out with predetermined components of the line spectrum of the characteristic frequencies prior to the start of casting, and this treatment processed the melt. For example, one of the generators described in [1] or [2] can be used as a source of torsion radiation.

Torsion radiation treatment was carried out in accordance with the functional scheme of the stand for torsion treatment of steel melt (Fig.1), where: 1 - torsion generator; 2 - radiating antenna of the torsion generator; 3 - reference radio frequency generators f1, f2, ..., fk; 4 - induction furnace; 5 - high-frequency block of induction furnace; 6 - power supply network; 7 - inductor; 8 - crucible.

It is clear that, in contrast to the described functional scheme, steel melt processing can also be performed by torsion radiation from individual torsion generators 1 with its radiating antennas 2, with the radiation of each torsion generator 1 having its reference frequency from its reference oscillator 3, and these emissions in The same time is processed by the melt in the crucible 8. However, such a functional scheme allows to obtain the same technical result, but only complicates the design. In addition, functional schemes are possible with the conversion of the reference frequency, its multiplication or division, which does not affect the essence of the claimed method. A feature of the method is the treatment of a steel melt with torsion radiation containing simultaneously at least three characteristic frequencies from a wide frequency range.

To achieve the required physicomechanical properties of the alloys (Fig.1), the torsion radiation with a spectrum consisting simultaneously of several characteristic frequencies from the torsion generator 1 is applied to the melt in the period before the change in its aggregate state. As a result of the action of torsion radiation on the melt in the crucible 8, the spin structure of the material changes, which leads to changes in the material properties shown in Table. 2-5. Characteristic frequencies are determined experimentally, for example, by examining the entire frequency range and choosing from it those characteristic frequencies that best satisfy the stated goal of the experiment and the required properties of the steel. When a pre-determined optimal spectrum of torsion frequencies is used, the spin structure induced in the melt forms a stable system. Torsion radiation creates torsion generator 1 and is formed due to the supply of radio signals to it at frequencies {fl, f2, ..., fk} from the reference generators 3 exciting certain characteristic frequencies.

The spectrum of characteristic impact frequencies for various materials can theoretically be in a very wide range from 1 Hz to 200 GHz. The frequency spectrum is a characteristic parameter for each steel. For steels of different brands, the corresponding components of the characteristic frequencies of the entire frequency spectrum are determined, which, according to studies, can lie in the intervals: 1 interval: 1 Hz - 20 MHz; 2 interval: 20.1 MHz - 200 MHz; 3 interval: 200.1 MHz - 2 GHz; 4 interval: 2.1 GHz - 200 GHz, and in accordance with the specific purpose of processing spectral components in some intervals may be absent.

It is a feature of the present invention that torsional radiation with certain characteristic frequencies in each individual interval mentioned is selected for treating the melt of steel, and practice shows that in most cases it is expedient to select a line spectrum. In addition, studies have shown that a given correction of steel parameters can be obtained when each of said characteristic frequencies is suitably selected in one of the intervals: 1 Hz to 20 MHz; 20.1 MHz - 200 MHz; 200.1 MHz - 2 GHz; 2.1 GHz - 200 GHz. Additionally, at least two of these characteristic frequencies can be simultaneously selected in one of the intervals: 1 Hz-20 MHz or 20.1 MHz-200 MHz or 200.1 MHz-2 GHz or 2.1 GHz-200 GHz.

Characteristic frequencies for specific chemical compositions of steels can lie, for example, on the edges of various frequency bands of intervals, in addition, in a number of situations it is necessary to form broadband noise rather than narrowband characteristic frequencies on specific frequency bands of intervals. For each particular impurity composition, the formation of the structure at the grain level, for example, their grinding, depends on the correct choice of the combination of the exposure time and the spectrum of the characteristic frequencies. At the same time, the changes in the crystal lattice depend mainly on the spectrum of the characteristic frequencies and, to a lesser extent, on the time of the action.

In particular, torsion radiation with characteristic frequencies of 10.5 Hz, 3 MHz, 50 MHz, 400 MHz, 1.3 GHz, and 20 GHz was used to treat the melt of 35 L steel and 45 L steel.

The duration of the torsion action on the melt is determined by the requirements for the parameters of the resulting metal and can range from 1 millisecond to 1 hour. In this case, the lower bound of the exposure time is determined by the minimum required specific (per unit volume) spin melt polarization (polarization with respect to the classical spin). The maximum time of the exposure interval is determined by saturation in the spin polarization of the composition of the entire volume of the material.

As shown by practical studies, when choosing frequencies from the frequency interval of less than 1 Hz, there is no significant change in the physico-mechanical properties of the steels. In turn, the use of frequencies from an interval above 200 GHz is economically impractical.

As a result of the experiments, samples with structural and mechanical characteristics were obtained: Experiment 1.

Steel 35 L (see Table. 2).

Experience 2.

Steel 45 L (see Table. 3).

Experience 3.

Steel 20 HFP (see Table. 4) Experience 4.

Steel 20 GL (see Table. 5).

As a result of the treatment of melts with torsional radiation simultaneously with several characteristic frequencies, the following main results were obtained: for steel 45, an increase in the yield stress st by 10.2%, a time limit of s s of 8.3%, grain size decreased by 1 point, cementite from lamellar became granular-lamellar; For steel 35 L - experiment 1: an increase in the yield stress st by 7.9%, a time limit of ss in 4.8%, the grain size decreased by 1 point, cementite from the lamellar became granular-lamellar; Experiment 2: an increase in the yield stress st by 13.7%, a time limit of s s of 10.6%, the grain size decreased by 2 points, the cementite from the lamellar became granular-lamellar; For steel 20 HFL, an increase in the yield strength of st by 7.4%, a time limit of s of 9.8%. The grain size decreased by 1 point, cementite from the lamellar becomes granular-lamellar; For steel 20 GL - an increase in the yield stress st by 8.7%, the limit of the time resistance s in 9.2%, the grain size decreased by 2 points, the cementite from the lamellar becomes granular-lamellar; When processing with torsion radiation using mono-frequency alone, rather than previously known methods for treating chemically pure non-ferrous metals or steels, as studies have shown for these steel grades, with some change in the structure (in particular, the average grain size), there is no appreciable change in the mechanical properties of steels (Table.

From a comparison of control and experimental samples, it can be seen that as a result of the application of the torsion radiation treatment of the melt, the following changes in the characteristic frequencies have occurred: a decrease in the grain size by 1-2 points; Instead of the lamellar form, granular (globular) cementite predominates; The size of globules of cementite is 1-3 µm; Perlite is located along the boundaries of ferrite grains. In addition, the grains become more rounded. Nonmetallic inclusions are distributed more evenly, and the dispersity of nonmetallic inclusions increases. In the experimental samples, the number of nonmetallic inclusions along the grain boundaries averages about 45%, while in the control samples, about 75%. As a result, the yield strength and ultimate strength of the steel increase.

Thus, when tungsten radiation is processed by a melt of steel with several characteristic frequencies, the improvement in mechanical properties is achieved by reducing the grain sizes to 8-9 points (while in the control samples of grain 7-8 points), more equilibrium forms of grains, increasing the dispersion and more uniform distribution of nonmetallic inclusions.

The most successful way to correct the structural characteristics of steel can be used in the metallurgical industry to produce steels with given physical and mechanical properties and with the improvement of their structure.

Sources of information 1. Patent of the USSR N 1748662, G 01 N 22/00, H 05 C 3/00, H 03 B 28/00, publ. 15.07.92 2. Akimov AE, Finogeev VP "Experimental

manifestation of torsion fields and torsional technologies". Ed. "NTC Informtekhnika", Moscow, 1996, p. 68h

FIELD: metallurgy, more specifically, methods for correction of microstructure in production of aluminium-base alloys with high mechanical and physical properties. SUBSTANCE: method consists in that in course of its melting and/or crystallization, alloy is exposed to torsion field with radiation frequency within the range from medium to extremely high ones. EFFECT: higher mechanical and physical properties of alloy of aluminium-silicon system due to reduced sizes of silicon crystals by 10 times.

The invention relates to the creation of alloys with increased physical and mechanical properties due to the correction of the microstructure of the metal in the melting and crystallization process.

There are known methods of changing the microstructure of alloys that affect the increase in their physicomechanical properties, by modifying various components in the melting process. In particular, a method is known for modifying the aluminum-silicon system by sodium and strontium eutectic aluminum alloy

However, the use of methods for modifying alloys in metallurgical production by other elements creates technological, economic and environmental problems.

A method for correcting the structure of the characteristics of materials is known [2], which consists in the action of a torsion field on the material.

Examples of exposure to this field with a radiation frequency of 6 and 1000 Hz on copper and tin melts during their crystallization have shown the possibility of changing the microstructure of the metal and increasing its mechanical properties. Thus, the microstructure of copper is obtained by ultradispersed, amorphous, and the hardness of tin is increased by 1.5 times.

The disadvantage of the known correction method is the fact that under the influence of torsion radiation in the above frequency range on the liquid metal, there is an insignificant ordering of the nuclear spins of the atoms of the individual components of the alloy, which has little effect on the change in the microstructure of the alloy and the increase in its physico-mechanical properties.

The object of the invention is to increase the physical and mechanical properties of metal casting alloys, preferably aluminum alloys.

The task is solved due to the fact that the alloy during its melting and / or / crystallization is affected by a torsion field with a radiation frequency in the ranges from medium to extremely high frequencies. These frequency bands are determined from the theoretical prerequisites of the greatest influence of torsion radiation on the ordering of the atoms of the alloy components due to the action of the spin moments of the atomic nuclei with an external torsion field and are confirmed experimentally. The positive result of the action on the alloy by the torsion field, both in the melting and crystallization process, and only during melting or crystallization is determined experimentally.

The carried out investigations of the aluminum-based alloy additionally showed that after the treatment of the alloy with a torsion field, there is a decrease in the electrical resistance of the metal.

Example. The aluminum-based eutectic alloy with a calculated silicon content of 12% by weight was melted in an induction furnace at 800 ° C, followed by pouring the metal into a container (chill) heated to 300 ° C. Weight of melting: 2 kg. Two ingots with a diameter of 50 mm and a height of 115 mm were cast from each melting. Ten ingots were cast in total, one of which was control and was irradiated with a torsion field with a frequency of 100 Hz, the remaining ingots were exposed to a torsion field with frequencies in the declared ranges. The effect of the torsion field was made with the help of broadband generators similar in design to the generator given in the information source [2]. The time of action of the torsion field on the alloy during its melting and / or crystallization depends on the chemical composition of the alloy, the mass of the liquid metal or ingot, the duration of crystallization, and the like. In this particular example, the exposure time to the alloy in the melting unit was 15 minutes and during the crystallization process it was 10 minutes.

To determine the physical and mechanical properties of the alloy, standard samples were cut from each ingot, tested for strength, plasticity, toughness, electrical conductivity, and microstructure studies of the alloy. The parameters of the effect on the alloy by the torsion field and the result of the tests are given in the table.

An analysis of the results of the tests shows that the effect on the alloy of the torsion field in the claimed frequency ranges makes it possible to substantially increase its physico-mechanical characteristics in comparison with the similar effect by 20%, the ductility has been increased almost twofold, the impact resistance has increased 1.3 times, the specific The electrical resistance decreased by 11%. The achieved improvement in physical and mechanical properties is due to a decrease in the silicon crystals in the microstructure of the aluminum alloy by almost 10 times.

The implementation of the invention opens wide opportunities for the production of cast alloys with increased physical and mechanical properties without using traditional methods to improve the properties of alloys by metallurgical modification.

Abstract

A device, system, apparatus, and method are disclosed for reducing stress in an individual by creating an enhanced informational spin field environment substantially surrounding the individual. Such informational spin field environment is at least partially derived from one or more dynamically produced informational spin fields wherein electromagnetic components associated with producing one or more of such dynamically produced informational spin fields are blocked from propagating therewith, such one or more dynamically produced informational spin fields being then conducted without accompanying electromagnetic signals to the environment substantially surrounding the individual.

1. Field of the Invention

This invention relates to a method, apparatus, and system for reducing stress in an individual.

2. Background of the Invention

The increasing complexity and population density of our society seems to be increasingly conducive to the creation of stress in the population. There has appeared, therefore, a growing need to identify more effective means of alleviating stress, and as a result a variety of new therapies and technologies for dealing with stress have surfaced over the past century.

Stress is viewed as the cause of many forms of unhappiness in people, such as irritability, depression, anger, emotional instability, withdrawal, restlessness, anxiety and frustration, and dysfunction in all living beings. The link between stress and health is well known. The Journal of Occupational and Environmental Medicine observes that health care expenditures are nearly 50% greater for workers who report high levels of stress. Medical symptoms widely attributed to stress include increased heart rate and blood pressure, headache, nausea, indigestion, and insomnia. In fact, the onslaught of disease more generally is increasingly being related to stress. The American Institute of Stress, founded in 1978 by such notables as Linus Pauling, Alvin Toffler, Herbert Benson, and numerous other prominent scientists and physicians, currently describes stress as "America's No. 1 health problem." In answer to the question as to how stress can cause so many diseases, the Institute states, "many of these effects are due to increased sympathetic nervous system activity."

It is well known that stress can be relieved in humans by rest, and by resorting to natural environments such as lakes, seashores, mountains, gardens, and forests. It is also well known that spas, soft lights and certain types of sound or music can relieve stress. In some cases light and color have been observed to have benefits with respect to both stress alleviation and healing. Spectro-Chrome, a colored light therapy introduced in 1920 by Dinshah Ghadiali, developed an impressive array of successes in healing a wide range of diseases over a thirty year period. Sound healing CDs have been produced by Andrew Weil, M.D., founder of the Program in Integrative Medicine at the University of Arizona, and Mitchell Gaynor, M.D., founder and president of Gaynor Integrative Oncology in New York City.

A device invented and patented by Barry McNew (U.S. Patent No. 6,544,165) uses a combination of music and light to accomplish stress reduction and healing. An individual lies in a horizontal cabinet designed to resonate with sound corresponding to a B minor (C flat minor) chord. Successful clinical results for this device are described in the Proceedings of the First Interdisciplinary International Conference on the Science of Whole Person Healing. McNew's device is specifically described as being directed at balancing the sympathetic and parasympathetic elements of the autonomic nervous system. McNew's international patent application, published under the Patent Cooperation Treaty (WO 2005/058144 & PCT/US2004/042451), describes the use of indicia such as involuntary eye or foot movements as references for the operator in adjusting sound and light inputs to the device to accomplish balancing the environment within the device to achieve the desired effect. Destressing is specifically claimed as an attribute of the device, with supporting evidence being accumulated on numerous subjects using HRV monitoring before and after exposure to the device. A typical exposure of an individual in the device is described as one hour at a session.

The past two decades have seen an increasing recognition by scientists of the existence of a new fundamental field in physics beyond the long recognized electrical, magnetic, gravitational, and strong and weak nuclear attraction fields, namely, the informational field (IF), with characteristics unique as compared with the classical fields. An example of an informational field is shown in the conservation of twin photons in entanglement experiments, where the transfer of information necessary to conserve spin can happen without energetic properties.

This more newly recognized field has been described by other names as well, such as torsion field, spin field, and informational spin field. The seminal work in understanding and demonstrating the reality of informational fields was done in the former Soviet Union by Russian physicist Anatoly E. Akimov, a coinventor of the present invention, and Russian theoretical physicist Gennady I. Shipov, both of the International Institute of Theoretical and Applied Physics of the Russian Academy of Natural Sciences. A summary of the theory and numerous technologies created as a result of this discovery appears in Dr. Akimov's paper delivered in Moscow in 2000, entitled, Horizons of XXI Century Science and Technologies. A description of the mathematical basis further elaborating and supporting the theory is described in Dr. Shipov's book, A Theory of Physical Vacuum-A New Paradigm, published in Russian in 1993, and in English in 1998.

In the experimental work with informational spin fields (ISFs), ISFs were found to have different properties than known classical fields. For example, they do not decrease with distance, as all of the other known fields do, according to the inverse square law. ISFs have a spatial structure corresponding to axial symmetry. Objects with like (left-oriented or right-oriented) spins attract, unlike objects with like electrical charges, which repel. ISFs are capable of spin-polarizing space, such that even when a source of an ISF is removed, the space where the field was tends to retain its ISF-influenced state for a period of time.

Informational spin fields have the ability to affect matter under certain circumstances, especially in materials undergoing a phase change, and tend to influence the alignment of electron, nuclear, and atomic spins. This fact was verified by experiments carried out in the Soviet Union using the Mossbauer Effect. In this effect, the only known interaction with the material under investigation is through spin, and the ISF created by devices designed by Anatoly Akimov did affect the materials. Thus, it was proven that these informational fields relate to spin, which is why the term "spin" is being included in the name of these informational fields described herein.

It is presently postulated by some scientists that ISFs carry information, and can impart that information to matter in the form of phase information associated with varying degrees in the precession of spins. Experiments by Dr. Akimov and others show that ISFs can, under certain circumstances, affect crystal structure and molecular structure, and consequently physical properties, in materials.

Informational spin fields are known to be generated in numerous ways. Statically generated ISFs occur inherently with physical geometry. For example, stationary objects, such as spheres, cones, cylinders, and tetrahedrons, all generate static ISFs. The intensity of static ISFs increases with specific ratios in the geometry of the object, such as, for example, the phi ratio of approximately 1.618, as well as with the increasing size of the object.

Dynamically generated ISFs are produced by bodies with angular motion, for example, rotating spheres and nuclear and atomic particles. Dynamically generated ISFs are produced by electromagnetic radiation as well, such as by light and by rotating magnetic fields. An example of an ISF created when rotating a magnet about an axis is illustrated in a device presently produced in Kazakhstan and marketed internationally by Alexander A. Shpilman. Dynamically generated ISFs can also be produced by combinations of geometry and changing electromagnetic fields. Soviet patent No. 1748662 patenting such a device together with its use in modifying the properties of materials was issued in 1992 with priority since 1990 to Anatoly Akimov et al.

The existence of biofields surrounding living beings has been established by scientists over the past several decades. Valerie Hunt, a Professor Emeritus of UCLA, was able use the patterns in electromyograph signals to consistently correlate patterns in the human biofield observed by individuals who could directly perceive them. The results of her 25 years of research and clinical studies demonstrating these results were presented in 1989 in her book, Infinite Mind. More recently, Konstantin Korotkov, Professor of Physics at St. Petersburg State Technical University in Russia, introduced a commercial device using a Gas Discharge Visualization (GDV) technique (Kirlian method), and is also able to correlate parameters measured by that device with those patterns observed by individuals who could directly perceive the human biofield. The GDV device outputs have successfully correlated with the real time introduction of stimulation to human subjects experiencing aromas, physical injury, and other stimuli. Biofields themselves appear to be informational spin fields, based upon research observations of Dr. Anatoly Akimov correlating images of biofields observed by individuals who could directly perceive them, with their direct perceptions of the outputs of dynamic ISF generators.

BRIEF SUMMARY OF THE INVENTION

The present invention mitigates stress in individuals and improves the efficiency of stress alleviation afforded by other available environments and techniques. The present invention provides a device, system, apparatus and method for reducing stress in an individual by creating an enhanced informational spin field environment substantially surrounding the individual. The term "informational spin field" or "ISF," as used herein, refers to a field also commonly known as a torsion field.

In embodiments of the present invention, an apparatus for destressing is provided that is configured to temporarily accommodate an individual, preferably such that the individual can assume a resting position. The apparatus is configured with a series of elements whose geometrical arrangement corresponds to a predetermined pattern. In one example, the apparatus comprises a support structure configured to act as a bed and two end structures joined to and orthogonal to the bed. In one embodiment of the present invention, the end structures each comprise multiple layers of electrically insulating material, such as wood. In embodiments of the present invention, a pattern of metallic tape, such as copper, is laminated between each wood layers comprising each end structure. In one embodiment of the present invention, the pattern of the copper tape comprises a six-pointed star geometry comprised of two superposed equilateral triangles, also know as a Star of David. Preferably, the patterns are arranged opposite each other such that each apex of a star pattern can be connected to a corresponding apex by a conductive member that is mutually orthogonal to both end structures. In one embodiment of the present invention, each end structure comprises a trilayer assemblage of wood layers, in which the middle layer includes a metallic tape pattern affixed thereto.

In one embodiment of the present invention, the end members are joined to each other by a series of six metallic tubes that are substantially orthogonal to each of the end members. Preferably, the orthogonal metallic tubes are mutually arranged to each interconnect a point of a metallic Star of David that is laminated between outer and inner boards of an end structure with a corresponding point in a similar structure on the opposite end member. The laminated Star of David pattern may be affixed to a middle board of trilayer structure, or alternatively may be at the interface of an inner and outer board of a bilayer end structure. Preferably, six metallic tubes are arranged to interconnect all six apices of a metallic Star pattern located in a first end structure with a corresponding six apices in a metallic Star pattern located in the opposite end structure to the first end structure. Accordingly, an individual resting on a bed disposed between the end structures lies within a hexagonal prism whose long edges parallel to the cylinder axis are defined by the metallic pipes.

In embodiments of the present invention, the apparatus for destressing further includes a hexagonal projector located in an upper portion of the apparatus and configured with a series of six cones. Preferably, the hexagonal projector is configured to slide in a direction parallel to the bed structure. Preferably, the destressing apparatus also includes a ball radiator that includes a small metallic sphere that is configured to slide in a direction parallel to that of the hexagonal projector.

In accordance with the above-described elements, a static informational spin field environment can be provided in a spatial region designed to accommodate individuals of varying size within the destressing apparatus. Once substantially inside a region corresponding to the hexagonal prism, the static ISF environment created by the destressing apparatus efficiently interacts with the biofield of the individual, such that a destressing process is initiated.

In other embodiments of the present invention, the disclosed device, system, apparatus and method provide an informational spin field environment substantially surrounding an individual which is at least partially derived from one or more dynamically produced informational spin fields, wherein electromagnetic components associated with producing one or more of such dynamically produced informational spin fields have first been substantially separated therefrom, such one or more dynamically produced informational spin fields being then conducted to the environment substantially surrounding the individual. The term "dynamically produced informational spin field," as used herein, refers to an ISF that is produced at least in part from the time-dependent variation of an entity, such as a varying magnetically-induced spin field, electromagnetic signal, electromagnetic current, or electromagnetic radiation.

In embodiments of the present invention, an apparatus is configured to establish an ISF environment in a region configured to accommodate a resting individual, wherein the ISF environment comprises a dynamically produced informational spin field resulting predominantly or in whole from inputs from a magnetic, electric, or electromagnetic source. In other embodiments of the present invention, the ISF environment is created by a combination of elements configured to generate static ISFs together with sources that serve to generate one or more dynamic ISFs, such as electromagnetic, magnetic, or electrical signals.

The present invention provides a system for alleviating or reducing stress in an individual comprising an informational spin field environment substantially surrounding an individual, which is at least partially derived from one or more dynamically produced informational spin fields, wherein electromagnetic components associated with producing one or more of such dynamically produced informational spin fields have first been substantially blocked from propagating with the informational spin field produced therefrom, such one or more dynamically produced informational spin fields being then conducted without any accompanying electromagnetic field to the environment substantially surrounding the individual.

The present invention also provides a method for alleviating or reducing stress in an individual, comprising providing an informational spin field environment substantially surrounding such individual, which is at least partially derived from one or more dynamically produced informational spin fields, wherein electromagnetic components associated with producing one or more of such dynamically produced informational spin fields have first been substantially separated blocked from propagating with the informational spin field produced therefrom, such one or more dynamically produced informational spin fields being then conducted without any accompanying electromagnetic field to the environment substantially surrounding the individual.

In one embodiment of the present invention, the dynamically produced informational spin field source utilizes an electromagnetic signal to generate an informational spin field, wherein the electromagnetic signal itself is substantially separated from the informational spin field produced therefrom, said informational spin field produced therefrom being then conducted to the environment substantially surrounding the individual. In one embodiment of the present invention, the dynamic informational spin field source utilizes an electromagnetic signal derived from a musical sound input to generate an informational spin field, wherein the electromagnetic signal itself is substantially blocked from propagating with the informational spin field produced therefrom, said informational spin field produced therefrom being then conducted without any accompanying electromagnetic field to the environment substantially surrounding the individual.

In one embodiment of the present invention, the dynamic informational spin field source utilizes an electrical signal from a compact disk (CD) or magnetic tape player to generate an informational spin field, wherein the electromagnetic components of the electrical signal itself are substantially blocked from propagating along with the informational spin field produced therefrom, wherein the informational spin field produced therefrom is conducted to the environment substantially surrounding the individual without accompanying electromagnetic radiation or electric signals.

In one embodiment of the present invention, the informational spin field environment is at least partially derived from one or more light sources wherein the electromagnetic components of the light emitted therefrom are substantially blocked from propagating with the informational spin field produced by the light, said informational spin field being then conducted without accompanying light to the environment substantially surrounding the individual.

In one embodiment of the present invention, means are provided to modify and/or adjust the informational spin field environment in either composition or intensity or both so as to be made harmonious for an individual substantially surrounded by such environment. In one embodiment, the informational spin field of the present invention is modified and/or adjusted in either composition or intensity or both in response to one or more autonomic responses of the individual substantially surrounded by said informational spin field environment so as to make it harmonious for said individual.

In one embodiment of the present invention, the informational spin field environment is partially derived from one or more statically generated informational spin fields.

In one embodiment of the present invention, means are provided to cause the primary localization of the information spin field environment within the vicinity of the individual.

In one embodiment of the present invention, either music or light is additionally provided to the individual directly in order to provide an aesthetic benefit.

The present invention offers the potential of improved efficiency as compared to means of achieving stress reduction by the practices of the prior art. Significantly positive results are observable in 15 to 30 minutes exposure to the informational spin field environment of the present invention. In a society in which the time to deal with one's own needs is frequently scarce, this advantage of the present invention is very important. Moreover, this feature offers the possibility for commercial employers to provide the benefit of such a device to employees in the work environment to improve morale and productivity, since the economic return in terms of increased worker efficiency does not have to be very large to justify perhaps only a 15-minute break exposure to the environment of the present invention.

While not wishing to be bound by any particular theory, it is believed that all destressing environments owe their effects to the presence of ISFs. Unlike the case with music and light healing environments, in which the inputs to such environments are acoustic and electromagnetic, any ISF intensity of such environments must be limited to lower levels because of potential discomfort or even harm to an individual at high levels of sound or light exposure. By virtue of the ability to prevent electromagnetic and acoustic signals from propagating in the environment surrounding an individual, the present invention provides a means to achieve higher ISF levels in the immediate physical surroundings of an individual without the need to incur high levels of electromagnetic radiation or acoustic signals in the same physical surroundings. This facilitates optimizing the destressing effect within a minimum of time without introducing unwanted or negative side effects of excessive electromagnetic or acoustic energy near the individual. Moreover, acoustic or electromagnetic components can in themselves create unwanted interactions in certain instances. The feature of the present invention of minimizing or eliminating any acoustic inputs and filtering out electromagnetic components from ISF inputs to the environment substantially surrounding the individual permits the creation of effects on the individual that are solely positive, and therefore adds to the efficiency of achieving the destressing result.

Unlike certain therapies, such as spas, hot tubs and saunas, which produce relaxation and stress alleviation at the expense of creating lethargy, individuals exposed to the informational spin field environment of the present invention report feeling energized, yet relaxed.

BRIEF DESCRIPTION OF THE DRAWINGS

In order that the invention will be readily understood, a more particular description of the invention will be rendered by reference to specific embodiments that are illustrated in the appended drawings. Understanding that these drawings depict only typical embodiments of the invention and are not therefore to be considered limiting of its scope, the invention will be described and explained with additional specificity and detail through the use of the accompanying figures, in which:

FIG. 1 depicts one embodiment of an apparatus in accordance with the present invention, in which an individual is situated in a reclining position appropriate to its use;

FIG. 2a is a schematic perspective view of a system for destressing, in accordance with an embodiment of the present invention;

FIG. 2b is a schematic diagram of a perspective view of a hexagonal prism region defined by longitudinal members, in accordance with one embodiment of the present invention;

FIG. 2c is a schematic diagram of a front view and side view of an end structure of the system of FIG. 2a, in accordance with one embodiment of the present invention;

FIG. 2d is a schematic diagram of an exploded view of the end structure of FIG. 2c, in accordance with one embodiment of the present invention;

FIG. 2e is a schematic diagram that illustrates an exemplary hexagonal metallic tape pattern and collector of the middle panel of the end structure of FIG. 2c, in accordance with an embodiment of the present invention;

FIG. 2f is a schematic diagram that illustrates the opposite side of the panel shown in FIG. 2e, showing details of the collector, according to an embodiment of the present invention;

FIG. 2g is a schematic diagram that illustrates details of a collector star plate, in accordance with one embodiment of the present invention;

FIG. 2h is a schematic diagram of a side view of the destressing system of FIG. 2a, showing the collector in relation to the system;

FIG. 2i is a schematic diagram that depicts details of an inner panel of the end structure of FIG. 2c, in accordance with an embodiment of the present invention;

FIG. 2j is a schematic diagram that depicts a side view of an end structure of FIG. 2c, showing carriage bolt locations, in accordance with an embodiment of the present invention;

FIG. 2k is a schematic perspective view of a system for destressing, in accordance with another embodiment of the present invention;

FIG. 2l is a schematic illustration that depicts elements of a system for destressing in accordance with an embodiment of the present invention;

FIG. 2m is a schematic illustration that depicts elements of a system for destressing in accordance with an embodiment of the present invention;

FIG. 3 is a schematic diagram that illustrates details of an end structure outer panel, in accordance with one embodiment of the present invention;

FIG. 4 is a schematic diagram that shows the configuration and dimensions of the two inner end panels of the system illustrated in FIG. 2k, with the copper tape shown in FIG. 4 applied to one side of each of the two inner end panels on the faces respectively away from the individual as they would recline within the apparatus, and with the slot shown situated on the edge of the respective inner end panel that would be on the reclining individual's left, permitting one copper tube on that side to be removed to permit convenient ingress and egress of the individual from the apparatus, according to an embodiment of the present invention;

FIG. 5 is a schematic diagram of an assembly drawing for a bed of the system illustrated in FIG. 2a, upon which the individual is shown reclining in FIG. 1;

FIG. 6 is a schematic diagram of an assembly drawing for a top assembly configured for use in the system illustrated in FIG. 2a;

FIG. 7a is a schematic diagram of an assembly drawing for a foot assembly configured for use with the apparatus depicted in FIG. 2a, according to an embodiment of the present invention;

FIG. 7b is a schematic diagram of an assembly drawing for a foot assembly configured for use with the apparatus depicted in FIG. 2k, according to another embodiment of the present invention;

FIG. 8a is a schematic diagram of an assembly drawing of an exemplary dynamic ISF generator component configured for use with the apparatus depicted in FIG. 2a, according to an embodiment of the present invention;

FIG. 8b is a schematic diagram of an assembly drawing of another exemplary dynamic ISF generator component configured for use with the apparatus depicted in FIG. 2k, according to an embodiment of the present invention;

FIG. 9 is a schematic diagram of a diagram showing detail of electrical connections for the capacitor component of the ISF generators shown in FIGS. 8a and 8b, according to an embodiment of the present invention;

FIG. 10 is a schematic diagram showing an exemplary configuration and exemplary dimensions of the copper cone component of the ISF generators of FIGS. 8a and 8b, according to an embodiment of the present invention;

FIG. 11 is a schematic diagram showing an exemplary configuration and exemplary dimensions of the bottom Teflon(TM) cone mount component of the ISF generator of FIGS. 8a and 8b, according to an embodiment of the present invention;

FIG. 12 is a schematic diagram showing an exemplary configuration and exemplary dimensions of the top Teflon(TM) cone mount component of the ISF generator of FIGS. 8a and 8b, according to an embodiment of the present invention;