rexresearch.com

Philip BRASHER

Pneumatic Breakwater

Pneumatic Breakwater

Popular Science ( December 1924, p. 61 )

"Air Bubbles Employed To Form

Breakwater"

A new type of breakwater consisting of nothing more than air bubbles recently was devices for quieting even the highest waves of the sea. It is the invention of Phillip Brasher, an American. One of the units is said to have been operated successfully at El Segundo, CA, to protect a concrete pier.

The air breakwater consists of a perforated pipe that is laid along the sea bottom and connected with a land air-compressing station. In rough weather it is merely necessary to allow the compressed air to escape from the holes in the pipe, the air bubbles quickly rising to the surface. The wall of bubbles is said to break up the waves and retard their forward motion. When the water from a broken wave flows back to form a base for the next incoming wave, it finds no support and the next wave curls over and breaks.

The repetition of this process is said to result in a smooth surface beyond the pipeline, no matter how rough the weather. A simple installation of the pipe system, the inventor says, is sufficient to provide a harbor of smooth water in exposed points around coasts that have caused trouble in the past.

http://books.google.com/books?id=fpkiAQAAMAAJ&pg=PA9924&lpg=PA9924&dq=Philip+Brasher+breakwater&source=bl&ots=t0t0iMO3IO&sig=vKurN5j3BPf8PTyCZgJAWG6Mplk&hl=en&sa=X&ei=h1meU9erEo-2yATQrIC4Dw&ved=0CCcQ6AEwAg#v=onepage&q=Philip%20Brasher%20breakwater&f=false

Compressed Air Magazine ( January 1921, pp. 9924-27 )

http://books.google.com/books?id=mBFbAAAAYAAJ&pg=PA526&lpg=PA526&dq=Philip+Brasher+breakwater&source=bl&ots=CLh37-a5Ll&sig=NnuydtNxUrEqUi2EddlGpKp0fuo&hl=en&sa=X&ei=h1meU9erEo-2yATQrIC4Dw&ved=0CCkQ6AEwAw#v=onepage&q=Philip%20Brasher%20breakwater&f=false

Princeton Alumni Weekly, Volume 21

http://books.google.com/books?id=YptAAQAAMAAJ&pg=RA5-PA24&lpg=RA5-PA24&dq=Philip+Brasher+breakwater&source=bl&ots=60HXz09ATv&sig=cNPsI8j0TkutDW_KJ1Nz9haRip0&hl=en&sa=X&ei=h1meU9erEo-2yATQrIC4Dw&ved=0CCsQ6AEwBA#v=onepage&q=Philip%20Brasher%20breakwater&f=true

The Literary Digest ( February 21, 1921, pp. 24-25 )

Similarly :

US Patent # 2,325,937

Method & Apparatus For Collapsing Water Waves

Method & Apparatus For Collapsing Water Waves

My invention relates to an improved method of and apparatus for use in connection with water waves, being more particularly adapted for collapsing water waves to produce a relatively quiescent area of appreciable size in proximity to a ship, whereby planes can be launched from the ship without the use of a catapult, and may be picked up again without the necessity of the ship coming to rest.

More specifically the present invention provides for collapsing water waves continuously from a ship which may be proceeding at 12 or 15 knots or even at higher speeds, the quiescent area thus produced overlapping in extent to permit the launching of a plane from the moving ship without a catapult and to permit the plane t be picked up again without stopping the ship.

My invention, it will be appreciated, is of great practicable worth in connection with combating submarines, in that any ship large enough to carry a plane, but which may be too small to carry a catapult, can be employed for reconnaissance purposes and for actual bombing of submarines, launching and picking up of the plane being feasible and practicable with the ship under way so that she may be maneuvered if desired.

It will be seen from the description hereinafter given that the equipment necessary for the practice of my invention is simple, and takes up only a fraction of the space required for catapult launching apparatus. The plane can be launched and picked up with a crane. As a consequence the number of ships which may carry one or more planes is enormously increased as compared with existing practice.

In the accompanying drawings I have shown an embodiment of my invention more or less diagrammatically:

Figure 1 showing the invention in plan; and

Figure 2 being an elevational view.

Referring to the drawing in detail: 2 designates a ship carrying an air compressor 4, to which an air hose 6 is adapted to be coupled. The air compressor is mounted at the forward part of the ship, and as the hose 6 is to be towed overboard, its length will depend upon the height and length of the ship. In practice it should be long enough to extend rearwardly of the ship about as shown in the drawing. This hose is flexible and open at its outer end 8.

In practicing my invention the hose is thrown overboard and towed by the ship when a plane is to be launched or picked up. As above noted, launching and picking up are performed with the ship traveling at say 12 or 15 knots which will give it the desired steerage way and maneuverability. The open end 8 of the hose 6 is to be submerged to a depth of 75 to 100 feet. For this reason and in order that the open end of the hose may be maintained at the desired distance from the ships' hull, and will not simply trail beside the ship, I equip the hose with a paravane 10.

When an elastic fluid such as air is discharged by the compressor through the submerged outer end of the hose 6, air and water will be forced to the surface to provide in effect an upwardly moving wall or damp against which approaching waves will dash and be collapsed. Back of this fluid breakwater or dam, that is, between it and the ship, there will be a quiescent area 12 of substantial proportions into which a plane may be launched from the ship simply by lowering the same overboard and from which a plane may be picked up. This quiescent area will be maintained even on intermittent operation of the compressor for two or three minutes after the compressor is shut off.

Inasmuch as the quiescent area persists some two or three minutes after the compressor is shut off, it will be apparent that with a ship proceeding at say the equivalent of 5 miles per hour I can produce a quiescent area one-half to three-quarters of a mile long and of substantial width. The width of the quiescent area will depend, of course, upon the distance between the outer end of the hose 6 and the ship.

It will be appreciated, furthermore, that not only will the provision of such a quiescent area enable a plane to be launched from the ship without a catapult and to be picked up, but the ship itself will be in this area so as to provide a steady gun platform for both horizontal and antiaircraft fire should demands require it.

It is to be understood that for illustrative purposes I have shown but a single hose 6. Several may be employed if desired from the same or from opposed sides of the ship.

It will be seen that the equipment necessary for the practice of my invention is simple and inexpensive, requires by very small space on shipboard, and that no expensive controlling mechanism is necessary.

I wish it to be understood that any dimensions above mentioned as to length of hose, depth of submergence, size of hose, etc., are illustrative and not for purposes of limitation, and that the same may be changed within the purview of my invention.

US2492949

Apparatus for collapsing water waves

Apparatus for collapsing water waves

US1593863

Breakwater

US1391992

Protecting objects from wave action

US84392

PROTECTING OBJECTS FROM WAVE ACTION.

GB190725654

Improvements in or relating to the Protection of Objects from the Action of Water Waves.

CA219680

APPARATUS TO COUNTERACT WAVE ACTION

http://journals.tdl.org/icce/index.php/icce/article/viewFile/2052/1724

CHAPTER 43

AN EXPERIMENTAL STUDY OF HYDRAULIC BREAKWATERS

AN EXPERIMENTAL STUDY OF HYDRAULIC BREAKWATERS

[ PDF ]

Lorenz G. Straub

Director, St. Anthony Falls Hydraulic Laboratory

John B. Herbich

Assistant Professor, Lehigh University

C. E. Bowers

Research Associate, St. Anthony Falls Hydraulic Laboratory

INTRODUCTION

A hydraulic or water-jet breakwater is formed by- forcing water through a series of nozzles mounted on a pipe which is installed perpendicular to the direction of the incident waves. The jets create a surface current which results in breaking of the incident wave. Apparently, this effect is primarily responsible for attenuation of the incident wave. An earlier development, the pneumatic breakwater, operates on a similar principle with a horizontal surface current induced by rising air bubbles...

http://calhoun.nps.edu/public/bitstream/handle/10945/24879/useofpneumaticbr00howe.pdf?sequence=1

The Use of a Pneumatic Breakwater

...

http://books.google.com/books?id=aoM3AQAAMAAJ&pg=PA403&lpg=PA403&dq=Philip+Brasher+breakwater&source=bl&ots=jRxx0D8gU9&sig=HORkVZfW-eMYLWy1yNXFYFfgphc&hl=en&sa=X&ei=kWOeU8rlAsGfyAS6iIKoBw&ved=0CCgQ6AEwADgK#v=onepage&q=Philip%20Brasher%20breakwater&f=false

Scientific American, Volume 114

http://www.icevirtuallibrary.com/content/article/10.1680/ipeds.1956.11769

DOI: 10.1680/ipeds.1956.11769

E-ISSN: 0534-2767

ICE Proceedings: Engineering Divisions, Volume 5, Issue 1, 01 February 1956 , pages 91 –93

PNEUMATIC AND SIMILAR BREAKWATERS.

Author: J T EVANSPaper No 6090 PNEUMATIC AND SIMILAR BREAKWATERS by John Turle Evans, O.B.E., B.Sc.(Eng.), M.I.C.E. (Ordered by the Council to be published in abstract form) 7 A PROCESS for calming waves by injecting air bubbles beneath the surface waa first developed and patented by American, Mr Philip Brasher, in the early years of the an present century. I n 1915, and for several years after, the method was successfully used to protect from wave action a pier used by the Standard Oil Company at El Segundo, California...

Method for diminishing wave heights

US 3103788

US 3103788

G. E. GROSS

This invention relates to wave control and particularly to simple and economical means for eliminating or substantially reducing waves, as on a lake, ocean, or the like.

Waves in large bodies of water (and sometimes in small ones) cause no end of trouble. They make swimming difficult and often lead to a dangerous undertow. Waves often seriously damage shore installations such as piers and boat houses, and frequently erode the shoreline. Small boats can find the going difficult. Wave conditions can mean the difference between success and failure of a military landing operation. Loading and unloading of small boats at piers can be dilficult or impossible.

Accordingly, it is an object of this invention to provide an improved apparatus and method for eliminating or greatly reducing the magnitude of waves.

More particularly, it is an object of this invention to provide such an apparatus and method which eliminate the usual massive and expensive breakwaters.

A further object of this invention is to provide a mobile wavebreaker for reducing wave magnitude in a localized area.

Another object of this invention is to provide an apparatus and method for causing waves to tumble over into the preceding troughs whereby greatly to reduce the magnitude of the waves.

Specifically, it is an object of this invention to provide an apparatus and method for discharging water below the level of troughs between waves in opposition to the movement of the waves, whereby to cause the Waves to tumble over and diminish greatly in magnitude.

I have observed that water at different temperatures acts as if it has different viscosities and resists mixing, a stream of water at one temperature discharged into a body of water at a different temperature tends to remain as a coherent stream without mixing with the body of water.

Therefore, a more specific object of this invention is to provide an apparatus and method for discharging water at one temperature into wave water in opposition to the waves to cause the waves to topple over.

Other and further objects and advantages of the present invention will be apparent upon consideration of the following description when taken in connection with the accompanying drawings, wherein:

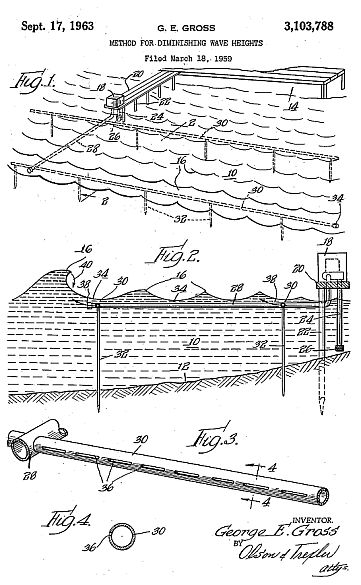

FIG. 1 is a perspective view of a wave breaking apparatus in accordance with this invention;

PEG. 2 is a side view thereof, partly in section as taken along the line 2-2 in FIG. 1;

FIG. 3 is a perspective view of a water-discharge device as used in the invention; and

FIG. 4 is a cross-sectional view through the device of FIG. 3 as taken along the line 44 thereof.

Referring now in greater particularity to the drawings, there will be seen a large body of water 10, such as an ocean or large lake, and having a bottom 12 and a shore 14 which is to be protected. The body of water It) has waves 16 on the surface thereof. The waves may vary in height and spacing according to various factors, including the size of the body of water, the location of the part of the body of water under consideration, and conditions of climate and weather. The waves progress toward the shore, to the right in FIG. 2 and generally up and to the right in FIG. '1.

The wave breaking apparatus according to this invention includes a motor-pump unit 18 supplied with power from a suitable source. This unit is shown as mounted on a pier 20 having supporting posts 22 and extending from the shore out into the water. The posts 22 are shown as having spiked or sharpened lower ends for facile installations of the pieras for an installation that is to be installed quickly. Alternatively (and preferably), the motor-pump unit 18 could be sealed and disposed on the bottom 12, or it could be floated on the surface by suitable float means for temporary installations, such as for military landings. The motor pump unit 18 is provided with an intake pipe 24 having a screened inlet 26. The inlet 26 is in the water, and for best results is disposed near the bottom 12 thereof.

The motor-pump unit 18 is provided with a discharge pipe 28 running out from the shore and having one or more transverse jet pipes 39. The jet pipes 30 as oriented substantially parallel to the wave crests (perpendicular to the direction of Wave movement). In general, this is substantially parallel to the shore. The jet pipes are supported horizontally by stakes 32 driven into the bottom 12 and are disposed below the wave troughs a distance spending on wave conditions. Of course, for portable installations such as military landings, the jet pipes could be supported by floats. Alternatively, the pipes could be made of suitable lightweight material with integral air chambers, if necessary. Ropes or cables from such floating pipes preferably would be tied to anchors resting on the bottom to minimize bubbling up and down of the pipes.

The jet pipes 30 are closed at the ends as at 34 and are provided with openings which preferably may take the form of longitudinal (horizontal) slots 36. Hence, water from the motor-pump unit 18 issues from the slots 36 as streams, ribbons or jets as indicated by the arrows 38. These jets are generally horizontal, being disposed from about 10 above to about 10 below horizontal. The jets are generally in opposition to the direction of wave movement, but may be in diagonal opposition. The water jets act as a sort of underwater breakwater, slowing down the undersides of the waves and upsetting the natural forces in the waves to cause the tops or crests thereof to tumble over into the preceding troughs as indicated by the arrow 40.

It is difficult to state generalities as to sizes and positions since these are so dependent on wave conditions and the area to be protected. However, it may be stated that the jet pipes must be disposed below the surface of the water at the bottoms of the troughs, but close enough to the trough bottoms to be within the zone of wave action. As one specific example a jet pipe disposed three inches below the trough bottoms reduces 18 inch waves on the jet or offshore side of the jet pipe to eight inches on the back or onshore side. Small, wind driven Waves were completely eliminated. A second jet pipe may be used (as illustrated) further to reduce the height of the waves. Larger slots and/or a larger pump may be provided for greater reduction of wave height. Obviously, installation should be below .the draft of small boats, with suitable spacing apart to accommodate larger vessels.

The piping system heretofore shown and described is excellent for reducing waves in fairly large areas. If it is desired to reduce wave height in only a local area, as for unloading and loading small boats at a pier, then most of the piping could be eliminated. In fact, the motor-pump unit could be used alone, submerged to the proper depth, and this would make for ready portability.

Elimination or substantial elimination of waves in accordance wtih the foregoing greatly improves swimming and boating, and protects shore installations and shores themselves. Furthermore, undertow is eliminated. Installation is simple and inexpensive. Operation also is inexpensive, and is necessary only when waves tend to exceed a predetermined size, or when wave control is otherwise desired.

Marina protective wave breaker

US 3822555

US 3822555

A simplified air burst wave breaker for the protection against wave action of Marina installations and the like. The air burst unit comprises a duct in the form of two vertical U portions arranged with their openings toward each other, having a common leg and in which at least the bottom free leg is longer than the common leg. The lower free leg provides a water inlet stem and the upper free leg provides the air burst or burp outlet stem. The U portion open at the bottom an air inlet connection in the upper bend thereof.

ABSTRACT A simplified air burst wave breaker for the protection against wave action of Marina installations and the like. The air burst unit comprises a duct in the form of two vertical U portions arranged with their openings toward each other, having a common leg and in which at least the bottom free leg is longer than the common leg. The lower free leg provides a water inlet stem and the upper free leg provides the air burst or burp outlet stem. The U portion open at the bottom an air inlet connection in the upper bend thereof.

Marina installations and other floating structures are subject to severe wave damage resulting from storm winds of unusual velocity. Stationary solid breakwaters are expensive, and not expedient for use in lakes in which the water level may very considerably due to the effect of rainfall on the one hand and irrigation usage on the other hand. It is desirable to provide a breakwater which can be submerged to a depth of noninterference with boating but which is effective to break up waves at the surface of the water. A desirable wavebreaker which is effective for the purpose, which is relatively inexpensive, which can be submerged to avoid interference with boating and fishing and which can be operated economically is the air bubble type of installation.

The concept of the air bubble wavebreaker is old in the art. For example, the utilization of small air bubbles passing upward through a body of waterto break and diminish waves is disclosed in Brasher U.S. Pat. No. 843,926 issued on Feb. I2, 1907. In addition, Brasher U.S. Pat. No. 1,593,863 issued July'27, 1926 discloses that the intermittent release of bubbles can effectively serve to break up waves with more efficient expenditure of compressed air. The use of airrelease devices which alternately fill with water and air to abruptly release the air to form large bubbles or burps is disclosed in U.S. Pat. No. 3,068,655 to Murray et al. issued Dec. 18, 1962. The present invention concerns a much simplified air burst generator and air bubble screen apparatus for wave breaking having particular advantages in the protection of economicallylimited installations such as lake marinas and the like.

The airburst generator or burper of the present invention is simple and rugged and has the advantage that commercially available plastic materials such as polyethelene, polyvinal, chloride chlorinated polyvinal chloride, butadiene-styrene, rubber styrene and the like pipe and fittings are readily applicable to their fabrication. A plurality of the burpers are strung in a level submerged position across the lake to provide the wavebreaker barrier. The burpers are connected to a compressed air line from which air is metered into each of the burpers at a selectedrate which is easily controllable by adjustment of the air pressure. The units are intended to be submerged to an appreciable depth such as thirty feet for example for avoidance of contact with surface objects and to obtain enhancement of the wave breaking effect of the air bursts due to their expansion to double the size of the originally emitted bubbles by the time the air bursts break the surface.

The operation of the device is simple and automatic. Compressed air introduced at the top of the U adjacent to the inlet stem forces water equally, substantially, out of the inlet stem and the common leg of the U sections until air starts to pass into the outlet stem. The weight of the water in the outlet stem is immediately reduced so that water rushes into the inlet stem with increasing velocity resulting in the stored air being violently ejected in a sudden gush out of the top of the outlet stem. Air again starts to accumulate at the metered rate to repeat the process. The air pressure fed to the burpers exceeds the hydrostatic pressure existing at the depth at which the units are submerged. The frequency of discharge is controlled by regulating the air pressure in the connecting manifold which in turn controls the period at which the burpers discharge.

It is desirable to secure the burpers and associated apparatus at a depth which avoids interference with passing boats and fishing tackle. Where the nature of the lake body admits, a depth such as 30 feet is considered desirable.

The burper of the present invention comprises. a molded or fabricated duct in the form of two integrally connected oppositely directed U sections having a common leg and having at least the lower free leg of a length at least slightly in excess of the common leg. One free leg which is open upward is termed the outlet stem and the other free leg which is open downward is termed the inlet stern. In other words the functional position of the unit is such that it is supported so that the U section which is open downwardly includes the inlet stem and the U section which is open upward includes the outlet stem. An air inlet fixture is attached to and communicates with the top bend of the downwardly open U section. The U sections may be joined in any selected orientation ranging from lying in a common plane to form a lazy S to that orientation in which the inlet and outlet stems are adjacent each other, i.e., side by side similar to bugle shape. The latter configuration admits of a more compact construction and increased strengthbecause the inlet and outlet stems can be attached to each other by any binding means such as cement, encircling bands or one or :more through fasteners such as bolts.

In anchored operating position, the burper unit is intended to be supported by buoyant and weighting means so that the inlet and outlet stems are verticalor substantially vertical. Some variation from the vertical is permissible as long as the inlet stems extends below the bottom band of the upwardly open U section. Air introduced into the air inlet duct displaces water to an equal extent, substantially, from the inlet stem and the common leg of the U sections until air commences to enter the bottom of the outlet stem. At this stage in the cycle, the weight of the water inthe outlet stem is reduced below the pressure of the water in the inlet stem with the result that the imbalance :in pressure increases at a rapid rate and water rushes into the inlet stem to till the entire device and in so doing, abruptly expells the air previously accumulated in a sudden gush out of the top of the outlet stem. Immediately thereafter, air again starts to accumulate in the duct to repeat the pro cess. The pressure of the air fed to the plurality of burpers forming the breakwater chain is selected to exceed the hydrostatic pressure of the water at the selected level of submersion of the burpers. The frequency of discharge of the air bubbles may be selectively controlled by regulating the rate of introduction of air into the units.

Other objects, features and advantages of the invention will appear from the-detailed description which will now be given of illustrative embodiments shown in the accompanying drawings in which:

FIG. 1 is a horizontal illustrative view of a Marina situated in a lake portion protected by the breakwater of the present invention,

FIG. 2 is a diagrammatic vertical plan view of the breakwater of the present invention in functional position.

FIG. 3 is a side plan view of one embodiment of the bumper of the present invention.

FIG. 4 is a slightly oblique side view of an alternative embodiment of the burper of the. present invention.

FIG. 5 is a side plan view partly in section showing fabrication from commonly shaped plumbing fixtures and parts.

Referring now to FIG. 1 of the drawings, the wavebreaker 9 of the present invention is adapted to be attached to the shore at least at the air compresser end for installation across the lake or other body of water to provide a wave breaker barrier between the main body of water 11 and the water 13 situate about the Marina and small boat mooring zone 15. A source of compressed air 19 and a pressure reducer 20 is supported on the shore and is connected to the burpers by a compressed air line manifold 21. In permanent installations it may be desired to bury the shore portion of .the compressed air line for protection against physical damage.

The manner of supporting the burper chain in submerged position is shown in FIG. 2. The floor of the lake 9 under the selected wave breaker barrier is indicated by reference numeral 23. The burper chain is provided with means for buoyancy such as by a hollow air manifold 31 or buoys 60 and is prevented from rising by a plurality of anchors and tie lines 27. It is generally preferred to maintain the burper chain on a horizontal level line in order that the compressed air in the air feeder line operates against equal static water pressure at all of the burpers 29 to achieve approximately the same frequency of burping at all the burpers. The burpers 29 are shown diagrammatically in FIG. 2. The manifold line 31 in this version is a hollow plastic tube which provides the functions of buoyancy, air delivery, and position fixation.

When the burper-chain is prepared at the time of submersion or fabrication, the depth of the lake bottom 23 is sounded to provide the measurement for the length of anchor lines 27. The depth is not critical but when prises an inverted U tube U connected by a common leg 49 to an upright U tube U The inlet leg 41 of U must be longer than common leg 49. This configuration may be termed a lazy S. The length of inlet leg 41 is chosen of a length to prevent air escape when legs 49 and 41 are filled with air from inlet until the bottom level of the air reaches the level of the bend between legs 49 and 43. At this point the weight of the water in leg 43 plus the static water pressure at the top of stem 43 becomes less than the static pressure at the bottom of stem 41 less the weight of the water in stem 41. The difference in pressures increases rapidly as air enters leg 43 resulting in water rapidly filling the burper resulting in the sudden discharge of the stored air as a large bubble or air burst at the upper end of leg 43. The air burst enlarges as it enters lower water pressures as it ascends to the top.

FIG. 4 shows an alternative configuration of the burper of the present invention. In this embodiment U and U are in substantially opposition, forming a loop of bugle shape. An advantage of this shape lies in its compactness and adaptability to be threaded at the bend of U, by the air manifold for both buoyancy and compressed air feed.

The burpers of both embodiments may be provided with means 51 for afiixing anchor lines 27 to a bottom portion and buoy fastening means 53 when additional buoyancy or buoy markers are desired. Air manifold 31 in the embodiment of FIG. 4 is provided with a short stub tube of selected internal diameter which may be cemented in apertures in manifold 31 or other types of air supply and the bottom of the bend of inverted U In cases where the air manifold, i.e., the line of burpers, calculated pressure at each burper to obtain substantially equal air admission.

The burper of FIG. 3 may also be provided with buoyant support byeither resting on an air manifold inserted under the bend of inverted U, as shown or by buoys. If buoys are used, the airline connected to air inlet fixture 55 may be of any size suitable for the correct delivery of air without regard for adequate buoyancy.

In any case it is desired that the direction of buoyancy pull and anchor pull be on a common vertical line to maintain the burper in correct vertical attitude. The burpers can also be maintained in a sufficiently vertical attitude if the manifold line is affixed to the burpers and is maintained in the correct radial direction by fixtures attached thereto and to anchor lines.

US 3068655

MOBILE PNEUMATIC BREAKWATER

MOBILE PNEUMATIC BREAKWATER

J. B. MURRAY

This invention relates to the calming of waters in harbors and in other areas requiring protection of installations or equipment subject to the destructive and otherwise disturbing actions of waves created by winds or tides or both. It has heretofore been suggested that such calming of waters may be brought about by the creation of a wall or screen of air bubbles through the release of air bubbles under suitable pressure at a suitable distance below the surface of the water. In accordance with the present invention this principle is applied through the use of apparatus which may be produced and installed economically, may be operated at a minimum expense, and may be readily transported from one position to another to meet the requirements of a particular situation.

While the invention is adaptable to a wide variety of uses, it has been developed for particularly advantageous use in connection with the dredging of channels or the like in harbors and unprotected waters which are subject to wave motions of such magnitude as to interfere seriously with the proper performance of the dredging operations. It has been found that in such operations any substantial wave movements directed against the dredgingequipment interfere seriously with the conduct of the work and greatly reduce the efficiency of the operation. Methods and means have long been sought for the economical and efficient elimination of the difiiculties resulting from wave movements in the performance of such dredging operations. One factor which has complicated the problem is the necessity of providing means for this purpose which may be readily shifted from one position to another as the dredging operations progress over a large area of a harbor or the like. Similar situations are encountered in other cases in which it is necessary to calm the waters in a number of different areas of an expanse of water. It is frequently desirable, for example, to calm the surface in widely scattered areas of a body of water to enable the safe and smooth landing of aircraft, such as hydroplanes, in the vicinity of a vessel which may be shifted from one station to another. Other situations in which the mobility of a unit or system for calming waters is of importance will occur to those familiar with the problems involved.

One difiiculty in connection with the problem to which the present invention is directed is the need for the provision of wave calming means which is capable of economical operation and is at the same time of such construction so as to be readily rendered effective for its intended purpose and is also readily rendered easily transportable from one position to another.

In accordance with the present invention the various problems indicated have been solved by the provision of a unit capable of producing an efiicient and effective air bubble screen for the calming of waters over a large area, the unit being equipped with a simple means for floating it at will so that it may readily be transported from one position to another and may then be readily submerged and caused to rest upon the bottom of a harbor or the like so as to be effective for its intended purpose. Moreover, the construction as a whole must be such that it will not interfere with the free movement of ships through the harbor, in the course of prolonged dredging operations for example.

A feature of the invention is the provision of a long,

relatively lightweight, but durable pipeline which may be used effectively as a means for alternately floating and sinking the devices required for producing the desired air screen. This pipeline, which may be of any required length, say to 1000 feet or more, must be of sufficiently sturdy construction to withstand wave action and tidal currents when floating at the surface of the water. The pipeline, when the apparatus is in its operative position, is adapted to rest upon the bottom of the harbor and the apparatus carried by the pipeline for the production of the air screen must not project upwardly from the latter to such an extent as to interfere with the free passage of ships of the character the harbor is designed to receive. It will be appreciated that the bottom of the harbor upon which the pipeline rests is of irregular contour, in elevation, and that the pipeline must be capable of conforming with these irregularities or of spanning depressions or cavities in the surface upon which it rests without subject ing the pipe to undue strains.

When the pipeline is submerged it is filled with water and when it is to be shifted it is filled with air from a cornpressor unit. This air which displaces the water must be supplied under a pressure somewhat greater than the hydrostatic pressure of the water to be dislodged and to expedite operations should be substantially greater. The capacity of the pipeline must be suflicient to provide the necessary buoyancy, when it is filled with air, to lift it, and the equipment which it carries, to the surface of the water so that at least the upper portion of the line is exposed above the water level to enable the equipment to be readily transported from one location to another. Toward this end the invention contemplates the provision of relatively lightweight structure on the pipeline for the production of the desired air screen and for retaining such means firmly in proper position. Moreover, the center of gravity of the pipeline and its equipment must be such that the air screen producing devices will extend upwardly as required for proper performance. As will be explained, the pipeline is formed in sections having ball joint connections so that the location of the center of gravity becomes important, otherwise one or more of the sections may turn about the ball joints at their ends and discharge the air downwardly rather than upwardly.

A further feature of the invention is the provision of means in the overall combination which is adapted to bring about the discharge of air at appropriate periodic intervals at a plurality of points adjacent the bottom of the harbor or the like to produce the desired air screen over an effective area throughout the length of the pipeline. While such an air' screencould be produced by the continuous release of air throughout the length of the pipeline, this would require an excessive amount of air to be discharged, thus calling for excessively large com:- pressor units to supply the air and greatly increasing the expense of the operation. It has been found that the desired wave calming or reducing action may be brought about with the intermittent discharge of air, thus greatly reducing the total amount of air required, but the provision of means for producing such. intermittent. release of air has necessarily added to the overall weight of the equipment which must be floated to make possible the ready transportation of the equipment from one location to another. The present inventionhas solved all of these problems in an eflective and economical manner;

Briefly, the present invention contemplates the use of a barge at the inlet endof the pipeline and a tugboat, or the like, at the opposite end of the line. The barge is equipped With air compressors and power means, such as diesel or gasoline engines, for driving the sameand suitable hose lines for supplying air under-the required pressure to the main floating and sinking pipeline discussed above and also to the devices for intermittently discharging air to produce the air screen. In some situations it is possible to eliminate the barge and place the compressors and the like on a fixed land structure which may permit movement of the equipment to different points as the location of the pipeline is shifted. The compressors must be capable of delivering air under sufficient pressure to overcome the loss of head in the supply lines and the hydrostatic head of the water at the bottom of the harbor and at an appropriate rate to expel the water from the main pipeline to float the same within a reasonable time interval and to supply air to produce the desired air screen when the system is in operation. It will be understood that air is required for these two purposes at different times so that the capacity of the compressors need be sufiicient only to serve one purpose at a time. The boat at the opposite end of the pipeline is provided with a hoist which, through a wire rope or cable having its free end connected with the adjacent end of the pipeline, is adapted to lift this to the surface when it is desired to change the location of the equipment. This end of the pipeline is normally open when the line is submerged, and it may remain open at all times 'if it is held on the boat after the water has been discharged from it and as it is towed from one location to another. However, the pipeline may be capped olf at its end remote from the compressor, after substantially all of the water has been blown out of it, and the equipment may then be towed in its floated condition with the boat at the far end simply assisting in maintaining the pipeline along a relatively straight path.

The means for creating the desired bubble screen may comprise a plurality of so-called burpers which are open at their tops and bottoms to admit water but are provided with baffles or partitions to divide the interior into a plurality of ditferent zones. Air introduced into the bottom of the burper serves to expel the main body of water in it and then allows a sudden gush of air to pass upwardly and out at the top of the unit. Water is then permitted to reenter the unit and substantially fill the same under the hydrostatic pressure existing at .the depth to which the unit is submerged. Preferably a value is provided in the unit for temporarily preventing the discharge of air when the main chamber of the unit is refilled with water; The continued intrTaduction of air under pressure serves to repeat the operation, so that the unit automatically releases a quan- 'tity of air mixed with water at periodic intervals. The frequency of discharge of air may be controlled by regulating in various ways the rate at which the air is intro- .duced into the unit. 7

Other objects, features and advantages of the invention will appear from the detailed description which will now be given of certain illustrative embodiments of the same shown in the accompanying drawings, in which:

FIG. 1 is a plan view of a portion of a pipeline equipped with the air screen producing units;

FIG. 2 is an enlarged elevational view of the structure shown in FIG. 1 with substantial portions of the pipeline broken away to condense the view;

FIG. 3 is an enlarged elevational view of a portion of the pipeline in the region of the ball joint coupling between two sections thereof, portions of the pipe sections and coupling being broken away and shown in section;

FIG. 4 is a transverse sectional view through the pipeline in the region in which two of the air releasing units are connected therewith and shows such units and the supporting means therefor;

FIG. 5 is a perspective view, partly in section, showing the construction of one of the air releasing units;

FIG. 6 is a plan view of a spider-like bracket provided for the support of the unit shown in FIG. 5; 7

FIG. 7 is a sectional view, along the broken line 7--7 of FIG. 6, showing the connection between the spiderlike bracket and the unit of FIG. 5;

FIG. 8 is a schematic view showing the means for delivering air under pressure to the pipeline and the air releasing units;

FIG. 9 is a schematic view showing the air bubble discharge unit in section immersed in a body of water represented by the rectangular outline;

FIGS. 10 and 11 are views similar to FIG. 9 but show the unit at different stages in a cycle of operation;

FIG. 12 is a schematic view showing the means for delivering air under pressure to a modified form of pipeline and related parts;

FIG. 13 is a plan view of a portion of the modified pipeline With its air screen producing units;

FIG. 14 is a side elevational view of the parts shown in FIG. 13;

FIG. 15 is a plan view of a spider-like bracket used to support an air releasing unit;

FIG. 16 is a sectional view taken along the broken line 16-16 of FIG. 15 showing the manner of mounting the unit on the spider-like bracket; and

FIG. 17 is a transverse sectional view through the modified form of pipeline in the region of a pair of the air releasing units and shows the means for supporting and supplying air to such units.

Turning now to the drawings, the mobile pneumatic breakwater of the present invention comprises a series of sections of pipe connected together by ball joint couplings to provide a breakwater of any desired length. In FIGS. 1 and 2 portions of three such pipe sections 10, 11 and 12 are shown. Each section may suitably he, say, 96 feet long and may be provided with air bubble releasing units at 8-foot intervals along its length. Any number of such pipe sections may be connected together to form a breakwater of desired length. The main portion of each pipe section may suitably have a diameter of about 18 inches, the pipe being formed of steel plate of suitable thickness, say inch, to enable the pipeline to withstand the distorting forces mentioned hereinbefore. The pipe should also be of sufiicient strength to prevent buckling or serious bending in the course of handling the apparatus.

At each end of each pipe section there is provided one part of a ball joint coupling consisting of a ball and a bell. The ball portion of the coupling is indicated at 13 and it is provided with a collar 13a which is welded to the end of the section 10 of the pipe, for example. Pipe 11 (FIG. 3) carries the bell portion of the coupling shown at 1-4 which has a collar 14a welded to the end of pipe section 11. Obviously the location of the ball and bell portions of the coupling may be reversed if desired. Members 13 and 14 have, respectively, a convex and a concave partial spherical surface arranged to ride upon each other with a substantially air-tight and water-tight fit provided by a rubber gasket. To enable assembly of the coupling and the retention of the parts in assembled relation there is provided a ring 15 having a partial spherical inner surface arranged to ride upon the outer surface of ball member 13. The ring 15 may be formed in two sections to facilitate assembly or it may be formed as a closed ring which is loosely applied to the pipe section 10 or to the member 13 before the latter is welded to the pipe section 10. Member 14 has a plurality of outwardly extending ears 14b around its periphery, adjacent pairs of such ears being "arranged to pivotally retain an eye bolt 16. Each of these bolts is arranged to have its shank swung into a recess 15a, one of which is provided in the periphery of ring 15 in longitudinal alignment with each of the bolts 16. A nut 17 provided on each bolt enables clamping of the ring 15 in appropriate relation to the end of the member 14 to provide a relatively close fit in relation to member 13, but in a manner to permit relative sliding between the cooperating spherical surfaces of member 13 on the one hand, and member 14 and ring 15 on the other hand.

The interior of each pipe section is partitioned oif to provide a passage or chamber 19 of suitable cross-sectional area for the delivery of air under pressure to the air bubble releasing units. For this purpose there may be provided a longitudinally extending partition 20 which is suitably welded into the plate structure forming the main pipeline to provide the indicated air passage 19. Vertical partitions 21 at each end of the passage serve to close ofl the latter from the main passage through the pipe section at a point adjacent each end of the latter. The passage 1? of one pipe section, such as 16 (FIG. 3), is connected to a corresponding passage in the pipe section 11 through an elbow member 22 extending downwardly from the partition 20 and connected by a coupling 23 with a flexible hose line 24 which in turn is connected by a coupling 25 with a flexible hose line 26. The latter is connected by coupling 27 with an elbow member 28 extending downwardly from the partition 26 in the pipe section 11. It will be understood that the flexible hose line 24, 26 permits the two pipe sections to be angled in any direction in relation to each other without disrupting the connection between their passages 19. Similar connections are provided between the passages 19 in the successive pipe sections throughout the length of the main pipeline being employed.

At spaced intervals along each pipe section, say at 8-foot intervals, there is provided a frame structure 29 (FIG. 4) suitably secured to and projecting transversely from the pipe section. This frame structure may be of angle iron construction and, as best shown in FIGS. 1 and 4, has horizontally disposed members arranged to provide a diamond configuration in plan, as shown in FIG. 1. Other members of the frame structure extend downwardly to provide transverse angle members arranged to rest upon the bottom of the harbor or the like when the apparatus is in operative position. At each end of the frame structure, as shown in FIG. 4, there is mounted an air bubble releasing unit 30. These are connected with the air passage 1? by means of pipes 31 and 32 connected with a T-fitting 33 extending through the main pipe section into communication with the passage 19. At their opposite ends the pipes 31 and 32 are provided with T-fittings 34 having upwardly extending short pipes or nipples 35 entering the bottoms of the units 30. Short pipes 36 extend downwardly from the T connections 34 and are secured to the frame structure 29 by members 36:: having a plate-like base and an upwardly extending collar. The pipes 36 are preferably sealed off at their upper ends by a suitable block or disc so as to eliminate the accumulation of water therein. Various portions of the frame structure are welded together at points of contact to provide a rigidly and firmly connected structure. For a pipe section 96 feet long there may be provided twelve of such frame structures, with those adjacent the ends of the pipe section being disposed 4 feet inwardly from the ends.

Referring now to FIG. 8, a suitable compressor or compressors and an air tank indicated schematically at 37 is mounted either on short or on a barge, as the case may be, at one end of the system. Preferably the air tank 37 is arranged to deliver air under a pressure of about 125 lbs. per sq. in. to a pipe 33 having a valve 380 for either closing off or throttling down the delivery of air from the compressor. A valve 39 is also provided in the line 38 for cutting off the delivery of air to the main flotation passage through the pipeline 1t 11, 12, etc. and to permit the release of air from the latter whenever it is desired to sink the pipeline. The end of pipe 38 is connected through a flexible hose line 39a of suitable length with the end of pipe section 10, the hose being connected with a fitting 4% at the center of a closure disc 41 clamped to the end of the ball joint member 14. This disc may be secured in place by the bolts 16 previously described. A branch pipe 42, having a pressure reducing valve 43 therein, serves to deliver air to a flexible hose line 44 connected into the passage 19 which, as explained, is connected with the air releasing units 30. When the main pipeline is submerged to a depth of 40-50 feet, or somewhat more, the valve 43 may be adjusted to deliver air at 30 lbs. per sq. in. to the air releasing units. The air compressor system should be capable of supplying air to the units at such pressure at an appropriate rate, which may be about 1500 cu. ft. per minute for a pipeline 500 feet long. This is adequate to create the desired air screen for calming the water under conditions normally encountered. The rate of release may, however, be either increased or decreased to provide the desired calming action for waves of different heights and lengths. In working in deeper harbors where the pipeline must be submerged to a greater extent than indicated above, the air delivered to the releasing units should be under a somewhat higher pressure. It must be under a pressure somewhat in excess of the hydrostatic pressure of the water at the depth to which the units are submerged.

The construction of the units 30 and their mode of operation is illustrated in FIGS. 5 and 9-11, inclusive. Each unit comprises an outer shell 45 of frusto-conical configuration and formed preferably of polyethylene or a similar plastic which is relatively light in weight, resistant to corrosion and capable of withstanding the stresses to which it is subjected. In fact, the entire unit 36 is preferably formed of such a plastic. Centrally disposed within the shell 45 is a cup member 46 which is closed at its bottom. Within the member 46 is provided a tube 47 which is open at its bottom and serves to provide an annular passage between its external surface and the interior of cup member 46. At its upper end, the tube 47 has a laterally extending flange provided with screw thread formations cooperating with similar formations on the shell 30. Cup member 46 has a laterally extending flange 49 which is secured to the portion 48 of member 47 in any suitable way. The flange 49 is formed at the outer end-of a skirt-like extension from the member 46 which provides a small chamber at the upper end of said member. Cup member 46 and tube member 47 may be united to form a sub-assembly before application to the shell 45. An axially extending flange 50 carried by member 47 is screw threaded to receive the lower end of a screw threaded, dome shaped, discharge member 51. The latter may be provided with a series of perforations or a series of slots in its dome through which air may be discharged in the manner to be described, and through which water may enter the interior of the tube 47 and the cup 46 at times. The conical skirt toward the upper end of the cup 46 is provided with a series of openings 52 around itscircumference to permit the passage of either air or water from within the shell 45 into the small chamber formed by the skirt at the upper end of the cup. Openings 53 through the upper portion of the vertical wall of the cup 46 likewise permit the passage of air into the space between the inner surface of the cup and the outer surface of the tube 47. A ring 54, however, having a laterally extending flange at its top is arranged to close off the ports 53 when the ring is raised into its uppermost position by the action of the water passing through the openings 52 in the manner to be explained. This valve ring is lowered in the course of operation of the unit when the water is forced downwardly by the air.

For mounting the unit 30 on the frame structure of FIG. 4 the shell 45 is provided with three outwardly extending ears 55. These ears are provided with openings arranged to receive bolts 57 by which the shell 45 may be secured to a spider-like bracket 56 arranged to be carried by the pipe or nipple 35. The spider for this purpose is provided with a downwardly extending tube or cup 58 mounted over or within the pipe 35. and welded or otherwise secured thereto. If desired,.the cup 58 may be mounted directlywithin and secured to the upper branch of the T-fitting 34. Atits upper end the cup 58 is largely closed off bya disc 59 arranged to receive an air metering element 60 preferably formed of bronze or a suitable plastic. The arrangement is such that meteringelements having openings of different diameter may be inserted within the discs 59 of the various air releasing units to thus control the rate of delivery of air into the several units 30. This will enable proper adaptation of the system as a whole to deliver air into the various units at substantially the same rate regardless of the location of the units in relation to the compressor. Those units most remote from the compressor should have somewhat larger openings through the metering elements 60 than the units which are closer to the source of air supply.

The operation of the foregoing system will now be briefly described. When the system is to be set up in a particular area of a harbor, the main pipeline and its connected parts, all susbtantially free of water, will be transported to the desired area by a number of boats and a barge which carries the compressor equipment and possibly the adjacent end of the pipeline. One of the boats may carry the opposite end of the pipeline and additional boats may be required to assist in towing the pipeline and maintaining it in a reasonably straight line. When the de- 'sired location is reached the ends of the pipeline will be dropped from the barge and boat carrying the same and the main pipeline will then become filled with water and, as a result of this, sink to the bed of the harbor. A number of boats may be required along the length of the pipeline to maintain it in the desired substantially straight line as it is being submerged. The number of such boats required will depend upon the overall length of the pipeline which may vary from several hundred feet to about 1,000 feet or more. p The direction in which the pipeline is extended and its distance from the dredging equipment, or any other equipment the operation of which is to be protected, will depend upon a variety of circumstances, chiefly the direction from which the waves are approaching the equipment. In all instances the pipeline should, of course, be so disposed that the equipment to be protected is on the lee side of the line. As applied to dredging operations, it the waves are approaching the dredging equipment from a direction at right angles to the channel to be dredged, the pipeline may suitably be disposed about 100 feet from such channel, whereas if the waves are approaching from a direction substantially parallel with the desired channel, the pipeline may be submerged at a distance of say 500 feet from the initial working position of the dredge. In the second situation the dredge in the course of its operation, may be advanced about 400 feet toward the pipeline before it become necessary to float the pipeline and shift it to a new location. Where the waves are approaching the dredge at substantially right angles to the direction of the channel to be dredged, a pipeline 1000 feet in length may permit the dredge to advance from 600 to 800 feet before it is necessary to relocate the pipeline. The frequency with which the pipeline must be floated and relocated thus depends upon the foregoing considerations as well as the length of the pipeline and the character and amount of the material to be removed from the bottom of the harbor to create the desired channel, which determine the speed with which the removal may take place. Other factors will also enter into this phase of the operation, such as the nature of the wave motion to be calmed. The air screen produced in accordance with the invention is more effective on certain types of wave motion, involving a particular relationship between the height and length of thewaves, than other types. Also the extent to which the pneumatic breakwater will be effective in the regions adjacent its ends will vary with the character of the waves to be calmed.

It will be understood that the hose lines 39a and 44 "will be of sufficient length, say 100 feet or more, so as to extend from the barge to the inlet 40 of the main passage in the pipeline and-t0 the passage 19, respectively, when the pipeline rests on the bed of the harbor at a suitable distance from the barge. The valve 38a may be closed during this period so that no air is delivered from the compressor equipment to any part of the system. However, if desired, the valves 38a and 39 may be opened partially during the towing operation to prevent the entry of water into the passage 19 through the metering elements 60 and also replenish the air which might leak through the ball joints.

In lieu of retaining the far end of the pipeline on a tug or the like, as explained above, in transporting the system to the desired location, the end of the pipeline may simply be closed off by applying a closure plate or cap to the ball joint member 13 or 14 at the far end of the line. If this were of the form of member 14 the closure could be readily retained in the same manner as the disc 41 of FIG. 8. When so applied to the pipeline filled with air it will serve to maintain the water tightness of the main passage through the pipeline so that the latter will float the equipment as a Whole and permit it to be readily towed, with the barge at the forward end, to the desired location. One or more boats may, however, be required to maintain the pipeline along the desired path. When the desired loca tion is reached the far end of the pipeline may be hoisted from the water to remove the closure and thus permit the introduction of water as this end of the pipeline is lowered again. It is desirable in the course of this stage of the operation to attach a buoy to the pipeline, adjacent its end, so as to provide a marker for its location. The rope connecting the buoy to the pipeline should be slightly longer than the depth of the water in its area. At the opposite end of the pipeline the barge, which is firmly anchored, will provide an indication as to the approximate location of that end of the line.

When it is desired to create the air screen for calming the waves approaching the equipment to be protected, the valve 38a will be opened while the valve 39 will remain closed. This will bring about delivery of air through the branch line 42, reducing valve 43, and hose line 44 to the passage 19. The passage 19 may have become filled with water during the submersion operation through the access provided by the metering discs 60 of the various units 30. The air delivered to the passage 19 will first serve to remove this water and then deliver air through the metering discs 60 into the interior of the shells 45. At this time the units will be substantially filled with water except for a small amount of air which may be entrapped at the tops of the chambers 61 and 62 indicated in FIG. 9. At this time the ring 54 will have been lifted by the water into the position indicated in FIG. 9 so as to close 011 the openings 53, but the chamber 62 will be in communication with the main chamber 61 through the openings 52. As the air under pressure rises within the chamber 61 it will gradually accumulate at the top and force the water downwardly within the shell. As the water level within the shell is lowered the ring 54 will be' lowered and will eventually open up completely the passages 53. At this time the continued delivery of air will not only continue to lower the level of the water within the chamber 61 but also within the annular channel 63, as indicated in FIG. 10. Continued delivery of air serves to force the water level down to the point indicated in FIG. 11 which serves to open up the mouth of the chamber 64 within the tube 47. When this is achieved there will be a sudden rush of air under pressure from within the shell 45. This air will pass through the openings 52 and 53 and downwardly through the channel 63 and then upwardly through the chamber 64. In the latter it will mix with the water column still present therein and create an aerated mass of water which, because of its lower density than the surrounding water, will rise and be emitted upwardly through the openings in the cap 51 with a mushrooming efliect in the manner indicated in FIG. 9. In the course of expelling the air in this manner, the water will quickly rise within the chamber 61 to a level close to the top of the latter and in doing so will lift the valve ring 54 into the position shown in FIG. 9, thus closing off the openings 53. The device is now ready for a repet1- tion of the same operation.

It will be understood that the devices 30 distributed along the length of the pipeline will all operate in the same manner each operating independently of the other so that they do not discharge the air simultaneously but all dischargea given amount of air at periodic intervals the duration of which is determined by the rate of discharge of air through the orifice disc 60. In the normal use of the equipment it is desirable to have such air discharge take place from each unit about every 3 to 7 seconds, depending upon the conditions being encountered. The air mixed with the water thus rising from the bottom of the harbor to the top serves to provide an air screen which has a remarkable calming action upon the waves at the surface of the water.

As the mixture of air and water is periodically released from each of the units 39 throughout the length of the pipeline, the rising current of bubbles, forming in effect a curtain or screen, has a tendency to spread both longitudinally and transversely of the pipeline so that as the mixture of air and water reaches the surface of the body of water a relatively large area, having substantial length and width, is placed in a state of turbulence which has a remarkable effect upon the destructive or disturbing actions of the wave movements. Preferably the waves are largely reduced to a surf-like condition before they reach the dredge or other object to be protected.

The frequency of the discharge of air from each unit may be varied to suit the requirements at any particular time by regulating the reducing valve 43 and simultaneously controlling the speed of the compressor to meet the demand. Also it is possible to vary the frequency of discharge, in the use of the equipment under different conditions, by changing the metering discs 60 to suit the requirements of a particular situation. The pressure of the air delivered to the passage 19 through the reducing valve should always be sufficiently greater than the hydrostatic pressure at the level of the lowermost air releasing unit in the series that air will be discharged into said unit, and in fact all of the units, at a desired rate. The extent to which the air pressure exceeds such hydrostatic pressure at each unit will determine the rate of fiow of the air through the orifice in the disc 60 of each unit and thus determine the time interval between successive discharges of air. In some instances in which long, relatively small diameter hose or pipelines are employed in this portion of the system, the reducing valve may be omitted or by-passed.

If desired, the units 30 on the opposite sides of the main pipeline need not be disposed in pairs having their axes in the same plane transverse to the pipeline. Those on one side of the pipeline may be located intermediate those on the opposite side. For this purpose the frame construction 29 may be modified to enable the frame as a whole to be disposed at an angle of 45 to the axis of the pipeline or it may be so modified that each frame extends outwardly toward only one side of the pipeline, at right angles to the axis thereof, alternate frames extending in one direction and the others extending in the opposite direction from the pipeline. The T-fittings 33 in this event will be replaced by elbow fittings. The disposition of the units 30 on one side of the pipeline midway between those on the opposite side of the pipeline, in the direction of the axis of the latter, has certain advantages with respect to the character of the air screen formed. Whatever arrangement is employed it is important that the structure as a whole is balanced about the axis of the main pipeline and has its center of gravity below such axis. This is necessary to insure against tilting of the frame structure carried by a certain pipe section and turning of the pipe section as would be 10- readily permitted by the ball joint couplings between the same and the adjacent pipe sections.

Referring now to FIGS. 12-17, inclusive, there is shown a modified construction of the pipeline and its attachments for producing the air bubble screen in accordance with the invention. An important advantage of the modified construction is that it reduces the overall height of the apparatus which is submerged and thus enables use of the equipment in harbors having little more than the depth required for the maximum draft vessels which enter the harbor. The arrangement is such that the maximum vertical dimension of the equipment is no greater than the diameter of the ball joint couplings for the main pipeline sections.

The modified system comprises a series of pipe sections two of which are shown at 65 and 66. These may suitably be each 96 feet in length. Successive sections are connected by substantially airtight and Watertight ball joints provided by members 67 and 68 similar tomembers 13 and 14 of the first embodiment. These are assembled and held together in the same manner as ex plained in connection with the first embodiment. At suitable spacings, say 8 feet, along the pipeline there are provided along each side thereof units 69 similar to the air releasing units 39 of the first embodiment. The units 69 are carried by pipes 7 i and 71 extending horizontally from the main pipe sections at right angles to the axis thereof, as shown in FIG. 17. These pipes are welded to the main pipe section, such as 65, at points well below the horizontal plane extending through the axis of the main pipe section. They are braced and firmly retained on the main pipe section by means of brackets or plates 72, 73 and 74 which are welded to the main pipe section and to the pipes 70 and 71, the plates 72 and 74 being disposed vertically and the plates 73 being disposed hor-izontally. In this way a firm and rigid connection of the pipes 76 and 71 with the main pipe section is pro.- vided. At the outer end of each of the pipes 76 and 71 there is provided a T-fitting 75 the bottom of which is closed off by a screw cap or plug 76. The upwardly extending arm of the T-fitting is arranged to receive a sleeve 77 extending downwardly from a three-armed spider 78 which is suitably secured, as by welding, to the sleeve 77. The latter may be firmly connected with the T-fitting 75 in any suitable way as by the provision of a small telescoping nipple or pipe section received within the sleeve 77 and also within the upper arm of the T- fitting. Any other suitable means for providing a firm and airtight connection of the parts may be employed. Each of the units 69 is provided with an outer shell similar to the shell 45 of FIG. 5 and. this, adjacent its lower end, is provided with three outwardly extending ears 79 arranged to cooperate with the arms of the spider 78 and adapted to be secured to the latter by screws 80. The upper end of sleeve 77 is closed by a ring or disc 81 carrying at its center a metering disc 82. The latter has a discharge opening at its center which may be of different diameter for different units, thus enabling the delivery of air at substantially the same rate to all of the units along the length of the pipeline in spite of their varying distances from the source of compressed air.

For delivering air to the pipes 70 and 71, and hence to the units 69, there is provided a small pipeline '83 at each side of the main pipeline 6 5, 66, etc. The pipelines 83 are secured to the equipment at each of the pipes 70 or 71 throughout the length of the system by means of T-fittings 84 provided at these points in the pipelines 83. T-fittings 84 are in turn connected with the upper ends of the short, upwardly extending pipes 85 projectingfrom the pipes 70 and 71. To permit angular movement of one main pipe section, such as 65, in relation to another, such as 66, at the ball joint coupling, a flexible hose line 86 is provided to interconnect the adjacent ends of the successive sections of the small pipelines 83 carried by the main pipe sections. These hose lines 86 may be formed of flexible metal or of polyethylene. In fact, the pipelines 83 may also be formed of polyethylene, if desired, in order to reduce to a minimum the danger of clogging the air line through the accumulation of corrosion particles and the like therein resulting from the introduction of water through the metering discs when no air is being delivered through the air lines while the apparatus is submerged. However, if the pipelines 83 are formed of polyethylene it may be desirable to provide bracing members formed of angle irons or the like, between successive pipes 70 on one side and successive pipes 71 on the other to render greater rigidity to the structure. If the pipelines 83 are formed of metal on the other hand, they will provide adequate rigidity to the structure. Also, to eliminate corrosion problems, the pipes 70 and 71 may be replaced by polyethylene or other plastic tubing, and in this event metal frames may be provided to extend outwardly from the main pipeline sections to carry the plastic tubing and also the air releasing units.

As explained in connection with the first described embodiment of the invention, the pipes 70 and 71, or the suggested substitute structure, may be arranged to extend outwardly from the main pipeline in such a way as to position the air releasing units on one side of the main pipeline intermediate those on the opposite side of the pipelinein the direction of the axis of the latter. This, in the illustrative example, will provide an air releasing unit every four feet along the length of the main pipeline. Good results may be obtained if the spacing of the units is increased to six feet.

As shown in FIG. 12, the system includes an air tank 87 connected with a compressor of suitable capacity to supply the air necessary for the flotation of the main pipeline 65, 66, etc. and for operation of the units 69. This equipment, as in the case of the first embodiment, is preferably carried by a barge located adjacent one end of the main pipeline. Air is delivered from the tank 87 through a line 88 to a valve 89 and from the latter to the center of the first main pipe section 65. The connection with the latter may be similar to that shown at 40 in FIG. 8. It will be understood that valve 89 is mounted on the barge and serves to control the delivery or cutting oil of the supply of air to the main pipeline. Between the valve 89 and the main pipeline there is provided a suitable length of flexible hose to connect line 83 with the pipe section 65 when the latter is submerged to the bed of the harbor in a position in which its free end is spaced a suitable distance horizontally from the barge to avoid any interference with the latter. A branch line 90 from the line 88 is arranged to receive air from the tank 87 when a valve 91 is opened. In the line 90 there is preferably provided a pressure reducing valve 92 which enables reduction of the pressure of the air from that in the tank 87, say 125 lbs. per sq. in., to that desired for delivery through a T-fitting 93 and branch lines 94, 95 to flexible hose lines connected with the near ends of the pipelines 83 carried by pipe section 65. The desired pressure for this purpose will vary, as explained in connection with the first embodiment, but should ordinarily be such as to maintain a pressure of about 30 lbs. per sq. in. at the most remote air release unit 69.

The operation of the modified system is substantially the same as explained for the first embodiment. By operation of the valve 89 air may be admitted to the main pipeline 65, 66, etc. to expel the water therefrom and to raise it to the surface whenever it is desired to move the equipment from one location to another. When the main pipeline has been raised to the surface the far end may 'be hoisted on to a boat and either retained there during transportation, or it may be capped in the manner explained in connection with the first embodiment and then returned to the Water, so that the pipeline will remain afloat as it is towed to a new location. A suitable num- '-ber of tug boats should be provided to maintain the pipeline in a substantially straight condition as it is being towed and to position it properly at .a new location. When it reaches the new location, the cap is removed from the far end of the main pipeline and the latter is permitted to fill with water and thus again submerge the equipment to the bed of the harbor. The hose connecting the compressor system with the main pipeline will at this time be disconnected from the source of air supply to permit the escape of air from the main pipeline, or a special valve may be provided for this purpose. It will be understood that during the sinking operation the valve 89 will be closed so that no air is delivered beyond this valve. Now the system is ready for the creation of the desired pneumatic breakwater by opening the valve 91 to provide a continuous supply of air at the desired pressure to all of the units 69. The air so delivered will be periodically released by each of the units 69 at suitable intervals in the same manner as explained in connection with the first embodiment.

Method of producing relatively calm

water area

US 3221503

US 3221503

Dec. 7, 1965

Allen B. Wilson

The present invention relates to improvements in the art of protecting harbors and other chosen areas from the damaging effects of waves, and more particularly to a highly improved method and apparatus for causing waves in a body of water to subside.

Because of the huge amounts of energy that are transmitted by waves of any substantial size on bodies of water, the matter of providing adequate protection against wave damage, and the provision of safe, quietwater areas, have been problems with which men have struggled for hundreds of years. The amounts of energy that must be dissipated when waves on relatively large bodies of water are arrested often becomes almost unbelievably great, and a very substantial amount of literature exists concerning the forces produced by waves and the difficulties involved in building ordinary breakwater structures of suflicient mass and secure foundation to withstand these forces. One brief but interesting article on the subject, for example, may be found in the 1955 edition of the Encyclopaedia Britannica, volume 4, at pages 68 to 70, where it is pointed out that sections of ordinary stone, steel and concrete breakwaters weighing more than 1,000 tons have been known to have been moved by the forces of waves striking the sections. It is there also mentioned that the force exerted by waves against one masonry breakwater was calculated to have been two tons per square inch. It will thus be appreciate that the building and maintenance of ordinary, massive breakwater structures has been and remains an extremely expensive and time consuming undertaking even when the waves that are expected to strike the structures are not especially large.

Because of the time and expense involved in the building of breakwater structures of the traditional type just referred to, they can seldom be resorted to when the need for protection against waves is only temporary, such as during certain military operations or during exploratory off-shore drilling operations, for example. Furthermore, breakwater structures of the traditional type, when used to protect shipping harbors and the like, must have one or more sizable openings therein through which ships and other surface-craft may pass. Such openings readily admit waves into the harbor area, and objectionable harbor conditions often arise as a result thereof.

The present method and apparatus for causing waves in a body of water to subside involves a complete departure from traditional concepts, and it involves in part a utilization of the wave energy itself to cause the waves to subside.

It is a known fact that, although waves created by wind and the like appear to involve progressive linear movement or flow of water in the direction of the movement of the waves, there is no such flow of any consequence. On the contrary, each wave is manifested by a local orbiting of the individual particles of water in substantially vertical planes. Each wave, at any particular moment, involves this local orbiting of Water particles not only adjacent the water surface but also well down below the portion of the wave that can be seen from the surface, the size of the individual orbits of the separate water particles progressively decreasing with depth. Each wave at any given moment, therefore, has a body defined by the area in which the water particles are in motion in their individual orbits. The body, in