Pulsating

through the air in much the same manner as employed by the

jellyfish in propelling itself through water, a weird

parachute artillery spotter is expected by its inventor, John

A. Domenjoz of New York City, to supersede the ordinary

kite-balloon in observation work during war.

Greater maneuverability with resultant greater safety for the

pilot, economy, and the elimination of ground crews are among

the advantages claimed for this type of craft.

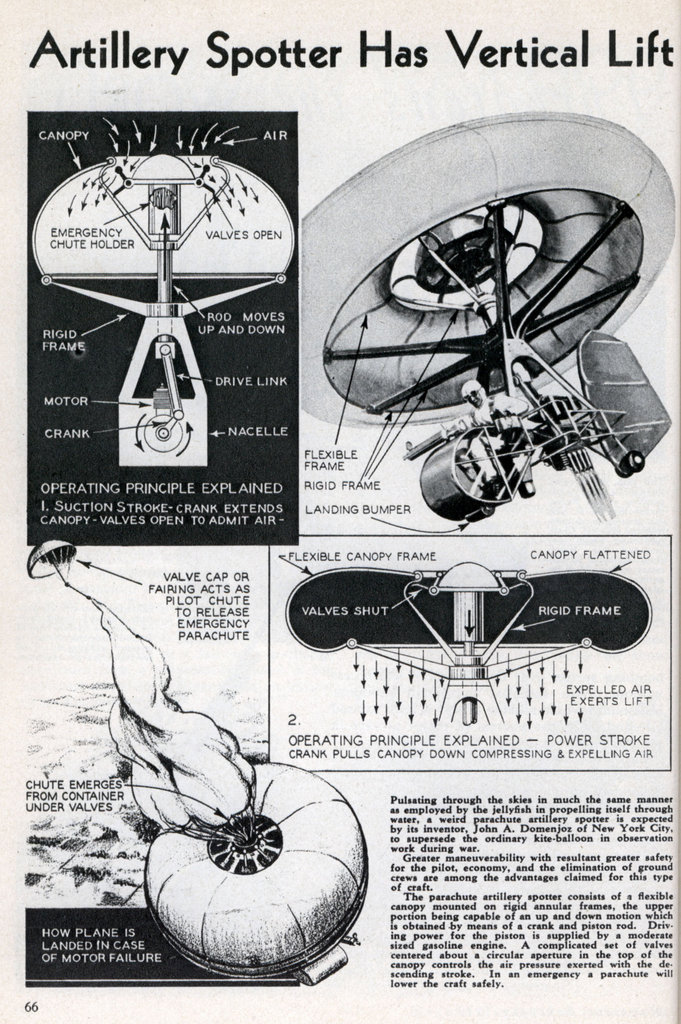

The parachute artillery spotter consists of a flexible canopy

mounted on a rigid annular frame, the upper portion being

capable of an up and down motion which is obtained by means of

a crank and piston rod. Driving power for the piston is

supplied by a moderate sixes gasoline engine. A complicated

set of valves centered about a circular aperture in the top of

the canopy controls the air pressure exerted with the

descendig stroke. In an emergency a parachute will lower the

craft safely.

This invention relates to aeronautical

machines and in general is a power actuated apparatus of a

type to take the place of the observation balloon for military

use and consists of an improved design adn arrangement,

inexpensive in its initial cost and in its operation and which

possess many important advantages over the customarily

employed observation balloon particularly as to

maneuverability so as to materially improve the safety factor

for the pilot and the machine.

An important feature of the present invention consists of an

improved motor driver means for obtaining the ascensional

force comprising a flexible motive canopy, preferably of

fabric and in the general form of a parachute, connected to be

operated by a motor to operate in the nature of a flexible

piston to produce power or lifting stroke as the result of

suction above and pressure on the air beneath the motive

canopy. The canopy is secured at its outer margin to a rigid

frame or carrier for the motor and pilot and its central

portion is connected to be vertically reciprocated by the

motor and is provided with a one-way valve or shutter

operative to close on the descending stroke of the canopy thus

under the action of the motor to create an ascensional force

governed by the speed of the motor. The pilot can thus readily

control the elevation of the machine by varying the speed of

the motor and additional means for vertical maneuvering is

proivided in the form of a manually operated air valve to

permit rapid change of elevation when desired while

maintaining motor speed for prompt checking of the descent

upon release of the valve.

Further important features include the provision of a

supplemental, readily releasable, parachute to check the

descent upon failure of the motor thereby with safety allowing

the use of a motive canopy of lesser diameter than would

otherwise be practicable.

The foregoing and other important features and advantages of

the present invention will be more fully understood by

reference to the accompanying drawing wherein like reference

characters are applied to the corresponding parts in the

several views.

In the drawings:

Fig. 1 is a view in

central, vertical section showing my improved machine.

Fig. 2 is a similar

view of the motive canopy and associated parts showing the

position at the bottom of the power stroke.

Fig. 3 is a plan view

of the central portion of the canopy and shutter arrangement.

Fig. 4 is a plan view

of the carrier member or wherry.

Fig. 5 is a central,

vertical sectional view showing a modified form employing a

supplemental parachute carried by the central portion of the

canopy.

Fig. 6 is a view in

elevation showing the parachute in use and

Fig. 7 is a detail

view in plan showing the central member of the canopy thereof.

In the approved construction embodying the features of my

invention as shown in Figs. 1 to 4, a rigid carrier is shown

comprised of a rectangular wherry 1 housing a driving motor m

of the internal combustion type and having a compartment 2 for

the pilot. The wherry is rigidly connected at each corner by

means of posts or rods 4, with the annulus 5 formed to provide

anchoring means for the outer margin of a flexible motive

canopy 6, the central portion of which is connected to be

vertically reciprocated by the motor m. To this end, the fly

wheel 8 of the motor is provided with a crankpin 9 pivotally

connected by pitman 10 to vertically movable rod 11 fitted

within a vertical bearing or bracket 12 supported at the top

of the wherry. The rod 11 is pivotally conected as shown to

the tubular extension rod 14 which is pivotally connected at

15 to a central hub of a movable annulus 16; the hub portion

as shown being connected by radial spokes 17 to the annulus.

Accordingly, operation of the motor will transmit a vertical

reciprocating motion to the movable annulus 16 to which the

inner margin of the flexible canopy is attached so that the

canopy is vertically reciprocated from its inner margin.

The movable annulus 16 is also formed with an upper hub

portion 18 supported by radial spokes 19 defining segmental

openings 20 adapted to be closed by segmental shutters 21

pivotally supported at 23 on the hub 18 in position to open

upon swinging downwardly and inwardly and upon upward movement

to close the openings 20 by engagement with the spokes 19 and

under surface of the annulus. Each of the shutters is as shown

provided with weighted rods 24 affixed upon its upper surface

and inwardly curved to obtain a counter balanced and improved

shutter action. The hub 18 is also formed as shown with

central openings 26 closed by a spring pressed valve 27 to

which a cable 28 is attached and carried downwardly within the

rod 14 to a point accessible to the operator. The flexible

motive canopy 6 is secured to the respective rigid annulus 5

and the movable annulus 16 by means of cables 30 and 31 about

which its margins are wrapped and secured. At 32 there is

provided a suitable slide bearing for the rod 14 supported

upon spoke members 33, and 34 indicates tension connecting

wires between the annulus and the wherry.

The flexible motive canopy 6 is formed of a suitable fabric

such as rubberized canvas in circular dome contour and of such

diameter as required to produce the desired ascensional force

when its central portion is vertically reciprocated by the

motor, it being understood that upon the upward stroke of the

motor and annulus 16 the shutters 21 will open responsive to

air pressure from above as shown in Fig. 1 wherein the parts

are shown at the end of the up stroke and that upon the

dowward stroke of the annulus 16 the shutters will

automatically close so that upon the downward stroke a strong

ascensional force is created as a result of suction above the

motive canopy and air pressure beneath. Fig. 2 illustrates the

position of the parts at the end of the power stroke.

As will be understood from the structure described the

elevation of the machine may be readily controlled by the

throttling of the motor and for more rapid descent the pilot

may at will open the valve 27.

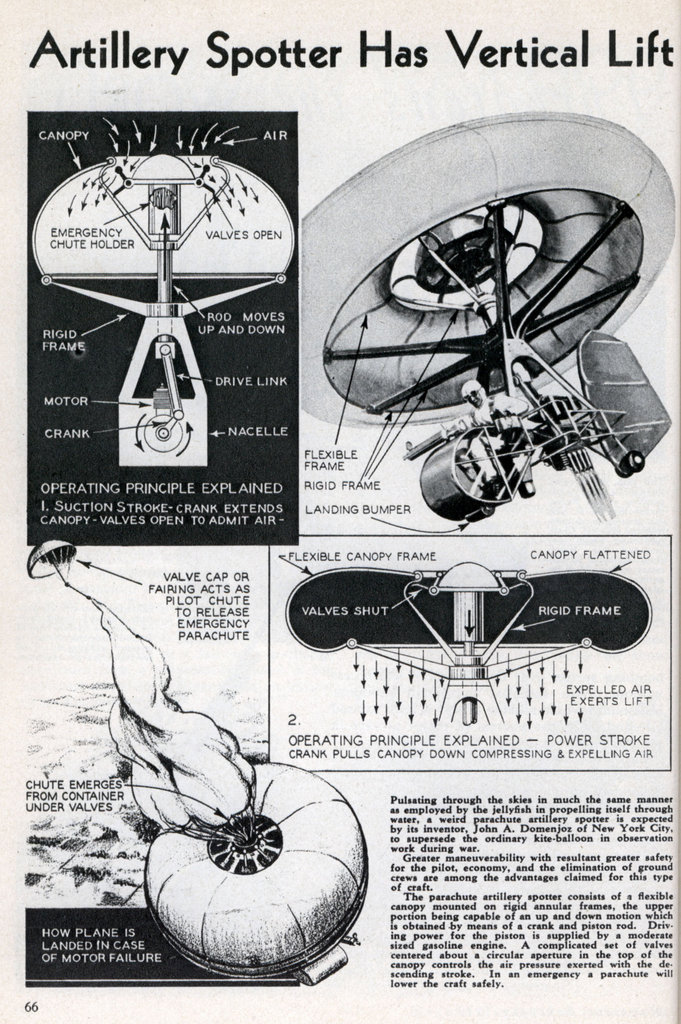

In Figs. 5 to 7, I have shown a desirable modified

construction wherein for the purpose of added safety in the

event of stoppage of the motor there is provided a

supplemetnal parachute which may be manually released thus to

supplement the parachute effect of the motive canopy and

accordingly allow of the employment of the canopy of minimum

dimensions with full parachute protection. As shown, the

supplemental parachute is carried by the movable annulus 16

which is of modified form omitting the valve of the first

described structure and having its upper hub portion provided

with a cylindrical housing 40 for the supplemental parachute

41 folded in the usual manner with its outer margin connected

by cords 42 to the housing at 43 while the inner marginal

portion is folded over and into a central tube 44 and is

connected to an ejector member 45 of tubular form slidably

fitted at its bottom portion within a cylinder 47 secured to

the lower hub 15 of the annulus. Beneath the ejector 45 there

is positioned a compression spring 48 and the ejector member

is held in position against the influence of the spring by a

latch 49 from which an operating cable 50 is extended

downwardly and accessible to the pilot. The ejector member has

pivotally secured thereto at its upper portion at 52 an

umbrella-like pilor parachute 53 to assit the full ejection of

the parachute 41. The top of the housing 40 is normally closed

by pivoted flaps 54 pivoted at 55. The movable annulus as

shown is further modified by the arrangement of a double

series of air valve sutters 56-57 pivoted at 58-59 upon the

annulus member. In emergency as will be understood the

operator releases the hatch 49 allowing the spring to upwardly

eject the parachute 41 with the pilot parachute assisting as

shown in Fig. 6.

My improved machine, as will readily be appreciated, is

particularly adapted for military observation with materially

increased safety to the pilot as compared to the free balloon

and further is advantageous by reason of compactness and

portability, is economical as compared to the gas balloon. Its

motive canopy is at all times available as a parachute for

safety and with the manually controlled valve is active as a

balanced parachute for improved control in maneuvering of the

machine. As will be unerstood varied modification may be made

in my improved machine without departing from the invention as

defined in the appended claims... [ Not included here ]