http://www.foodproductiondaily.com

New Food Dehydration Kit Delivers “Revolutionary” Benefits

by Mike Stones

6-Mar-2009

After a 10-year development programme, a Canadian company has made the first sale of what it claims to be revolutionary food dehydration equipment.

EnWave Corporation has sold its continuous nutraREV food dehydration system to Cal-San Enterprises; one of British Columbia’s largest blueberry producers.

Compared with the industry standard, freeze drying technology, the new equipment cuts processing time to minutes rather than hours or days, cuts energy use by one third and capital costs by one sixth, according to Jennifer Thompson, the company’s vice president of Corporate Development.

The new technology also reduces the potential for large batch losses with continuous processing, improves the retention of flavour and colour and facilitates value-added attributes such as puffing, Thompson told FoodProductionDaily.com.

Energy transfer

REV technology combines microwave energy transfer with pressure control to dehydrate and alter structures and drive chemical reactions. This creates unique product characteristics for both food products and medical applications, claims the company.

Following pre-commercial test results with fruits, vegetables and herbs, nutraREV dried products are said to contain similar shelf-life to freeze dried products.

EnWave has sold the equipment to Cal-San under a license which requires a royalty of up to 10 per cent of the company’s gross revenues from the sale of dried food products processed using the nutraREV technology.

Dave Sandhu, president of Cal-San said: “NutraREV gives the market a major advancement in food dehydration technology, and I believe that it will revolutionize the value-added food processing sector.”

Dr Tim Durance, EnWave chairman and Co-CEO said: “I believe that we have developed a competitive new method for food dehydration which offers consumers rich textures, concentrated flavours and excellent nutritional and environmental benefits.”

EnWave predicts sales of this equipment will range in price between $800,000 and $1m.

Dehydrated tomatoes

The company now intends to focus on the North American market for dehydrated tomatoes, potatoes, onions, herbs, blueberries, cranberries, strawberries and sour cherries. The combined size of these markets is estimated at US $1.2bn.

Longer term, the company plans to search for a global manufacturing and distribution partner to provide service and support for its machines. It is also continuing to develop its powderREV technology designed to dry bulk liquids containing sensitive biological organisms such as probiotics and enzymes.

APPARATUS AND METHOD FOR DEHYDRATING BIOLOGICAL MATERIALS

WO2009033285

2009-03-19

Inventor(s): DURANCE TIMOTHY D [CA]; FU JUN [CA];

YAGHMAEE PARASTOO [CA]; PIKE ROBERT

Applicant(s): ENWAVE CORP [CA]; DURANCE TIMOTHY D [CA]; FU

JUN [CA]; YAGHMAEE PARASTOO [CA]; PIKE ROBERT

Classification: - international: C12M1/42;

A61K9/14; A61K39/00; C07K1/00; C12M1/00; C12N1/04; F26B3/347;

F26B23/08; C12M1/42; A61K9/14; A61K39/00; C07K1/00; C12M1/00;

C12N1/04; F26B3/32; F26B23/00

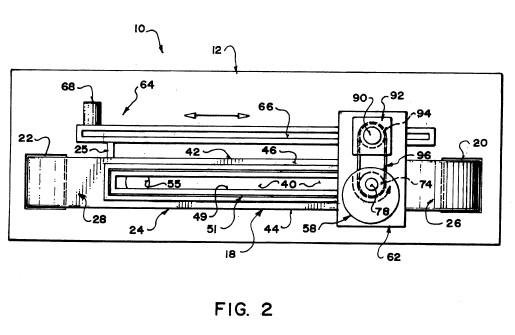

Abstract -- An apparatus for dehydrating a liquid sample of biological material has a microwave waveguide that is open to the atmosphere. It has a microwave generator, means for introducing a container of the material into the waveguide, means for evacuating the container, means for rotating the container and means for removing the container from the waveguide. It can include means for moving the container through the waveguide and for sealing it. In a dehydration method, a container of the liquid sample is put into the open waveguide, evacuated, rotated at high speed and microwaved. The container of dehydrated material is then removed from the waveguide. The apparatus and method are particularly suitable for dehydrating vaccines.