rexresearch.com

Gareth

McKINLEY, et al.

Fog Fence

Fog Fence

http://www.newyorker.com/tech/elements/could-harvesting-fog-help-solve-the-worlds-water-crisis?intcid=mod-latest

March 22, 2016

Could

Harvesting Fog Help Solve the World’s Water Crisis?

By

Pauls Toutonghi

By

Pauls Toutonghi

…As Dar Si Hmad has reckoned with the cultural implications of fog harvesting, the technology itself has evolved. While the basic science at its heart is not new—Bartolomé de las Casas mentions it in his sixteenth-century magnum opus, “History of the Indies”—the advancement of the harvesting equipment, in recent years, has been significant. “By changing the size of the holes, and the size of the fibres, and thinking about the coating on those fibres, we’ve improved the fog-collecting efficiency by about five hundred per cent,” Gareth McKinley, a professor of teaching innovation at M.I.T.’s School of Engineering, has said. The nets in Morocco, their designers say, are more durable and easier for locals to repair than similar nets built in the nineteen-nineties and early two-thousands in Eritrea, Chile, and Yemen...

https://www.youtube.com/watch?v=P631ymG8or8

Voyage

of the Mimi - Season 1 Episode 10

Making Dew Water Water Everywhere - 1984

Making Dew Water Water Everywhere - 1984

http://www.aqualonis.com/

Aqualonis GmbH Peter Trautwein CEO

Westendstraße 147

D-80339 München

Germany

Tel + 49(0)89-48 08 81-24

Fax + 49(0)89-48 08 81-11

info@aqualonis.com

Obtaining

drinking water with fog

In dry mountainous and

coastal regions with high fog concentration, the CloudFisher

collects water from fog and provides hundreds of thousands of

people with a secure supply of drinking water.

The CloudFisher is the first standard fog collector that can withstand high wind speeds. It is quick and easy to install, and requires no energy and only minimal maintenance. All the materials are food-safe. The CloudFisher can supply people with high-quality drinking water that meets WHO standards, and can also provide water for agriculture and forestry. It is mainly deployed in mountainous and coastal regions where rainfall is scarce but clouds and fog are plentiful.

Aqualonis GmbH has developed the CloudFisher Pro and CloudFisher mini for the Water Foundation Aqualonis GmbH, based in Munich, was founded to implement this technology worldwide. As a licensee of the WaterFoundation, the company markets and sells the CloudFisher products. Aqualonis develops, plans, builds and maintains fog water collection systems for non-profit and commercial projects alike. It is thus distinct from the WaterFoundation, a strictly non-profit organization that cannot engage in or accept liability for activities involving a commercial aspect.

The amounts yielded per fog-day differ according to region and season. They vary between 6 and 22 litres per square metre of net surface.

52.8 sqm total net surface

6 liter/sqm 316.8 liter

22 liter/sqm 1161,6 Liter

CloudFisher mini test collector and domestic user

16.5 sqm total net surface

6 liter/sqm 99 liter

22 liter/sqm 363 Liter

Each fog project starts with the collection of meteorological data on wind speeds and directions, relative humidity and temperature, precipitation and amounts of accumulated water. These findings are used to decide whether the location is appropriate for a fog water production system. How can the CloudFisher mini help with this?

Inventor(s): PARK KYOO-CHUL [US]; CHHATRE SHREERANG S [US]; MCKINLEY GARETH H [US]; COHEN ROBERT E [US] +

Applicant(s): MASSACHUSETTS INST TECHNOLOGY [US] +

A structure for collecting liquid droplets from an aerosol can have a structure and properties that are selected for efficient liquid collection. In particular, the strand radius and spacing of a mesh, and a material for coating the mesh, can be selected to provide efficient collection of water droplets from fog.

PRIORITY CLAIM

[0001] This application claims priority to U.S. Provisional Application 61/751,039, filed Jan. 10, 2013, which is incorporated by reference in its entirety.

TECHNICAL FIELD

[0002] The present invention relates to a liquid collecting permeable structures.

BACKGROUND

[0003] According to WHO statistics, less than 0.007% of all water on the earth is readily accessible for human consumption. About a billion people lack access to safe drinking water. More than 3.5 million people die every year due to water-related diseases. Water insecurity is one of the leading causes for school dropouts, especially among girls, and more than 200 million working hours are spent (almost exclusively by women) daily for the collection of domestic water.

[0004] The water crisis is worsened in arid parts of the world due to abuse of groundwater, water-intensive crop cultivation, rapid industrialization, and changing lifestyle. In some dry regions, the appearance of fog in the early morning is common. Fog is a completely untapped water resource. Fog harvesting provides an opportunity to “produce” water locally for rural communities, which will reduce the stress on groundwater. Consider a country like Chile, where a persistent advection fog is occurs due to the long and mountainous coastline. By one estimate, 10 billion m <3 >of fog water per year is available in Chile. Currently, water consumption in northern Chile is 391 million m <3 >per year, i.e., only 4% of the total water content in the fog. Water collection from fog harvesting thus has enormous potential to locally satisfy the need for a pure and dependable supply of water in arid locations.

SUMMARY

[0005] Highly efficient permeable structures for collection of liquid droplets or small particles are described. The surface wetting properties and topography of the material can guide the design of the permeable structures. For example, the fog harvesting ability of woven meshes can be increased greatly by judiciously choosing the physico-chemical properties of the mesh surfaces. A working model for the interaction of liquid with the permeable structures allows design of highly efficient liquid collecting structures for a variety of possible conditions.

[0006] The permeable structures can be used for applications including fog harvesting; elimination of mist in engines and turbines; or elimination of small droplets or colloidal particles in the chemical process industries. These mist eliminators decrease pressure drops across unit operations, such as distillation columns, and therefore save energy required for pumping. Filters based on the permeable structures can selectively capture hazardous colloidal emissions based on size...

BRIEF DESCRIPTION OF THE DRAWINGS

[0033] FIG. 1 is a series of microscope images of various permeable structures with different wire radii (R) and spacing ratio (D*).

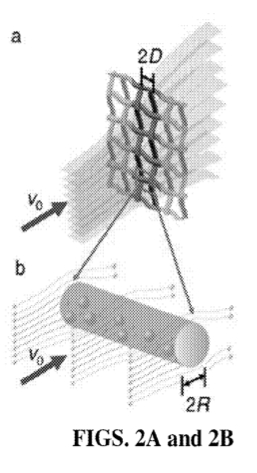

[0034] FIGS. 2A-2C are a diagrams depicting fog flow through a woven mesh surface, and a contour plot of the fog harvesting efficiency. FIG. 2A is an illustration indicating the stream surfaces of fog laden wind and their divergence after passing through a woven mesh surface. FIG. 2B is an enlarged drawing focusing on the interaction between incoming fog droplets and a horizontal mesh element. FIG. 2C is a contour plot of the fog harvesting efficiency (η) s a function of the ratio of radius of the fog droplets to the radius of the wire (R*=r fog/R) and the spacing ratio of the woven mesh (D*=(R+D)/R).

[0035] FIGS. 3A-3E represent two factors that reduce collection efficiency, and the surface modification design space that depicts the relative resistance to re-entrainment and drainage. Two factors that inhibit fog harvesting and reduce collection efficiency are ( FIG. 3A) re-entrainment of collected droplets in the wind and ( FIG. 3B) blockage of the mesh. FIG. 3C shows a plot that identifies the range of droplet sizes where the forces of adhesion dominate the drag forces, and establishes a criterion for a threshold droplet size for re-entrainment. FIG. 3D shows a plot that represents a second constraint arises from comparing the weight of the droplet with the surface pinning force arising from contact angle hysteresis. The threshold size where gravity dominates hysteretic pinning can be decreased by minimizing CAH=cos θ rec−cos θ adv. FIG. 3E shows a graph depicting the design space constructed from two dimensionless parameters related to work of adhesion (abscissa) and contact angle hysteresis (ordinate) depicts the relative resistance to re-entrainment and drainage. Measured values for droplets of water (V ″10 μL) deposited on several different coatings are shown in the plot. Wetting characteristics corresponding to a higher work of adhesion and lower contact angle hysteresis are ideal for the maximum fog collection efficiency.

[0036] FIG. 4 is a contour map of the predicted aerodynamic capture efficiency of fog droplets of radius r fog using a mesh with a wire radius R and a spacing ratio D*, assuming a wind velocity of 2 m/s. The efficiency is expected to increase with decreasing R (increasing R*) and at an intermediate value of D*.

[0037] FIG. 5 illustrates clogging and bridging problems associated with draining of collected liquid and a how a coating having a low contact angle hysteresis and a high receding contact angle can address these problems.

[0038] FIGS. 6A-6B show contour plots of fog harvesting efficiency of woven mesh surfaces with either ( FIG. 6A) a polypropylene (PP) coating, or ( FIG. 6B) a POSS-PEMA coating.

[0039] FIG. 7 illustrates a fabrication process of liquid-collecting permeable surfaces with different wettability by dip-coating and spray-coating.

[0040] FIG. 8 is a schematic depiction of an artificial fog harvesting experimental setup. The experiments were carried out in a humidity chamber at T=26° C., and a relative humidity of 100% to eliminate the effects of condensation and evaporation of water.

[0041] FIGS. 9A-9D illustrate results of fog harvesting experiments with woven wire meshes of different dimensions and surface coatings. FIGS. 9A-9C show design chart based on spacing ratio D* and dimensionless width R*. FIG. 9D displays the experimentally observed collection efficiency for the 5 dip-coated wire meshes along with coated and uncoated Raschel mesh.

[0042] FIG. 10 is shows predicted fog harvesting efficiency for a double layered Raschel mesh (blue) and for a woven mesh with R=127 μm and D*=3.5 (red) under different conditions of fog droplet size and wind velocity. Velocities and fog droplet radii were: (1) 0.5 m/s and 3 μm; (2) 0.5 m/s and 6 μm; (3) 2 m/s and 3 μm (conditions used in lab experiments); (4) 2 m/s and 6 μm; (5) 8 m/s and 3 μm; and (6) 8 m/s and 6 μm (Chilean fog conditions).

[0043] FIG. 11 is a schematic diagram depicting a water droplet on a cylindrical mesh filament.

[0044] FIG. 12 is a micrograph depicting a coated mesh.

[0045] FIG. 13 is a diagram and graph depicting contact angles of water droplets on surfaces...