rexresearch.com

Peter GRANDICS

Transmutation

Transmutation

Essence : Reflux concentrated (saturated) NaOH solution at 100-110°C for 5-24 hours (Sealed flask); Cool to room temperature. Add HCl solution (1:1) to pH is 4-5 w/ ice-bath cooling 20°.)

Add NaOH solution to adjust to pH 8. Let stand overnight, decant the liquid, and dry the precipitate. Heat at 70°C for about 7 hours to obtain a completely dry powder of constant weight. This "solid catalyst" powder consists of Na, Mg, Al, Si and O (!? -- probably it digests the flask). The reflux time is directly proportional to the amount of precipitate produced; the longer the reflux, the more precipitate. Heat the solid catalyst at 1000°C for 1 hour. The resulting material contains elements not previously present. Mix the catalyst with any desired element and heat it to 1000°C. The added element joins in the transmutation and yields a variety of elements elements heavier and lighter than the added element.

This is similar to T. Paracelsus' alkaline transmutations, K. Brecheisen's alkaline process, and Ormus extractions.

US2009317281

METHOD OF ATOMIC TRANSFORMATION

METHOD OF ATOMIC TRANSFORMATION

This invention provides a method for atomic transformations carried out under conditions akin to chemical catalysis. Liquid and solid state catalysts are used in a two-step process. We have found that the high ionic/electric activity of concentrated sodium hydroxide solution in combination with heating is sufficient to induce atomic transformation and provide a solid phase catalyst of high aluminum and silicon content. This product when heated at a temperature of 1000 DEG C. yields numerous elements of higher atomic masses. Thus, atomic transformation (transmutation) is demonstrated by using common chemicals and simple laboratory procedures

BACKGROUND OF THE INVENTION

[0001] This invention relates to atomic transformation reactions, in particular to the synthesis of magnesium, calcium, aluminum, silicon, iron, nickel, chromium, manganese, copper, silver, gold, palladium, zirconium, tungsten and others. Currently, the conversion of elements into each other is performed in nuclear reactors or utilizing other sources of nuclear radiation. These methods are unsuitable for the low-cost mass production of elements and produce many undesirable radioisotopes. The present invention aims to provide a method allowing low-energy atomic transformations under conditions akin to chemical catalysis.

SUMMARY OF THE INVENTION

[0002] Previously, we have introduced a new model of the atom that predicted that atomic transformations (transmutation) could be carried out under conditions akin to chemical catalysis. This invention provides a proof of this model, using liquid and solid phase catalysts in a two-step process. We have found that the high ionic activity of concentrated sodium hydroxide solution in combination with heating is sufficient to induce atomic transformation and generate a solid phase catalyst of high aluminum and silicon content. This catalyst when heated at a temperature of 1000° C. yields a variety of elements, including magnesium, calcium, iron, nickel, chromium, manganese, palladium, gold, silver, tungsten and copper. Thus, atomic transformation has been demonstrated using common chemicals and simple laboratory procedures.

[0003] Accordingly, one aspect of the present invention is a method of elemental transformation comprising:

[0004] (1) providing a liquid phase catalyst utilizing high ionic/electric energy;

[0005] (2) heating the liquid phase catalyst;

[0006] (3) neutralizing the liquid phase catalyst to prepare a solid phase catalyst;

[0007] (4) performing solid phase catalysis by heating the solid phase catalyst at high temperature; and

[0008] (5) heating the solid phase catalyst with an element or its compound to achieve elemental transformation.

[0009] Another aspect of the present invention is a method of use of a product produced by the method described above in a biological system.

BRIEF DESCRIPTION OF THE DRAWINGS

[0010] The following invention will become better understood with reference to the specification, appended claims, and accompanying drawings, where:

[0011] FIG. 1 is a graph showing the time-course of the white precipitate formation in the first reaction step.

[0012] FIG. 2 is a graph showing the Scanning Electron Microscopy-Energy Dispersive Spectroscopy (SEM-EDS) analysis of the white precipitate.

[0013] FIG. 3 is a graph showing the SEM image of the white precipitate.

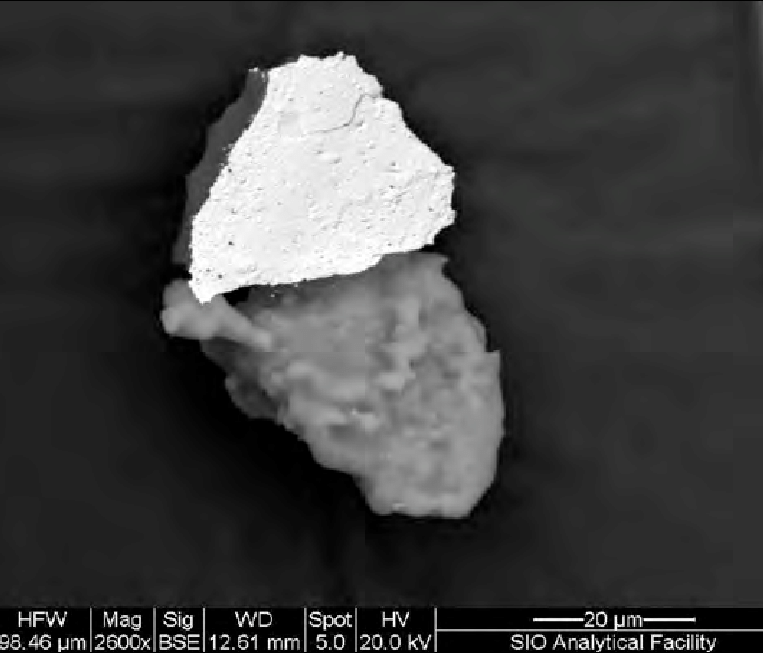

[0014] FIG. 4 is a graph showing the SEM image of the heated white precipitate. [ Click to enlarge ]

[0016] FIG. 6 is a graph showing the SEM image of crystal 2.

[0017] FIG. 7 is a graph showing the SEM image of crystal 3.

[0018] FIG. 8 is a graph showing the matrix composition of the heated white precipitate.

[0019] FIG. 9 is a graph showing the SEM-EDS analysis of crystal 1.

[0020] FIG. 10 is a graph showing the SEM-EDS analysis of two areas in FIG. 4.

[0021] FIG. 11 is a graph showing the SEM-EDS analysis of crystal 2.

[0022] FIG. 12 is a graph showing the SEM-EDS analysis of crystal 3.

DETAILED DESCRIPTION OF THE INVENTION

[0023] Over the past two decades, numerous research reports have emerged on low energy nuclear reactions, e.g., the formation of tritium from deuterium on Pd (1), the formation of Fe in gold electrodes, or the formation of helium and cadmium in a Pd electrode (2), as well as the formation of other elements (3). These data were largely viewed with skepticism as low energy nuclear reactions are not explainable within our current understanding of atomic processes.

[0024] We recently introduced a new theory of the atom that provides a theoretical framework for the design of low energy nuclear reactions (4, 5). The theory proposes that atoms are complex electromagnetic waveforms that are circulators of the space lattice, the carrier medium for electromagnetic interactions. We suggested that only electromagnetic energy exists, and therefore electromagnetic pressure waves of sufficient intensity should induce atomic transformation. In addition, the atom should be viewed as a whole, irrespective of whether chemical or nuclear reactions are concerned. For this reason, we introduce here the term low energy atomic transformation to replace the currently used term “nuclear reaction” to describe the synthesis of elements under conditions akin to chemical catalysis.

[0025] We hypothesized that sufficient electric pressure could be generated by utilizing high ionic activities of molecules, a method commonly used in chemical catalysis. We reasoned that a single catalytic step may be enough to produce elements of lower atomic masses, and such a procedure is demonstrated in this invention. The synthesis of elements of higher atomic masses requires an additional catalytic step.

[0026] Accordingly, one aspect of the present invention is a method of elemental transformation comprising:

[0027] (1) providing a liquid phase catalyst utilizing high ionic/electric energy;

[0028] (2) heating the liquid phase catalyst;

[0029] (3) neutralizing the liquid phase catalyst to prepare a solid phase catalyst;

[0030] (4) performing solid phase catalysis by heating the solid phase catalyst at high temperature; and

[0031] (5) heating the solid phase catalyst with an element or its compound to achieve elemental transformation.

[0032] In one alternative, electric pressure is generated in order to facilitate elemental transformation. In another alternative, heating and electric pressure are used in combination.

[0033] The liquid phase catalyst can be a base or an acid.

[0034] Typically, the reaction temperature of the liquid phase catalytic step is between about 80° C. and about 250° C. Typically, the reaction time for the liquid phase catalytic step is from about 5 hours to about 24 hours. Typically, the heating temperature of the liquid phase catalyst is between about 100° C. and about 120° C.

[0035] The neutralization step can yield a solid phase catalyst in the form of a white precipitate. The white precipitate can contain sodium, aluminum, silicon, and oxygen as main constituents. The white precipitate catalyst can be heated at a temperature range of from about 800° C. to about 1700° C., optionally with an element.

[0036] New elements can be generated by the method; for example, the new elements can include at least one element selected from the group consisting of magnesium, aluminum, calcium, palladium, copper, gold, silver, zinc, tungsten, iron, manganese, nickel, zirconium and chromium.

[0037] The synthesized elements produced by the method can have an atomic mass higher than sodium.

[0038] Another aspect of the present invention is a method of use of a product produced by the method described above in a biological system. The biological organism can be a microorganism or a eukaryote, such as a higher plant or a human.

Materials and Methods

[0039] All chemicals were obtained from Sigma-Aldrich and were of ACS grade or equivalent. All containers coming in contact with reaction media were glass. The elemental transformation method described here involves a two-step reaction. In the first step, 4.5 liters of 3.7 M NaOH were gently refluxed for 5-24 h in a round-bottom glass reactor. After cooling to room temperature on a chilled water bath, the pH was adjusted slowly to slightly acidic (pH 4-5) with 1:1 HCl under gentle stirring. The solution became turbid; a white precipitate began to form early in the neutralization process. It is important to avoid significant warming up of the solution. The best approach is to perform the neutralization on a chilled water bath and keep the temperature at around 20° C.

[0040] From the slightly acidic pH, the mixture was re-adjusted to mildly alkaline by using 1M NaOH solution until pH 8 was reached. After stirring was stopped, the supernatant slowly cleared and a white precipitate settled out. After the precipitate settled overnight the supernatant was carefully aspirated off using a peristaltic pump. The precipitate was re-suspended in 8 L of deionized water and allowed to settle overnight again. The settled precipitate was transferred into 1-L centrifuge tubes with deionized water and spun at 3,500 rpm for 35 m in a Sorvall model RC3B centrifuge. The precipitate was washed 3 more times by resuspension in deionized water to remove residual salts, and spread out on a glass tray to air dry. Subsequently, it was heated at 70° C. for 7 hours to reach a constant weight and weighed. The granular, soft white material was ground to a fine powder in a porcelain mortar and stored in a plastic jar at room temperature. The second catalytic step involved heating the white precipitate to 1000° C. for 1 hr in a Sentrotech STT-1600 tube furnace in an air atmosphere. SEM-EDS analyses were performed using a Philips Quanta 600 instrument.

Results and Discussion

[0041] In a new theory of the atom and atomic processes (4, 5), we proposed that the atom is a complex electromagnetic waveform with constituents that form a balanced, coupled system. We also suggested that the atom should be treated as a whole, regardless of whether chemical or nuclear reactions are concerned. For this reason, we have introduced the term low energy atomic transformation as opposed to the currently used nuclear reaction to describe the synthesis of new elements under conditions similar to chemical catalysis. As the atom is formed out of the space lattice by electromagnetic pressure waves (4, 5), the atom may also be transformed (transmuted) by electromagnetic force alone.

[0042] A large body of evidence is now accumulating on low energy nuclear reactions demonstrating that electromagnetic effects may be sufficient to achieve atomic transformation (1-3). As chemical reactions are electric, we reasoned that the high ionic/electric activity of extreme pH could be sufficient to drive atomic transformation reactions. Heating the reaction mixture amplifies the electric activity of high pH and should thus increase reaction rates.

[0043] To study whether atomic transformation may occur in a heated NaOH solution, we first set up the reflux of a 3.7M NaOH solution for increasing times (FIG. 1). We also hypothesized that reaction product could become enriched in silicon, because this element resides at wave amplitude of the 5th octave in the spiral periodic table of elements [6] and so it is a potential end product of the transformation of sodium. Therefore, after neutralization with acid, the silicon-rich reaction product should precipitate out. In fact, we found a white precipitate forming early in the neutralization process. No precipitate forms before boiling takes place. For neutralization, we used both acetic and hydrochloric acids and found that HCl neutralization yields a more robust precipitate. Despite this, settling of the precipitate takes a long time and even with centrifugation a small loss of fines occurred. The precipitate was subsequently dried at 70° C. and weighed.

[0044] We also noticed a minor breakdown of the glass material of the reaction vessel, and an average mass loss of 2 g of the reaction flask over a 24 h refluxing. This is only 1/10th of the amount of precipitate obtained during the reaction. In the 5 h reactions, an average weight loss was observed of 0.9 g of the reaction vessel. The average yield of the white precipitate in three reactions was 20.1 g. The amount of precipitate generated in the reaction mixture increased nearly linearly with the boiling time indicating that the reaction potential was not exhausted over 24 h of boiling (FIG. 1).

[0045] The elemental composition of the white precipitate differs substantially from that of the starting neutralized NaOH as well as the glass material of the reaction vessel. In Table 1, the compositions of the starting neutralized NaOH, the white precipitate and the reactor glass material were compared by ICP-MS. Analysis of the white precipitate by SEM-EDS (FIG. 2) and ICP-MS (Table 1) demonstrated a high concentration of silicon that was not present in the starting reagents. In fact, the silicon concentration in the HCl neutralized NaOH solution at zero time was merely 1.5 ppm, consistent with ACS grade chemicals. The concentrations of magnesium, aluminum, and calcium were also greatly increased compared with the starting reagents. As 666 g of NaOH yielded 20.1 g of precipitate, a conversion factor of 33.13 can be used to estimate the relative concentration changes of elements.

[0046] The data demonstrate that Mg, Ca, Al and Si appeared (likely in the form of a mixed sodium silicate compound) as the main new constituents during boiling of NaOH. The reactor glass contributes just 8% of the silicon content of the white precipitate. The consumption of Na during reflux was also evident. In addition, the concentration of a number of other elements increased to varying degrees in the white precipitate relative to time zero. Among these, the greatest increases were shown by Cu, Fe, Ti, Mn, Zn and Zr. The concentrations of Al, C, Na, and Si in the samples were confirmed by X-ray fluorescence.

[0047] This observation can be interpreted by our new theory of the atom (4, 5) as well as the theory of spiral periodic table of elements introduced by Russell (6, 7). He suggested that all elements are aggregates of light units progressing through their evolutionary cycle of disappearance and reappearance. In other words, all elements follow a similar life cycle and therefore “stable” elements do not exist. According to Russell, all elements of matter are positioned along a nine-octave sine wave cycle of motion. Each octave has 7 tones (elements) plus a “supertone” noble gas that records all information of elements of its octave. Atoms can be considered merely as various states of motion of one cosmic substance, and are locked into their energetically permitted positions on their octave waves.

[0000]

TABLE 1

Elemental Compositions of the Zero-Time Neutralized NaOH, the White Precipitate and the Reactor Glass

Neutralized NaOH White precipitate Reactor glass material

ppm ppm ppm ppm ppm ppm C 4,200

Al 0.63 Mo 0.005 Al 20,000 Mo 0.12 Al 14,200 Mo 6.7

Sb ND Nd ND Sb 0.49 Nd 0.43 Sb 0.44 Nd 0.52

As ND Ni 0.1 As ND Ni 250 As 0.43 Ni 1.4

Ba 0.18 Nb ND Ba 3.8 Nb ND Ba 7.9 Nb 0.29

Be ND Os ND Be 0.15 Os ND Be 0.13 Os ND

Bi ND Pd ND Bi ND Pd 0.15 Bi ND Pd 0.22

B 1.3 P ND B 590 P 10 B 24,600 P 12

Br ND Pt ND Br ND Pt ND Br ND Pt ND

Cd ND K 11 Cd 0.08 K 480 Cd ND K 1810

Ca 0.49 Pr ND Ca 2,100 Pr 0.11 Ca 265 Pr 0.14

Ce ND Re ND Ce 74 Re ND Ce 1.8 Re ND

Cs 0.007 Rh ND Cs 0.27 Rh ND Cs 1.12 Rh ND

Cr 0.031 Rb 0.005 Cr 7.3 Rb 0.82 Cr 7.7 Rb 1.09

Co ND Ru ND Co 6.4 Ru 0.1 Co 1.29 Ru ND

Cu 0.006 Sm ND Cu 12 Sm 0.08 Cu 0.89 Sm 0.09

Dy ND Se ND Dy 0.1 Se ND Dy 0.13 Se ND

Er ND Si 1.5 Er 0.09 Si 400,000 Er 0.11 Si 338,700

Eu ND Ag ND Eu ND Ag 2.7 Eu ND Ag ND

Gd ND Na 66,000 Gd 0.2 Na 43,400 Gd 0.13 Na 29,000

Ga ND Sr 0.053 Ga 2 Sr 14 Ga 1.26 Sr 2.77

Ge ND Ta ND Ge 0.1 Ta ND Ge 1.13 Ta 0.07

Au ND Te ND Au ND Te ND Au ND Te ND

Hf ND Tl ND Hf 7.6 Tl ND Hf 8.69 Tl ND

Ho ND Th ND Ho ND Th 0.37 Ho ND Th 0.19

I ND Tm ND I ND Tm ND I ND Tm ND

Ir ND Sn ND Ir ND Sn 1.1 Ir ND Sn ND

Fe 0.27 Ti ND Fe 450 Ti 84 Fe 233 Ti 31

La 0.019 W ND La 0.92 W ND La 0.9 W 1.49

Pb ND U 0.004 Pb 18 U 0.47 Pb 1.39 U 0.22

Li 0.018 V ND Li 0.28 V 0.09 Li 9.23 V 0.42

Lu ND Yb ND Lu ND Yb 0.16 Lu ND Yb 0.16

Mg 0.038 Y ND Mg 880 Y 0.64 Mg 33 Y 0.81

Mn 0.019 Zn 0.035 Mn 17 Zn 32 Mn 5.89 Zn ND

Hg ND Zr ND Hg ND Zr 510 Hg ND Zr 459

ND not detectable

[0048] In the reflux reaction, high purity NaOH is used which contains sodium, the element consumed during reflux. Sodium is positioned as the first element of the fifth octave of the spiral periodic table of elements (6, 7). Silicon is at wave amplitude of the fifth octave, i.e., it is the element of highest orbital velocity, the highest melting point, the most compact crystallization, and the hardest one among the elements of the fifth octave.

[0049] As objects of matter can be considered to be accumulations of electric energy (5, 6), elements may be converted into each other by the proper injection of electric energy, which can switch an element's gyroscopic plane of motion to the next locked position on its octave wave, or up to octave wave amplitude or even further up into higher octaves.

[0050] In our atomic transformation reaction, we have relied on the high ionic/electric activity of extreme pH to inject the electric pressure necessary to cause a switch of the gyroscopic sodium atom into other locked positions on its octave wave, and thus transform it into Mg, Al and Si at increasing concentrations in the very same order. Heating is necessary because heating destabilizes the normally locked gyroscopic oscillatory motion of elements, and facilitates transition into other locked positions that correspond to other elements.

[0051] We have tested whether the white precipitate had an autocatalytic effect on itself and could give rise to previously absent elements. We heated 0.2 g of white precipitate in a platinum crucible at 1000° C. for 1 hr in air atmosphere. On SEM-EDS analysis, the heated sample showed significant composition changes compared to the starting sample (FIGS. 3 & 4). Numerous bright, highly electron-dense crystals appeared, highly variable in appearance and elemental composition (FIGS. 4-6 and 7-9). These were previously undetectable.

[0052] The elemental composition of the silicate matrix in FIG. 4 also differs from that of the starting white precipitate (FIG. 2). The concentration of Na increased, with Mg and Ca appearing as prominent new elements (FIG. 8). Some loss of Si was also evident. We have performed the analysis of a bright, electron dense cluster located in the center of FIG. 4. Analyses show high Fe concentration, accompanied by Cr, Ni, Mn and Cu (FIGS. 10A & 10B). Subsequently, we selected stand-alone crystals for analysis. Crystal 1 contains high concentrations of Al and Zr (FIGS. 5 & 9). Crystal 2 (FIG. 6) is mainly composed of Au and Pd (FIG. 11), while crystal 3 (FIG. 7) is composed of almost pure W (FIG. 12). Au and W were both undetectable in the white precipitate.

[0053] These observations indicate an innate catalytic ability, and raise the possibility of the de novo synthesis of a wide range of metals of industrial significance. Possibly, the white precipitate is an “electrically activated” substance, a property common to catalysts, capable of stimulating atomic transformations of its own. Although the overall yield of elements of higher atomic numbers is low, this will be possible to improve with further research.

[0054] The results confirm our hypothesis that atomic transformation requires electric pressure along with heating, which may be Nature's method of synthesizing matter. We have also confirmed fundamental observations of the spiral periodic table of elements (6, 7). In agreement with Russell's theory, we have redefined atomic transformation as atomic rather than “nuclear” (5) and now propose that the nuclear atom hypothesis is inconsistent with Nature's processes. If atomic bodies are generated by external electromagnetic pressure waves (4-7), the atom cannot have an energy of its own capable of attracting from the inside, e.g., from a solid nucleus. Instead, the atom should be viewed as a wound-up spring that seeks equilibrium with its low-pressure environment, and will do so unless maintained by a continuous input of energy. The physical nature of such an energy source remains to be determined.

[0055] We have proven that atomic transformations are feasible under conditions typical of chemical catalysis, and so it is plausible that the ancient art of alchemy could have had substance. Acidic (vinegar) and basic (lye) chemicals have been known since ancient times. Silicate compounds are widely distributed in Earth's crust. High temperatures and alkaline as well as acidic conditions are also present there. Therefore, the geochemical conditions are given for the ongoing de novo synthesis of elements in Earth's crust, and it is likely that some marine chemicals may actually help build continents.

[0056] Kervran described that egg-laying hens when fed with calcium-deficient but potassium and silicon-containing diet still laid hard-shell eggs (8). In our experiment, calcium formation was also observed in the white precipitate, as well as during its subsequent heating. We have demonstrated the formation of elements of higher atomic numbers during heating of the white precipitate. Living organisms have the ability to catalyze reactions that would require temperatures of 1000° C. by nonbiologic methods of chemistry. It is possible that an electrically activated silicon compound, when ingested, could be transformed into elements of higher atomic numbers inside living cells and thus provide a novel avenue of mineral supplementation.

[0057] This study opens the possibility of low energy controlled synthesis of elements, and demonstrates the need for a revision of our theoretical framework of atomic processes. Further studies in this field could help resolve a number of environmental problems including the accumulation of radioactive waste, as well as pollution caused by mining operations. It appears that new theoretical considerations of the atom may well propel physical and material sciences into a new era of inconceivable possibilities.

REFERENCES

[0000]

1. Storms, E. “Critical review of the “Cold Fusion” effect.” 1996. J. Sci. Explor. 10, 185-245.

2. Bockris, J. O'M., Lin, G. H. and Bush, R. T. 1996. “Do nuclear reactions take place under chemical stimulation?’ J. Sci. Explor. 10, 245-249.

3. Ho, M-W. 2007. “Transmutation, the alchemist dream come true.” http://www.isis.org.uk/alchemistsDream.php

4. Grandics, P. 2002. “The genesis of electromagnetic and gravitational forces.” J. New Energy, 6, (3) 33-45.

5. Grandics, P. 2007. “The genesis of fundamental forces acting at a distance and some practical derivations.” Infinite Energy, 12, (71) 13-24.

6. Russell, W. 1953. “A new concept of the Universe.” The University of Science and Philosophy, Swannanoa, Waynesboro, Va., pp. 112-119.

7. Russell, W. and Russell, L. 1957. “Atomic suicide?” The University of Science and Philosophy, Swannanoa, Waynesboro, Va., pp. 2645.

8. Kervran, C. L. 1972. “Biological Transmutations,” Swan House Publishing Company, New York, N.Y., p. 41.

ADVANTAGES OF THE INVENTION

[0066] This study opens the possibility of low energy controlled synthesis of elements. Electric pressure is generated by the combination of the high ionic/electric activity of extreme pH that is operational at both ends of the pH spectrum; i.e., both basic and acidic catalysis can be used to different ends. In addition, heating is required. The solid phase catalyst may react with other elements of the periodic table and induce atomic transformation reactions. Among these elements, both stable and radioactive elements may be used. Further studies could help resolve a number of serious environmental problems, including the accumulation of radioactive waste. Also, polluting and dangerous mining operations and foundries could be replaced by a new synthetic metals industry...

https://www.researchgate.net/profile/Peter_Grandics2

Peter Grandics

A-D Research Foundation · Research and Development

A-D Research Foundation · Research and Development

Peter Grandics currently works at the Research and Development, A-D Research Foundation. Peter does research in Cancer Research, Biophysics and Experimental Physics. Their most recent publication is 'Rebuttal of Heisenberg's Uncertainty Principle: Replacing Uncertainty with Absolute Certainty'.

https://www.researchgate.net/publication/255709850_A_Method_of_Atomic_Transformation_I

A Method of Atomic Transformation I.

Peter Grandics / A-D Research Foundation

Abstract -- Previously, we introduced a new model of the

atom that predicted that atomic transformation (transmu-tation)

could be carried out under low energy conditions akin to chemical

catalysis. In this paper, we provide proof of this model, using

liquid and solid state catalysis in a two-step process. We have

found that the high ionic/electric activity of a concentrated

sodium hydroxide solution in combination with heating is

sufficient to induce atomic transformation and provide a product

high in sodium, alu-minum and silicon. When heated at a

temperature of 1,000°C, this product yields numerous elements of

higher atomic masses. Thus, atomic transformation was

demon-strated using common chemicals and simple laboratory

procedures. Our results suggest that current theories of the atom

and atomic processes should be revised to account for low energy

atomic transformation. Introduction At this time, elemental

transformation (transmutation) is carried out in nuclear reactors

or using other sources of nuclear radiation. These methods are

unsuitable for low cost, mass production of elements and generate

many radioiso-topes. Over the past two decades, numerous research

reports have emerged on low energy nuclear reactions, e.g., the

for-mation of tritium from deuterium on Pd, 1 the formation of Fe

in gold electrodes, or the formation of helium and cad-mium in a

Pd electrode, 2 as well as the formation of other elements. 3

These data were largely viewed with skepticism, as low energy

nuclear reactions are not explainable within our current

understanding of atomic processes. We recently introduced a new

theory of the atom that provides a theoretical framework for the

design of low ener-gy nuclear reactions. 4,5 The theory proposes

that atoms are complex electromagnetic waveforms that are

circulators of the space lattice, the carrier medium for

electromagnetic interactions. We suggested that only

electromagnetic energy exists, and therefore electromagnetic

pressure waves of suffi-cient intensity should induce atomic

transformation. In addition, the atom should be viewed as a whole,

irrespective of whether chemical or nuclear reactions are

concerned. For this reason, we introduce here the term low energy

atomic transformation to replace the currently used term "nuclear

reaction" to describe the synthesis of elements under condi-tions

akin to chemical catalysis. We hypothesized that sufficient

electric pressure could be generated by utilizing high ionic

activities of molecules, a method commonly used in chemical

catalysis. We reasoned that a single catalytic step may be enough

to produce ele-ments of lower atomic masses, and such procedure is

demonstrated in this invention. The synthesis of elements of

higher atomic masses requires an additional catalytic step.

Materials and Methods All chemicals were obtained from

Sigma-Aldrich and were of ACS grade or equivalent. All containers

coming in contact with reaction media were glass. The elemental

transforma-tion method described here involves a two-step

reaction. In the first step, 4.5 liters of 3.7M NaOH were gently

refluxed for 5-24h in a round-bottom glass reactor. After cooling

to room temperature on a chilled water bath, the pH was adjusted

slowly to slightly acidic (pH 4-5) with 1:1 HCl under gentle

stirring. The solution became turbid and a white precipitate began

to form early in the neutralization process. It is important to

avoid significant warming up of the solution. The best approach is

to perform the neutraliza-tion on a chilled water bath and keep

the temperature at around 20°C. From the slightly acidic pH, the

mixture was re-adjusted to mildly alkaline by using 1M NaOH until

pH8 was reached. After stirring was stopped, the supernatant

slowly cleared and a white precipitate settled out. After the

precipitate set-tled overnight, the supernatant was carefully

aspirated off using a peristaltic pump. The precipitate was

re-suspended in 8L of deionized water and allowed to settle

overnight again. The settled precipitate was transferred into 1L

centrifuge tubes with deionized water and spun at 3,500 rpm for

35min in a Sorvall model RC3B centrifuge. The precipitate was

washed three more times by re-suspension in deionized water to

remove residual salts, and spread out on a glass tray to air dry.

Subsequently, it was heated at 70°C for 7h to reach a constant

weight and then was weighed. The granular, soft white material was

ground to a fine powder in a porcelain mortar and stored in a

plastic jar at room temperature. The second catalytic step

involved heating the white precipitate to 1,000°C for 1h in a

Sentrotech STT-1600 tube furnace in an air atmosphere. SEM-EDS

analyses were performed using a Philips Quanta 600 instrument.Peter Grandics / A-D Research Foundation

See also:

https://www.researchgate.net/publication/291671451_Method_to_capture_atmospheric_electrostatic_energy

Method to capture atmospheric electrostatic

energy

https://www.researchgate.net/publication/255709598_The_Pyramidal_Electric_Transducer

The Pyramidal Electric Transducer

https://www.researchgate.net/publication/242669679_A_DC_to_RF_Converter_for_the_Capture_of_Atmospheric_Electrostatic_Energy

A DC to RF Converter for the Capture of

Atmospheric Electrostatic Energy