LUNENBURG ó At the waterís edge of a 119-year-old boatyard in

Lunenburg, engineers are perfecting a surprisingly simple method

of harnessing the sunís energy to melt metals.

The Prometheus Project uses an ordinary mirror ó albeit quite huge

at five metres square ó that bounces the sunís energy onto a

smaller mirror that then directs it into a crucible where it melts

a lump of aluminum at 660 C.

Inventor Peter Kinley said the groundbreaking results have

astonishing potential for the industrial and residential sectors.

It can be used as an environmentally friendly way to melt metal

and to heat water to warm houses.

"Itís a good time to look at renewables."

With the high cost of oil, it is expensive to melt the metals the

foundry needs to create parts for boats and ships, and burning oil

hurts the environment. Kinley wanted to find a way to concentrate

the sunís energy and harness it to melt metals.

This invention started out as a little experiment four years ago

behind his farmhouse in Lilydale, just outside Lunenburg.

"We wanted to find a renewable source of energy for the foundry,

something that was able to give us a reduction in costs over our

current methods and that was sustainable and long term," said

Kinley, president and CEO of Lunenburg Industrial Foundry

& Engineering Ltd.

The folks working on this solar furnace, with its patented Kinley

Dual Mirror System, are usually refurbishing boats ó from Theodore

Too to the Bluenose II and luxury yachts. But Kinley said itís an

ideal setup for his invention ó he has the carpenters,

electricians, plumbers and welders he needs to refine the

technology, as well as the space to store the contraption in a

huge boat shed.

His first prototype, Alpha, was rudimentary, using polished

stainless-steel sheets inside plywood casing.

"I was surprised at how well our system worked from the get-go. We

were able to melt metal the first time out."

It generated a temperature of 407 C, melting a metal called

babbit, which is made from lead and zinc.

He called the National Research Council the next day to see who

else was studying such technology and was shocked to learn no one

was in Canada or anywhere else in the world.

His team has been refining that original prototype a little more

each year.

"We decided to find a way to inexpensively duplicate what a

magnifying glass would be able to do on a much larger scale,"

Kinley said.

With his initial success, he knew he had something big on his

hands, but he didnít want word to get out before he patented the

design. So he dubbed the project Prometheus, for the Greek

mythological character who stole fire from Zeus and gave it to

people.

"Prometheus is a name that we adopted as a code word for the

project because our patent attorneys advised us to keep it under

wraps until the patenting process was complete. So the name sort

of stuck."

Instead of telling people he was working on a solar project, he

would tell the curious he was working on Prometheus, and they just

assumed it was a boat.

As the foundry tweaks its invention, it has been working with

Dalhousie University in Halifax to create a computer model of the

temperatures the current system, Gamma II, has generated.

It has reached recorded temperatures of 1,800 C, although Kinley

suspects it gets far hotter, even though it hasnít been proved yet

because the Gamma II has melted the platinum thermocouples that

were used to measure the temperature. They can withstand

temperatures of 1,755 C. There were signs of vaporization when the

Gamma II melted iron recently, and that happens at 2,800 C.

As the Prometheus team continues to refine the Gamma II so that it

can melt larger amounts of metals, and do it safely, a smaller

version is undergoing six months of testing by Alberta Innovates ó

Technology Futures, the former Alberta Research Council, in

Edmonton.

The foundry is looking at the potential to commercialize the Gamma

II by making it more automated and to provide solar heat in houses

by heating water that passes through pipes.

Kinley said he would also like to work with a university doing

research in high-temperature physics.

In the short term, the foundry plans to use the Gamma II to create

all its smaller castings, such as decorative door knockers,

souvenir dories and Bluenose II replicas, by this summer.

"Itís completely carbon neutral, and weíd also like to increase

the amount of metal it melts to displace our regular forms of

melting."

WO2008046187

TWO-STAGE SOLAR CONCENTRATING

SYSTEM.

Inventor(s): KINLEY PETER J [CA] + (PETER J.

KINLEY)

Applicant(s): LUNENBURG FOUNDRY &

ENGINEERIN

Classification: - international:

F24J2/10; F24J2/52; F24J2/00; F24J2/06 -

European: F24J2/14; F24J2/16; F24J2/18;

F24J2/54B4

Also published as: CA2562615 // EP2069694 // CN101460788 //

WO2008046187

Abstract -- An improved

solar concentrating system (100) uses a two-stage arrangement of

mirrors wherein the rays of the sun are reflected and concentrated

to a point focus. The solar concentrator ( 100) may be used to

increase the temperature of a substance such as metal, for use in

a variety of applications including the melting of metals in a

foundry furnace. The solar concentrating system (100) comprises at

least two single-curved parabolic mirrors (10, 20) connected in an

operable arrangement. The rays of the sun are reflected from a

first single-curved parabolic mirror ( 10) to a second

single-curved parabolic mirror (20). The plane of symmetry of the

second single-curved parabolic mirror is arranged substantially

orthogonal to the plane of symmetry of the first single-curved

parabolic mirror thereby concentrating the rays of the sun to a

point focus.

FIELD OF INVENTION

The present invention relates to a solar concentrator. In

particular, the present invention relates to a two-stage solar

concentrating system wherein the rays of the sun may be reflected

and concentrated to a desired focus- optionally, a square focus.

More particularly, the present invention relates to a two-stage

solar concentrating system wherein the rays of the sun are

reflected and concentrated to a point focus. Such a solar

concentrator may be used to increase the temperature of a

substance such as, for example, metal, for use in a variety of

applications including, inter alia, melting of metals in a

foundry.

BACKGROUND OF THE INVENTION

As the world- wide demand for energy increases exponentially,

there is a heavy burden placed on traditional sources of energy,

such as non-renewable fossil-based fuels. The price of crude oil

has shown significant historical fluctuations. The spiraling cost

of crude oil in recent years adversely effects the bottom-line of

many small and medium scale energy- intensive industries such as

foundries and the like. Therefore, alternate sources of energy,

e.g., solar power, have become increasingly attractive in recent

times. There is an environmental benefit to adopting cleaner

energy sources as reduction of burning of fossil fuels helps to

reduce greenhouse gas emissions

Solar energy technology has developed significantly since the

ancient Greek civilization learned the art of concentrating sun's

rays. Over the years, solar energy research has helped develop

systems that have improved efficiency and are more economical.

However, a dearth of information, materials, complexity, and

manufacturing skills remain an impediment to large-scale

production and utilization of this abundantly available energy

source.

Solar concentrators are characterized and classified based on

several criteria including the means of concentration: reflection

or refraction; type of focusing: point, line, or non- focusing;

type of concentrator: fixed or tracking concentrator; and, type of

receiver: fixed or tracking receiver. As will be described and

illustrated hereinafter, there are three primary types of

reflective solar concentrating systems based on the type of

focusing they produce, viz. , (a) parabolic trough concentrators

that produce line focus; (b) central receiver-type concentrators

that concentrate sunlight onto distant and centralized towers;

and, (c) parabolic dish concentrators that produce a point focus.

Based on the end application, the different types of solar

concentrators are employed to achieve optimum results. For

example, the parabolic trough concentrators are employed to

produce electricity and heat. However, troughs have a low maximum

solar concentration, high receiver heat loss, and are expensive.

Central receiver-type concentrators are typically employed in

large scale applications for electricity generation and require

vast real-estate for proper deployment and are thus not economical

for small and medium-scale industries. On the other hand,

parabolic dish concentrators are highly efficient in concentrating

the sun's rays. The biggest impediment to parabolic dish

concentrators include, inter alia, the prohibitive costs

associated with compound and complex reflector curves and

expensive mirror substrates.

In a typical solar concentrating system used in furnace

applications, a high energy density solar radiation is provided to

a target receiver, thus raising the temperature of the target.

Depending on the degree of concentration, the optical properties

(solar absorption and radiation) of the target surface, the system

may be utilized to melt a target surface, thus forming a solar

furnace.

Over the years attempts have been made to design and construct

solar concentrators that provide point focus (high solar

concentration) with minimum complexity and cost. United States

Patent No. 5,374,317 (Lamb et al.) discloses a multiple reflector

concentrator solar electric power system. In this system, the

sun's rays first reach a plane of individual primary reflectors

(which may be flat or curved). The primary reflectors then reflect

the solar radiation to the location of secondary reflectors (which

may again be flat or curved) and are then passed through to the

photovoltaic component. The system disclosed by Lamb et al. uses a

large number of components other than primary and secondary

reflectors such as tertiary reflectors, optional cover plates, and

heat dissipation components particularly suited for solar power

generation. This results in a system that is complex and

expensive.

United States Patent No. 6,530,369 (Yogev et al.) also describes a

system comprising two reflectors that are successively arranged

along an optical path of the system so that the first of the two

reflectors reflects the radiation towards the second reflector.

The concentrated radiation from the second reflector is directed

to a solar receiver. However, the second reflector is realized as

a tower reflector. As discussed earlier, central receiver-type

concentrators are typically employed in large scale applications

for electricity generation and require vast real-estate for proper

deployment and are thus not economical for small and medium-scale

industries.

International Patent Publication No. WO 2005/022047 A2 (Shifman)

discloses a solar energy utilization unit comprising a solar

radiation concentrating component and a solar energy receiving

component. The concentrating component comprises a concave primary

reflector and a convex secondary reflector, for concentrating

incident solar radiation and forwarding the concentrated radiation

into the receiving component. However, the reflectors are

dish-shaped and require high precision curved surfaces for

obtaining proper concentration effects.

United States Patent No. 4,784,700 (Stern et al.) describes a

point focus solar concentrator which uses various geometries of

cylindrical reflector strips as primary and secondary reflectors

to simulate a point focus by overlapping the line foci of each

segment at a coincident point. Although, the Stern et al. device

uses cylindrical rather than dish- shaped parabolic mirrors that

are easier to form and polish since they have a simple curvature,

the arrangement of the reflector strips in a Fresnel-type mirror

arrangement requires high manufacturing skills and therefore

increases its cost.

United States Patent No. 3,118,437 (Hunt) discloses a system of

two reflective surfaces or two sets of reflective surfaces facing

each other in an arrangement that causes all rays striking the

first reflective surface to converge onto a substantially one

point or limited area. Although Hunt discusses a system of two

reflective surfaces, wherein the effective axes of curvature of a

second surface or set of surfaces are being normal to the

effective axes of curvature of the first surface or set of

surfaces, the practical embodiments of Hunt's reflective system

are complex and require elaborate infrastructure, such as, for

example, carriages and tracks.

There is accordingly a need for an improved solar concentrating

system that overcomes the limitations associated with using

complex construction requiring high degree of skills. Moreover,

there is a need for an improved solar concentrating system wherein

the prohibitive costs associated with manufacture and deployment

of a traditional solar concentrating system are minimized thereby

making it attractive for use by small and medium scale

energy-intensive industries.

SUMMARY OF THE INVENTION

An object of the present invention is thus to provide an improved

solar concentrating system using a two-stage construction wherein

the rays of the sun are reflected and concentrated to a point

focus. Such a solar concentrator may be used to increase the

temperature of a substance such as metal, for use in a variety of

applications including melting of metals in a foundry furnace.

According to an aspect of the present invention, there is provided

, a solar radiation concentrating system comprising: a first

single-curved reflective surface and a second single- curved

reflective surface, said system including a mounting structure

associated therewith, said mounting structure being so arranged as

to cause variance between said first and second curved reflective

surface, wherein the rays of the sun are reflected from the first

single-curved reflective surface to the second single-curved

reflective surface, and wherein the principal plane of symmetry of

the first reflective surface is arranged substantially orthogonal

to the principal plane of symmetry of the second reflective

surface, thereby concentrating the rays of the sun to a point

focus.

According to another aspect of the present invention, there is

provided, a solar radiation concentrating system comprising: one

or more than one first single-curved reflective surface and one or

more than one second single-curved reflective surface; and a

mounting structure, the mounting structure comprising: a platform;

and a primary and secondary boom mounted to the platform, wherein

the primary boom and the secondary boom are hingedly attached so

as the angle between the first and second boom be varied and,

wherein the principal plane of symmetry of the first reflective

surface is arranged substantially orthogonal to the principal

plane of symmetry of the second reflective surface.

The first single-curved reflective surface has a focal length

greater than that of the second single-curved reflective surface.

In one embodiment of the present invention the first and second

reflective surfaces are parabolic cylinders.

In another embodiment of the present invention, the single-curved

reflective surfaces are mounted on a support frame. The support

frame may be made of wood, steel, aluminum, thermoplastic,

composite materials, bronze alloy, copper based alloy or other

synthetic material.

In a preferred embodiment of the present invention the support

frame comprises means for accommodating the reflecting surface,

means for changing the curvature of the reflective surface, or

both thereof. In still another preferred embodiment of the present

invention the support frame comprises fasteners, stiffeners,

braces, or combinations thereof to maintain the shape of the

reflective surface and for preventing gravitational sag.

In still another preferred embodiment of the present invention the

reflective surface is made from polished stainless steel, mirrored

glass, polyester film (PET) sheets, preferably coated with

aluminum or synthetic material having a suitable refractive index

so that it may be effectively used for the mirror surfaces, or

combinations thereof.

In still another preferred embodiment of the present invention the

mounting structure comprises a support member for each reflective

surface, wherein the support member is provided with tilting means

to adjust its tilt angle. The support member preferably comprises

a sliding mechanism engaged with and movable along the first and

secondary boom.

In still another preferred embodiment of the present invention the

solar radiation concentrating system comprises a tilt angle

adjusting means and a folding and deploying means. Preferably the

tilt angle adjusting means comprises one or more winch &

pulley mechanisms, gear trains, hydraulic cylinders, or

combinations thereof. Preferably, the folding and deploying means

comprises one or more hydraulic cylinders or threaded rods for

effecting movement of the sliding mechanism, folding or deploying

the mounting structure, or combinations thereof.

In still another preferred embodiment of the present invention a

tension wire, chain, or rope and a pulley are used to adjust the

tilt angle of the reflective surfaces in connection with the

support member.

In still another preferred embodiment of the present invention the

solar radiation concentrating system comprises solar tracking

means for tracking the sun and maintaining the focus on a desired

position. The solar tracking means may comprise wedges, hinges,

castors, rails, bearings, foundation mounts, etc. and may be

actuated manually or by electric or hydraulic motors and

associated control devices.

In still another preferred embodiment of the present invention the

mounting structure sits on a trailer for ease of transportation.

The trailer preferably, but not limited to, comprises a trailer

chassis, a plurality of wheel supports attached to the trailer

chassis, a ground engaging wheel rotatably mounted to each of the

wheel supports, and a drawbar attached to the trailer and

projecting outwardly therefrom to a free end carrying a trailer

hitch adapted to be hitched to a tow bar for towing the trailer

chassis behind a vehicle. According to an aspect of the present

invention, there is provided a method for concentrating radiation

to a coincident focus comprising reflecting an incident radiation

off a first single-curved reflective surface onto a second

single-curved reflective surface, wherein the principal plane of

symmetry of the first single-curved reflective surface is arranged

substantially orthogonal to the principal plane of symmetry of the

second single-curved reflective, whereby the second single-curved

reflective surface concentrates the incident radiation to the

focus and wherein the first and second reflective surfaces are

interconnected by a mounting structure the mounting structure

comprising: a platform or base; and a primary boom, or a primary

boom and secondary boom operably associated with the platform,

wherein the primary boom and the secondary boom are adapted for

operable attachment, whereby the angles between the first and

second boom, and base may be selectively varied.

According to another aspect of the present invention there is

provided a method for concentrating radiation to a substantially

rectangular, cross sectional area comprising reflecting an

incident radiation off a first single-curved reflective surface

onto a second single-curved reflective surface, wherein the

principal plane of symmetry of the first single- curved reflective

surface is arranged substantially orthogonal to the principal

plane of symmetry of the second single-curved reflective, whereby

the second single-curved reflective surface concentrates the

incident radiation to the focus and wherein the substantially

rectangular, cross sectional area is defined by a plane orthogonal

to the principal axis of the second single-curved reflective

surface at an intermediate point between a vertex and the focus of

the second reflective surface and wherein the first and second

reflective surfaces are interconnected by a mounting structure the

mounting structure comprising: a platform, or base; and a primary

boom, or a primary boom and secondary boom operably associated

with the platform, wherein the primary boom and the secondary boom

are adapted for operable attachment, whereby the angles between

the first and second boom, and base may be selectively varied.

According to yet another aspect of the present invention there is

provided A method for concentrating radiation to a substantially

rectangular, cross sectional area comprising reflecting an

incident radiation off a first single-curved reflective surface

onto a second single-curved reflective surface, wherein the

principal plane of symmetry of the first single- curved reflective

surface is arranged substantially orthogonal to the principal

plane of symmetry of the second single-curved reflective, whereby

the second single-curved reflective surface concentrates the

incident radiation to the focus and wherein the substantially

rectangular, cross sectional area is defined by a plane orthogonal

to the principal axis of the second single-curved reflective

surface at a point situated after the focus of the second

reflective surface and wherein the first and second reflective

surfaces are interconnected by a mounting structure the mounting

structure comprising: a platform or base; and a primary boom, or a

primary boom and secondary boom operably associated with the

platform, wherein the primary boom and the secondary boom are

adapted for operable attachment, whereby the angles between the

first and second boom, and base may be selectively varied.

According to another aspect of the present invention, there is

provided a method for forming single-curved mirrors from polished

sheets comprising bending the polished sheets into a single-curved

shape and supporting the bent polished sheets in the single-curved

shape by support frames for use in a solar concentrating system.

In other preferred embodiments the reflective surfaces may be

formed into a curve, preferably a parabolic curve, by applying

opposite compression forces at the ends thereof, the compression

forces may be applied by using, for example, tension wires. In

another preferred embodiment the reflective surfaces may be formed

into a curve by means of, for example, curved slots. In still

another preferred embodiment the reflective surface may be formed

into a curve using gravity sag. When silvered mylar is used, the

reflective surface may be formed into a curve, for example, by

slinging the silvered mylar sheet by cords from supports at each

end thereof (catenary method).

According to a further aspect of the present invention, there is

provided a solar concentrating kit comprising at least two

single-curved parabolic mirrors and a corresponding number of

support frames and, optionally, a mounting structure.

BRIEF DESCRIPTION OF THE DRAWINGS

Embodiments of the present invention will be further described

with reference to the accompanying drawings, in which:

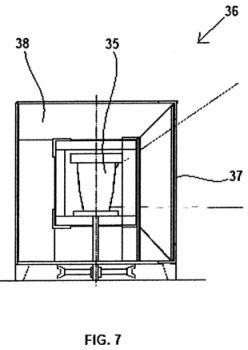

Fig. 1 is a representation

of different types of conventional solar concentrating systems

based on the type of focusing; (a) parabolic trough concentrator;

(b) central receiver concentrator; and (c) parabolic dish

concentrator;

Fig. 2 is a ray diagram

illustrating the principle of a two sheet mirror solar

concentrating system;

Fig. 3 is a schematic

representation of an embodiment of the two-stage solar

concentrating system according to the present invention;

Fig. 4 is a schematic

representation of another embodiment of the two-stage solar

concentrating system according to the present invention.

Fig. 5 is a schematic representation of an example of a

two-stage solar concentrating system according to the present

invention mounted on a trailer;

Fig. 6 is a schematic

representation of an example of a frame support according to the

present invention;

Fig. 7 is a

cross-sectional view of a receiver/target according to the present

invention;

Fig. 8 is a schematic

representation of an example of a two-stage solar concentrating

system according to the present invention mounted on a watercraft;

and

Fig. 9 is a top side elevational view of an exemplary

cigarette lighter using the two- stage solar concentrating system

according to the present invention.

DETAILED DESCRIPTION OF THE INVENTION

Fig. 1 shows three primary types of reflective solar concentrating

systems based on the type of focusing they produce, viz. , (a)

parabolic trough concentrators that produce line focus; (b)

central receiver-type concentrators that concentrate sunlight onto

distant and centralized towers; and, (c) parabolic dish

concentrators that produce a point focus. The underlying principle

of a two-stage solar concentrating system is illustrated in

Fig. 2. A two-stage solar concentrating system comprises two

single-curved mirrors (1, 2) curved in a parabolic shape so that

the rays of the sun are reflected and concentrated to a point

focus at a location (3). The two mirrors have two different focal

lengths. The primary mirror (1) has a long focal length and the

secondary mirror (2) has a short focal length. The rays of the sun

are concentrated to a line focus by the primary mirror (1). The

secondary mirror (2), with its plane of symmetry substantially

orthogonal to that of the primary mirror (1), then intersects and

concentrates the reflection from the primary mirror ( 1 ) so that

the total reflected rays converge to a point focus at the target

location (3). The secondary mirror (2) is located a distance away

from the focal point of the primary mirror (1) that is equal to

focal length of the secondary mirror (2).

Fig. 3 shows an exemplary embodiment of the two-stage solar

concentrating system (100) according to the present invention. A

first sheet mirror and a second sheet mirror are bent/curved into

first and second single-curved parabolic mirrors (10, 20) by a

first support frame (15) and a second support frame (25),

respectively. The support frames (15, 25) are constructed such

that the focal length of the first single-curved parabolic mirror

( 10) is longer than focal length of the second single-curved

parabolic mirror (20). The second single-curved parabolic mirror

(20) is located at a distance equal to its focal length in front

of the point of focus (line focus) of the first single-curved

parabolic mirror (10) so as to maximize the incidence of the

reflected radiation from the first single-curved parabolic mirror

(10). The rays of the sun (shown by dashed lines) are concentrated

to a line focus by the first single- curved parabolic mirror (10).

The second single-curved parabolic mirror (20), with its plane of

symmetry substantially orthogonal to that of the first

single-curved parabolic mirror (10), intersects and concentrates

the reflection from the first single-curved parabolic mirror (10)

to a point focus in the vicinity of a target (35). The first and

second support frame (15, 25) may be mounted on a solar tracking

means, such as heliostats, to maintain orientation with the sun

over time (not shown). In a preferred embodiment the first and

second support frame (15, 25) are made of wood, steel, aluminum,

plastic, composite materials, bronze alloy, copper based alloy, or

combinations thereof. The first and second support frame (15, 25)

may comprise means for accommodating the first and second

single-curved parabolic mirrors (10, 20), means for changing the

curvature of the first and second single-curved parabolic mirrors

(10, 20), or both thereof. In a preferred embodiment the support

frames (15, 25) comprise fasteners, stiffeners, braces, curved

slots, or combinations thereof for controlling the curvature of

the mirrors and for preventing gravitational sag. In still a

preferred embodiment of the two-stage solar concentrating system

according to the present invention the first and second support

frame (15, 25) may be mounted each on primary and secondary booms

(11) and (12), respectively. The primary and secondary boom (11,

12) may be, optionally, mounted to a platform (13). However, the

primary and secondary boom (11, 12) may be supported by any other

supporting structure envisaged by a skilled artisan. The primary

and secondary boom (11, 12) are attached, optionally, by means of

a hinge mount (28) so as the angles between the first and second

boom (11, 12) and the platform (13) be selectively varied so as to

track the rays of the sun and keep the point focus on the target

(35). Any means for manual and/or automatic variance of the angle

between the first and second boom (11, 12) may be used,

optionally, operably connected with sun tracking means and/or

indicia, to cause adjustment of the relative position of the

mirrors with respect to each other and the sun so as to produce a

coincident and/or a square focus according to the present

invention. In the embodiment illustrated in Fig. 3, the first

single-curved parabolic mirror (10) is shown to have its plane of

symmetry substantially parallel to the ground while the second

single-curved parabolic mirror (20) is shown to have its plane of

symmetry substantially orthogonal to the ground. However, any

other orientation of the two mirrors may be employed as long as

the planes of symmetries of the two mirrors are substantially

orthogonal to each other and the second single-curved parabolic

mirror (20) receives and further concentrates the sun rays

reflected from the first single-curved parabolic mirror (10) to a

point focus in the vicinity of the target (35). The size (area) of

the first single-curved parabolic mirror may be chosen in

accordance with the amount of energy needed. The continuous curved

mirror surfaces of the two-stage solar concentrating system

according to the present invention yield a very hot point focus.

For example, a 4ft (width) x 8ft (height) first single-curved

parabolic mirror (10) and an 8ft (width) x 4ft (height) second

single-curved parabolic mirror (20) arranged in accordance with

the present invention, resulted in a 4in x 4in square focus area

providing a concentration ratio of approximately 300:1. The

highest temperature recorded was 542[deg.] C. This temperature was

sufficient to melt Babbitt metal.

In another embodiment of the present invention, a plurality of

first (primary) and second (secondary) single-curved mirrors may

be employed to increase the concentration of solar energy. In an

exemplary embodiment Fig. 3 shows three first (primary)

single-curved mirrors (10) with support frames (15) and one second

(secondary) single-curved mirror (20) with support frame (25).

However, it is to be understood that the number of primary and/or

secondary mirrors may be suitably adapted, by a person skilled in

the field pertaining to the present invention, so as to fit

specific applications of the two-stage solar concentrating system.

However, it is to be understood that the underlying optical

principle of concentrating the sun rays with use of a two-stage

arrangement of mirrors remains the same. For example, a number of

primary mirrors may be arranged to focus through a single

secondary mirror thereby increasing the effective concentration

ratio. The plurality of primary mirrors may be mounted on a

supporting frame and made to track the sun directly as a single

unit in order to cast their combined reflection on a secondary

mirror and then onto a point focus. Alternatively, the secondary

mirror may also be mounted on the supporting frame together with

the primary mirrors. Additionally, different combinations of focal

lengths of the primary and secondary mirrors may also be employed.

The solar collector can be multi-purpose. That is more than one

receiver can me mounted so that the concentrated beam may be

redirected simply by changing the angle of the secondary mirror.

Different receivers can be installed for different purposes, such

as: melting, steam generation, heat extraction, electrical

generation, cooking, or others. Each receiver would have a

standard mount so that they would be modular. Different receivers

may be plugged in to the apparatus thus changing its application.

Furthermore, due to mirror aberration and/or mirror

irregularities, there may be a hot spot near the middle of the

focus area while peripheral areas are cooler. The depth of the

focus field may also be varied with different mirror arrangements.

For example, there may be a warm spot before the focus, a hot spot

in the center of the focus and a relatively cooler spot after the

focus. Thus, the temperature of the target may be controlled by

locating the target slightly off the point focus of the two-stage

solar concentrating system. Multiple mirror systems may spread the

energy to a number of targets within the same apparatus. Tertiary

focusing mirrors may also be employed to increase the focus. An

example of a tertiary focusing mirror is an internally mirrored

cone or a parabolic dish concentrator.

In the example described earlier, polished 20-gauge stainless

steel sheets were used to form the continuously curved cylindrical

parabolic mirrors (10, 20). Other materials such as mirrored

glass, silvered mylar(TM) or polyester film (PET) sheets,

preferably coated with aluminum or synthetic material having a

suitable refractive index so that it may be effectively used for

the mirror surfaces.

The first and second support frame (15, 25) were made from plywood

frame in the experimental example (see Fig.6). However, frames

using aluminum extrusions, wood, steel, plastic, or other suitable

natural and synthetic material may also be used. The mirrors are

held in a cylindrical parabolic shape by inserting the two

opposing edges of the mirror sheets (usually the long sides) into

a curved slot (61) provided in a side panel (63) of the support

frame (15). The support frame may have separate slot holders that

are independent of the support frame for changing the curvature of

the mirror surfaces. Additional braces may be employed for

preventing gravitational sag and to maintain proper cylindrical

parabolic form of the mirrors. The support frame may be made up of

simple beam elements, or may be combined into a truss-like

structure. Fig. 6 shows an example of a support structure (15)

with adjustable focal length made of plywood. The support

structure is made of a back panel (62), side panels (63) and top

and bottom panels (64). The side panels (63) are provided with

separate slotted holders that are independent of the support frame

(15) so as to allow adjustment of the curvature of the reflective

sheet. Other braces may be employed to keep the ruled surface

elements straight to prevent gravitational sag and maintain the

cylindrical form of the reflective sheet. For example, diagonal

braces (65) are provided on the back panel for support. In

addition, hinges (66) may be provided to allow relocation of the

reflective sheet. It is to be noted that the main consideration in

the construction of the support frame is that it should be strong

enough to support the weight of the mirrors as well as possible

wind loads to maintain the desired alignment.

Fig. 4 shows an exemplary embodiment of a truss-like structure,

wherein a plurality of first single-curved mirrors (10) and a

second single-curved mirror (20) are mounted on a ring base (16).

As shown in Fig. 4 the truss-like structure may comprise means for

adjusting the relative position of the single-curved mirrors (10,

20) as well as means for retaining the mirrors in the desired

position. Other embodiments may be envisaged featuring, inter

alia, high hinge mount and balance beam boom connecting primary

and secondary mirrors. The two-stage solar concentration system

according to the present invention may further comprise solar

tracking means to adjust the orientation of the system to

correspond with local height and direction of sun at a particular

time. The tracking means may comprise wedges, hinges, castors,

rails, bearings, foundation mounts, etc. and may be actuated

manually or by electric or hydraulic apparatus and associated

control devices. Another embodiment of the two-stage solar

concentrating system according to the present invention mounted on

a trailer (75) is illustrated in Fig. 5. The trailer (75) may be

fitted with a pivot (30) and adjustable castors (29) and wheels

(85) so that it may rotate sideways to track the sun through the

day. Variance of the angles between the first boom (11) and the

second boom (12) and between the booms (11, 12) and platform/base

(14) as well as the pan and tilt angles of mirrors may be achieved

by a combination of winch and pulley mechanism (31 ) operably

interconnected to the frame support (15,20) and the booms (11, 12)

and the platform/base (14) by a tension wire, chain, or rope (95).

The position of the first and second support frame (15, 20) may be

adjusted along the boom (11, 12) by use of a sliding mechanism

engaged with and slidable along the first and second boom (11,

12). In an exemplary embodiment the sliding mechanism employs a

sliding carriage (23). In a similar manner the relative position

of the receiver (36) containing the target (35), in respect of the

first and second single-curved mirror (10, 20), may also be

adjusted by use of a sliding mechanism or any other adjusting

means known to a skilled artisan in the art pertaining to the

present invention.

The tilt angle of mirrors may be adjusted through the day to

provide desired focus arrangement. The individual elements of the

two-stage solar concentrating system may be folded, stacked and

packaged for transportation and erected in kit form for

application in many different locations. The trailer mounted units

may be towed to remote locations, unfolded and put into use.

An exemplary embodiment of a receiver (36) containing a melting

pot or target (35) is shown in Fig. 7. The exemplary receiver (36)

shown in Fig. 7 is shaped like a cube with one vertical side (37)

being made from a transparent material such as, for example, SiO2

or acrylic glass. The receiver (36) may have an insulation (38)

purposed to minimize thermal exchange between the target and the

environment. Any known insulation material may be used provided

that the various technical aspects known to person skilled in the

art such as the suitable thickness, reaction to high temperature,

means for attaching the insulation material to the wall of the

receiver, etc. are selected according to the design and purpose of

the specific application of the solar concentrating system of the

present invention. Different receiver and target designs should be

applied for melting solids, boiling liquids, or for electrical

production. Some targets may be vertical while others, horizontal

as the top of a pot. Receivers may or may not: be insulated, have

covers, be dish shaped, be movable or fixed and have valves for

control.

Although the solar concentrating system described herein has been

employed for concentrating solar energy for foundry applications,

the system may be employed for several other applications. The

applications of the two-sheet (cylindrical parabolic) mirror

focusing system are many and varied for wherever and whatever heat

energy is required. For example, the solar concentrating system

may be employed for providing thermal energy to space heating,

industrial processes, high temperature reduction of hazardous

wastes, metal extrusion forming, roll forming, surface treatment,

welding, fusing, annealing, or heat treatment of metals, and in

petrochemical industries. Applications may include thermal

industrial processes such as metal melting in foundry work for

metal casting, melting scrap for recycling or reduction of ores in

metal production. Units may be developed that serve the purpose of

metal welding, brazing or soldering. It is envisioned that the

solar concentrating system according to the present system may be

useful for processing oil sands and shale into usable oil products

with minimum emission of greenhouse gasses. It may be useful for

production of synthetic fuels using solar photochemical and/or

solar thermo-chemical processes and may include Hydrogen

production. The two-sheet (cylindrical parabolic) mirror focusing

system may be used for electrical production through a steam cycle

generating system, Sterling heat engine or, photovoltaic electric

generation systems. The two-sheet focusing system may be used for

space heating, domestically (home heating), institutional or

public space heating, whether the heat energy may be used right

away or stored in a thermal storage device for later use and/or

with heating ducts or thermal conduits to distribute the thermal

energy across a distance to other locations. The two-sheet

focusing system may be used for food processing, such as cooking

or drying. Barbecue sized units could be developed for backyard

applications on sunny days. The system may also be used in

cremation facilities. The two-sheet focus might be taught to

woodsmen or boy-scouts as a way to start a campfire. Small

hand-held units might be developed to provide a sort of novelty

cigarette lighter. For purposes of exemplification two

applications of the two-stage solar concentrating system are

illustrated in Figs. 8 and 9 and should not be construed as

restrictive in any way. Fig. 8 shows an exemplary application of

the two-stage solar concentrating system mounted on a barge to

allow tracking the sun through the day and concentrating the solar

radiation to a target area (35). A primary single-curved mirror

(10) is mounted on the barge (80) through legs (81). A secondary

single-curved mirror (20) is operably connected to the first

single- curved mirror (10) by one or more struts (82). The struts

may be attached directly to the barge and/or to the primary

mirror, preferably by means of a hinge mount (28). The struts are

provided at each end thereof with means to allow tilting and

movement of the mirrors. Preferably, but not limited to, the

mirrors are hingedly attached to the struts. In addition, means

for adjusting the relative position of the struts with respect to

the barge may be provided. Preferably, a sliding mechanism (83)

may be provided to allow horizontal movement of the struts with

respect to the barge. Solar tracking means may also be employed.

The position adjusting means and/or the solar tracking means may

comprise wedges, hinges, castors, rails, bearings, foundation

mounts, etc. and may be actuated manually or by electric or

hydraulic apparatus and associated control devices.

Fig. 9 shows another exemplary application of the two-stage solar

concentrating system. In particular, Fig.9 shows a cigarette

lighter (90) constructed according to the two- stage solar

concentrating system disclosed herein. The cigarette lighter (90)

may have a pedestal (91) as a base for a pillar (92). The pillar

(92) may be provided with a U-shaped structure (93) having

attached at the two ends thereof a horizontal arm (94) to which at

least one primary mirror and at least one secondary mirror may be

mounted in accordance with the present invention. The cigarette

lighter as described above may further comprise means for

adjusting the relative position of the single-curved mirrors (10,

20) as well as means for retaining the mirrors into a desired

position with a view to capturing solar radiation and

concentrating the radiation to an area so as to cause ignition.

Various modifications to the disclosed embodiments will be readily

apparent to those skilled in the art or science, and the general

principles defined herein may be applied to other embodiments and

applications without departing from the spirit and scope of the

invention. Thus, the present invention is not intended to be

limited to the embodiments disclosed, but is to be accorded the

widest scope consistent with the principles and features disclosed

herein. Accordingly, the principle of concentration and collection

of solar energy remain the same, only that is suitably chosen in

accordance with the end application.

The aforesaid description and drawings presented herein teach in

considerable detail workable embodiments within the broad concept

of the present invention. However, it is particularly noted that

the inventor has as a result of his experimental activity, testing

and further general development, arrived at possible additional

and alternative working structures, the specific operational

details will be readily discernible by a man skilled in the art.

Accordingly, the embodiments listed on the following 25 sheets of

drawings which include written footnotes to the drawings

identifying the subject matter thereof are presented as

alternative embodiments which are inextricably bound up in one and

the same inventive concept as the embodiments previously taught

herein.

INDUSTRIAL APPLICABILITY

INDUSTRIAL APPLICABILITY

The invention provides a solar concentrating system wherein the

rays of sun may be reflected and concentrated to a desired focus.

The solar concentrator may be used to increase the temperature of

substance such as, for example, metal, for use in a variety of

application including, e.g., melting of metals.

rexresearch.com

rexresearch.com