rexresearch.com

Gertjan MEEUWS, et al.

LED Vertical Farming

LED Vertical Farming

http://www.plantlab.com

http://www.greenprophet.com/2012/02/pink-leds-grow-future-food-with-90-less-water/

Pink LEDs Grow Future Food with 90% Less Water

10,000 years after inventing agriculture, will we 7 billion take this strange next step?

A Netherlands-based company called PlantLab has devised a method for growing plants indoors using an unearthly pink-purple light made by a combination of red and blue LED lights, instead of sunlight.

Significantly, for a sustainable future anywhere on a planet with 7 billion already – and 9 billion by century’s end – this means we could grow crops with 90 percent less water. Agriculture uses most of the water around the world.

Nowhere is this need for managing on less water more crucial than in the countries of the Middle East and Africa – from Saudi Arabia and Israel, to Yemen and the Sudan – that face the threat of real water scarcity already.

PlantLab has invented a way to grow plants under LED lights indoors, with all the water recycled within the indoor environment for reuse. Plants, it turns out, are not that dependent on using the sun for photosynthesis. And they certainly don’t mind being separated from their pests. And they are fine with 90 percent less water, if they get it over and over again.

Importantly, in an age of peak oil, PlantLab has also found a way to grow crops that eliminates the two ways that food is dependent on oil.

They have engineered the crops to be able to be grown using fewer fertilizers – which are made from oil.

The second huge use of oil is in transporting food. But because this indoor habitat can be replicated anywhere in the world, regardless of climate or season – food would no longer rack up unsustainable carbon miles on the way to your table.

Because these eerie new farms can be many stories high, crops can be grown within cities, leaving the most possible land to work naturally as nature’s utility, cleaning the air we breathe and the water we drink, instead of being used for agribusiness that pollutes our rivers with fertilizer runoff from agribusiness.

And, being indoors, away from their pests, there is no need for pesticides. You can imagine how that might ultimately begin to affect their evolution, if we change farming so much that we have have generations of plants grown separated from their natural pests in the open. We live in interesting times.

But PlantLab believes we must rethink food production to survive.

“In order to keep a planet that’s worth living on, we have to change our methods,” says PlantLab’s Gertjan Meeuws in an interview with the Associated Press.

The methods PlantLab is suggesting are revolutionary. The company grows plants indoors, vertically stacking acres upon acres of plants. They use LED lamps to grow the plants and water them with a slow trickle that drains through the soil and is collected and reused. The neon pink light of the lamps make the space look more like a nightclub than an indoor farm.

Computers capture over 160,000 reports per second to determine the exact amount, cycle, and color spectrum of light that’s optimal for the plant, as well as water, so that no resource is wasted and the plant is neither undernourished nor overexposed.

Plants convert light from the sun into energy through the process of photosynthesis, but plants only need some parts of the sun’s color spectrum. Blue and red LEDs can provide just the light a plant needs, making the process more efficient and growing a stronger, healthier plant.

LEDs and climate-controlled indoor farms not only use less energy, less water, and less space than traditional agriculture; they also reduce the unpredictability of our food supply. Indoor farms aren’t at the mercy of droughts, torrential rains, unexpected frosts, and pests. They reduce the danger of food shortages and waste.

Apples from Chile, asparagus from Peru -- an average of six to 12 percent of every dollar we spend on food goes to transportation costs.

Traditionally, most agriculture has been limited to large swaths of land with rich soil, controllable pests, and a predictable climate, but even under optimum conditions traditional methods of agriculture drain our water supply, require intensive resources, and produce a crop dependent on an undependable climate.

Until now, vertical greenhouses like AeroFarms Vertical Farming have seemed a little impractical, because our one and only real sun really needs to reach deep into each floor to ripen food crops, but this unearthly pink agriculture would solve that.

But are we ready for such a drastic step?

http://www.independent.co.uk/news/science/shoots-in-the-dark-farming-without-sunlight-2360833.html

The Independent, September 26 2011

Shoots in the dark: Farming without sunlight

It's

more efficient, reduces transport costs and won't fail because

of the weather. Is farming without sunlight the future of

food?

by

Hal Hodson

Hal Hodson

Sunlight. It is the foundation of life on Earth, the daily pacemaker of human existence and, with the exception of geothermal, the basis for all energy consumed on our little marble. Without it, Earth would be cold, dark, and unrecognisable.

Light's contribution to food is particularly important. Crop plants use it to convert carbon dioxide and water into sugars and oxygen, for eating and breathing respectively. It's our most precious chemical reaction but, as global population diverges from the planet's ability to feed it, one group of Dutch scientists thinks we need a new approach. This approach isn't to meddle with genes, or to plug extra fertiliser into nitrate-soaked soils. The Dutch group, called PlantLab, have scrapped sunlight altogether.

"The plants look black," says Gertjan Meeuws, one of the five-strong team. That's not because they're rotten or genetically engineered, it's because they are bathed solely in blue and red light – there is no green light in the PlantLab hanger for the plants to reflect.

The hanger looks like something a character in Blade Runner might have dreamt about. Huge sliding trays of leafy greens (blacks), are tended by an army of robotic arms, and given, according to Meeuws, precisely what they need to thrive. He and his team have been studying plants since 1989, working to better understand their needs and to make the growing process more efficient. They are scientists and engineers, not just businessmen.

"Growing in an open field or greenhouse is not enabling plants to maximise their potential," Meeuws says. "You have to look at our system as taking two steps at once. Firstly, we grow plants in totally controlled conditions – plant paradise as we call it. The second step is placing these nurseries right at the end of the supply chain, to produce around the corner from the consumer."

PlantLabs's controlled conditions are underpinned by some interesting physics. Plants are green because they reflect green light, meaning those specific wavelengths are not involved in the process of photosynthesis. If you tried to grow a tomato plant under a green light, it would die. In the process of reflection, the plant heats up. Like humans, plants have a mechanism for cooling down, but it costs energy which the plant would otherwise use to grow.

"Plants have a very intelligent way of cooling themselves," Meeuws explains. "They take up water through their roots and evaporate it through their leaves. Energy is needed for evaporation, and this energy is taken from the leaves, cooling the plant."

By giving the plants only blue and red light, PlantLab can avoid heating its plants up unnecessarily, leaving more energy for growth. The atmosphere in the underground hanger is completely controlled for the same reason – to give plants the ideal conditions for growth, rarely found in the real world.

Although there are technical kinks behind farming in the dark, the potential benefits are broad: more nutritious produce, eradicated air-miles, year- round access to fresh vegetables, in any environment on earth. "We have been talking to people in winter sport areas. In the seasons where those areas have the most guests, they have no real fresh salads. It's a very interesting idea to serve really fresh, just-picked salads right where the consumers are," Meeuws says.

Human convenience factors are important, but not fundamental. Water is fundamental, and it's one resource that PlantLab's vertical farm does a very good job of conserving. Meeuws says that PlantLab's system uses 90 per cent less water than conventional open-field growing. The only water which ever leaves the facility is in the form of plant matter for human consumption. The rest – run off and evaporation – is collected and fed back into the system.

"Water savings are probably the most important part of our work," Meeuws says. "Water will be more important in the future than energy."

Another benefit of growing indoors is the flexibility it allows for the grower. Dixon Despommier, a microbiologist from Columbia University and the blue-sky thinker behind the vertical farm, puts it: "Let's say you have a breakdown in your growing system. When is the next opportunity for an outdoor farmer? Next year. The opportunity for an indoor farmer is tomorrow."

This agility is down to the increased number of available growing hours for the indoor farmer. Meeuws gives a rough calculation: "In our climate, there are maybe 1,000 or 1,500 growing hours a year. When you go to the equator, they have a lot of sunlight, but it's so hot that the plants can't breathe properly. In our system we can give light to plants 24 hours a day, but it's usually 20 hours, to let them sleep."

Twenty hours a day, every day of the year amounts to 7,300 hours of growing time, a five-fold improvement over relying on natural light. Vertical farming comes with the bonus of easing the strain on diminishing agricultural real estate, perhaps even allowing for "re-wilding" of swathes of land previously dedicated to cucumbers.

But, as Kevin Frediani, puts it, "we're not there yet". Frediani is the man behind VertiCrop, a vertical farming experiment adjoined to Paignton Zoo in Devon, where he is the curator of plants and gardens. His project, which has run for three years, backs up PlantLab's numbers for water savings, which Frediani says can be pushed as low as 4-6 per cent of conventional use.

Energy use is usually the number one concern among vertical farming naysayers. Everyone knows the story of the tomatoes, grown in British greenhouses and polythene tunnels, which, due to the cost of heating, actually have a larger carbon footprint than those shipped more than a thousand miles from Spain. Similar concerns surround the idea of artificially lighting and heating acres of underground crops.

The financial and energetic costs are big, but new technologies can help. By growing the plants in an insulated environment, temperature is easier and cheaper to control; polythene tunnels and glasshouses are rubbish at keeping heat in or cold out.

A new generation of lightbulbs are answering the lighting question too. Humanity has been stuck on the glowing strip of metal passing an electric current since Edison made the idea a commercial reality in 1879. New light sources – LEDs, high-pressure sodium lamps and fluorescent bulbs – cost less to run, and in the case of LEDs can deliver the exact colour of light which PlantLab requires.

Technology aside, there is the issue of public perception. Another step "away from nature", further removing ourselves from our hunter-gatherer ancestors, might not be popular with some sectors of the green contingent, but Meeuws has an answer for this too. "We have to let technology come into our lives where it concerns food production. A cell phone is normal, intensive care in hospitals is normal, and accordingly technology will be normal in order to save our world by producing food in a smart way."

Frediani's VertiCrop is one of the best examples of that "smart way". If you head to dinosaur country, south-west England, you'll find Frediani tucked away in the centre of Paignton Zoo, surrounded by the whirring and dripping of the UK's first attempt at growing vertical crops.

Made from re-purposed manufacturing line equipment which was designed for making JCB engines, Frediani's farm consists of multiple stacks of shelves which rotate around the room, sharing the sun. While the system uses natural light rather than LEDs, Frediani says it has shown that vertical farming is viable.

"As a pilot project, what it's demonstrated is that food can be grown in urban areas that are higher density, and at a lower embedded energy than we currently do growing it far away from cities. If you can put your food supply into your packing house and put your packing house into your distribution centre, and pack all that into the building people are living in, there's got to be an advantage in that," he says.

He compares Paignton's VertiCrop pilot to the earliest cars: "You wouldn't want to drive at 4mph behind a man holding a red flag, but you might drive a new Mercedes on modern highways – and it's the same with this technology."

For the moment, he also has his doubts about LED-only growing. He points to a beautiful crisp lettuce as it trundles by on its carousel. "That red tinge only comes when you grow lettuce under the full spectrum of natural light," he says. He adds that light from current LEDs peters out after about 30cm, severely limiting what can be done in an all-LED set-up.

But technology and knowledge tend to improve, and one day we may know the exact absorption spectrum for each and every crop we grow. Within five years, Frediani sees LEDs becoming good enough and cheap enough to provide plants with all the light they need. His set-up is pretty good right now, even if not on a commercial scale. "Try a bit of rocket," he suggests. I nip a leaf off with my thumbnail and bite. It's hot and crisp, perfect. My mouth tingles, and we eat some more.

US2011252705

System and method for growing a plant in an at least partly conditioned environment

System and method for growing a plant in an at least partly conditioned environment

Also published as: WO2010044662 // NL2002091 // MX2011003918 // KR20110094280

The present invention relates to a system for growing a plant in an at least partly conditioned environment, comprising a cultivation base for receiving a culture substrate with a root system of the plant therein, root temperature control means which are able and adapted to impose a predetermined root temperature on the root system, and comprising lighting means which are able and adapted to expose leaves of the plant to actinic artificial light. The invention moreover relates to a method for growing a plant in at least partly conditioned manner, wherein actinic light is supplied to the plant and wherein a root temperature of a root system of the plant is maintained at a desired value.

Such a system and such a method are applied on a significant scale in the glass horticulture in greenhouses. An artificial climate is created here in an at least substantially closed and conditioned environment behind glass, and is adapted as far as possible to the optimal growth conditions of the plant for cultivating. It is hereby possible to grow plants in areas and seasons in which the plant would not survive outdoors, or would at least not reach full development. Furthermore, the production of the plant can thus be precisely adapted to a desired harvesting time. It is thus possible to estimate relatively precisely beforehand how much of which plant will be ready, and when. If desired, the same product can moreover be grown throughout the year and plants and flowers at all stages of life can be cultivated.

In traditional glass horticulture sunlight is applied as the main source of actinic light, i.e. optionally visible light of a wavelength such that a plant response is thereby initiated or influenced, such as a photosynthesis in the leaf or a determined mode of growth. Sunlight moreover provides heat in the form of infrared radiation, whereby an increased air temperature can be maintained in greenhouses relative to an outside temperature. In the absence of sunlight, such as particularly at night, heating is possible in order to maintain such an increased air temperature, while excessive entry of sunlight can be prevented during the day by means of partial blinding and filtering, and the climate can also be regulated by means of ventilation. All in all, a climate in a greenhouse can thus be controlled within certain limits and can be adapted to a desired growth development of a plant for cultivation, which is further controlled by means of a controlled dosage of moisture and nutrients, in addition to pesticides. An additional component here is the root temperature. It has been found that the growth of the plant can be influenced by control of the root temperature. With a view hereto, root temperature control means can be provided in order to maintain a root temperature varying from the air temperature.

Classic glass horticulture does however also have drawbacks. Firstly, the environment must be particularly taken into account here. It costs energy to keep a greenhouse warm and, for some plants, lighted day and night. It is therefore important to regulate the energy management as efficiently as possible. Where greenhouses are built in or close to densely populated areas, the aspect of space is moreover an important factor. Traditional greenhouses do after all require entry of sunlight and take up a relatively large amount of expensive land area in these areas, which could otherwise be employed for offices, house-building or infrastructure. In order to address this problem, low-daylight, in particular underground, daylight-free and multi-layer solutions are being sought in order to enable multiple use of the same land area.

Because not only heat but also actinic light will in such a case be supplied artificially, the energy management is even more of a problem, and there is therefore a need for a cultivation of plants which is as efficient as possible.

The present invention has for its object, among others, to provide a system and method for growing a plant in an at least partly conditioned environment which enable a further improvement in efficiency.

In order to achieve the stated object, a system of the type described in the preamble has the feature according to the invention that leaf heating means are provided, which are able and adapted to impose on the leaf of the plant a leaf temperature varying from an ambient temperature. The system according to the invention thus provides the option of a controlled evaporation and carbon dioxide assimilation via the leaf by regulating a correct amount of energy on the leaf, in addition to a controlled lighting, both in respect of the amount of light and in respect of spectral ratios, with a view to plant growth reactions, such as blue/red and red/far-red ratios, and in respect of light spectra necessary for specific reactions such as pigment formation, and in addition to a control and optimization of the root pressure activity. This all takes place in an at least partly conditioned environment in which the climate can be controlled within narrow limits in respect of, among other factors, an air humidity balance, a room temperature and a carbon dioxide concentration as well as water and nutrition for the plant.

The invention is based here on the insight that three factors are essentially responsible for a successful plant development, i.e. the photosynthesis, the sap flow in the plant pushed upwards under the influence of a prevailing root pressure, and the carbon dioxide assimilation through mainly the leaf system of the plant, and that these three factors must at all times be adapted to each other in order to actually realize an optimal plant growth. In addition to the root temperature and the entry of actinic light, a carbon dioxide assimilation management of the plant can also be controlled by providing the leaf heating means in the system according to the invention. Due to additional heating the stomata in the leaf will open further, so enhancing entry of carbon dioxide to the leaf and evaporation of moisture from the leaf. This latter is particularly important if a sap flow in the plant is stimulated by an increased root temperature, as this flow will have to exit via the same stomata. Conversely, the leaf temperature can be decreased at a lower sap flow in order to prevent undesired plant dessication. All in all, the most important climate parameters responsible for the development of the plant can thus be controlled so that an optimal efficiency can be realized in each of these components with a minimal energy consumption.

A particular embodiment of the system has the feature according to the invention that the lighting means are able and adapted to emit a lighting spectrum which can be adapted to an intended photosynthesis and/or mode of growth of the plant to be cultivated. The actinic light components necessary for the development of the plant can thus be supplied only in precisely sufficient intensity, while non-actinic components or an excess can be avoided as far as possible in order to limit the overall energy consumption of the system and/or possible harmful effect on the plant development.

In a further particular embodiment the system according to the invention is characterized here in that the lighting means comprise a set of light-emitting diodes, these diodes being able and adapted to emit radiation at different wavelengths and being individually controllable, optionally in groups. Such so-called LED elements produce substantially monochromatic light and are obtainable for different wavelengths, particularly in the far-red, yellow, green and blue visible part of the spectrum. A photosynthetically active (PAR) spectrum which best suits the concrete needs of the plant can thus be constructed, and optionally modified, by combination and selection of individual LEDs.

The leaf heating means can be formed per se in various ways, although in a preferred embodiment the system according to the invention is characterized in that the leaf heating means comprise at least one heat source able and adapted to irradiate the leaf with infrared radiation. Other than heating means which, wholly or partially through guiding of an intervening medium, are capable of heat-exchanging contact with the leaf, such a heat source enters into heat-exchanging contact mainly through direct irradiation. Not only does this result in a highly effective and efficient heating of the leaf system, the intended temperature difference with the environment contributing toward a desired widening of the stomata is hereby also achieved in particularly effective manner. In a further preferred embodiment the system according to the invention is characterized here in that the lighting means and the heat source are accommodated in mutually separated fittings in order to thus exclude a possibly disruptive influence of an inevitable heat dissipation in the heat source itself from the conditioning sphere of the actinic light source. Although the root temperature control means per se can also be realized in diverse ways, a preferred embodiment of the system according to the invention has the feature that the root temperature control means comprise a closed conduit system for receiving therein during operation a liquid flow with a controlled temperature, wherein the conduit system is able and adapted to enter into heat-exchanging contact with the culture substrate. Such a conduit system can for instance be formed by a system of tubes or fins in or under the culture substrate, in which a liquid flow meanders altematingly. The root temperature can be uniformly controlled by thus heating or cooling the culture substrate in which the root system is received. A further embodiment of the system according to the invention has the feature here that a control is provided between the leaf heating means and root temperature control means which imposes a mutual dependence on the leaf temperature and the root temperature. In for instance a normal growth trajectory the leaf temperature will thus follow, optionally in directly proportional manner, a change in root temperature so that the assimilation management keeps pace with a variation in the root pressure.

In order to achieve the stated object, a method of the type described in the preamble has the feature according to the invention that a carbon dioxide assimilation management of a leaf system of the plant is also influenced, and that a supply of actinic light, the root temperature and the carbon dioxide assimilation management are adapted to each other. This method is in line with the above described insight that the root temperature, the supplied light spectrum and the carbon dioxide assimilation management of the leaf are not separate entities but will only arrive at the optimal result in mutual relation. The method according to the invention provides the option of arranging this mutual relation in the form of for instance a plant-dependent and/or growth phase-dependent modification of these growth factors.

In a particular embodiment the method according to the invention is characterized in that the carbon dioxide assimilation management is influenced by regulating a leaf temperature of the leaf system so that it differs from an ambient temperature. The above described system according to the invention is highly suitable for an implementation of this method in that the leaf temperature can hereby be regulated so that, if desired, it differs from the environment, in addition to a control of the other stated growth factors. In a further particular embodiment the method according to the invention is characterized here in that the supply of light, the root temperature and the leaf temperature are adapted to each other depending on the plant.

For the purpose of an optimal photosynthesis and mode of growth of the plant, a further particular embodiment of the method according to the invention has the feature that actinic artificial light is supplied with a spectrum adapted to an intended photosynthesis and/or mode of growth of the plant. By thus specifically adapting the mutual ratio and intensity of the various light components which play a part in the photosynthesis and growth development of the plant, a high yield can nevertheless be realized at a relatively low total light intensity and energy consumption. Within the context of the present invention a further particular embodiment of the method according to the invention has the feature here that the artificial light spectrum, a leaf temperature of the leaf and the root temperature are controlled individually of each other but in mutual relation, depending on the plant.

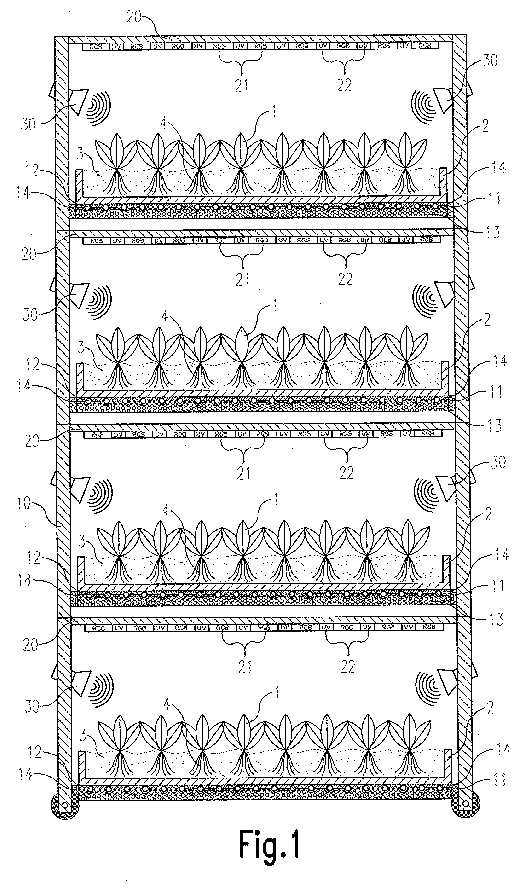

The invention will now be further elucidated on the basis of an exemplary embodiment and an accompanying drawing. In the drawing: figure 1 shows a cross-sectional partial view of a device in an exemplary embodiment of a system according to the invention.

The figure is otherwise purely schematic and not drawn to scale. Some dimensions in particular may be exaggerated to greater or lesser extent for the sake of

clarity. Corresponding parts are designated as far as possible in the figure with the same reference numeral.

The system shown in figure 1 makes use of a multi-layer cultivation of plant 1 so as to enable the best possible use of an available surface area. The plant is accommodated here in culture trays 2 with a suitable culture substrate 3 therein, such as earth, glass wool, rockwool or simply water, for the purpose of receiving a root system 4 of the plant therein. Culture trays 2 are placed one above the other on beams 11 of a frame 10 constructed almost entirely from stainless steel. Any desired number of such carriages 10 can thus be combined to form a complete cultivation system in a conditioned environment, wherein the plant is brought to full development in fully controlled manner. Irrigation and fertilizing provisions (not further shown) are arranged at or in carriages 10 in order to provide the plant with sufficient water and the necessary nutrients.

Beams 11 of the carriages each comprise a closed conduit system 12 of a hose or tube which meanders at a regular pitch. In this respect a system of successive hollow fins can optionally also be applied as conduit system. This conduit system 12, through which a heat-carrying medium such as water of a controlled temperature can be guided in order to control a temperature of the root system, forms part of root temperature control means. The heated medium relinquishes heat during operation to for instance the beams, which in turn conduct the heat via the culture trays to the culture substrate with the root system of the plant therein. Conversely, heat can also be extracted from the root bed by means of a cooled heat-carrying medium. The root system is thus kept more or less precisely at a desired root temperature during operation according to the method described here. In order to give this heat transport a more specific control, and thereby a more efficient heat-exchanging capacity, the beams take a multi-layer form with an insulating base 13 of foamed plastic such as polyurethane foam or polystyrene foam, with a reflective top layer 14, for instance a reflective metal coating or an additional intermediate layer provided with such a coating, followed by conduit system 12 and thereon a metal plate 15, for instance of stainless steel, having good thermal conductivity.

Each layer of cultivation system 10 is provided with an artificial light source 20 in the form of a light fitting having therein groups 21 of light-emitting diodes (LEDs), in addition to possible other light sources 22 such as ultraviolet or infrared radiators. The LED diodes in the first groups emit light at least mainly in the visible part of the spectrum, in particular red, yellow, green or blue light, while the second groups 22 add invisible components such as infrared light and near-ultraviolet light thereto. Light fittings 20 are provided with a control (not further shown) with which the different groups and the elements within the groups can be controlled selectively and individually in order during operation to then adapt a specific spectral composition of the emitted light to the requirements and type of the plant 1 being cultivated. Because the beams are optically separated from each other to a significant extent, a different spectrum can if desired thus be supplied per beam in order to thus cultivate different plants in combination with each other and provide each with an optimal spectrum. The system is highly suitable here for application in a low-daylight or even daylight- free environment, such as for instance in an underground situation.

Further provided in the cultivation system are leaf heating means 30 in the form of infrared radiators which are disposed in layers on either side on the shelves of the carriages. The infrared radiators emit direct heat radiation in the direction of the leaf of the plant and thus, if desired, increase a leaf temperature of the leaf relative to the ambient temperature. The carbon dioxide assimilation management of the leaf can thus be controlled to a significant degree and particularly be adapted to the root pressure of the sap flow in the plant which is produced by root system 4. This because heating of the leaf results in a widening of the stomata in the leaf, whereby they will be better able to relieve surplus root pressure by allowing water to evaporate, while a sufficient carbon dioxide assimilation required for the photosynthesis, which is in turn activated and controlled using the lighting means, nevertheless continues via these same stomata. If on the other hand cuttings of the plant are taken, the leaf system is however not heated, or at least heated less, at an increased root simulation so as to thus limit evaporation and ensure an excess of moisture on the cutting surface. All in all, the main growth factors, i.e. the photosynthesis, the root pressure and the carbon dioxide assimilation, can thus be regulated individually in the system according to the invention, and these factors are precisely adapted in mutual relation at each stage of growth and for each plant in order to enhance optimum growth and mode of growth.

Although the invention has been further elucidated above on the basis of only a single exemplary embodiment, it will be apparent that the invention is by no means limited thereto. On the contrary, many other variations and embodiments are possible without requiring a skilled person to depart from the scope of the invention in a manner which is less obvious. The root temperature control means can thus also comprise a conduit system directly in the culture substrate which is in more or less direct heat-exchanging contact with the root system. In the case of cultivation on water or a watery substrate, such as glass wool or rockwool, the root temperature can also be controlled by a controlled control of the temperature of the water supplied thereto.

Use is made in the example of artificial light by means of light-emitting diodes (LEDs), although within the scope of the invention conventional incandescent growing lamps are also suitable instead, and the invention can also be applied in full or partial daylight.

Use is made in the given example of multi-layer cultivation on mobile carriages, although cultivation in a single layer and/or cultivation in a fixed arrangement can also be envisaged within the scope of the invention.

Within the scope of the invention the carbon dioxide assimilation and moisture evaporation via the leaf system can be controlled and adapted to particularly the root pressure. Instead of by means of direct infrared lamps, this can also be achieved by means of spiral filaments, heat panels or the like disposed close to the leaf system. If desired, the leaf heating means, such as the infrared radiators in the example, can further be integrated in the same fitting as the artificial lighting means, for instance for the purpose of saving space and/or ease of installation.

What is really important in the invention is that the growth development of the plant is determined by the weakest link in a chain of the most important growth factors, i.e. photosynthesis, root pressure and carbon dioxide assimilation, and that all these factors are controlled in mutual relation according to the invention and, if desired, are artificially modified in order to realize an optimal chain.