Hokei MINATO

Magnet Motor

John Dodd: "The Techno Maestro's Amazing

Machine" (Japan, Inc., March 2004)

Kohei Minato: US Patent # 4,751,486

K. Minato: US Patent # 5,594,289

Henry Curtis: KeelyNet BBS Posts

Michael Randall Emails

Padrak: INE Press Release

Photos

The Techno Maestro's

Amazing Machine

Kohei Minato and the Japan Magnetic Fan Company

A maverick inventor's breakthrough electric motor uses

permanent magnets to make power -- and has investors

salivating

by John Dodd

When we first got the call from an excited colleague

that he'd just seen the most amazing invention -- a magnetic motor

that consumed almost no electricity -- we were so skeptical that

we declined an invitation to go see it. If the technology was so

good, we thought, how come they didn't have any customers yet?

We forgot about the invitation and the company until several

months later, when our friend called again.

"OK," he said. "They've just sold 40,000 units to a major

convenience store chain. Now will you see it?"

In Japan, no one pays for 40,000 convenience store cooling fans

without being reasonably sure that they are going to work.

The Maestro ~

The streets of east Shinjuku are littered with the tailings of

the many small factories and workshops still located there --

hardly one's image of the headquarters of a world-class

technology company. But this is where we are first greeted

outside Kohei Minato's workshop by Nobue Minato, the wife of the

inventor and co-director of the family firm.

The workshop itself is like a Hollywood set of an inventor's

garage. Electrical machines, wires, measuring instruments and

batteries are strewn everywhere. Along the diagram-covered walls

are drill presses, racks of spare coils, Perspex plating and

other paraphernalia. And seated in the back, head bowed in

thought, is the 58-year-old techno maestro himself.

Minato is no newcomer to the limelight. In fact, he has been an

entertainer for most of his life, making music and producing his

daughter's singing career in the US. He posseses an oversized

presence, with a booming voice and a long ponytail. In short,

you can easily imagine him onstage or in a convertible cruising

down the coast of California -- not hunched over a mass of wires

and coils in Tokyo's cramped backstreets.

Joining us are a middle-aged banker and his entourage from

Osaka and accounting and finance consultant Yukio Funai. The

banker is doing a quick review for an investment, while the rest

of us just want to see if Minato's magnetic motors really work.

A prototype car air conditioner cooler sitting on a bench looks

like it would fit into a Toyota Corolla and quickly catches our

attention.

Seeing is Believing ~

Nobue then takes us through the functions and operations of

each of the machines, starting off with a simple explanation of

the laws of magnetism and repulsion. She demonstrates the

"Minato Wheel" by kicking a magnet-lined rotor into action with

a magnetic wand.

Looking carefully at the rotor, we see that it has over 16

magnets embedded on a slant -- apparently to make Minato's

machines work, the positioning and angle of the magnets is

critical. After she kicks the wheel into life, it keeps

spinning, proving at least that the design doesn't suffer from

magnetic lockup.

She then moves us to the next device, a weighty machine

connected to a tiny battery. Apparently the load on the machine

is a 35kg rotor, which could easily be used in a washing

machine. After she flicks the switch, the huge rotor spins at

over 1,500 rpms effortlessly and silently. Meters show the power

in and power out. Suddenly, a power source of 16 watt or so is

driving a device that should be drawing at least 200 to 300

watts.

Nobue explains to us that this and all the other devices only

use electrical power for the two electromagnetic stators at

either side of each rotor, which are used to kick the rotor past

its lockup point then on to the next arc of magnets. Apparently

the angle and spacing of the magnets is such that once the rotor

is moving, repulsion between the stators and the rotor poles

keeps the rotor moving smoothly in a counterclockwise direction.

Either way, it's impressive.

Next we move to a unit with its motor connected to a generator.

What we see is striking. The meters showed an input to the

stator electromagnets of approximately 1.8 volts and 150mA

input, and from the generator, 9.144 volts and 192mA output. 1.8

x 0.15 x 2 = 540mW input and 9.144 x 0.192 = 1.755W out.

But according to the laws of physics, you can't get more out of

a device than you put into it. We mention this to Kohei Minato

while looking under the workbench to make sure there aren't any

hidden wires.

Minato assures us that he hasn't transcended the laws of

physics. The force supplying the unexplained extra power out is

generated by the magnetic strength of the permanent magnets

embedded in the rotor. "I'm simply harnessing one of the four

fundamental forces of nature," he says.

Although we learned in school that magnets were always bipolar

and so magnetically induced motion would always end in a locked

state of equilibrium, Minato explains that he has fine-tuned the

positioning of the magnets and the timing of pulses to the

stators to the point where the repulsion between the rotor and

the stator (the fixed outer magnetic ring) is transitory. This

creates further motion -- rather than a lockup. (See the sidebar

on page 41 for a full explanation).

Real Products ~

Nobue Minato leads us to the two devices that might convince a

potential investor that this is all for real.

First, she shows us the cooling fan prototype that is being

manufactured for a convenience store chain's 14,000 outlets (3

fans per outlet). The unit looks almost identical to a

Mitsubishi-manufactured fan unit next to it, which is the unit

currently in wide use. In a test, the airflow from both units is

about the same.

The other unit is the car air conditioning prototype that

caught our eye as we came in. It's a prototype for Nippon Denso,

Japan's largest manufacturer of car air conditioners. The unit

is remarkably compact and has the same contours and size as a

conventional unit. Minato's manufacturing skills are clearly

improving.

The Banker and his Investment ~

Minato has good reason to complain about Japan's social and

cultural uniformity. For years, people thought of him as an

oddball for playing the piano for a living, and bankers and

investors have avoided him because of his habit of claiming that

he'd discovered a breakthrough technology all by himself --

without any formal training.

However, the Osaka banker stands up after the lecture and

announces that before he goes, he will commit \100 million to

the investment pool.

Minato turns to us and smiles. We brought him good luck, and

this was his third investor in as many weeks to confirm an

interest.

Bringing the Tech to the Table ~

With the audience gone, we ask Minato what he plans to do to

commercialize the technology. His game plan is simple and clear,

he says. He wants to retain control, and he wants to

commercialize the technology in Japan first -- where he feels he

can ensure that things get done right. Why doesn't he go

directly to the US or China? His experiences in both countries,

he suggests, have been less than successful. "The first stage is

critical in terms of creating good products and refining the

technology. I don't want to be busy with legal challenges and IP

theft while doing that."

Still, the export and licensing of the technology are on his

agenda, and Minato is talking to a variety of potential partners

in other countries.

Whereas another inventor might be tempted to outsource

everything to a larger corporation, part of what drives Minato

is his vision of social justice and responsibility. The 40,000

motors for the convenience store chain are being produced by a

group of small manufacturers in Ohta-ku and Bunkyo-ku, in the

inner north of Tokyo -- which is becoming a regional rust belt.

Minato is seized with the vision of reinvigorating these small

workshops that until the 80s were the bedrock of Japan's

manufacturing and economic miracle. Their level of expertise

will ensure that the quality of the motors will be as good as

those from any major company.

International Prep ~

Despite his plan to do things domestically first, Minato is

well prepared for the international markets. He is armed with

both six years of living and doing business in Los Angeles in

the early 90s -- and with patent protection for over 48

countries. His is hardly a provincial perspective.

His US experience came after playing the piano for a living for

15 years. He began tinkering with his invention in the mid-70s.

The idea for his magnetic motor design came from a burst of

inspiration while playing the piano.

But Minato decided to drop everything in 1990 to help his

daughter Hiroko, who at the age of 20 decided that she wanted to

be a rhythm and blues star in the US. Minato is a strong

believer in family: If Hiroko was going to find fame and fortune

in the US, Dad had better be there to help manage her. He

suceeded in helping Hiroko to achieve a UK dance chart number

one hit in 1995.

In 1996 Minato returned to Japan and his magnetic motor

project. The following year he displayed his prototypes to

national power companies, government officials and others at a

five-day conference in Mexico City. Interest was palpable, and

Minato realized that his invention might meet a global need for

energy-saving devices.

Subsequent previews and speeches in Korea and Singapore further

consolidated his commitment to bringing the invention to

fruition, and he was able to bring in several early-stage

investors.

During the late 90s, Minato continued to refine his prototypes.

He also stayed in constant contact with his lawyer, registering

patents in major countries around the world. Through his

experiences in the US he realized that legal protection was

critical, even if it meant delaying release of the technology by

a couple of years.

Ironically, by the time he'd won patents in 47 countries, the

Japanese patent office turned him down on the grounds that "[the

invention] couldn' t possibly work" and that somehow he was

fabricating the claims.

But a few months later they were forced to recant their

decision after the US patent office recognized his invention and

gave him the first of two patents. As Minato notes: "How typical

of Japan's small-minded bureaucrats that they needed the

leadership of the US to accept that my invention was genuine."

By 2001, the Minatos had refined their motors and met enough

potential investors to enter into a major international

relationship, initially with a Saudi company, to be followed

thereafter by companies in the US and elsewhere.

However, fate dealt the investors and Minato's business a

serious blow when the World Trade Center was attacked in New

York. The Saudis retreated, and Minato's plans fell back to

square one.

Now Minato is once again ready to move. With the first order in

the works and more orders pending successful prototypes, he has

decided that investors don't have to be primary partners. He is

actively accepting inquiries from corporate investors who can

bring strategic advantages and corporate credibility with them.

His company, Japan Magnetic Fan, will make a series of

investment tie-up announcements in the first and second quarters

of 2004.

Implications ~

Minato's motors consume just 20 percent or less of the power of

conventional motors with the same torque and horse power. They

run cool to the touch and produce almost no acoustic or

electrical noise. They are significantly safer and cheaper (in

terms of power consumed), and they are sounder environmentally.

The implications are enormous. In the US alone, almost 55

percent of the nation's electricity is consumed by electric

motors. While most factory operators buy the cheapest motors

possible, they are steadily being educated by bodies like NEMA

(National Electrical Manufacturers Association) that the costs

of running a motor over a typical 20-year lifespan comprise a

purchase price of just 3 percent of the total, and electricity

costs of 97 percent. It is not unusual for a $2,000 motor to

consume $80,000 of electricity (at a price of .06 cents per

kilowatt hour).

Since 1992, when efficiency legislation was put into place at

the US federal level, motor efficiency has been a high priority

-- and motors saving 20 percent or so on electrical bills are

considered highly efficient. Minato is about to introduce a

motor which saves 80 percent, putting it into an entirely new

class: The $80,000 running cost will drop to just $16,000. This

is a significant savings when multiplied by the millions of

motors used throughout the USA and Japan -- and eventually,

throughout the world.

The Devices ~

Minato's invention and its ability to use remarkably less power

and run without heat or noise make it perfect for home

appliances, personal computers, cellphones (a miniature

generator is in the works) and other consumer products.

The magnetic motor will be cheaper than a standard motor to

make, as the rotor and stator assemblies can be set into plastic

housings, due to the fact that the system creates very little

heat. Further, with the motor's energy efficiency, it will be

well suited for any application where a motor has limited energy

to drive it. While development is still focused on replacing

existing devices, Minato says that his motor has sufficient

torque to power a vehicle.

With the help of magnetic propulsion, it is feasible to attach

a generator to the motor and produce more electric power than

was put into the device. Minato says that average efficiency on

his motors is about 330 percent.

Mention of Over Unity devices in many scientific circles will

draw icy skepticism. But if you can accept the idea that

Minato's device is able to create motion and torque through its

unique, sustainable permanent magnet propulsion system, then it

makes sense that he is able to get more out of the unit than he

puts in in terms of elctrical power. Indeed, if the device can

produce a surplus of power for longer periods, every household

in the land will want one.

"I am not in this for the money," Minato says. "I have done

well in my musical career, but I want to make a contribution to

society -- helping the backstreet manufacturers here in Japan

and elsewhere. I want to reverse the trends caused by major

multinationals. There is a place for corporations. But as the

oil industry has taught us, energy is one area where a

breakthrough invention like this cannot be trusted to large

companies."

Minato was once close to making a deal with Enron. But today,

he is firmly on a mission to support the small and the

independent -- and to go worldwide with them and his amazing

machine. "Our plan is to rally smaller companies and pool their

talent, and to one day produce the technology across a wide

range of fields."

Content provided by J@pan Inc. Magazine --

http://www.japaninc.com

US Patent # 4,751,486

(Cl. 335/272)

Magnetic Rotation Apparatus

(June 14. 1998)

Kohei Minato

Abstract --- The magnetic rotation apparatus of the

present invention has first and second rotors rotatably

supported and juxtaposed. The first and second rotors are

connected so as to be rotatable in opposite directions in a

cooperating manner. A number of permanent magnets are arranged

on a circumferential portion of the first rotor at regular

intervals, and just as many permanent magnets are arranged on a

circumferential portion of the second rotor at regular

intervals. Each permanent magnet has one magnetic polarity

located radially outward from the rotors, and has the other

magnetic polarity located radially inward toward the rotors. The

polarity of each permanent magnet, which is located radially

outward from the rotors, is identical. When the first and second

rotors are rotated in a cooperating manner, the phase of

rotation of the permanent magnets of one rotor is slightly

advanced from that of the permanent magnets of the other rotor.

One of the permanent magnets of one rotor is replaced with the

electromagnet. The radially outward polarity of the

electromagnet can be changed by reversing the direction in which

a current is supplied to the electromagnet.

Claims ~ [ Claims not included here ]

Description

TECHNICAL FIELD

The present invention relates to a magnetic rotation apparatus

in which a pair of rotors are rotated by utilizing a magnetic

force.

BACKGROUND ART

An electromotor is well known as a rotation apparatus utilizing

a magnetic force. For example, an AC electromotor comprises a

rotor having a coil, a stator surrounding the rotor, and a

plurality of electromagnets, disposed on the stator, for

generating a rotating magnetic field. An electric power must be

constantly supplied to the electromagnets in order to generate

the rotating magnetic field and keep the rotor rotating, i.e.,

an external energy, or electric energy, is indispensable for the

rotation of the rotor.

Under the circumstances, a magnetic rotation apparatus, which

employs permanent magnets in lieu of electromagnets and can

rotate a rotor only by a magnetic force of the permanent

magnets, is highly desirable.

The present application proposes a magnetic rotation apparatus

which comprises a pair of rotors rotatable in opposite

directions in a cooperating manner, and a plurality of permanent

magnets stationarily arranged at regular intervals on the

peripheral portion of each rotor. One end portion of each

permanent magnet of both rotors, which has the same polarity, is

located radially outward of the rotors. When the two rotors are

rotated in a cooperating fashion, a permanent magnet on one

rotor and a corresponding permanent magnet on the other, which

form a pair, approach and move away from each other

periodically. In this case, the phase of rotation of the magnet

on one rotor advances a little from that of the corresponding

magnet on the other rotor. When the paired permanent magnets

approach each other, magnetic repulsion causes one rotor to

rotate. The rotation of one rotor is transmitted to the other

rotor to rotate the same. In this manner, other pairs of magnets

on both rotors sequentially approach each other, and magnetic

repulsion occurs incessantly. As a result, the rotors continue

to rotate.

In the above apparatus, in order to stop the rotation of the

rotors, a brake device is required. If an ordinary brake device

is mounted on the magnetic rotation apparatus, the entire

structure of the apparatus becomes complex, and a driving source

for the brake device must be provided separately.

The present invention has been developed in consideration of

the above circumstances, and its object is to provide a magnetic

rotation apparatus including a brake device for suitably

stopping the rotation of rotors.

DISCLOSURE OF THE INVENTION

The magnetic rotation apparatus of the present invention is

provided with magnetic force conversion means which is

substituted for at least one pair of permanent magnets of the

paired rotors. In a normal state, the magnetic force conversion

means causes a magnetic repulsion, as in the other pairs of

permanent magnets. When it is intended for the rotors to stop,

the magnetic force conversion means causes a magnetic attraction

force. Since a magnetic attraction force can be produced between

the rotors at any time, the magnetic attraction force serves to

stop the rotors. The brake device constituted by the magnetic

force conversion means differs from an ordinary brake device

which forcibly stops a pair or rotors by using a frictional

force. In the brake device of this invention, by converting a

magnetic repulsion force to a magnetic attraction force, the

rotors can be braked in the state that the movement of the

rotors is reduced. Thus, the rotors can be stopped effectively.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a schematic perspective view showing a magnetic

rotation apparatus according to an embodiment of the invention;

FIG. 2 is a schematic plan view showing the relationship

between the first and second rotors;

FIG. 3 is a perspective view of a permanent magnet;

FIG. 4 shows an electromagnet, a permanent magnet cooperating

with the electromagnet, and a driving circuit the electromagnet;

and

FIG. 5 is a view for explaining how a pair of rotors rotate.

BEST MODE OF CARRYING OUT THE INVENTION

FIG. 1 shows a magnetic rotation apparatus embodying the

present invention. The magnetic rotation apparatus has frame 1.

Frame 1 is provided with a pair of rotation shafts 2 which

extend vertically and in parallel to each other. Shafts 2 are

located at a predetermined distance from each other. Upper and

lower ends of each shaft 2 are rotationally supported on frame 1

via bearing 3.

First rotor 4a is mounted on one of rotation shafts 2, second

rotor 4b is mounted on the other rotation shaft 2. First and

second rotors 4a and 4b are arranged on the same level. Rotors

4a and 4b have similar structures. For example, each rotor 4a

(4b) comprises two ring-shaped plates 5 which are spaced apart

from each other in the axial direction of the rotation shaft 2.

Gears 6a and 6b made of synthetic resin are, as cooperating

means, attached to lower surfaces of first and second rotors 4a

and 4b. The diameters of gears 6a and 6b are identical but

larger than those of rotors 4a and 4b. Gears 6a and 6b mesh with

each other. First and second rotors 4a and 4b are thus rotatable

in opposite directions in a cooperating manner. In FIG. 1,

reference numeral 7 indicates support arms for supporting first

and second rotors 4a and 4b.

For example, 16 magnets are arranged at regular intervals on a

peripheral portion of first rotor 4a. These magnets are secured

between two ring-shaped plates 5. In this embodiment, among the

16 magnets, one is electromagnet 9a (see FIG. 2), and the others

are permanent magnets 8a. FIG. 2 shows only some of permanent

magnets 8a.

As shown in FIG. 3, permanent magnet 8a comprises case 10, and

a plurality of rod-like ferromagnetic members 11 housed in case

10. Ferromagnetic member 11 is, for example, a ferrite magnet.

Ferromagnetic members 11 of each permanent magnet 8a are

arranged such that ferromagnetic members 11 have the same

polarity at one end. In first rotor 4a, for example, an

N-polarity end portion of each permanent magnet 8a faces

radially outward, and an S-polarity end portion of magnet 8a

faces radially inward. As shown in FIG. 2, when each permanent

magnet 8a is located between two shafts 2, angle C formed by

longitudinal axis A of magnet 8a and imaginary line B connecting

two shafts 2 is, for example, set to 30.degree. C. On the other

hand, electromagnet 9a is, as shown in FIG. 4, constituted by

U-shaped iron core 12, and coil 13 wound around core 12.

Electromagnet 9a is arranged such that both N- and S-polarity

end portions face radially outward of first rotor 4a, and the

above-mentioned angle C is formed, similarly to the case of

permanent magnet 8a.

The same number of permanent magnets (8b,9b) as the total

number of all permanent magnets and electromagnet (8a,9a) of

first rotor 4a are secured on a peripheral portion of second

rotor 4b at regular intervals. In FIG. 2, when first and second

rotors 4a and 4b are rotated in opposite directions, each

permanent magnet of second rotor 4b periodically moves toward

and away from the corresponding one of the magnets (8a,9a) of

first rotor 4a.

The permanent magnets (8b,9b) of second rotor 4b will now be

described in greater detail. Permanent magnets 8b of second

rotor 4b, which periodically move toward and away from permanent

magnets 8a of first rotor 4a in accordance with the rotation of

rotors 4a and 4b, have a structure similar to that of permanent

magnets 8a of first rotor 4a. The polarity of that end portion

of each permanent magnet 8b which is located radially outward

from second rotor 4b, is identical with that of the end portion

of each permanent magnet 8a of first rotor 4a. That is, the

radially outward portion of each permanent magnet 8b has an

N-polarity.

Permanent magnet 9b of second rotor 4b, which periodically

moves toward and away from electromagnet 9a of first rotor 4a,

has a structure shown in FIG. 4. Permanent magnet 9b has a

structure similar to that of permanent magnets 8a. Both

polarities of electromagnet 9a face radially outward from first

rotor 4a. Permanent magnet 9b has two different polarities which

face radially outward from second rotor 4b and correspond to

both polarities of electromagnet 9a.

As shown in FIG. 2, when each permanent magnet 8b,9b is located

between two rotation shafts 2, angle E formed by longitudinal

axis D of the magnet (8b,9b) and imaginary line B connecting two

shafts 2 is, for example, set to 56.degree. C. In addition, when

rotors 4a and 4b are rotated in opposite directions, as shown by

arrows, the magnets (8a,9a) of first rotor 4a move a little

ahead of the corresponding permanent magnets (8b,9b) of second

rotor 4b, in a region in which both magnets (8a,9a; 8b,9b)

approach one another. In other words, the phase of rotation of

the magnets (8a,9a) of first rotor 4a advances by a

predetermined angle in relation to the permanent magnets (8b,9b)

of second rotor 4b.

As shown in FIG. 4, electromagnet 9a of first rotor 4a is

electrically connected to drive circuit 14. Drive circuit 14

includes a power source for supplying an electric current to

coil 13 of electromagnet 9a. While rotors 4a and 4b rotate,

drive circuit turns on electromagnet 9a upon receiving a signal

from first sensor 15 only when electromagnet 9a and permanent

magnet 9b are in a first region in which they periodically

approach each other. First sensor 15 is an optical sensor

comprising a light-emitting element and a light-receiving

element. As shown in FIG. 1, first sensor 15 is attached to a

portion of frame 1 above first rotor 4a. First sensor 15 emits

light in a downward direction. The light is reflected by

reflection plate 16 projecting radially inward from the inner

edge of first rotor 4a. First sensor 15 receives the reflected

light, and feeds a signal to drive circuit 14. Thus, drive

circuit 14 turns on electromagnet 9a.

The circumferential length of reflection plate 16 is equal to

that of the above-mentioned first region. When magnets 9a and 9b

enter the first region, first sensor 15 is turned on, and when

they leave the first region, first sensor 15 is turned off. When

drive circuit 14 receives a signal from first sensor 15, it

excites electromagnet 9a such that both polarities of

electromagnet 9a correspond to those of permanent magnet 9b of

second rotor 4b.

Drive circuit 14 is electrically connected to switching circuit

17. When brake switch 18 is operated, switching circuit 17

reverses the direction in which an electric current is supplied

to electromagnet 9a. When the current supplying direction of

drive circuit 14 is reversed, drive circuit 14 excites

electromagnet 9a only in a time period in which drive circuit 14

receives a signal from second sensor 19. Second sensor 19 has a

structure similar to that of first sensor 15, and is attached to

frame 1 so as to be located closer to the center of rotor 4a

than first sensor 15. Reflection plate 20, which corresponds to

the position of second sensor 19, is formed integral to an inner

edge portion of reflection plate 16. As shown in FIG. 2,

compared to reflection plate 16, reflection plate 20 extends in

rotational direction of first rotor 4a, indicated by the arrow.

The operation of the above-described magnetic rotation

apparatus will now be explained with reference to FIG. 5.

In FIG. 5, rotation shaft 2 of first rotor 4a is denoted by 01,

and rotation shaft 2 of second rotor 4b is denoted by 02. Only

the radially outward polarity, that is, N-polarity, of the

magnets of rotors 4a and 4b is shown, for the sake of

convenience. Although electromagnet 9a and permanent magnet 9b

have both polarities located radially outward, only the

N-polarity thereof is shown.

When first and second rotors 4a and 4b are put in a position

shown in FIG. 5, magnetic pole Nb1 of one permanent magnet of

second rotor 4b is located in a line connecting shafts 01 and

02. In this case, polarity Na1 of first rotor 4a, which is

paired with polarity Nb1, is a little advanced from polarity Nb1

in the rotational direction of first rotor 4a. For example, as

shown in FIG. 5, magnetic pole Na1 is advanced from polarity Nb1

by an angle of X.degree.. Polarities Na1 and Nb1 exert repulsion

force F1 upon each other along line L. Supposing that an angle,

formed by line M, which is drawn from shaft 01 perpendicularly

to line L, and the line connecting shafts 01 and 02 is

represented by Y, and that the length of line K is represented

by R, torques Ta1 and Tb1 caused by repulsion force F1 to rotate

first and second rotors 4a and 4b can be given by:

Ta1=F1.multidot.R.multidot.cos (Y-X)

Tb1=F1.multidot.R.multidot.cos Y

Since cos (Y-X)>cos Y, Ta1>Tb1.

As shown in FIG. 5, since magnetic pole Na1 is advanced from

magnetic pole Nb1 by angle X.degree., first rotor 4a receives a

greater torque than second rotor 4b. Thus, first rotor 4a

forwardly rotates in the direction of the arrow in FIG. 5.

Mention is now made of paired magnets of rotors 4a and 4b in

the vicinity of magnetic poles Na1 and Nb1. Magnetic poles Nan

and Nan-1 of first rotor 4a are advanced ahead of magnetic pole

Nal in the rotational direction. Magnetic poles Nan and Nan-1

receive a torque produced by a repulsion force acting between

magnetic poles Nan and Nan-1 and corresponding magnetic poles

Nbn and Nbn-1. In FIG. 5, magnetic poles Nan and Nan-1 receive a

smaller torque, as they rotate farther from the location of

magnetic pole Na1. It is well known that a torque of first rotor

4a, which is caused by a repulsion force acting on magnetic

poles Nan and Nan-1, is decreased in inverse proportion to the

square of the distance between paired magnetic poles Na and Nb.

Magnetic poles Na2 and Na3, behind magnetic pole Na1, receive a

torque which tends to rotate rotor 4a in the reverse direction.

This torque is considered to be counterbalanced with the torque

acting on magnetic poles Nan and Nan-1.

In FIG. 5, attention should be paid to the region of magnetic

poles Na1 and Na2. As first rotor 4a forwardly rotates, the

direction in which a torque applies to magnetic pole Na2, is

changed from the reverse direction to the forward direction,

before magnetic pole Na2 reaches the position of magnetic pole

Na1. The torque for forwardly rotating rotor 4a is larger than

that for reversely rotating rotor 4a. Therefore, first rotor 4a

is easily rotated in the direction shown in FIG. 2.

Second rotor 4b is considered to receive a torque in a

direction reverse to the direction shown in FIG. 2, as seen from

the description of first rotor 4a. It is obvious that second

rotor 4b receives a maximum torque at the position of magnetic

pole Nb1. As seen from the above formula, torque Tb1 applied to

second rotor 4b in a direction reverse to that denoted by the

arrow is smaller than torque Ta1 applied to first rotor 4a in

the forward direction. The rotation of first rotor 4a is

transmitted to second rotor 4b through gears 6a and 6b. By

determining the relationship between the strengths of torques

Ta1 and Tb1, second rotor 4b is thus rotated in a direction

reverse to the rotational direction of first rotor 4a, against

the torque applied to second rotor in the direction. As a

result, first and second rotors 4a and 4b are kept rotating,

since a torque for rotating rotors 4a and 4b in a cooperating

manner is produced each time magnetic poles Na of first rotor 4a

pass across the line connecting shafts 01 and 02.

In a diagram shown in the right part of FIG. 5, a solid line

indicates a torque applied to first rotor 4a, and a broken line

indicates a torque applied to second rotor 4b. The ordinate

indicates a distance between each magnetic pole and the line

connecting shafts 01 and 02 of rotors 4a and 4b. The first

region in which electromagnet 9a of first rotor 4a is turned on

is set in a range of Z during which a torque is applied to first

rotor 4a in the forward direction.

In order to stop the cooperative rotation of rotors 4a and 4b,

brake switch is turned on to operate switching circuit 17. Thus,

the direction in which drive circuit 14 supplies a current to

electromagnet 9a is reversed. The polarities of electromagnet 9a

are reversed. The torque applied to electromagnet 9a in the

forward direction is stopped. When electromagnet 9a approaches

permanent magnet 9b, a magnetic attract:on force is produced. As

a result, the rotation of rotors 4a and 4b is effectively slowed

down and stopped. Since the second region, in which

electromagnet 9a is excited, is larger than the first region, a

large braking force can be obtained from a magnetic attraction

force.

In the above embodiment, since electromagnet 9a is excited only

in a specific region, a large electric power is not required. In

addition, since electromagnet 9a rotates and brakes rotors 4a

and 4b, a braking mechanism for a magnetic rotation apparatus

can be obtained without having to make the entire structure of

the apparatus complex.

The present invention is not restricted to the above

embodiment. With the exception of the paired electromagnet and

permanent magnet, all permanent magnets of the rotors are

arranged such that their end portions of the same polarity face

radially outward from the rotors. However, it is possible that

the polarities of the radially outward end portions of the

permanent magnets are alternately changed. Namely, it should

suffice if the polarities of the radially outward end portions

of the first rotor are identical to those of the corresponding

radially outward end portions of the second rotor. The magnets

may have different magnetic forces. Furthermore, an electric

power for exciting the electromagnet can be derived from the

rotation of the rotors or from the revolving magnetic field of

the permanent magnet.

Angles C and E are not restricted to 30.degree. and 56.degree..

They may be freely determined in consideration of the strength

of the magnetic force of the permanent magnet, a minimum

distance between adjacent magnets, angle x, and the like. The

number of magnets of the rotor is also freely chosen.

Industrial Applicability ~

As described above, the magnetic rotation apparatus of the

present invention can be used as a driving source in place of an

electric motor, and as an electric generator.

US Patent # 5,594,289 (Cl. 310/152)

Magnetic Rotating Apparatus

(January 14, 1997)

Kohei Minato

Abstract --- On a rotor which is fixed to a

rotatable rotating shaft, a plurality of permanent magnets are

disposed along the direction of rotation such that the same

magnetic pole type thereof face outward. In the same way,

balancers are disposed on the rotor for balancing the rotation

of this rotor. Each of the permanent magnets is obliquely

arranged with respect to the radial direction line of the rotor.

At the outer periphery of the rotor, an electromagnet is

disposed facing this rotor, with this electromagnet

intermittently energized based on the rotation of the rotor.

According to the magnetic rotating apparatus of the present

invention, rotational energy can be efficiently obtained from

permanent magnets. This is made possible by minimizing as much

as possible current supplied to the electromagnets, so that only

a required amount of electrical energy is supplied to the

electromagnets.

Claims --- [ Claims not included here ]

Description

BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to a magnetic rotating apparatus,

and more particularly, to a magnetic rotating apparatus which

utilizes repulsive forces produced between a permanent magnet

and an electromagnet.

2. Description of the Prior Art

In a conventional electric motor, an armature as a rotor

consists of turns of wires, and electric field as a stator

consists of a permanent magnet. In such the conventional

electric motor, however, current must be usually supplied to

windings of the armature which is rotated. When the current is

supplied, heat is generated, which gives rise to the problem

that not much driving force is efficiently generated. This, in

turn, gives wise to the problem that the magnetic forces cannot

be efficiently obtained from the permanent magnet.

In addition, in the conventional electric motor, since the

armature is so constructed as consisting of the windings, the

moment of inertia cannot be made very high, so that enough

torque cannot be obtained.

To overcome the above-described problems of such the

conventional electric motor, the inventor proposed, in Japanese

Patent Publication No. 61868/1993 (U.S. Pat. No. 4,751,486) a

magnetic rotating apparatus in which a plurality of the

permanent magnets are disposed along the two rotors,

respectively, at a predetermined angle, and in which an

electromagnet is disposed at one of the rotors.

In a generally constructed conventional electric motor, there

is a limit as to how much the efficiency of energy conversion

can be increased. In addition, the torque of the electric motor

cannot be made high enough. For the above reasons, hitherto,

various improvements have been made on existing electric motors,

without any success in producing an electric motor so

constructed has providing satisfactory characteristics.

In the magnetic rotating apparatus disclosed in Japanese Patent

Publication No. 6868/1993 (U.S. Pat. No. 4,751,486) a pair of

rotors is rotated. Therefore, it is necessary for each of the

rotors to have high precision, and in addition, measures must be

taken for easier rotation control.

SUMMARY OF THE INVENTION

In view of the above-described problems, the object of the

present invention is to provide a magnetic rotating apparatus in

which rotational energy can be efficiently obtained from the

permanent magnet with a minimum amount of electrical energy, and

in which rotation control can be carried out relatively easily.

According to one aspect of the present invention, there is

provided a magnetic rotating apparatus comprising a rotating

shaft; a rotor which is fixed to the rotating shaft and which

has disposed thereon permanent magnet means and means for

balancing rotation, the permanent magnet means being disposed

such that a plurality of magnetic poles of one (or first)

polarity type is arranged along an outer peripheral surface in

the direction of rotation, and a plurality of magnetic poles of

the other (or second) polarity type arranged along an inner

peripheral surface, with each pair of corresponding magnetic

poles of one and the other polarities obliquely arranged with

respect to a radial line; electromagnet means, which is disposed

facing this rotor, for developing a magnetic field which faces

the magnetic field of the permanent magnet means of the rotor

and detecting means for detecting rotating position of the rotor

to allow the electromagnet means to be energized.

According to another aspect of the present invention, there is

provided a magnetic rotating apparatus comprising a rotating

shaft a rotor which is fixed to the rotating shaft and which has

disposed thereon a plurality of permanent magnets and balancers

for balancing rotation, the permanent magnets being disposed

such that one magnetic polarity type is arranged along an outer

peripheral surface in the direction of rotation and the other

magnetic polarity type arranged along an inner peripheral

surface, with each pair of corresponding magnetic poles of one

and the other polarities obliquely arranged with respect to a

radial line; an electromagnet, which is disposed facing this

rotor, for developing a magnetic field which produces the other

magnetic polarity type on the facing surface; and energizing

means for intermittently energizing the electromagnet means from

where the leading permanent magnet, based on the rotation of the

rotor, passes the facing surface of the electromagnet in the

direction of rotation.

According to still another aspect of the present invention,

there is provided magnetic rotating apparatus comprising a

rotating shaft; a first rotor which is fixed to the rotating

shaft and which has disposed thereon permanent magnet means and

means for balancing rotation, the permanent magnet means being

disposed such that a plurality of magnetic poles of the second

polarity type is arranged along an outer peripheral surface in

the direction of rotation, and a plurality of magnetic poles of

the first pole type arranged along an inner peripheral surface,

with each pair of corresponding magnetic poles of one and the

other polarities obliquely arranged with respect to a radial

line; a second rotor which rotates along with the first rotor

and is fixed to the rotating shaft, having disposed thereon a

plurality of permanent magnets and balancers for balancing

rotation, the permanent magnets being disposed such that one

magnetic polarity type is arranged along an outer peripheral

surface in the direction of rotation and the other magnetic

polarity type arranged along an inner peripheral surface, with

each pair of corresponding magnetic poles of one and the other

polarities obliquely arranged with respect to a radial line a

first and a second electromagnet means, which are magnetically

connected and disposed facing the first and second rotors,

respectively, for developing a magnetic field which faces the

magnetic field of the permanent magnet means of the first and

second rotors; and detecting means for detecting rotating

position of the rotors to allow the electromagnet means to be

energized.

The nature, principle and utility of the invention will become

more apparent from the following detailed description when read

in conjunction with the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

In the accompanying drawings:

FIG. 1 is a perspective view schematically illustrating a

magnetic rating apparatus according to one embodiment of the

present invention

FIG. 2 is a side view of the magnetic rotating apparatus

illustrated in FIG. 1;

FIG. 3 is a plan view of a rotor of the magnetic rotating

apparatus illustrated in FIGS. 1 and 2;

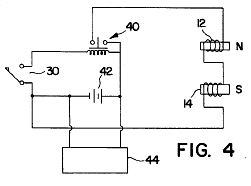

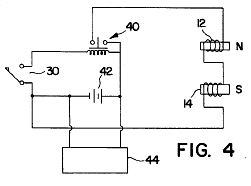

FIG. 4 is a circuit diagram illustrating a circuit in the

magnetic rotating apparatus shown in FIG. 1;

FIG. 5 is a plan view showing a magnetic field distribution

formed between the rotor and the electromagnet of the magnetic

rotating apparatus shown in FIGS. 1 and 2, and

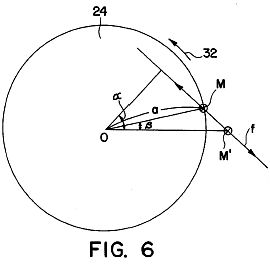

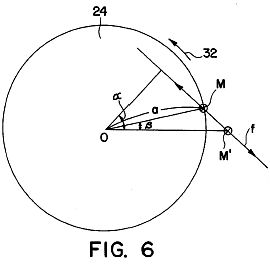

FIG. 6 is an explanatory view illustrating a torque which

causes rotation of the rotor of the magnetic rotating apparatus

shown in FIGS. 1 and 2.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

The magnetic field developed by an electromagnet means and that

of a permanent magnet means of a rotor repel each other. In

addition, the magnetic field of the permanent magnet means is

flattened by the magnetic fields of other nearby permanent

magnets and electromagnet means. Therefore, a torque is produced

therebetween to efficiently rotate the rotor. Since the rotor

has a high inertial force, when the rotor starts rotating, its

speed increases by the inertial force and the turning force.

A magnetic rotating apparatus related to one embodiment of the

present invention will be described with reference to the

following drawings.

FIGS. 1 and 2 are schematic diagrams of a magnetic rotating

apparatus related to one embodiment of the present invention. In

the specification, the term "magnetic rotating apparatus" will

include an electric motor, and from its general meaning of

obtaining turning force from the magnetic forces of permanent

magnets, it will refer to a rotating apparatus utilizing the

magnetic forces. As shown in FIG. 1, in the magnetic rotating

apparatus related to one embodiment of the present invention, a

rotating shaft 4 is rotatably fixed to a frame 2 with bearings

5. To the rotating shaft 4, there are fixed a first magnet rotor

6 and a second magnet rotor 8, both of which produce turning

forces and a rotated body 10, which has mounted therealong a

plurality of rod-shaped magnets 9 for obtaining the turning

forces as energy. They are fixed in such a manner as to be

rotatable with the rotating shaft 4. At the first and second

magnet rotors 6 and 8, there are provided, as will be described

later in detail with reference to FIGS. 1 and 2, a first

electromagnet 12 and a second electromagnet 14 respectively are

energized in synchronism with rotations of the first and second

magnet rotors 6 and 8, both of which face each other and are

each disposed in a magnetic gap. The first and second

electromagnets 12 and 14 are respectively mounted to a yoke 16,

which forms a magnetic path.

As shown in FIG. 3, the first and second magnet rotors 6 and 8

each have disposed on its disk-shaped surface a plurality of

tabular magnets 22A through 22H for developing a magnetic field

for generating the turning forces and balancers 20A through 20H,

made of non-magnetic substances, for balancing the magnet rotors

6 and 8. In the embodiments, the first and second magnet rotors

6 and 8 each have disposed along the disk-shaped surface 24 at

equal intervals the eight tabular magnets 22A through 22H along

half of the outer peripheral area and +the eight balancers 20A

through 20H along the other half of the outer peripheral area.

As shown in FIG. 3, each of the tabular magnets 22A through 22H

are disposed so that its longitudinal axis 1 makes an angle D

with respect to a radial axis line 11 of the disk-shaped surface

24. In the embodiment, an angle of 30 degrees and 56 degrees

have been confirmed for the angle D. An appropriate angle,

however, can be set depending on the radius of the disk-shaped

surface 24 and the number of tabular magnets 22A through 22H to

be disposed on the disk-shaped surface 24. As illustrated in

FIG. 2, from the viewpoint of effective use of the magnetic

field, it is preferable that the tabular magnets 22A through 22H

on the first magnet rotor 6 are positioned so that their N-poles

point outward, while the tabular magnets 22A through 22H on the

second magnet rotor 8 are positioned so that their S-poles point

outward.

Exterior to the first and second magnet rotors 6 and 8, the

first and second electromagnets 12 and 14 are disposed facing

the first and second magnet rotors 6 and 8 respectively in the

magnetic gap. When the first and second electromagnets 12 and 14

are energized, they develop a magnetic field identical in

polarity to the their respective tabular magnets 22A through 22H

so that they repel one anther. In other words, as shown in FIG.

2, since the tabular magnets 22A through 22H on the first magnet

rotor 6 have their N-poles facing outwards, the first

electromagnet 12 is energized so that the side facing the first

magnet rotor 6 develops an N-polarity. In a similar way, since

the tabular magnets 22A through 22H on the second magnet rotor 8

have their S-poles facing outwards, the second electromagnet 14

is energized so that the side facing the tabular magnets 22A

through 22H develops a S-polarity. The first and second

electromagnets 12 and 14, which are magnetically connected by

the yoke 16, are magnetized so that the sides facing their

respective magnet rotors 6 and 8 are opposite in polarity with

respect to each other. This means that the magnetic fields of

the electromagnets 12 and 14 can be used efficiently.

A detector 30, such as microswitch, is provided to either one

of the first magnet rotor 6 or second magnet rotor 8 to detect

the rotating position of the magnet rotors 6 and 8. That is, as

shown in FIG. 3, in a rotational direction 32 of the tabular

magnets 22A through 22H, the first and the second magnet rotors

6 and 8 are respectively energized when the leading tabular 22A

has passed. In other words, in the rotational direction 32, the

electromagnet 12 or 14 is energized when starting point So,

located between the leading tabular magnet 22A and the following

tabular magnet 22B coincides with the center point Ro of either

the electromagnet 12 or 14. In addition, as illustrated in FIG.

3, in the rotational direction 32 of the tabular magnets 22A

through 22H, the first and the second magnet rotors 6 and 8 are

de-energized when the last tabular magnet 22A has passed. In the

embodiment, an end point Eo is set symmetrical to the starting

point So on the rotating disk-shaped surface 24. When the end

point Eo coincides with the center point Ro of either the

electromagnet 12 or 14, the electromagnet 12 or 14 is

de-energized, respectively. As will be described later, with the

center point Ro of the electromagnet 12 or 14 arbitrarily set

between the starting point So and the end point Eo, the magnet

rotors 6 and 8 start to rotate when the electromagnets 12 and 14

and their tabular magnets 22A through 22H face one another. When

a microswitch is used as the detector 30 for detecting the

rotating position, the contact point of the microswitch is

allowed to slide along the surface of the rotating disk-shaped

surface 24. A step is provided for the starting point So and the

end point Eo so that the contact of the microswitch closes

between the starting point So and the end point Eo. The area

along the periphery therebetween protrudes beyond the other

peripheral areas of the rotating disk-shaped surface 24. It is

apparent that a photo sensor or the like may be used instead of

the microswitch as the detector 30 for detecting the rotating

position.

As shown in FIG. 4, the windings of the electromagnets 12 and

14 are connected to a DC power source 42 through a movable

contact of a relay 40, which is connected in series with the

windings. A series circuit containing the relay 40 (solenoid)

and the detector 30 or microswitch is connected to the DC power

source 42. In addition, from the viewpoint of energy

conservation, a charger 44 such as a solar cell is connected to

the DC power source 42. It is preferable that the DC power

source 42 is constantly chargeable using solar energy or the

like.

In the magnetic rotating apparatus illustrated in FIGS. 1 and

2, a magnetic field distribution shown in FIG. 5 is formed

between the tabular magnets 22A through 22H, disposed on each of

the magnet rotors 6 and 8, and the electromagnets 12 and 14

which face them, respectively. When the electromagnet 12 or 14

is energized, a magnetic field of a tabular magnet of the

tabular magnets 22A through 22H, adjacent to the electromagnet

12 or 14, is distorted in the longitudinal direction in

correspondence with the rotational direction. This results in

the generation of a repulsive force therebetween. As is apparent

from the distortion of the magnetic field, the repulsive force

has a larger component in the longitudinal or perpendicular

direction, and produces a torque, as shown by an arrow 32.

Similarly, a magnetic field of a tabular magnet of the tabular

magnets 22A through 22H, which next enters the magnetic field of

the electromagnet 12 or 14, is distorted. Since it moves toward

an opposite pole of the preceding tabular magnet of the tabular

magnets 22A through 22H, its magnetic field is distorted to a

larger extent, and thereby flattened. This means that the

repulsive force produced between the tabular magnets of the

tabular magnets 22A through 22H, which have already entered the

magnetic field of the electromagnets 12 or 14, is larger than

the repulsive force developed between the next-entering tabular

magnets of the tabular magnets 22A through 22H and the

electromagnets 12 or 14. Accordingly, a turning force, shown by

the arrow 32, acts upon the rotating disk-shaped surface 24. The

rotating disk-shaped surface 24, having been imparted thereto

turning force, continues to rotate due to inertial forces, even

when it has been de-energized after the end point Eo has

coincided with the center point Ro of the electromagnet 12 or

14. The larger the inertial force, the smoother the rotation.

At the initial stage of the rotation, an angular moment, as

that shown in FIG. 6, is imparted to the rotating disk-shaped

surface 24. That is, at the start of the rotation, as shown in

FIG. 6, when the pole M of a tabular magnet is slightly

displaced in the rotational direction from the pole M' of an

electromagnet, a repulsive force operates between both of the

poles M and M' of the tabular magnet at the rotating side and

the electromagnet at the stationary side, respectively.

Therefore, from the relationship illustrated in FIG. 6, an

angular torque T is generated based on the formula: T=F. a.cos

(.alpha.-.beta.), where in a is a constant. The angular torque

starts the rotation of the rotating disk-shaped surface 24.

After the rotating disk-shaped surface 24 has started rotating,

its rotating speed gradually increases due to an inertial moment

thereof, which allows a large turning driving force to be

produced. After a stable rotation of the rotating disk-shaped

surface 24 has been produced, when a necessary electromotive

force can be developed in an electromagnetic coil (not

illustrated) by externally bringing it near a rotated body 10 to

be rotated along with the rotating disk-shaped surface 24. This

electric power can be used for other applications. This rotating

principle is based on the rotating principle of the magnetic

rotating apparatus already disclosed in Japanese Patent

Publication No. 61868/1993 (U.S. Pat. No. 4,751,486) by the

inventor. That is, even if an electromagnet, provided for one of

the rotors of the magnetic rotating apparatus disclosed in the

same Patent Application, is fixed, it is rotated in accordance

with the rotating principle disclosed therein. For details,

refer to the above Japanese Patent Publication No. 61868/1993

(U.S. Pat. No. 4,751,486).

The number of tabular magnets 22A through 22H is not limited to

"8" as shown in FIGS. 1 and 3. Any number of magnets may be

used. In the above-described embodiment, although the tabular

magnets 22A through 22H are disposed along half of the

peripheral area of the disk-shaped surface 24, and the balancers

20A through 20H are disposed along the other half of the

peripheral area, the tabular magnets may further be disposed

along other areas of the disk-shaped surface 24. It is

preferable that balancers, in addition to magnets, are provided

along a portion of the peripheral area on the disk-shaped

surface. The counter weights, which do not need to be formed

into separate blocks, may be formed into one sheet of plate

which extends on the outer peripheral area of the disk-shaped

surface. In addition, in the above-described embodiments, while

the construction is such as to allow the electromagnets to be

energized for a predetermined period of time for every rotation

of the rotating disk-shaped surface, the circuit may be so

constructed as to allow, upon increased number of rotations,

energization of the electromagnets for every rotation of the

rotating disk-shaped surface, starting from its second rotation

onwards. Further, in the above-described embodiment, a tabular

magnet has been used for the permanent magnet, but other types

of permanent magnets may also be used. In effect, any type of

magnet may be used as the permanent magnet means as long as a

plurality of magnetic poles of one type is disposed along the

outer surface of the inner periphery and a plurality of magnetic

poles of the other type are disposed along the inner peripheral

surface of the disk-shaped surface, so that a pair of

corresponding magnetic poles of one and the other polarities is

obliquely arranged, with respect to the radial line 11, as shown

in FIG. 3.

Although the tabular magnets 22A through 22H are mounted on the

magnet rotors 6 and 8 in the above embodiment, they may be

electromagnets. In this case, the electromagnets 12 and 14 may

be the alternative of electromagnets or permanent magnets.

According to the magnetic rotating apparatus of the present

invention, rotational energy can be efficiently obtained from

permanent magnets. This is made possible by minimizing as much

as possible current supplied to the electromagnets, so that only

a required amount of electrical energy is supplied to the

electromagnets.

It should be understood that many modifications and adaptations

of the invention will become apparent to those skilled in the

art and it is intended to encompass such obvious modifications

and changes in the scope of the claims appended hereto.

KeelyNet: BBS Posting from Henry Curtis (11-18-1997)

Korean Magnetic Perpetual Motion Wheel

I must apologize for not having all the details of this

interesting device but will update the file when I get more info

from the source. In email communications with John Schnurer, I

happened to mention it and he's been on me since then to send

him a diagram, yet I felt like it would simply be confusing

because its operation is not clear or readily apparent from the

information I had.The information that I have comes directly

from long time friend Henry Curtis of Colorado. We both attended

the 1997 ISNE conference in Denver and Henry was telling about

this interesting machine he had seen while on a trip to the

Phillipines. He said there was a free energy conference held

there and he noticed a spinning bicycle wheel that was attached

to a stand that sat on a table.The wheel was running when he

first saw it, yet there did not appear to be any driving force

such as a motor, belts, gears, etc..Henry said he watched it for

quite awhile and it never stopped running. On expressing

curiosity about the wheel, he was invited to stop it and start

it up without any outside assistance.Henry reports the wheel was

brought to a complete stop, then he gave it a spin with his hand

and it began moving on its own. I am uncertain if it followed

the tendency of other such devices to establish its own speed.

Some devices like this can be spun up to high speed from an

outside source, then will slow to a speed which is determined by

the geometry and strength of the repelling or attracting forces

that operate it.Henry swears it was the neatest thing he'd ever

seen and drew a crude diagram of the arrangement on my notepad.

Unfortunately, we were a bit rushed and I did not achieve a

complete understanding of how it operated. That is why I did not

want to blow smoke about it until more detail had been received,

god knows, we don't need any more of that.However, perhaps

someone can figure it out from the limited information I do

have. The following drawing shows the wheel arrangement, one

half was weighted, the other half had slanted magnets. I do not

know whether they are all repelling, attracting or a mix of

these forces.

As you can imagine, the weight of the magnets must equal the

weight of the other half of the wheel to balance out. Apparently

the force of the magnetic repulsion or attaction provides the

actual imbalance.Henry also said there was a patent on this

device that is dated January 14, 1997. The inventor is a

Japanese man named Minatu. The spelling of this name is

uncertain. I did a search on the IBM server but found nothing

even remote. Henry specifically said this was a United States

patent. So, here it is. Perhaps Henry can come up with some more

detail which can be used to update this file in future. Good

luck....

KeelyNet: Update and Corrections from Henry Curtis (Wed, 19

Nov 1997) ~

From: Henry Curtis ~ To: Jerry Decker

Subject: Bicycle wheel correction and update Jerry,

Again we see that communication is difficult and memories are

fallable. Obviously I am remiss in not having sent this to you

months ago as I intended to, but as a sage of old observed "The

spirit is willing, but the flesh is slow." During the first

weekend of May, 1997, a group in Soeul, Korea headed up by Mr.

Chi San Park, held The First International New Energy Conference

in Seoul, Korea. I attended this conference and gave a talk on

various approcahes to free energy. It was at this conference in

Seoul, Korea that I saw the bicycle wheel and had the

opportunity to work with it unattended by anyone else.The

inventor is Kohei Minato, a Japanese rock musician, who reports

that he has spent a million dollars out of his own pocket

developing magnetic motors, because the world needs a better

source of energy. He has several patents in various countries.

His latest patent that I am aware of is United States Patent #

5,594,289. His development efforts have gone in the general

direction of the Adams motor which the above patent is similar

to. He had a working prototype of this design at the conference

and reported that it used 150 watts power input and produced 450

watts output on a sustained basis. About a year ago CNN (in the

US) had a 10 minute segment about him and his motors. In this

video he is shown demonstrating two of his magnetic motors. I

have a copy of this film clip that he gave to me. I will make a

copy and send it to you. Unfortunately, the editors were not

attuned to technical details and the pictures of the running

machines show little useful detail. The Phillipine connection

that you mention is completely erroneous. It was in Korea. The

drawing on the web site is essentially correct with the

following exceptions. The counter weight is a single curved

piece of aluminum covering 180 degrees. Each of the several

individual magnets on the other half of the wheel are slightly

asymmetric, crescent shaped and nested. They are magnetised end

to end with the N poles out. The motor is actuated by moving the

N pole of a large permanet magnet (the drive magnet) toward the

wheel. As this magnet is moved toward the wheel, the wheel

starts to spin. As the magnet is moved closer to the wheel it

spins faster. The acceleration of the wheel is rapid. So rapid

in fact, as to be startling. To put it another way I was very

impressed. The motor works. And it works very well. In the film

clip a slight pumping action of Minato's hand holding the magnet

is apparent. When I braced my hand so that there was no pumping

action, the motor still ran. In fact it seemed to run better.

Pumping action by the hand held magnet is not the power that

drives the motor. When the drive magnet is moved away from the

wheel it coasts rather quickly to a stop and comes to rest in a

manner typical of any spinning bicycle wheel. Again when the

wheel is at rest and a large magnet is moved up to the wheel it

starts to spin. At no time is it necessary to touch the wheel to

get it to rotate. Simply bring the N pole of a large magnet

several inches from the wheel. The particular orientation of the

wheel when it is at rest seems to have no effect on how well it

starts to turn. Irrespective of how the wheel and the magnets on

it are sitting; move the drive magnet near, it starts to spin.

Move the magnet closer it spins faster. Move the magnet further

away it slows up. The wheel was mounted on a stand made of

aluminum angle pieces bolted together similar to the diagram in

the above mentioned patent. The axle of the wheel was mounted

parellel to the surface of the planet. I have attached a rough

diagram of the wheel. Apparently the geometry of the magnets on

the wheel is very important and subtle. I have built several

small models none of which have shown the free energy effects of

Minato's machine. The conference in Seoul was attended by

several hundred people, most appeared to be under 40 and evenly

divided between men and women. Presenters were from Korea, US,

Japan, and China. Simultaneous translation was provided for all

talks in the 3 day conference. Jerry, I hope this information is

useful. I may be contacted by e-mail at

mailto:hcurtis@mindspring.com or by phone at 303.344.1458.

KeelyNet: Email from Gene Mallove at Infinite Energy ~

I spoke to Bob Vermillion of Tri-Cosmos Development (Los

Angeles, CA 310-284-3250 or fax 310-284-3260) today, just before

he left for the three-day demonstrations of the Minato magnetic

motor being held in Mexico City, Mexico on July 8, 9, 10th.Three

(3) Minato Motors (MM), covered by US Patents # 5,594,289 (Jan

14, 1997) and # 4,751,486 (June 14, 1988), have been brought

over from Japan. One was allegedly tested last evening by Grupo

Bufete Industrial (supposedly one of the largest power

generation construction companies in Mexico and South America).

The company engineers were said (by Vermillion) to have measured

an output /input ratio of 4.3 / 1. The printed literature, which

I received in a Fedex packet from Vermillion states that the

device can put out 500 watts (maximum) with an input of 34

watts.For those of you who wonder why the device is not

self-sustaining -- oral info from Vermillion is that Minato

*will* in the course of one of the demonstrations *remove the

battery power supply* and let the device self-run -- presumably

with a load. The press release makes no bones about the

physics-busting character of the MM: "As rotations per minute

(rpm's) increase, the electromagnetic consumption of the stator

decreases. This phenomenon is in direct conflict with accepted

laws of physics and is achieved through the repelling magnetic

fields. It operates without heat, noise, or pollution of any

kind. It can be produced in size from ultra-small to very

large." It is said in the press release that applications from

cell phones to laptop computers are under development.

Vermillion told me of other parties who were planning to attend

the demonstrations, which will be conducted both in public

displays and with private party measurements. These include:

ENRON, Bechtel, Tejas (a division of Shell Oil Corporation),

Fluor Daniels, Kellogg Corp. .He told me that Hal Fox of New

Energy News and the Fusion Information Center will be there (I

confirmed with Hal that he will be there and will give us a full

report.) I considered going myself (I was invited), but I trust

Hal Fox to provide a full report -- he should be back this

weekend. Mr. Kohei Minato will be there -- he has already

arrived, I understand. He hand carried one of the motors that

was already tested yesterday. The wealthy Japanese individual

who owns Tri-Cosmos Dev. Co. is Mr. Charly Fujiki. Attendance is

by invitation only, but let me here provide the Grupo Bufete

numbers: (723-45-78 and Fax 723-47-18 in Mexico City). The

exhibition will be in the Grupo Bufete Industrial building.The

invitation says: "Mr. Minato, the inventor, will be present to

explain and demonstrate his remarkable breakthrough in

technology to government and business leaders in Mexico. He will

also discuss the possible use (and) application for various

other industries, including a giant generator project, based on

the principal mechanism being displayed."Daily demonstrations

are from 10:30 am to Noon, 4:30 to 5:30 pm and 6 to 7:30 pm. A

block diagram of the motor indicates that it is about 500 kg. An

arrow indicates that its 500 watt output goes to a load --

schematically indicated as an array of light bulbs. The unit is

within a cube 1.2 meters on edge.The diagram shows a solar

panel(!!) providing input to the battery that powers the device

- I supposes for completeness, but that is obviously silly in

view of the claim. Vermillion assured me that this solar panel

was not an essential part of the system. One of the two color

brochures in the package shows the Minato motor with its

charactersitic coils that have their pole faces toward the

perimeters of permanent magnet containing wheels that are

stacked on an axle. If you look at the thing quickly, you'd

think you were looking at a steam turbine. The 1997 patent

#5,594,289 states in its abstract: "On a rotor which is fixed to

a rotatable rotating shaft, a plurality of permanent magnets are

disposed along the direction of rotation such that the same

magnetic pole type therof face outward. In the same way,

balancers are disposed on the rotor for balancing rotation of

this rotor. Each of the permanent magnets is obliquely arranged

with respect to the radial direction line of the rotor. At the

outer periphery of the rotor, an electromagnet is disposed

facing this rotor, with this electromagnet intermittently

energized based on the rotation of the rotor.According to the

magnetic rotating apparatus of the present invention, rotational

energy can be efficiently obtained from permanent magnets. This

is made possible by minimizing as much as possible current

supplied to the electromagnets, so that only a required amount

of electrical energy is supplied to the electromagnets." It will

be interesting, indeed, to learn what comes out of this.Perhaps

the famous white rabbit disappearing down a hole, or maybe the

birth of a revolution? We shall see.

Best wishes,

Dr. Eugene F. Mallove,

Editor-in-Chief Infinite Energy Magazine Cold Fusion Technology,

Inc. -- http://www.infinite-energy.com

P.O. Box 2816 Concord, NH 03302-2816

Ph: 603-228-4516 ~ Fax: 603-224-5975

editor@infinite-energy.com

KeelyNet: Response from STAG group on Minato Wheel

(12-04-97) ~

To: Jerry ~ From: David Heard

Subject: Re: Howdy! Thanks for your mail regarding Minato's

Rotation Aparatus. My apologies for the slight delay in

replying. Yes, please feel free to put up a link to our site and

the photos. I should explain that our group is not in any way

conected with Mr. Minato himself. The group STAG is run by

foreign scientists who are living in Japan with the aim of

distrubuting information between themselves, improving links

between Japan and the UK (and elsewhere) and of course to have

the odd beer or two. We hold meetings every couple of months and

invite speakers to speak on interesting or topical subjects. Mr.

Minato was one of the speakers who gave a presentation at one of

our meetings. Hence the pictures. I also heard about the Korean

conference, and saw a significant report written about it in the

conference proceedings (albeit in Korean!). I think it would be

really good if other people did produce similar devices. I will

pass your comments on to Mr. Minato. He did have a Web page, (in

Japanese) with information on it, but I haven't been able to

connect to it recently. Thanks again for your mail. Regards,

David Heard, Vice Chairman, STAG

At 02:46 21/11/97 -0800, you wrote:

Hello from Texas! A friend told me he saw the bicycle wheel

version at a Korean conference so I posted all the details at

KeelyNet...one of our readers found your site and informed me,

so I will put up a link to your photos.... Do you think there

will be full details on how to build the simple self-running

bicycle version posted so that others can duplicate it....this

would really set it off if these things were being shown all

over the world.... I got copies of the three patents (two by

Minato, one by Gavaletz) and have their locations posted on my

page....thanks for providing the pictures....I don't think it go

bigtime until at least a simplified version that self-runs has

beend duplicated by many others....this will set the fire that

will draw attention to the rest.....good luck, I and a lot of

others will be watching....and please congratulate Mr. Minato on

his achievement....if you would like to check out our site;

http://www.keelynet.com/index0.htm

http://www.keelynet.com/gravity/curtis.htm (the device

file)

Jerry W. Decker / jdecker@keelynet.com

http://www.keelynet.com /

Dr. David Heard

273-1 Kashiwa

Functional Device Labs. ~ Sharp Corporation

Kashiwa, Chiba 277 Japan

Tel. : 0471-34-6116 ~ Fax. :

0471-34-6119

e-mail : david@kasiwa.sharp.co.jp

From: Michael Randall --

mailto:mrandall@earthlink.net ~ To: Bill Beaty

(www.eskimo.com) ~ December 4, 1997

"Minato is going Big-Time!"

Subject: Minato's PPM Update Vortexians: Here is an

update on Kohei Minato's over-unity permanent magnet inventions.

Minato is currently having manufactured, over in Japan, a large

unit, (4) connected 10 foot long units, that can power 30 homes.

It is estimated to be finished by February. CNN is scheduled to

report on it when ready. Minato also has a home powering unit.

Both size units are based on his USA Patent 5,594,289 that uses

a battery to start and stop the unit. The USA sales

representative is Bob Vermillion and his e-mail address is:

polenetic@aol.com

No web site yet but Bob Vermillion's office is in Century City,