rexresearch.com

Norbert MUELLER

Wave Disk Engine

Wave Disk Engine

http://www.cbsnews.com/8301-501465_162-20044720-501465.html

March 18, 2011

Shock Wave Engine for Cars gets closer

Despite several attempts to take technology in a different direction, Gottlieb Daimler's century-plus-old still invention of the internal combustion engine still reigns supreme - though it's not been for a lack of trying.

In the mid-1990s, for example, the noted technology venture capitalist Ben Rosen gained attention for an ambitious plan to commercialize an engine alternative which featured a small turbogenerator and a carbon-fiber flywheel. He was even able to demo the technology for a road test. But the idea failed to catch on and after four years and $24 million down the drain, Rosen and his brother (who had co-founded Rosen Motors), decided to shut down their project after failing to interest any big automakers.

But with $4 a gallon gasoline signs moving from worst-case scenario to no big deal anymore, the impetus to invent our way out of the energy crisis remains stronger than ever. And now, a team of researchers is reporting progress for an idea featuring a prototype generator for hybrid automobile engines that does not use pistons, crankshafts or valves.

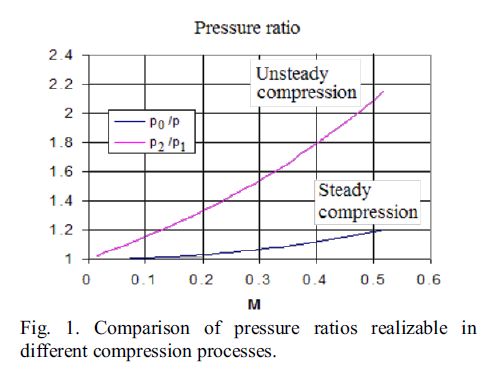

If it works as advertised, the so-called Wave Disk Engine would use shock waves to more efficiently compress fuel and transmit energy. The research team at Michigan State University claims that its prototype could potentially decrease auto emissions by up to 90 percent. The invention, which doesn't have a radiator or valve train, uses a generator connection to serve as a vehicle's engine, according to Norbert Mueller, an associate professor of Mechanical Engineering at MSU.

The idea here being that compression becomes more efficient if there are no moving parts involved in the process. The MSU team contends that their prototype thus would more efficiently process automobile fuel. What's more, they estimate it would subtract almost 1,000 pounds from the weight of a car that now gets taken up in the way of a conventional engine, transmission, cooling system, emissions, and fluids. Vehicles incorporating the system would be able to run on myriad fuels - including compressed natural gas, hydrogen, gas or renewable fuels.(You can listen to Mueller explain this in more detail in the above video filmed a couple of years ago when MSU received the grant to undertake the project).

The prototype was presented last week to the Advanced Research Projects Agency Energy,, which is backing the Michigan State University Engine Research Laboratory with $2.5 million in funding. Also, check out this 2008 paper on wave disk technology.

Numerical Investigation of the Wave Disc Micro-Engine

Concept

by

Janusz Picchna & David Dyntar

Warsaw Univ. of Technology

by

Janusz Picchna & David Dyntar

Warsaw Univ. of Technology

[

PDF ]

Video

http://www.egr.msu.edu/mueller/

Dr. Norbert Müller

Associate Professor

Michigan State University

Address: 2455 Engineering Building

East Lansing, MI 48824-1226, USA

Phone: (517) 432-9139

Fax: (517) 353-1750

Email: mueller@egr.msu.edu

Research Interests: Turbomachinery, Centrifugal Compressors -- Wave Rotors-- Refrigeration and HVAC (Heating, Ventilation, Air Conditioning) with Natural Refrigerants -- Micro-Fabricated Energy Systems such as Brayton and Rankine Cycle Devices, Heat Exchangers and Fuel Cells with integrated Nano Sensors -- Highly Efficient and Environmentally Friendly Energy Conversion Systems, Including the Use of Solar, Wind, Tidal, Geothermal Energy and Clean Fuels -- High-Speed Drives and Bearings -- Mechatronics

Additional Information:

Norbert Müller is an Assistant Professor of Mechanical Engineering at Michigan State University and chair of the ASME PID Compressor Committee. He recently became the faculty advisor of the MSU SAE chapter with Formula Team and Baja Team and the faculty advisor of the Solar Car Team. He has received his Ph.D. from Technische Universität Dresden, Germany in 1999.

His teaching interests are in the thermal-fluid science and engineering, such as gas and fluid dynamics, thermodynamics, turbomachinery, energy systems, refrigeration and HVAC and design.

His research focuses on Turbomachinery, Wave Rotors, Centrifugal Compressors, Refrigeration Systems Using Water as Refrigerant, Micro-Fabricated Energy Systems such as Brayton and Rankine cycle devices and heat exchangers. From 1993 to 1999 he worked for the industrial research center Institut für Luft- und Kältetechnik (ILK) Dresden gGmbH, the largest refrigeration & HVAC research center of its kind in Germany. There he developed a strong background in industrial research. He has also worked in Aerospace at MTU Aero Engines in Munich, Germany's leading engine manufacturer, and at Bath University in Great Britain. Just prior to joining Michigan State University, he was an Adjunct Assistant Professor for Turbomachinery and a Research Scientist at Columbia University in New York, working on Micro-Energy Systems.

Patents

METHOD FOR CONTROLLING A FUEL INJECTION SYSTEM OF AN INTERNAL COMBUSTION ENGINE

US2009105928

METHOD FOR HEATING A CATALYTIC CONVERTER

US2010024392

METHOD FOR STARTING AN INTERNAL COMBUSTION ENGINE

KR20090102770

CN101573523

METHOD AND APPARATUS FOR DETECTING A CONTINUOUS INGRESS OF FUEL INTO THE LUBRICATING OIL OF AN INTERNAL COMBUSTION ENGINE DURING COLD STARTING

US2010070152

Method for controlling warming up in internal combustion engine

DE102007054817

Catalyst heating method for exhaust gas of internal combustion engine

DE102006061694

DE102006061687

Method and Device For Monitoring a Fuel Injection Device For an Internal Combustion Engine

US2008249699

Catalyst temperature maintaining method for control device

FR2873756

Process to operate an automotive fuel injection system by checking for misfire and rectification

DE102004019780 (A1) - 2005-11-17

Controlling device for a hydromotor

EP1431627