Contact : Stan Widows

Inventive Research

Div. S.R. Widows Co. Inc.

800-357-6290

Jason Oliver

& AC Solar Generator

Inventive Research, a

Division of S. R. Widows Company, Inc., of Indiana, has patented a

way to generate AC power directly from a solar panel. Why is this

so important? It makes it possible to simply hook the solar panels

directly into the power grid without the need for expensive DC to

AC power conversion equipment. This invention, when

commercialized, will make the cost of solar power more practical

and affordable.

We’ve heard about the promise of cheap solar energy now for

decades. You’d think by now that at least in the world’s sunniest

areas all the cities would be supplementing their power with clean

renewable solar power. Sadly this is not the case.

Here’s the problem. Solar panels today produce DC power which has

to be converted to AC to be used by by most homes and businesses.

The price of solar panels combined with the price of inverters,

phase synchronizers, installation and maintenance has made the

price of solar prohibitive. Add to that the loss of power from the

different components used in the DC to AC conversion process and

it becomes even more unattractive. But what if there was a better

way?

Nearly a century ago a battle between two of America’s most

influential inventors decided the power we use today. Thomas

Edison’s inventions generated and utilized DC power and Nikola

Tesla’s inventions used his newly discovered AC power. Tesla’s AC

eventually won out because it could be transfered over long

distances more efficiently.

Jason Oliver, lead

inventor for Inventive Research is not the typical researcher;

he’s an automotive master mechanic from Indiana who more than a

decade ago developed a passion for the inventions of Tesla. He

looked for clues from how power is generated today to come up with

their newest invention, the AC generating solar panel.

Today AC power is produced for the power grid by AC generators.

The generators are powered by mechanical energy provided by water

turbines (hydro-electric) or steam turbines powered from coal,

natural gas or nuclear fuel. The mechanical energy rotates the

coils of the generator in a magnetic field to produce voltage.

Because the conductor coil of the generator flips direction during

rotation in the magnetic field the resulting voltage produced is

sinusoidal or AC.

Inventive Research replicated this sinusoidal voltage by

mechanically manipulating alternate banks of solar cells to turn

off and on. They spent many years years developing this

technology. They call it the AC Solar Generator. It’s so simple

and practical you won’t believe it hasn’t been done before, but it

hasn’t. Inventive Research and their attorneys did an exhaustive

patent search to make sure of that.

The process Inventive Research used to do this is simple but pure

genius in its application. Jason arranged modified standard solar

cells into a circular pattern mounted on a base.

Half of the cells are wired in one circuit and half in another

circuit

Mounted above the solar cells is a spinning disk powered by a DC

electric motor. The DC motor gets its power from four small DC

solar cells mounted in the corners of the base. The disk has

portals cut into it allowing light to pass through to every other

solar cell below it. As the disk spins each of the banks of solar

cells is alternately exposed to light and alternately produce

power. When the portal is half way between the two cells the

voltage cancels and drops to zero. The resulting voltage is

sinusoidal or AC. It can even be configured to produce three phase

AC power...

Combining the phase matching with the alternating current

generation is what allows the AC solar generator to create AC

power without the losses and cost associated with the AC to DC

power conversion process.

Other benfits include:

• Generates free energy from the sun

• Non-polluting energy reduces emissions: Has no direct impact on

the environment

• It’s easily scalable

• Grid-Tie systems allow you to sell excess electricity back to

the utility

• Can be installed and operated anywhere including areas of

difficult access and remote locations

• Helps get us off dependence on foreign oil

• PV cells make no noise and give off no exhaust

This is truly a transforming technology. The AC solar generator

has the potential to reduce the use of fossil fuels tremendously

if you just imagine them installed photovoltaic solar power

centers around the country generating supplemental power for the

grid.

Inventive Research is expecting to receive the final patents later

this year. If you are interested in licensing or purchasing the

patents for this technology you can contact Stan Widows at

Inventive Research a division of S.R. Widows Co. Inc. at

800-357-6290

Inventor: OLIVER JASON ALLEN

EC: IPC: H01L25/00;

H01L25/00

Abstract -- A device,

system and method for generating alternating current (a/c)

electricity directly from photovoltaic cells utilize an array of

photovoltaic cell pairs that are each connected in anti-parallel

to form an a/c junction. The system, device and method

mechanically gradually exposes and shades photovoltaic cell pairs

to sunlight to generate alternating current electricity at an a/c

junction of the solar cell pairs. Gradually and alternately

exposing and shading the two anti-parallel connected solar cells

of each solar cell pair causes the amplitude and polarity of the

electricity at the a/c junction to gradually rise and fall to

produce alternating current electricity. The gradual, alternating

exposure and shading of the two anti-parallel solar cells is

accomplished by mechanically covering and exposing the solar cell

pairs. This is efficiently accomplished by a rotating segmented

disc positioned over an array of solar cell pairs.

Description

BACKGROUND OF THE INVENTION

Field of the Invention

The present invention relates to photovoltaics (i.e. technology

and research related to the application of photovoltaic cells in

producing electricity for practical use) and, more particularly,

to devices, systems and methods for generating alternating current

electricity from photovoltaic cells.

Background Information

The demand and need for clean and renewable energy is becoming

more urgent as earth undergoes global climate changes. Generation

of electricity from coal produces over 50% of the carbon dioxide

released into the atmosphere each year. Coal and other fossil

fuels will also eventually run out. The hydroelectric power

generation of electricity is limited to places where there is an

adequate water source. Nuclear energy for the creation of

electricity has the drawback of creating nuclear waste. However,

one type of clean renewable energy is solar energy or sunlight.

Solar energy is a constant source of clean energy that can shine

on all areas of the surface of the planet. Solar energy or

sunlight can be converted into electricity by a photovoltaic cell.

A photovoltaic cell known as a solar cell captures and converts

sunlight into electricity. A solar cell is made from a

semiconducting material (a semiconductor) such as silicon that

absorbs the sunlight which generates a flow of electricity through

the solar cell. Because of the properties of semiconductors,

positive and negative terminals of the solar cell are static and

electron flow from a solar cell is uni-directional (i.e. the

electricity can only flow in one direction). Thus, as with all

photovoltaic cells, the solar cell produces only direct current

(d/c) electricity. The problem with direct current electricity is

that direct current electricity is difficult to transmit any

appreciable distance, which limits its use. Thus, alternating

current electricity is more usable than direct current

electricity. Moreover, most electrical devices utilize alternating

current (a/c) electricity.

Various prior art devices have attempted to provide suitable

alternating current electricity from photovoltaic or solar cells.

For instance, U.S. Patent No. 4,075,034 issued to Butler on

February 21 , 1978 (hereinafter, "Butler") provides a solar

converter for producing variable amplitude alternating current

waveforms directly from solar energy by using a photo-voltaic cell

bank array formed of a plurality of weighted photo-voltaic

segments. A multi-sided high speed, rotating and light

concentrating concave mirror system provides light on and past the

weighted segments of the photo-voltaic bank to produce

instantaneous output which are proportional to the number of cells

scanned in each segment. A simulated alternating current (a/c)

waveform is produced by suitable arrangement of the photo-voltaic

segments. The simulated a/c waveform of Butler and its fragile

manner (glass mirrors) of producing the simulated a/c waveform by

the high speed rotating mirror is not efficient. Moreover, Butler

is not easily scalable to produce larger voltages/amperes nor is

it relatively maintenance free. In U.S. Patent Publication No.

2005/0034750 by Rabinowitz published February 17, 2005

(hereinafter, "Rabinowitz"), a solar cell alternating current

generator is provided that uses a dynamic spinning ensemble of

mini-mirrors to both concentrate and modulate rays from the sun

onto a photovoltaic collector array. The focusing and superimposed

spinning action produces single phase and multiphase alternating

current electricity. The problem with Rabinowitz is again, the use

of glass mirrors, the need for focusing the mini-mirrors and

maintain their high speed spinning is not efficient.

In U.S. Patent No. 6,774,299 issued to Ford on August 10, 2004

(hereinafter, "Ford"), a solar alternating current electricity

generator is provided that utilizes a rotating, partitioned array

of photovoltaic cells. Contact brushes and wiring are provided to

transfer the electric current to an applied load. The drawback to

Ford is the need for contact brushes and wiring to generate the

alternating current electricity. Moreover, the rotating

photovoltaic cell vanes of Ford are not efficient.

In U.S. Patent No. 4,728,878 issued to Anthony on March 1 , 1988

(hereinafter, "Anthony"), a solar energy electric generating

system is provided for space vehicles which directly generates

alternating current from ambient light without power conversion.

Light incident to photocell arrays is mechanically or electrically

gated to produce fluctuating direct current (d/c) electricity. A

number of transforming devices are provided to convert the

fluctuating d/c current to alternating current (a/c). Through

variation of the frequency and duty cycle of the pulsing output

voltage, frequency and phase relative to a reference may be

controlled. However, with the Anthony solar energy electric

generating system, the mechanical gating provides a square wave

that is then conditioned to provide an alternating current

waveform.

Last, in U.S. Patent No. 4,577,052 issued to Schutten et al. on

Mach 18, 1986 (hereinafter, "Schutten"), an alternating current

solar cell is provided by connecting solar cells (P/N junctions)

in anti-parallel between a pair of main terminals. Light is

provided alternately on the P/N junctions through a mirror system

that splits the beam and causes the split beam to impinge on the

P/N junctions.

It is clear from the above that the prior art devices for

generating alternating current electricity directly from

photovoltaic or solar cells are complicated, difficult to align

and maintain, and cannot provide adequate scaling for small and

large a/c current production.

In view of the above, it is desirable to have a solar powered

alternating current (a/c) electricity generator, system and method

that produces single or multi-phase a/c electricity that is

simple, efficient and easily scalable in voltage and/or amperage.

SUMMARY OF THE INVENTION

The present invention is a system, device and method for directly

generating alternating current electricity from photovoltaic

cells. The system, device and method mechanically gradually

exposes and shades photovoltaic cell pairs connected in

anti-parallel to sunlight to generate alternating current

electricity at an a/c junction of the solar cell pairs. Gradually

and alternately exposing and shading the two anti-parallel

connected solar cells of each solar cell pair causes the amplitude

and polarity of the electricity at the a/c junction to gradually

rise and fall to produce alternating current electricity. The

gradual, alternating exposure and shading of the two anti-parallel

solar cells is accomplished by mechanically covering and exposing

the solar cell pairs.

In particular, while one solar cell of an anti-parallel connected

solar cell pair undergoes gradual exposure to sunlight from 0%

exposure (100% shaded) of the solar cell electricity generating

area to 100% exposure (0% shaded) of the solar cell electricity

generating area, the other solar cell of the solar cell pair

undergoes gradual shading from sunlight from 0% shaded (100%

exposure) to 100% shaded (0% exposure). Such gradual, alternating

exposure and covering of each solar cell of each anti-parallel

connected solar cell pair is periodic. The rate of exposure and

shading determines frequency.

In one form, a rotating disc situated over the solar cell pairs

has spaced apart openings forming coverings between each opening

to alternately expose and shade the solar cell pairs during

rotation. A direct current motor is utilized to rotate the

segmented disc. The motor is preferably powered by separate solar

cells.

The present invention also provides a phase synchronizer for

maintaining a desired alternating current frequency. The phase

synchronizer controls the motor to control rotation of the

segmented disc.

The present invention makes solar energy a viable, cost effective,

environmentally friendly option for residential and/or commercial

use. The present invention is capable of being used on a minute,

small or large scale through appropriate scaling the solar cell

a/c electricity generator and/or the use of a plurality thereof.

Solar cell a/c electricity generator arrays can easily produce the

power equivalent to an average power plant today, while being

environmentally friendly enough to be located proximate a

playground, school or in any urban environment. Large scale solar

cell a/c electricity generator arrays can be easily set up even in

the most remote places in the world. The present invention reduces

the need of other forms of power. Moreover, the present solar cell

a/c electricity generator can be set up and used anywhere.

It is thus an object of the present invention to produce

alternating current electricity of specific frequencies, single or

three phase, from solar cells in a cost efficient and simple

manner.

BRIEF DESCRIPTION OF THE DRAWINGS

The above mentioned and other features, advantages and objects of

this invention, and the manner of attaining them, will become

apparent and the invention itself will be better understood by

reference to the following description of an embodiment of the

invention taken in conjunction with the accompanying drawings,

wherein:

Fig. 1 is a perspective

view of a photovoltaic alternating current (a/c) electricity

generator fashioned in accordance with the principles of the

present invention;

Fig. 2 is a lower

perspective view of the photovoltaic a/c electricity generator of

Fig. 1 taken from another side of the generator;

Fig. 3 is a perspective

view of the photovoltaic a/c electricity generator of Fig. 1 with

the rotating disk thereof removed;

Fig. 4 is a perspective view of the rotating disk of the

photovoltaic a/c electricity generator of Fig. 1 ;

Fig. 5 is a schematic view

of the underside connections of the photovoltaic a/c electricity

generator of Fig. 1 ;

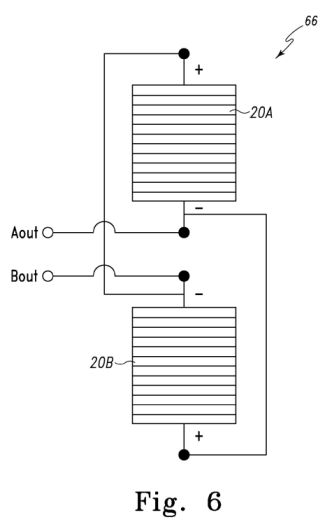

Fig. 6 is a diagram illustrating the anti-parallel

connection of a photovoltaic cell pair as used in the photovoltaic

a/c electricity generator of Fig. 1 ;

Fig. 7 is a diagram illustrating the parallel connection

of an exemplary photovoltaic cell pair array as may be used in the

photovoltaic a/c electricity generator of Fig. 1 ;

Fig. 8A is a first diagram in a sequence of

representative diagrams illustrating the manner of generating a/c

electricity from a photovoltaic cell pair of a photovoltaic cell

pair array of the photovoltaic a/c electricity generator of Fig. 1

;

Fig. 8B is a second diagram in the sequence of

representative diagrams illustrating the manner of generating a/c

electricity from a photovoltaic cell pair of a photovoltaic cell

pair array of the photovoltaic a/c electricity generator of Fig. 1

; Fig. 8C is a third diagram in the sequence of representative

diagrams illustrating the manner of generating a/c electricity

from a photovoltaic cell pair of a photovoltaic cell pair array of

the photovoltaic a/c electricity generator of Fig. 1 ;

Fig. 8D is a fourth diagram in the sequence of

representative diagrams illustrating the manner of generating a/c

electricity from a photovoltaic cell pair of a photovoltaic cell

pair array of the photovoltaic a/c electricity generator of Fig. 1

;

Fig. 8E is a fifth diagram in the sequence of

representative diagrams illustrating the manner of generating a/c

electricity from a photovoltaic cell pair of a photovoltaic cell

pair array of the photovoltaic a/c electricity generator of Fig. 1

;

Fig. 9 is a schematic diagram of an exemplary phase

synchronizer as used in the photovoltaic a/c electricity generator

of Fig. 1 ; and

Fig. 10 is a flow chart illustrating a logic diagram of

an exemplary embodiment of the phase synchronizer of the

photovoltaic a/c electricity generator of Fig. 1.

Like reference numerals indicate the same or similar parts

throughout the several figures.

A description of the features, functions and/or configuration of

the components depicted in the various figures will now be

presented. It should be appreciated that not all of the features

of the components of the figures are necessarily described. Some

of these non discussed features as well as discussed features are

inherent from the figures. Other non discussed features may be

inherent in component geometry and/or configuration.

DETAILED DESCRIPTION OF AN

EMBODIMENT OF THE INVENTION

Referring to Figs. 1-5, there is depicted various views of an

exemplary embodiment of a photovoltaic alternating current (a/c)

electricity generator, generally designated 10, fashioned in

accordance with the present principles. The photovoltaic a/c

generator 10 is embodied as a solar cell a/c electricity generator

10, but it should be appreciated that a photovoltaic a/c

electricity generator fashioned in accordance with the present

principles may use photovoltaic cells other than solar cells.

The solar cell a/c electricity generator 10 has a base, frame or

other mounting structure 12 ("base 12") that supports the various

components thereof. The base 12 may be formed of wood, plastic or

other suitable material which is preferably, but not necessarily,

a non conducting material. It should be understood that while the

base 12 is shown as a box or a box-like structure, the base may be

a substrate, board or other suitable mounting or supporting

structure. The base 12 includes an alternating current (a/c)

electricity production portion 14 formed by a disk 15 and a

plurality of photovoltaic or solar cells 20 (hereinafter, "solar

cells 20"). As best seen in Fig. 3, the plurality of solar cells

20 is arranged in a generally circular array 21 on an upper

surface 13 of the base 12. It should be appreciated that arrays

other than circular may be used within the present principles. It

should also be appreciated that while the solar cells 20 are shown

as rectangles, the size and shape of the solar cells 20 may be

otherwise, such as truncated conical, triangular, polygonal or

square.

As best seen in Fig. 4, the disc 15 has a generally flat body made

of a sunlight blocking material that is generally the

circumference of the solar cell array 21 in order to extend over

the solar cell array 21 when in use (see, e.g., Figs. 1 and 2).

The disc 15 is also preferably made of a lightweight material that

resists warping or is not susceptible to warping. The disc 15 is

preferably reflective either inherently or via a coating, film,

overlay or the like. It should be appreciated that the disc 15 may

be partially reflective or non-reflective if desired. The disc 15

has a plurality of cutouts, openings, windows or the like 16

("cutouts 16") formed thereabout. The size and shape of the

cutouts 16 generally correspond to the size and shape of the solar

cells 20 and particularly is sized and shaped to allow total

exposure of a solar cell 20 to sunlight when the cutout 16 is

positioned over the solar cell 20. The cutouts 16 are situated and

spaced on the disc 15 so as to define a plurality of covers,

coverings, blocks or the like 18 ("coverings 18"). The coverings

18 are sized and shaped to completely cover or block a solar cell

20 when the covering is over the solar cell 20.

The cutouts 16 and coverings 18 are alternately radially situated

about the disc 15. The number of cutouts 16 corresponds by 1 /2 to

the number of solar cells 20 so that the number of coverings 18

corresponds by 1/2 to the number of solar cells 20. Therefore,

when the disc 15 is situated on frame 12 and over the solar cell

array 21 , the cutouts 16 and coverings 18 expose 1/2 of the total

solar cell array area and cover 1/2 of the total solar cell array

area. As the disc 15 rotates over the array 21 of solar cells 20,

the cutouts 16 and coverings 18 continuously gradually expose and

cover the array of solar cells.

The disc 15 is rotated over the solar cell array 21 by a direct

current motor 26 (see, e.g., Fig. 3) that is supported by the base

12. Rotation may be either clockwise or counterclockwise. A

counterclockwise rotation of the disc 15 is represented in the

figures by the curved arrow(s). The motor 26 is coupled to a phase

synchronizer 40 via a motor connection 44 (see Fig. 5). The phase

synchronizer 40 provides control/control signals to the motor 26

for varying the rotational speed of the disc 15. Rotational speed

of the disc 15 determines the frequency of resultant alternating

current(s) from the solar cell a/c electricity generator 10.

Additionally, the phase synchronizer 40 determines phase of the

resultant a/c electricity relative to a predetermined phase or

phase value (e.g. 60Hz) and causes the motor 26 to speed up or

slow down if necessary. The motor 26 is powered by photovoltaic

(solar) cells 22 that are situated on the base 12 so as to be

continuously exposed to any sunlight. As best depicted in Fig. 5,

the solar cells 22 are connected via connectors 23 to provide the

proper voltage and amperage to the motor 26 and motor controller

of the phase synchronizer 40) for properly operating the motor 26

for rotation of the disc 15. If desired, rechargeable batteries 28

may be connected to the phase synchronizer 40 that charge with

energy from the solar cells 22 and provide startup energy for the

motor 26.

The solar cell a/c electricity generator 10 may include a power

on/off switch 11 for making the solar cell a/c electricity

generator 10 operable or not operable. Alternately, or in

addition, the solar cell a/c electricity generator 10 may include

a light sensor 42 (shown in Fig. 5) that senses when sunlight is

present to then turn on the solar cell a/c electricity generator

10. Other configurations may be used.

As can be discerned from Figs. 1 and 2, rotation of the disc 15

causes the cutouts 16 and coverings 18 to alternately expose and

cover adjacent solar cells 20. The faster that the solar cells 20

are exposed and covered (rotation speed of the disc 15), the

higher the frequency of a/c electricity produced. The slower that

the solar cells 20 are exposed and covered (rotation speed of the

disc 15), the lower the frequency of the a/c electricity produced.

Since the solar cells are wired in anti-parallel, an alternating

current is generated between the a/c junction of the solar cell

pairs as the solar cell pairs are alternately, gradually exposed

and covered. Alternately stated, the total solar cell area of a

solar cell pair comprises 100% where one solar cell of the solar

cell pair defines 50% of the total area and the other solar cell

of the solar cell pair defines the other 50% of the total area.

The one solar cell of an anti-parallel connected solar cell pair

undergoes gradual exposure to sunlight from 0% exposure (100%

shaded) of the solar cell electricity generating area to 100%

exposure (0% shaded) of the solar cell electricity generating

area, the other solar cell of the solar cell pair undergoes

gradual shading from sunlight from 0% shaded (100% exposure) to

100% shaded (0% exposure). Such gradual, alternating exposure and

covering of each solar cell of each anti-parallel connected solar

cell pair is periodic.

This periodic sequence is illustrated in Figs. 8A through 8E.

Figs. 8A through 8E are a representation of the manner in which

two solar cells of a solar cell pair are alternately, gradually

exposed and covered to produce an a/c waveform. The principles of

the present invention are applicable to any connection

configuration of solar cell pairs, whether opposite one another as

in Figs. 8A through 8E, or adjacent one another as in Fig. 3.

Fig. 8A is an arbitrary beginning to the sequence wherein there is

represented a negative current at the output terminals Aout and

Bout of the solar cell pair, at its peak negative amplitude. In

Fig. 8A, solar cell 2OB of a solar cell pair is 100% exposed (0%

covered) while solar cell 2OA is 0% exposed (100% covered).

Particularly, a cutout 16 is fully over the solar cell 2OB thus

fully exposing solar cell 2OB, while at the same time, a covering

18 is fully over the solar cell 2OA thus fully shading (covering

or blocking) the solar cell 2OA. A peak negative current is thus

provided at output terminals Aout and Bout which is shown on the

graph of Fig. 8A as current point isA- In Fig. 8B of the sequence,

the rotating disc 15 has moved slightly counterclockwise such that

the opening 16 that was totally exposing the solar cell 2OB is now

exposing only 1/2 (and/or covering 1/2) of the area of the solar

cell 2OB, while the covering 18 that was totally shading the solar

cell 2OA is now covering only 1/2 (and/or exposing 1/2) of the

area of the solar cell 2OA. This results in a zero (0) current at

the output terminals Aout and Bout as shown on the graph of Fig.

8B as current point isB- It should be appreciated that the

rotational movement of the disc 15 from point shown in Fig. 8A to

that shown in Fig. 8B gradually exposes and covers the solar

cells, as described above, to create the gradual and not stepped

a/c waveform as depicted in the graph of Fig. 8B.

In Fig. 8C of the sequence, the rotating disc 15 has moved further

slightly counterclockwise. In Fig. 8C, solar cell 2OA of a solar

cell pair is now 100% exposed (0% covered) while solar cell 2OB is

now 0% exposed (100% covered). A cutout 16 is fully over the solar

cell 2OA thus fully exposing solar cell 2OA, while at the same

time, a covering 18 is fully over the solar cell 2OB thus fully

shading (covering or blocking) the solar cell 2OB. A peak positive

current is thus provided at output terminals Aout and B0Ut which

is shown on the graph of Fig. 8A as current point i8C. Again, it

should be appreciated that the rotational movement of the disc 15

from point shown in Fig. 8B to that shown in Fig. 8C gradually

exposes and covers the solar cells, as described above, to create

the gradual and not stepped a/c waveform as depicted in the graph

of Fig. 8C.

In Fig. 8D of the sequence, the rotating disc 15 has moved further

slightly counterclockwise such that the opening 16 that was

totally exposing the solar cell 2OA is now exposing only 1/2

(and/or covering 1/2) of the area of the solar cell 2OA, while the

covering 18 that was totally shading the solar cell 2OB is now

covering only 1/2 (and/or exposing 1/2) of the area of the solar

cell 2OB. While opposite to that of Fig. 8B, this results in a

zero (0) current at the output terminals Aout and Bout as shown on

the graph of Fig. 8D as current point i8D. Again, it should be

appreciated that the rotational movement of the disc 15 from point

shown in Fig. 8C to that shown in Fig. 8D gradually exposes and

covers the solar cells, as described above, to create the gradual

and not stepped a/c waveform as depicted in the graph of Fig. 8D.

Lastly, in Fig. 8E of the sequence, the disk has moved further

counterclockwise such that a cutout 16 has moved fully over solar

cell 2OB such that solar cell 2OB is again 100% exposed (0%

covered) while a covering 18 has again moved fully over the solar

cell 2OA such that the solar cell 2OA is 0% exposed (100%

covered). Particularly, the cutout 16 is fully over the solar cell

2OB thus fully exposing solar cell 2OB, while at the same time, a

covering 18 is fully over the solar cell 2OA thus fully shading

(covering or blocking) the solar cell 2OA. A peak negative current

is thus again provided at output terminals Aout and Bout which is

shown on the graph of Fig. 8E as current point i8E- Again, it

should be appreciated that the rotational movement of the disc 15

from point shown in Fig. 8D to that shown in Fig. 8E gradually

exposes and covers the solar cells, as described above, to create

the gradual and not stepped a/c waveform as depicted in the graph

of Fig. 8E. Fig. 8E completes a full cycle of the a/c waveform.

Referring back to Fig. 3, the total number of solar cells 20 must

be an even number since two solar cells 20 are utilized to provide

a solar cell pair having a single a/c junction. Multiple solar

cell pairs are connected together to increase the voltage or

amperage depending on the connection. Connection of all of the

solar cell pairs of the array 21 produces a single phase a/c

waveform. The solar cell pairs may use three connected banks of

solar cells pairs to achieve a three-phase a/c waveform. In Fig.

3, since the total number of solar cell pairs is fifteen (15) they

all can be connected to form a single phase a/c waveform, or they

can be divided into three (3) banks of five (5) solar cell pairs

each to achieve a three-phase a/c/ waveform.

Referring additionally to Fig. 6, a solar cell pair 66 of solar

cells 2OA and 2OB is shown. As can be seen, the solar cell pair 66

is connected in anti-parallel to provide an a/c junction (i.e. two

a/c output terminals Aout and Bout)- Particularly, the positive

terminal of the solar cell 2OB is connected to the negative

terminal of the solar cell 2OA, while the positive terminal of the

solar cell 2OA is connected to the negative terminal of the solar

cell 2OB. It should be appreciated that Fig. 6 is illustrative of

the manner in which solar cell pairs 66 are connected and form an

a/c junction. Other configurations are contemplated. In Fig. 3 for

example, two adjacent solar cells 20 are connected in

anti-parallel to provide a solar cell pair such that junctions 60

and 61 (as seen in Figs. 3 and 5) correspond to the two a/c output

terminals Aout and Bout-

A single solar cell pair 66 may be used to create a/c electricity

utilizing an appropriately fashioned rotating disc. A single solar

cell pair would thus produce a single phase a/c waveform. Three,

single solar cell pairs can produce a three-phase a/c waveform.

Multiple, single solar cell pairs can produce a multi-phase a/c

waveform. However, to generate a 60 Hz a/c waveform, the disc

(having only a single cutout) would have to spin at a rate of

sixty revolutions per second. Therefore, multiple solar cell pairs

may be connected together to provide a single a/c junction. This

allows voltage and amperage to be increased as desired since the

number of such series or parallel connected solar cells is

unlimited, as well as slow down the rate of revolution of the disc

15.

Referring to Fig. 7, the array 21 is shown connected for a single

phase a/c waveform wherein any number of solar cells represented

by solar cells 20Ai, 20A2, 20A3, 20A4, 20A5 through 20An are

coupled to form the single a/c junction terminal Aout, while any

number of solar cells represented by solar cells 20B1, 20B2, 20B3,

20B4, 20B5 through 20Bn are coupled to form the single a/c

junction terminal Bout> thereby forming a "solar cell pair".

The solar cells 20 are shown connected in parallel to increase the

amperage and maintain the voltage. Connecting the solar cells 20

in series would increase the voltage and maintain the amperage. In

Fig. 3, the solar cell array 21 is wired to produce single phase

a/c electricity. Each solar cell pair of the array 21 has the

first and second a/c junctions 60, 61 which can be seen in Fig. 5

to be connected to provide a single a/c junction 56, 58. As such

one of the output terminals 46, 48 would provide the single phase

a/c electricity.

The connections 24 to and from the phase synchronizer 40, as best

discerned in Fig. 5, provide a/c output from the phase

synchronizer and signal input to the phase synchronizer. Terminals

46 and 48 provide a/c electricity output. Terminal 51 provides a

shared signal input, while terminal 52 provide a commercial signal

input. These can be used by the phase synchronizer to regulate the

present a/c generator.

Fig. 9 is a schematic of an exemplary embodiment of the motor

control portion of the phase synchronizer 40. Motor speed is

controlled in order to adjust the rotation rate of the disc 15 to

provide a correct phase. As discerned in Figs. 2 and 3, the

present solar cell a/c electricity generator 10 includes three (3)

photo or opto transistors 30, 32, and 34 that are situated

proximate one solar cell 20. Particularly, a first phototransistor

30 is positioned ahead of the solar cell 2Op (see Fig. 3) as per

counterclockwise rotation of the disc 15. A second phototransistor

32 is positioned at the middle of the solar cell 2Op, while a

third phototransistor 34 is positioned at the end of the solar

cell 2Op. The first, second and third phototransistors 30, 32, 34

work to provide a signal to control the motor which controls the

rate of rotation of the disc 15 which controls the frequency of

the generated a/c electricity. Although 60 Hz is shown as an input

(a predetermined operating frequency) to the phase synchronizer,

other frequencies can be generated and synchronized by the present

solar cell a/c electricity generator 10. The inputted signal

provides power for the phototransistors 30, 32, 34 through

transistor Ti . The phototransistors detect phase of the waveform

through rotation of the disc 15 and, particularly the cutouts 16

and/or the coverings 18 relative to the phototransistors 30, 32,

34. The phototransistor 30 provides a slow phase signal, the

phototransistor 32 provides an in-phase signal, while the

phototransistor 34 provides a fast phase signal. The

phototransistors provide their signals to the signal conditioning

network TN which, in turn, provides a signal to the motor 26.

Phototransistor 30 connects through transistor T2, while

phototransistor 34 connects through transistor T3. An in-phase LED

68 is provided for indicated when the waveform is in phase. As

well, a bank of LEDs 770 may be provided to provide visual

indication of phase. It should also be appreciated that the

resistor Ri and R2 may be variable resistors if desired to provide

adjustment to the signal conditioning network TN.

Fig. 10 is a flow chart 100 of an exemplary manner of operation of

the present solar cell a/c electricity generator 10. Through use

of the photocell 42, the light intensity is checked via the light

sensor 102. If there is low light or no light, the generator 10

goes into a timed standby 104. At the end of the standby period,

light intensity is checked again 102. If there is sufficient

light, the phase choice is started 106. It should be appreciated

that the check light intensity portion may be excluded when there

is a switched on and off. After the start of phase choice 106, it

is determined whether a commercial signal is detected 108. If no,

then it is determined whether it is a shared signal 110. If yes

then on to motor control 114. If no, then it is determined whether

the signal is an internal signal 112. Motor control 114 is then

started if it is. If a commercial signal is detected at 108, then

motor control 114 is started.

Once motor control is started, it is determined whether phase

match is reached 116. If yes, then the generator 10 will connect

to a load 118. If no, then phasing is adjusted 120. Thereafter, it

is determined when phase match is reached in order to connect to

load 118. Also, there may be a periodic check or ongoing check to

determine phase match with a possible disconnect of the load if

phase match is not occurring.

It should also be appreciated that the present solar cell a/c

electricity generator 10 may be one of a plurality of solar cell

a/c electricity generators that can form a power station or any

wattage assembly. A plurality of solar cell a/c electricity

generators may be connected as desired to provide various power

configurations.

While the invention has been illustrated and described in detail

in the drawings and foregoing description, the same is to be

considered as illustrative and not restrictive in character, it

being understood that only a preferred embodiment has been shown

and described and that all changes and modifications that come

within the spirit of the invention are desired to be protected.