rexresearch.com

Gerald POLLACK

Structured Water

Structured Water

Videos

Dr. Mercola : Exclusion Zone Water

US2014137914 : METHOD AND SYSTEM FOR GENERATING ELECTRICAL ENERGY FROM WATER

US2011097218 : METHOD AND APPARATUS FOR GENERATING A FLUID FLOW

US2011036780 : METHOD AND APPARATUS FOR COLLECTING FRACTIONS OF MIXTURES, SUSPENSIONS, AND SOLUTIONS OF NON-POLAR LIQUIDS

US 7819259 / US7793788 : SEPARATING COMPONENTS OF AQUEOUS MIXTURES, SUSPENSIONS, AND SOLUTIONS

http://www.structuredwaterunit.com/Dr_Gerald_Pollack.html

Dr. Gerald Pollack and Structured

Water Science

Dr. Gerald Pollack, University of Washington professor of bioengineering, has developed a theory of water that has been called revolutionary. He has spent the past decade convincing worldwide audiences that water is not actually a liquid.

Dr. Pollack received his PhD in biomedical engineering from the University of Pennsylvania in 1968. He then joined the University of Washington faculty and is now professor of bioengineering. For years, Dr. Pollack had researched muscles and how they contract. It struck him as odd that the most common ideas about muscle contraction did not involve water, despite the fact muscle tissue consists of 99 percent water molecules.

Water Research happens at Pollack Laboratories, which states, "Our orientation is rather fundamental -- we are oriented toward uncovering some of nature's most deeply held secrets, although applications interest us as well."

Uncovering nature's secrets involving water is what Dr. Pollack, his staff and students do best.

In his 2001 book, "Cells, Gels and the Engines of Life," Dr. Pollack explains how the cell functions. Research suggests that much of the cell biology may be governed by a single unifying mechanism - the phase transition. Water is absolutely central to every function of the cell - whether it's muscle contraction, cells dividing, or nerves conducting, etc.

This extraordinary book challenges many of the concepts that have been accepted in contemporary cell biology. The underlying premise of this book is that a cell's cytoplasm is gel-like rather than an ordinary aqueous solution.

The key to Dr. Pollack's entire hypothesis lies in the properties of water. The water molecules become structured in arrays or strata when they interact with charged surfaces such as those presented by proteins. The cell's water is potentially structured. Water stays put in the cells because it's absorbed into the protein surfaces. Structured water adheres to the proteins of the cells.

Structured water does not have the same properties as bulk water. Water is the carrier of the most important molecules of life, like proteins and DNA. In the book, "Cells, Gels and the Engines of Life," evidence is presented that shows water is absolutely essential to everything the cell does. The water in our cells is not like water in a glass. It's actually ordered pretty much like a crystal. Like ice, it excludes particles and solutes as it forms. The space formed is called an exclusion zone (EZ).

Evidence that exclusion zone water/structured water is physically different from bulk water (H2O) :

Structured water forms an exclusion zone

that excludes particles and solutes.

Dr. Pollack discovered a new phase of water. Bulk Water is H2O but this new phase of water, the exclusion zone structured water, is H3O2. It's a newly discovered phase of water. If you count the number of hydrogen's and oxygen's, you find out it's not H2O.

Structured water is hexagonal crystalline structure between liquid water and crystal.

Hexagonal structured crystal sheet

H3O2 molecular level

Structured Water forms (honeycomb) hexagonal sheets very similar to ice because it's the next phase! Structured Water (liquid crystalline) is H3O2 . . . the fourth phase of water. It's a transition stage between water and ice.

The Fourth Phase of Water / EZ Water / Structured Water

The reason this fourth phase of water is called the exclusion zone or EZ is because the first thing Dr. Pollack's team discovered is that it profoundly excludes things. Even small molecules are excluded from structured water. Surprisingly, structured water appears in great abundance, including inside most of your cells. Even your extracellular tissues are filled with this kind of water.

Where can we get structured water?

Spring water -- under pressure (deep in the ground) becomes structured.

Glacial melt -- ice turns into Structured Water (EZ water) when melting . . . The phase between liquid and solid is structured water.

Vortexing -- A vortex occurs naturally in nature, as in streams, rivers, waterfalls, etc. The vortex is a kind of mechanical perturbation or agitation. Vortexing is a very powerful way of increasing structure. There are devices on the market which vortex water. One such device is the Natural Action Structured Water Unit.

Juicing -- is water that comes from the plant cells. Structured juice water!

Antioxidents -- Most of the tissues in our body are negative. Our cells are a negative charge; oxidants are a positive charge. Antioxidents maintain the negative charge in our body.

Sunlight -- critical to our health. Light builds Structured Water (EZ water.)

Circulation -- Red blood cells work their way through capillaries; light is the driver of flow. Add light and flow increases. Something other than the heart (pressure) is driving the blood.

Infared light -- energy is generated everywhere. It drives the processes in your body.

The fourth phase of water: starts with the basics of what we know about water . . . from simple experiments we figure out this fourth phase of water. What's the nature of this fourth phase? Why is this interesting? It applies to everything water touches. It's in the sky and the clouds. It's in the oceans, lakes and rivers, and it fills the inside of our body.

Sources:

Pollack, Gerald H., PhD. Cells, Gels, and the Engines of Life. Seattle. Ebner and Sons Publishers. 2001. Print.

Dr. Pollack's science and testing methods:

Pollack, Gerald H., PhD. The Fourth Phase of Water, Beyond Solid, Liquid, and Vapor. Seattle. Ebner and Sons. Publishers. 2013. Print.

Over the years Dr. Pollack has compiled a list of over 200 publications. His 1990 book, Muscles and Molecules: Uncovering the Principles of Biological Motion, won an Excellence Award from the Society for Technical Communication; his more recent book, "Cells, Gels and the Engines of Life," won the Societies Distinguished Award. In 2008, he was selected to receive the University of Washington's highest singular distinction: the Annual Faculty Lecturer Award.

Videos

http://www.youtube.com/watch?v=XVBEwn6iWOo

Water, Energy, and Life: Fresh Views From the Water's Edge.

http://www.youtube.com/watch?v=i-T7tCMUDXU

The Fourth Phase of Water: Dr. Gerald Pollack at TEDxGuelph

http://articles.mercola.com/sites/articles/archive/2013/08/18/exclusion-zone-water.aspx

Exclusion Zone Water

by

Dr. Mercola

by

Dr. Mercola

Water is clearly one of the most important factors for your health—especially when you consider that your body actually consists of over 99 percent water molecules! I sincerely believe water is a really underappreciated part of the equation of optimal health.

I’ve previously interviewed Dr. Gerald Pollack, who is one of the leading premier research scientists in the world when it comes to understanding the physics of water, and what it means to your health.

Besides being a professor of bioengineering at the University of Washington, he’s also the founder and editor-in-chief of a scientific journal called Water, and has published many peer-reviewed scientific papers on this topic. He’s even received prestigious awards from the National Institutes of Health.

His book, The Fourth Phase of Water: Beyond Solid, Liquid, and Vapor, is a phenomenal read that is easy to understand even for the non-professional.

It clearly explains the theory of the fourth phase of water, which is nothing short of ground-breaking. The fourth phase of water is, in a nutshell, living water. It’s referred to as EZ water—EZ standing for “exclusion zone”—which has a negative charge. This water can hold energy, much like a battery, and can deliver energy too.

For years, Dr. Pollack had researched muscles and how they contract, and it struck him as odd that the most common ideas about muscle contraction do not involve water, despite the fact that muscle tissue consists of 99 percent water molecules.

How could it be that 99 percent of the molecules were ignored? How could it be that muscle contracts without involving the water in some way? These questions help catalyze his passionate investigation into water.

So You Think You Understand Water?

Gilbert Ling, who was a pioneer in this field, discovered that water in human cells is not ordinary water (H2O), but something far more structured and organized.

“I began to think about water in the context of biology: if water inside the cell was ordered and structured and not bulk water or ordinary water as most biochemists and cell biologists think, then it is really important,” Dr. Pollack says.

Dr. Pollack’s book also touches on some of the most basic features of water, many of which are really not understood. For example, how does evaporation take place? Why does a tea kettle whistle? Also, despite the fact that conventional science tells us freezing is supposed to occur at zero degrees Celsius, experiments show that it can freeze in many different temperatures down to minus 50 degrees Celsius.

There’s actually no one single freezing point for water! Other experiments show that the boiling point of 100 degrees Celsius (or 212 degrees Fahrenheit) does not always hold true either.

“There’s a famous website1 put together by a British scientist, Martin Chaplin. Martin lists numerous anomalies associated with water,” Dr. Pollack says. “In other words, things that shouldn’t be according to what we know about water...

The more anomalies we have, the more we begin to think that maybe there’s something fundamental about water that we really don’t know. That’s the core of what I’m trying to do. In our laboratory at the University of Washington, we’ve done many experiments over the last decade. These experiments have clearly shown the existence of this additional phase of water.”

The reason this fourth phase of water is called the exclusion zone or EZ is because the first thing Dr. Pollack’s team discovered is that it profoundly excludes things. Even small molecules are excluded from EZ water. Surprisingly, EZ water appears in great abundance, including inside most of your cells. Even your extracellular tissues are filled with this kind of water.

The Water in Your Cells Give Them Their Negative Charge

Other inherent differences between regular water and EZ water include its structure. Typical tap water is H2O but this fourth phase is not H2O; it’s actually H3O2. It’s also more viscous, more ordered, and more alkaline than regular water, and its optical properties are different. The refractive index of EZ water is about 10 percent higher than ordinary water. Its density is also about 10 percent higher, and it has a negative charge (negative electrical potential). This may provide the answer as to why human cells are negatively charged. Dr. Pollack explains:

“Everybody knows that the cell is negatively charged. If you insert an electrode into any of your cells, you’ll measure a negative electrical potential. The textbook says that the reason for this negative electrical potential has something to do with the membrane and the ion channels in the membrane.

Oddly, if you look at a gel that has no membrane, you record much the same potential – 100 millivolts or 150 millivolts negative. The interior of the cell is much like a gel. It’s kind of surprising that something without a membrane yields the same electrical potential as the cell with a membrane.

That raises the question: where does this negativity come from? Well, I think the negativity comes from the water, because the EZ water inside the cell has a negative charge. The same is true of the gel—the EZ water in the gel confers negativity. I think the cells are negatively charged because the water inside the cell is mainly EZ water and not neutral H2O.”

What Creates or Builds EZ Water?

One of the greatest surprises is that the key ingredient to create EZ water is light, i.e. electromagnetic energy, whether in the form of visible light, ultraviolet (UV) wavelengths and infrared wavelengths, which we’re surrounded by all the time. Infrared is the most powerful, particularly at wavelengths of approximately three micrometers, which is all around you. The EZ water can build on any hydrophilic or water-loving surface when infrared energy is available.

It builds by adding layer upon layer of EZ water, and can build millions of molecular layers. This is how it occurs in nature. For example, ice doesn’t form directly from ordinary H2O. It goes from regular water to EZ water to ice. And when you melt it, it goes from ice to EZ water to regular water. So EZ water is an intermediate state.

“Glacial melt is a perfect way to get EZ water. And a lot of people have known that this water is really good for your health,” Dr. Pollack says.

Testing water samples using a UV-visible spectrometer, which measures light absorption at different wavelengths, Dr. Pollack has discovered that in the UV region of 270 nanometers, just shy of the visible range, the EZ actually absorbs light. The more of the 270 nanometer light the water absorbs, the more EZ water the sample contains. EZ water appears to be quite stable. This means it can hold the structure, even if you leave it sitting around for some time. Water samples from the river Ganges and from the Lourdes in France have been measured, showing spikes in the 270 nanometer region, suggesting these “holy waters” contain high amounts of EZ water. According to Dr. Pollack, there’s compelling evidence that EZ water is indeed lifesaving...

EZ Cellular Water Helps Explain Health Benefits of Light and Heat Therapies

Heating equates to applying infrared energy, and Dr. Pollack has found that if you apply infrared, the EZ water builds and doesn’t diminish. The implications of this are profound when you consider the health benefits of sitting in an infrared sauna, for example. Essentially, one of the reasons why infrared saunas make you feel so good is because your body’s cells are deeply penetrated by infrared energy, which builds and stores EZ water. The same goes for light therapy, spending time in the sun, and laser therapy.

“There are various kinds of light therapy using different wavelengths. We found that all wavelengths – some in particular – of light, even weak light, build EZ. If EZ is critical for the health of your cells, which I think is clear, these therapies have a distinct physical chemical basis,” Dr. Pollack explains.

EZ water also provides a mechanism that explains other biological mysteries. For example, Dr. Pollack describes another fascinating finding that further bolsters our understanding of the mechanism of action behind the health benefits of something as simple as exposing your body to the light and heat of the sun:

“We found that if we put a simple tube, like a straw, made of hydrophilic material, in water... there’s water flow through the tube at high speed. This happens spontaneously. But it shouldn’t happen spontaneously. The common idea is that if you want to drive fluid through a pipe or tube, you need to apply pressure. But we have no pressure here. There’s no pressure difference between the input and output. But flow builds up spontaneously, and it keeps going.

Recently, we found that if we add light, the flow goes faster. It means that light has a particular effect; especially ultraviolet light, but other wavelengths as well. It speeds up the flow. We think that somehow the exclusion zones (EZs) are involved because inside those tubes, there’s a little annular ring of exclusion zone, and inside that is an area full of protons... It seems that the exclusion zone and the pressure of these protons are driving the flow.”

Now, let’s apply these mechanisms to your body. Your capillaries receive radiant energy from outside all the time. Energy is also received from the inside of your body, as metabolic reactions continuously generate heat or infrared. So the question is, is it possible that the flow of blood occurring through your capillaries is automatically enhanced by exposure to light? It appears the answer may be yes...

“This is an important issue because the capillaries are puzzling,” Dr. Pollack says. “They’re so small. Some of the capillaries are smaller in diameter than the red blood cells that pass through them. Any competent engineer would never build a pipe that’s smaller than the junk that’s supposed to go through. But nature, apparently, has done that...

Now, that means there’s a lot of resistance. You need something to push those red blood cells through... One possibility is that the flow in your capillaries is aided by this kind of radiant energy... We’re starting to test this... It’s possible that your cardiovascular system is assisted by radiant energy in the same way that the flow in the tubes is assisted by radiant energy.”

One of the more interesting healing modalities I’ve been exploring lately is the use of a high-powered laser. The K-Laser also has frequencies in the infrared range, which can deeply penetrate tissue. This kind of laser therapy has shown to provide profound healing for many painful injuries in a very short amount of time—sometimes just minutes of treatment. While the benefits of laser therapy are thought to be due to its action on mitochondrial activity, it may very well be that the benefits are also related to “recharging” your damaged cells’ EZ water, as well as promoting increased capillary blood flow.

EZ water in your body also plays a role is in hyperbaric medicine, which is also good for injuries. In that case, your tissues are exposed to high oxygen under pressure.

“The results are in. We think we understand the mechanism as to why hyperbaric oxygen is so effective for wound healing... EZ water has a higher density than bulk water. If you take H2O and you put it under pressure, it should give you H3O2 because the EZ structure is denser than the H2O. We did the experiments and we found, indeed, that’s the case. If you put H2O under pressure, you get more EZ water.”

The same goes for oxygen. EZ also has more oxygen than H2O, and when you increase oxygen content, you get more EZ water. So, hyperbaric treatment builds EZ water in your body, particularly in injured areas where EZ water is needed.

Alkalinity and Your Body’s Negative Charge May Be Critical for Health

I personally drink vortexed water nearly exclusively as I became a big fan of Viktor Schauberger who did much pioneering work on vortexing about a century ago. Dr. Pollack found that by creating a vortex in a glass of water, you’re putting more energy into it, thereby increasing EZ. According to Dr. Pollack, virtually ANY energy put into the water seems to create or build EZ water.

“We have looked at acoustic energy that seems to effect some change in the water. We’re still not sure exactly what. Vortexed water puts enormous energy into the water. There are several groups in Europe studying this phenomenon right now. “

As mentioned earlier, EZ water is alkaline and carries a negative charge. Maintaining this state of alkalinity and negative charge appears to be important for optimal health. Drinking water can be optimized in a variety of different ways, by injecting light energy or physical energy into the water by vortexing, for example. This is fairly easy using magnets. Reversing the vortex every few seconds may even create more energy.

Clearly, more research needs to be done in this area, but some is already underway. My own R&D team is working on a careful study in which we use vortexed water to grow sprouts, to evaluate the vitality and effectiveness of the water.

As for a natural source of EZ water for drinking, an ideal source is glacial melt. Unfortunately, this is extremely inaccessible for most people. Another good source is water from deep sources, such as deep spring water. The deeper the better, as EZ water is created under pressure. Natural spring water is another excellent way to obtain this type of water and you can use FindaSpring.com to help you find one close to you.

Besides optimizing the water you drink, you can help generate an electron surplus, or support this negative charge within your body, simply by connecting to the Earth, which also has a negative charge. This is the basis of the earthing or grounding technique, which has been shown to have significant health benefits by allowing the transfer of negatively charged electrons from the ground into the soles of your feet. In a sense, it’s as though your cells are built like batteries that are naturally recharged by spending time outdoors — whether sunny or overcast, and walking barefoot, connecting to the negative charge of the earth!

“If you have an organ that’s not functioning wel l— for example, it’s lacking that negative charge — then the negative charge from the earth and... [drinking] EZ water can help restore that negativity. I’ve become convinced... that this negative charge is critical for healthy function,” Dr. Pollack says

PATENTS

METHOD AND SYSTEM FOR GENERATING ELECTRICAL ENERGY FROM WATER

US2014137914

METHOD AND SYSTEM FOR GENERATING ELECTRICAL ENERGY FROM WATER

US2014137914

BACKGROUND OF THE INVENTION

[0003] Satisfying the world's energy needs is a demanding endeavor. Presently, fossil fuels are responsible for supplying the bulk of these worldwide needs. However, fossil fuel supplies are finite, their consumption often has adverse environmental effects, their cost widely variable and somewhat unpredictable, and independence from them is long considered to be politically advantageous.

[0004] Alternative energy sources are being actively sought and developed. Solar and wind energy are attractive alternatives to fossil fuels. Wind farms have been developed and energy from them complements conventional energy supply. The promise of efficient and cost effective solar energy has yet to be realized, although considered to be a future solution to the worldwide energy problem.

[0005] Solar radiation, at its maximum produces about 1000 Watts/m <2>. Solar cells can operate up to 30% efficiency, but typical values of efficiency for the most economical units are about 15-20%. Hence, typical output is about 200 Watts/m <2>, or about 20,000 µW/cm <2 >at full solar radiation. Under more typical lighting conditions, the output would be an order of magnitude lower, about 2,000 µW/cm <2>. Typical photovoltaic output value is about 12,000 µW/cm <2 >at full sun at the equator during the vernal equinox at midday, which is the absolute peak. More typical values, but still under bright conditions, would be an order of magnitude lower, perhaps 1,200 µW/cm <2>. The benchmark for commercial photovoltaic cells in fairly bright light is from about 1,000 to about 2,000 µW/cm <2>.

[0006] Despite the advances made in harnessing energy from the sun, a need exists to develop solar energy systems that provide electrical energy in an efficient and cost effective manner. The present invention seeks to fulfill this need and to provide further related advantages.

SUMMARY OF THE INVENTION

[0007] The present invention provides a method and system for generating electrical energy from a volume of water.

[0008] In one aspect, the invention provides a method for generating electrical energy from a volume of water. In one embodiment, the method includes contacting a volume of water with a hydrophilic surface and applying energy to the volume of water to provide an exclusion zone in the volume of water at the interface of the hydrophilic surface and the water, and a bulk zone in the volume of water outside of the exclusion zone; providing a first electrode in the exclusion zone and a second electrode in the bulk zone; and extracting electrical energy from the volume of water by connecting a load across the electrodes.

[0009] The applied energy can be radiant energy from the sun or infrared radiant energy from a local environment.

[0010] The method for providing electrical energy from a volume of water includes comprising connecting a load across first and second electrodes in contact with a volume of charge-separated water, wherein the volume of water is in contact with a hydrophilic surface in liquid communication with the water defining an exclusion zone at an interface of the hydrophilic surface and the water, and a bulk zone in the volume of water outside of the exclusion zone, wherein the first electrode is in the exclusion zone, and wherein the second electrode is in the bulk zone.

[0011] In another aspect of the invention, a system for generating electrical energy from a volume of water is provided. The system includes a hydrophilic material having a hydrophilic surface; a vessel for receiving the hydrophilic material and a volume of water; a first electrode positioned in the vessel proximate to the hydrophilic surface; and a second electrode positioned in the vessel distal to the hydrophilic surface.

DESCRIPTION OF THE DRAWINGS

[0012] The foregoing aspects and many of the attendant advantages of this invention will become more readily appreciated as the same become better understood by reference to the following detailed description, when taken in conjunction with the accompanying drawings, wherein:

[0013] FIG. 1 is a schematic illustration of a representative system for carrying out a method of the invention;

[0014] FIGS. 2A and 2B are graphs comparing the exclusion zone expansion ratio as a function of wavelength of applied energy; 2A UV-Vis, 2B IR;

[0015] FIG. 3 is a graph illustrating voltage decrease over time in an open circuit with no infrared irradiation;

[0016] FIG. 4 is a graph illustrating current over time in a closed circuit with a 10K resistor;

[0017] FIG. 5 is a graph illustrating voltage over time in an open circuit with infrared radiation;

[0018] FIG. 6 is a graph showing power generated as a function of pH;

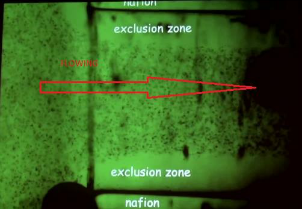

[0019] FIG. 7A is an image of an exclusion zone prior to exposure to infrared radiation, the exclusion zone (EZ) is denoted by the absence of microspheres;

[0020] FIG. 7B is an image of the exclusion zone after 5 min exposure to light from LED31-PR; approximate size of incident beam is shown;

[0021] FIG. 8A is a graph comparing exclusion zone expansion ratios as a function of exposure time for three infrared sources (LED17-PR, LED20-PR. and LED31-PR, lower power for LED31-PR);

[0022] FIG. 8B is a graph comparing exclusion zone expansion ratios as function of time during 10 min exposure at different intensities (0.21 mW, 0.34 mW, and 1.20 mW) using LED20-PR;

[0023] FIG. 9A is a graph comparing exclusion zone expansion ratios at different depths during 3.5 min, 5 min, and 7 min exposures of 3.1 µm radiation;

[0024] FIG. 9B is a graph comparing exclusion zone expansion ratios with 5 min exposure to 3.1 11 m radiation focused at a series of distances from a NAFION® surface;

[0025] FIG. 10A is a graph comparing pH change over time following addition of water to a NAFION sheet; pH values were measured at 5 s intervals using a miniature pH probe positioned at three distances from the NAFION sheet (1 mm, 5 mm, and 10 mm); a wave of protons is generated as the exclusion zone forms providing lower pH; at a distance of 1 mm, the pH drop transiently exceeds 3 pH units, which represents a hydrogen ion increase in excess of 1,000 times;

[0026] FIG. 10B is an image of a chamber containing a NAFION tube (bottom) filled with water containing pH-sensitive dye; view is normal to the wide face of a narrow chamber; image obtained 5 min after dye-containing solution was added to the tube; the dark color indicates pH<3; the lighter colors above indicate progressively higher pH levels with near neutrality at the top;

[0027] FIG. 11 is a graph comparing potential (mV) measured as a function of distance from the surface of representative hydrophilic materials (NAFION and poly(acrylic acid) gel) useful in the method of the invention; substances are depicted as “inside” and water is “outside;”

[0028] FIG. 12 is a graph of voltage (V) over time using a platinum cathode and zinc electrode;

[0029] FIG. 13 is a graph corresponding to FIG. 12 showing current (amperes) over time;

[0030] FIG. 14 is a graph of voltage (V) over time using a platinum cathode and zinc electrode using glass slides that are twice (2×) larger than those used to obtain the record shown in FIG. 12; and

[0031] FIG. 15 is a graph corresponding to FIG. 14 showing current (amperes) over time.

DETAILED DESCRIPTION OF THE INVENTION

[0032] The present invention provides a method and system for generating electrical energy from a volume of water. In the method, electrical energy is extracted from the volume of water that is subject to or has been subject to applied energy, such a radiant energy from the sun or the local environment.

[0033] In one aspect, the invention provides a method for generating electrical energy from a volume of water. In one embodiment of the method, a volume of water is contacted with a hydrophilic surface and subjected to the application of energy to provide an exclusion zone at the interface of the hydrophilic surface and the water. A bulk zone in the volume of water is formed outside of the exclusion zone. Charge separation is induced in the volume of water by applying energy to the volume of water. Electrical energy is extracted from the volume of water by providing a first electrode in the exclusion zone and a second electrode in the bulk zone, and connecting a load across the electrodes.

[0034] As used herein, the term “exclusion zone” refers to a region of the volume of water created at the interface of the hydrophilic surface and the water where solutes and particles are excluded. The term “bulk zone” refers to the region of the volume of water outside the exclusion zone. The exclusion zone results from the application of energy (e.g., radiant energy) to the volume of water. The exclusion zone builds with increasing applied energy.

[0035] Application of energy to the volume of water in contact with the hydrophilic surface results in the formation of the exclusion zone. In the process, charge separation is induced in the volume of water. As used herein, the term “charge separation” refers to the physical separation of negative charges (e.g., solutes, particles, ions) from positive charges (e.g., solutes, particles, ions) in the volume of water. In general, the exclusion zone is a region of negative charge and the bulk zone is a region of positive charge (e.g., hydronium ions, free protons).

[0036] The size and shape of the exclusion zone formed in the method of the invention varies greatly depending on the nature of the hydrophilic surface, its size and shape, the nature of the volume of water, and the energy applied. The size of the exclusion zone is variable and dependent on the applied energy: the greater the applied energy, the greater the size of the exclusion zone. The exclusion zone can extend up to a meter or more from the hydrophilic surface. The exclusion zone can therefore extend from the hydrophilic surface any distance from about 1 nm to a meter or more. In certain embodiments, the exclusion zone can extend a distance of from one to two millimeters from the hydrophilic surface. In other embodiments, the exclusion zone can extend a distance of from about 200 µm to about 700 µm from the hydrophilic surface. The shape of the exclusion zone is also variable. For example, when the hydrophilic surface is a sheet positioned against a wall of the vessel containing the volume of water, the exclusion zone extends into the volume of water away from the surface of the hydrophilic surface. When a sheet of material having two hydrophilic surfaces is placed in a volume of water, the exclusion zone extends into the volume of water away from each surface. For a sphere of hydrophilic material having a hydrophilic surface, the exclusion zone extends radially into the volume of water away from the sphere (e.g., shell). In other embodiments, the exclusion zone extends into the volume of water non-uniformly. For examples, the exclusion zone can have the form of a cone narrowing into the volume of water. Exclusion zones having a plurality of cones extending into the volume of water have also been observed. Schematic illustration of the volume of water having exclusion and bulk zones is shown in FIG. 1.

[0037] Exclusion zones were not observed with materials having hydrophobic surfaces, such as silicon rubber, nylon, carbon, quartz, and a plastic paraffin film (PARAFILM®, is a registered trademark of Bemis Co. INC. OF Neenah, Wis.), hereinafter referred to as “PARAFILM”. In general, the materials having surfaces that are highly charged (e.g., sulfonated tetrafluoroethylene copolymer (NAFION 117 polymer), polyacrylic acid gels) exhibit the largest exclusion zones, while those that are least charged (e.g., polyvinyl alcohol gels) exhibit the smallest exclusion zones. (NAFION®, hereinafter referred to as “NAFION” is a registered trademark of E.I. Du Pont De Nemours and Company Corporation of Wilmington, Del.) In all cases, the region beyond the exclusion zone had net positive charge, confirmed by measurements of pH, which showed low pH and therefore high hydrogen ion concentration. In some experiments the pH was as much as four units lower than the original water pH. However, the situation is reversed in the case of positively charged surfaces. These included positively functionalized polystyrene gel beads, and SELEMION® positively functionalized ion exchange resin (SELEMION®, hereinafter referred to as “SELEMION” is a registered trademark of AGC Engineering Co., LTD. of Chiba, Japan). In such cases the potential was 100-200 mV positive at the surface, declining to zero at the edge of the exclusion zone. The bulk water beyond had high pH instead of low pH. In these cases of positively charged surfaces, the exclusion zones were found to be smaller and somewhat more ephemeral than those next to the negatively charged surfaces.

[0038] The volume of water required for the method of the invention is not critical. The method is applicable to nanoscale volumes of water and to expansive volumes of water (e.g., lakes and oceans). The pH of the volume of water can vary (e.g., from about 2 to about 11). It has been observed that relatively more electrical energy can be obtained by the method at low pH (e.g., pH>about 4). The volume of water can include solutes such as salts. Suitable salts include potassium chloride and sodium chloride. Other salts, such as those used in chemical batteries can also be used. The ionic strength of the volume of water can also vary. Ionic strengths up to about 5M have provided reasonable output. Electrical energy has been extracted from volumes of water having ionic strength up to about 5M, and optimal energy has been obtained at ionic strengths from about 100 mM to about 2M.

[0039] In the method, the exclusion zone is formed adjacent to the hydrophilic surface. As used herein, the term “hydrophilic surface” refers to a surface of a material having a contact angle less than 90 degrees for water. The hydrophilic surfaces may be charged or uncharged. The charged hydrophilic surfaces may be mixed charge surfaces. The charged hydrophilic surfaces may have a net positive charge or a net negative charge.

[0040] Suitable materials having hydrophilic surfaces include hydrophilic gels (e.g., polyacrylic acid gels, polyvinyl alcohol gels, polyacrylamide gels, polyHEMA gels, collagen gels, actin gels, and agarose gels), biological materials (e.g., muscle tissue, vascular endothelium, xylem, oxtail tendon, seaweed, and plant root), self-assembled monolayers including carboxyl group-containing monolayers and polyethylene glycol-containing monolayers (e.g., supported on metal surfaces such as gold), polymeric surfaces (e.g., ionomer surfaces) including sulfonic acid-containing polymer surfaces (e.g., sulfonated tetrafluoroethylene copolymer surface also known as NAFION), inorganic surfaces (e.g., surfaces containing titanium dioxide, silicon, zinc, lead, tungsten, aluminum, tin, and mica), and ion exchange resins and materials.

[0041] As noted above, suitable materials having hydrophilic surfaces may have a variety of shapes. In one embodiment, the hydrophilic material is a sheet having a rectangular hydrophilic surface. In another embodiment, the hydrophilic material is a particle (e.g., microsphere or nanosphere). In other embodiments, the hydrophilic material includes a plurality of hydrophilic beads (e.g., mixed charged beads, negatively charged beads, positively charged beads).

[0042] In one embodiment, the hydrophilic material is ice. Exclusions zones have been observed for each of the hydrophilic materials noted above.

[0043] As noted above, in the method, a volume of water is contacted with a hydrophilic surface and subjected to the application of energy. Application of energy increases the size of the exclusion zone. In one embodiment, applying energy includes irradiating the volume of water with electromagnetic radiation. Suitable electromagnetic radiation includes radiation absorbed by the volume of water (e.g., wavelengths in the range from about 200 nm to about 10,000 nm). In the method, infrared wavelengths are the most effective wavelengths. In one embodiment, the radiant energy has a wavelength of about 3 µm.

[0044] The applied energy can be radiant energy from the environment such as solar energy (e.g., ultraviolet, visible, near infrared, and infrared radiation) and heat from the local environment (infrared radiation).

[0045] Although radiant energy is the source of energy applied to the volume of water, in one embodiment of the method, the size of the exclusion zone can be increased by applying a voltage across the electrodes.

[0046] In the method, electrical energy is extracted from the charge-separated volume of water by connecting a load across the first and second electrodes. The nature of the electrodes is not particularly critical. Suitable electrodes include platinum, zinc, aluminum, stainless steel, and copper electrodes. The first and second electrodes may the same or different.

[0047] The load can be connected after a predetermined period of time after inducing charge separation (i.e., after applying energy to the volume of water). Alternatively, the load can be connected during application of energy (e.g., applying radiant energy to the volume of water) in which case electrical energy is extracted from the volume of water at the same time that energy is applied to the volume of water.

[0048] Thus, in one embodiment of the method, electrical energy is extracted from a volume of water by connecting a load across first and second electrodes in contact with a volume of charge-separated water, wherein the volume of water comprises a hydrophilic surface in liquid communication with the water defining an exclusion zone at an interface of the hydrophilic surface and the water, and a bulk zone in the volume of water outside of the exclusion zone, wherein the first electrode is in the exclusion zone, and wherein the second electrode is in the bulk zone. As noted above, “charge-separated water” refers to water in contact with a hydrophilic surface that initiates the formation of the exclusion zone having a net charge opposite that of the bulk zone.

[0049] In another aspect of the invention, a system for extracting electrical energy from a volume of water is provided. In one embodiment, the system includes a hydrophilic material having a hydrophilic surface, a vessel for receiving a hydrophilic surface and a volume of water; a first electrode positioned proximate to the hydrophilic surface; and a second electrode positioned distal to the hydrophilic surface. When the vessel has received a volume of water and energy has been applied to the volume of water, the first electrode is positioned in an exclusion zone formed at the interface of the hydrophilic surface and the water, and the second electrode is positioned in a bulk zone in the volume of water outside of the exclusion zone.

[0050] In one embodiment, the system includes only those components described above (i.e., the system consists of the noted components). In another embodiment, the system includes those components described above and other components that do not alter the characteristics of the system (i.e., the system consists essentially of the noted components). Components that are excluded from this embodiment include components and conditions used in methods for the electrolysis of water, methods for analyzing water samples, and electrochemical analytical and synthetic methods carried out in water.

[0051] FIG. 1 is a schematic illustration of a representative system for carrying out the method of the invention. Referring to FIG. 1, system 100 includes vessel 10 that contains volume of water 12 and hydrophilic material 14 having hydrophilic surface 16. On application of energy (e.g., radiant energy), exclusion zone 20 and bulk zone 22 form in volume of water 12. Electrode 32 is positioned in the exclusion zone and electrode 34 is positioned in the bulk zone. Electrical energy is extracted from the volume of water by applying a load 40 across electrodes 32 and 34. Absent continued application of applied energy, the exclusion zone contracts. Application of energy during the application of a load allows for maintenance of the exclusion zone (i.e., charge separation) and simultaneous extraction of electrical energy. The following provides a further describes the method of the invention. Unexpected phenomenon was observed in water next to hydrophilic surfaces. In a zone up to several hundred micrometers from the hydrophilic surface, solutes were excluded. Subsequent studies showed that the solute-excluding region was physico-chemically different from ordinary water, and probably liquid crystalline. Qualitative differences between this vicinal water and the bulk water farther from the hydrophilic surface were demonstrated using NMR, infrared radiation, and UV-Vis optical absorption. An additional unexpected result was also observed: the excluding region was negatively charged. The potential difference between the vicinal water and water remote was approximately 200 mV, decreasing exponentially with distance from the surface, toward zero potential difference at the end of the exclusion zone.

[0052] The results indicate a loss of positive charge from otherwise neutral water. This lost positive charge was determined to reside in the aqueous zone beyond the exclusion zone. Methods showed a large proton concentration in this bulk region. In dynamic experiments with pH probes, a wave of protons was detected flowing away from the vicinal water and toward the more distant bulk water, as the exclusion zone was growing. The result is charge separation in the water.

[0053] When an entity whose surface is hydrophilic is placed into water, ordering of water molecules next to the surface immediately begins. The ordered entity is negative. As this zone builds, the quantity of negative charge builds. Meanwhile, the complementary positive charges build in the zone beyond this ordered zone to provide charge separation. The charge separation is sustained. In the method of the invention, electrical current is drawn and thereby useful work obtained from charge-separated water.

[0054] In the method of the invention, the buildup of water structure, and hence the separation of charge, is powered by incident radiant energy (i.e., photons). In an experiment, a chamber lined on one side with a hydrophilic surface (i.e., NAFION) was filled with an aqueous suspension of polystyrene microspheres. Within several minutes the microspheres moved away from the surface leaving an exclusion zone. This zone generally remained stable for hours. When light was added the exclusion zone immediately began growing, and within five minutes it had grown substantially. When the light source was extinguished, the exclusion zone returned to its initial size. The effect of incident light is reversible.

[0055] Growth of the exclusion zone was wavelength sensitive. FIGS. 2A and 2B are graphs comparing exclusion zone expansion ratio (defined as the ratio of the exclusion zone width after application of energy to the control state, which is the width of the exclusion zone prior to the application of energy) as a function of wavelength ( 2A UV-Vis and 2B IR). Throughout the ultraviolet-visible range the intensity was maintained constant; and, the same throughout the infrared range (on the order of 100 µW). In the latter series, intensities were lower than in the former series. All wavelengths increased the size of the negative zone, and the increase was wavelength sensitive. The most powerful effect occurred at a wavelength of 3 µm. With mode intensity (271 µW) at 3 µm, in five minutes the exclusion zone (EZ) increased by almost a factor of three.

[0056] It is noteworthy that 3 µm is the wavelength most strongly absorbed by water, and it causes heating. The temperature increase was measured at various points in the chamber. During the five-minute exposure, in no instance did the temperature increase exceed 1° C. demonstrating that any effect of heating must have been secondary. The major impact of these photons appears to be non-thermal, although the exact mechanism (i.e., how the photonic energy brings about ordering of exclusion zone water and charge separation) remains unclear.

[0057] The following experiments determined that electrical power can be drawn from the charge-separated water. The setup included a NAFION sheet, secured within a sandwich of plastic sheets each containing a large open window, so that the NAFION sheet was exposed to water. A stainless steel-mesh electrode was placed immediately adjacent to the exposed NAFION sheet on one side. This served as the negative electrode. The positive electrode, another stainless steel mesh, was placed some distance from the sheet, either on the same, or the opposite side as the negative electrode. The second electrode was positioned so as to lie beyond the exclusion zone. The entire assembly was immersed in water. The two electrodes were either left open circuited, for potential difference measurements, or connected by a load resistor, arbitrarily chosen at 10 Kohms, through which current could flow.

[0058] A potential difference on the order of 100-200 mV was typically recorded. The voltage was high at first, but generally declined with time, depending on whether the load resistor was or was not attached. Importantly, the voltage never fell to zero. A fraction of the initial voltage persisted indefinitely, implying that energy was consistently flowing into the system to recharge the system (infrared energy was continuously available to power the system). FIG. 3 is a graph illustrating voltage decrease over time in an open circuit with no infrared irradiation. FIG. 4 is a graph illustrating current over time in a closed circuit with a 10K resistor.

[0059] Experiments were then undertaken to demonstrate that incident infrared illumination increases power output in the system. FIG. 5 is a graph illustrating voltage over time in an open circuit with infrared irradiation. This data was obtained after the voltage had already diminished considerably from an initial value. Turning on the light caused an immediate (within several minutes) return to the initial (200 mV) voltage, which was sustained even for some time after the light had been turned off.

[0060] Lowering the pH of the volume of water tended to increase power as indicated in FIG. 6. Adding salt to the volume of water induces a substantial positive effect on power production, probably because of the increased conductivity of the solution. Potassium chloride and sodium chloride exert similar effects. In the concentration range 0.1 M to 1 M, power output increased to 150 microwatts. Considering the electrode-surface areas of approximately 3 cm <2>, this increase amounts to about 50 µW/cm <2>.

[0061] Examples of exclusion zones are illustrated in FIGS. 7A and 7B. Referring to FIGS. 7A and 7B, the exclusion zones are adjacent nucleating surfaces and are denoted by the absence of microspheres. As noted above, the exclusion zone is distinct from bulk water. A series of measurements including UV-Vis absorption spectra, infrared and NMR imaging, and electrical polarization showed that water in the exclusion zone was less mobile and more ordered than bulk water, and that it was charged.

[0062] Water is known to have a strong absorption peak at a wavelength 3.05-3.10 µm, corresponding to a symmetric OH stretch. A light source, LED31-PR, which has peak output at 3.1 µm and full width at half maximum (FWHM) of 0.55 µm, was used to irradiate water in contact with a hydrophilic surface. PERMA PURE® NAFION tubing (TT-050, 0.042 in. diam., (PERMA PURE® is a registered trademark of PERMA PURE LLC of Cincinnati, Ohio) was suffused with a 1 µm carboxylate-microsphere suspension (2.65% solids-latex, available from Polysciences Inc. of Warrington, Pa.) with a 1:500 volume fraction, to a depth of about 1 µm. The chamber was made using a thin cover glass adhered to the bottom of a 1-mm thick cover slide with a 9-mm circular hole cut in the center, and was placed on the stage of a microscope (ZEISS AXIOVERT-35, with camera CFW-1310C). (ZEISS® and AXIOVERT® are registered trademarks of Carl Zeiss AG Corp. of Oberkochen, Germany.) A pinhole (available from Edmund Optics of Barrington, N.J.), 50 µm in diameter and 0.25 mm thick, was used to obtain an incident beam of restricted diameter. A fabricated holder integrated the pinhole and LED into a single unit with the LED mounted close to the pinhole. The LED-pinhole axis was vertically oriented.

[0063] When the exclusion zone reached an apparent equilibrium state, the incident radiation was turned on. Optical power output was 33 µW, and the estimated power received through the pinhole was about 2.4 nW. After five minutes, the LED assembly was removed and the exclusion zone was photographed through the microscope. Referring to FIGS. 7A and 7B, it is apparent that even with modest IR exposure, the exclusion zone ( 7B) grew to approximately three times its control size ( 7B).

[0064] Exclusion zone width was also tracked over time. This was carried out not only with the 3.1 µm source, but also with 2.0 µm and 1.75 µm sources (FWHM=0.16 µm and 0.18 µm, respectively). For the latter two sources, intensities were maintained at approximately 190 µW; but for the 3.1 µm source, power was kept at the maximally attainable value, 33 µW.

[0065] During the 10 min exposure at all three wavelengths, exclusion zones continued to expand approximately linearly ( FIG. 8A). The largest effect was seen at 3.1 µm, despite lower incident power. To determine whether the EZ continues to expand beyond the 10-min exposure, the 3.1 µm source was left on at the same intensity as above for up to one hour. The ratios increased from 3.7±0.10 (10 min) to 4.7±0.12 (30 min) and 6.1±0.17 (1 hr) respectively. Hence, the exclusion zone continued to expand for up to at least one-hour of exposure.

[0066] Post-illumination exclusion zone size dynamics were examined. When the infrared light was turned off after 5 minutes exposure, exclusion zone width remained roughly constant with fluctuations for about 30 min. Then, the size of the exclusion zone began decreasing noticeably and continued to decrease for approximately one hour.

[0067] To determine the effect of beam intensity on exclusion zone expansion, the 2 µm source was employed at three power levels, 0.21, 0.34, and 1.20 mW. The rate of EZ expansion increased with an increase of incident power ( FIG. 8B).

[0068] The results demonstrate that exclusion zone expansion is a function of both time and intensity. Exclusion zone growth depends on the cumulative amount of incident energy.

[0069] To test whether the expansion arises out of some unanticipated interaction between the incident radiation and the particular type of microsphere probe, microspheres of different size and composition were tested. For carboxylate microspheres of diameters 0.5 µm, 1 µm, 2 µm, and 4.5 µm at the same volume concentrations (1:500), mean expansion ratios for 5-min exposure of 3.1 µm radiation were: 2.41, 2.97, 3.08, and 3.34, respectively (n=6). For varied 1 µm microspheres made of carboxylate, sulfate (2.65% solids-latex, available from Polysciences Inc. of Warrington, Pa.), and silica (SIO 2, available from Polysciences Inc. of Warrington, Pa.) under conditions the same as above, expansion ratios were 2.97, 3.10 and 1.50. Some material-based and size-based variations were noted; the latter arising possibly because of different numbers of particles per unit volume; but, appreciable radiation-induced expansion was nevertheless seen under all circumstances and with all materials. The presence of the expansion effect is not material specific.

[0070] The effect of illuminating with IR at different positions relative to the NAFION/water interface was compared. For these measurements, a sheet of NAFION 117 film (0.007 in. thick, Aldrich), approximately 6 mm long and 1.5 mm high, was held by a micro-clip (0.75×4-mm jaws, World Precision Instruments) and positioned in the vertical plane near the middle of the chamber, which was made from a rectangular glass block, length 7 cm, width 2.5 cm and height 1.5 mm with a rectangular hole, length 3.15 cm and width 1.2 cm, cut through from top to bottom and a 1-mm-thick glass slide sealing from beneath. The film's upper edge was positioned at the solution surface. The vertical scale was carefully calibrated using a 1-mm-thick glass slide with face markings; one millimeter corresponded to 634 divisions on the focus knob. A 50 µm pinhole was placed immediately above the specimen in order to restrict incident spot size. To estimate spot diameter at different solution depths, a visible source (microscope light with green filter, ?=550 nm) was substituted for the LED. Beam diameters increased approximately linearly from 160 µm at the solution surface, to 240 µm at 1.5 mm below the surface (these values are only approximate, as diameters will change with wavelength). For periods of observation and data collection, where some illumination was required, intensity was minimized by use of this same filter.

[0071] With the beam first positioned in the middle of the exclusion zone, the expansion ratios were measured at different depths. FIG. 9A shows that maximum expansion occurred at a depth of approximately 450 µm from the solution surface, and was detectable well beyond 1 mm. The fact that the maximum expansion occurred well below the surface is surprising given the limited IR penetration ordinarily expected in water.

[0072] With the same setup as above, the spot was then positioned at varying distances from the NAFION-water interface. Results are shown in FIG. 9B. Expansion was largest when light was focused in the center of the exclusion zone, and fell off on either side, although not appreciably. At deeper positions, the near-NAFION expansion peak tended to broaden somewhat, possibly because of incident-beam broadening; but, the trend was essentially similar at all depths. The most notable finding was that even when the beam was positioned far from the NAFION surface, the expansion effect was appreciable.

[0073] Infrared absorption in water causes a temperature elevation. To measure local temperatures, an OMEGAETTE 1M datalogger thermometer HH306 was used, with stainless-steel-sheathed, compact transition ground-junction probe (TJC36 series), small enough (250 µm) to fit within the exclusion zone. (OMEGAETTE® is a registered trademark of Omega Engineering, Inc., of Stamford, Conn.) With the incident beam positioned to elicit the maximum expansion, i.e., centered 175 µm from the NAFION surface, the measured temperature increases are shown in Table 1.

[0000]

TABLE 1

Temperature increases measured at different distances from the NAFION surface after 10 min. exposure to 3.1 µm radiation (n = 3)

Distance Mean temperature increase

175 µm 1.1° C.

250 µm 0.91° C.

350 µm 0.92° C.

4 mm 0.91° C.

6 mm 0.92° C.

[0074] Radiation-induced temperature increases were modest at all positions and fairly uniform over the chamber. Slight temperature variation was found with depth, implying that the thermal mass of the probe itself, immersed by varying extents for measurements at varying depths, did not introduce any serious artifact.

[0075] Dynamics of temperature rise were observed. The temperature increase occurred steadily, reaching a plateau of about 1° C. at 10-15 min after tum-on. This plateau was attained at a time that the exclusion zone continued to expand (see FIG. 8A). Not only was the temperature increase modest, but also the time course of temperature rise and exclusion zone expansion were not correlated.

[0076] Infrared effects were seen at depths on the millimeter scale, whereas infrared penetration into water is anticipated to extend down only on the micrometer scale. One possible explanation is that penetration through the exclusion zone is deeper than through bulk water.

[0077] The exclusion zone expansion's spectral sensitivity was determined. The experimental setup was similar to that described above. The about 200 µm wide light beam emerging from the pinhole was directed to the middle of exclusion zone, and expansion was measured 300 µm below solution surface.

[0078] For the UV and visible sources, maintaining consistent optical power output at all wavelengths was achievable within +/-10% by adjusting the driver current. IR sources were considerably weaker and output power was maintained at a lower level, three orders of magnitude lower than in the UV-visible ranges.

[0079] For ultraviolet and visible ranges all incident wavelengths brought appreciable expansion ( FIG. 2A). The degree of expansion increased with increasing wavelength, the exception being the data point at 270 nm, which was higher than the local minimum at 300 nm. The higher absorption may reflect the signature absorption peak at 270 nm characteristic of the exclusion zone. Clear wavelength sensitivity was also found in the infrared region, the most profound expansion occurring at 3.1 µm ( FIG. 2B). Recognizing that the optical power available for use in the IR region was 1/600 of that in the visible and UV regions, one can assume that with comparable power, the IR curve would shift considerably upward continuing the upward trend evident in FIG. 2A. The most profound effect is in the IR region, particularly at 3.1 µm.

[0080] Interestingly, the overall spectral sensitivity of expansion follows closely the spectral sensitivity of water absorption. In both cases, there is an overall minimum in the near-UV, plus a local maximum at 2.0 µm and a peak at 3.1 µm. If not by coincidence, then a connection is implied between IR absorption and EZ expansion, although the linkage is apparently not through temperature increase, which was both modest and temporally uncorrelated. Furthermore, increasing the bath temperature actually diminishes exclusion zone size. Evidence that the effect is apparently non-thermal.

[0081] FIGS. 10A and 10B present evidence that negative charge buildup next to NAFION is associated with proton buildup in the bulk water beyond. FIG. 10A shows the bulk-water pH transient that occurs during exclusion zone buildup, while FIG. 10B shows the pH distribution in the bulk measured after the exclusion zone had formed. Whereas the exclusion zone is negatively charged, both results, using independent techniques, confirm that the region beyond contains an abundance of protons. Indeed, electrodes placed in the respective zones are able to deliver substantial current to a load confirming charge separation between the exclusion zone and the bulk zone beyond.

[0082] FIG. 11 is a graph comparing potential (mV) measured as a function of distance from the surface of representative hydrophilic materials (NAFION and poly(acrylic acid) gel) useful in the method of the invention; the substances are depicted as “inside” and water is “outside.” Similar negative potentials have been observed with ion-exchange beads composed of crosslinked polystyrene divinylbenzene backbones functionalized with sulfonic acid groups.

[0083] The following is a description of the methods used in the experiments describe above.

[0084] Sample Preparation.

[0085] NAFION surfaces, sheets or tubes, were used for creating exclusion zones. NAFION was immersed in ultrapure water (NANOpure Diamond [trade] 1M p=18.2 MO-cm) to which microspheres were added for delineating the exclusion zone boundary. To supply incident energy, a series of LEDs were used. All experiments were carried out at room temperature in a darkened room.

[0086] Light Sources and Calibration. The LEDs used for infrared illumination (available from Gist Optics Co., LTD. of ChangChun, China) came in T0-18 packages with parabolic reflectors for reducing beam-divergence angle. For the visible range, the LED f 5 series (available from NICHIA Corporation of Tokushima, Japan) was used. For illumination in the UV region, LED model NSHU590 (NICHIA) emitting at 365 nm, and LED models UVTOP® 265 and UVTOP® 295 (available from SENSOR ELECTRONIC TECHNOLOGY, Inc. of Columbia, S.C.) encapsulated in metal-glass T0-39 packages with UV-transparent hemispherical lens optical windows, emitting, respectively, at 270 nm and 300 nm, were used. All LEDs were driven at 2 kHz by a Model D-31 LED driver (available from Gist Optics Co., LTD. of ChangChun, China). Output power was regulated for consistency using a model 1815-C optical power meter (available from NEWPORT Corporation of Irvine, Calif.) equipped with NEWPORT model 818-UV, 818-SL and 818-IR probes.

[0087] In another aspect, the invention provides a method for generating electrical energy from a volume of water through the formation of an exclusion zone at the interface of air and water. In one embodiment of the method, energy is applied to a volume of water contained in a vessel to provide an exclusion zone in the volume of water at the air-water interface and a bulk zone in the volume of water outside of the exclusion zone; a first electrode is provided in the exclusion zone and a second electrode in the bulk zone; and electrical energy is extracted from the volume of water by connecting a load across the electrodes.

[0088] Exclusion zones have been observed not only next to hydrophilic surfaces as described above, but also at the air-water interface of volumes of water contained in vessel having a surface (upper surface) exposed to air. These exclusion zones (i.e., top layer of water on the order of 1 mm) appear to be solute free. In several chamber-geometrical variants, microspheres were consistently excluded from this zone and measurements showed that the zone had a negative potential.

[0089] It is possible that the air is not per se that was responsible for the presence of the exclusion zone and that the exclusion zone was due to the glass surfaces at the chamber's edge. At the glass-water interface the meniscus rise was commonly solute-free, implying the presence of structure. This structure apparently propagates along the water-air interface, covering the water surface. In narrow chambers this cover was commonly 1-2 mm thick, whereas in wider chambers, where the menisci are more widely separated, the structure was thinner. However, replacing air with nitrogen, but not oxygen, diminishes the exclusion zone implying that oxygen may be playing an important role.

[0090] An array of thin glass sheets, positioned parallel to one another and spaced about 1 mm apart, was constructed. The surfaces were oriented perpendicular to the air-water interface, and the top of the array lay immediately beneath the water surface. The negative electrode consisted initially of platinum wires running along the top edge of each member of the glass array, situated just at the air-water interface. The positive electrode, placed at a selectable distance beneath the array, was a platinum mesh.

[0091] Electrical power was extracted from these conditions, just as in the presence of hydrophilic surfaces described above. The drop of voltage, from the initial value to the plateau, was typically only 30-35%, a more modest drop than the situation with immersed hydrophilic surface. Thus, ambient energy could apparently better sustain the power delivery. Absolute power levels were higher. With hydrophilic surface (e.g., NAFION) systems, 1 µA currents with 10K resistor were obtained, while in this aspect, even with the higher resistance 200K resistor used for these experiments, currents on the order of several µA to 10 µA were obtainable, giving power levels in the range roughly 1 µW/cm <2 >of surface (i.e., surface parallel to the air-water interface).

[0092] The effect of incident IR was found to be more consistent albeit less dramatic than in the hydrophilic surface (e.g., NAFION) systems. When IR light was applied from the onset, the drop-off of voltage was slowed by about five or six times; and, the plateau level remained somewhat higher. When the IR was turned on sometime during the plateau, the effect was smaller, sometimes being insignificant, other times causing a slight increase.

[0093] Several experimental variants were evaluated including the use of different types of electrode materials instead of platinum and the addition of salts into the pure water.

[0094] Regarding electrode materials, various combinations of platinum, zinc, aluminum and copper were explored. Depending on the combination, the voltages were either higher or lower than with platinum-platinum. In one advantageous embodiment, the electrode combination was platinum (negative) and zinc (positive), which gave an initial potential difference on the order of about 1 V.

[0095] FIGS. 10A 12- 15 are graphs demonstrating the effectiveness of generating electrical energy from an air-water interface as described above. FIG. 12 is a graph of voltage (V) over time using a platinum cathode and zinc electrode. FIG. 13 is a graph corresponding to FIG. 12 showing current (amperes) over time. FIG. 14 is a graph of voltage (V) over time using a platinum cathode and zinc electrode using glass slides that are twice (2×) larger than those used to obtain the record shown in FIG. 12 (note voltage increase). FIG. 15 is a graph corresponding to FIG. 14 showing current (amperes) over time. When using electrodes of two different metals, rather than the same metals for each electrode, some difference of output power may be due to the metals' electrochemical surface potentials.

[0096] Regarding the addition of salt, modest amounts of salt caused the potential difference to increase. To check the effect, the salt was added in low concentration during the voltage falloff. Voltage magnitude immediately increased, followed by a less steep falloff than in the absence of salt, by 0.2 to 0.3V.

METHOD AND APPARATUS FOR GENERATING A

FLUID FLOW

US2011097218

US2011097218

An apparatus includes a hydrophilic surface configured to drive flow of a polar fluid responsive to an exclusion zone (EZ) effect, the EZ being formed near the hydrophilic surface. An energy source may provide energy to form or maintain the EZ.

BACKGROUND

[0002] Previous academic work has described the phenomenon of an exclusion zone (EZ) generated in proximity to a hydrophilic surface.

SUMMARY

[0003] According to embodiments, methods and applications are described for attaining useful fluid flows in various practical devices. The fluid flows are driven via the generation of an exclusion zone (EZ) in a polar fluid in proximity to a hydrophilic surface. The flows may be produced substantially without conventional energy input, and have been found to persist for extended periods of time.

[0004] According to an embodiment, fluid flow may be maintained responsive to energy absorbed from the environment. Such absorbed energy may be converted to an entropic gradient that maintains the fluid flow.

[0005] According to an embodiment, a fluid flow generator includes a tube having an inner wall, an inlet end, and an output end. A hydrophilic surface formed on at least a portion of the inner wall of the tube. The hydrophilic surface of the inner wall is configured to form a proximate exclusion zone in polar fluid in the tube, and the exclusion zone provides a propulsive force to drive fluid flow from the inlet end to the output end of the tube.

[0006] According to an embodiment, a fluid flow generator includes a tube having an inlet end, an output end, and an inner wall including at least a portion that is hydrophilic; a first fluid reservoir coupled to admit a polar fluid to the inlet end of the tube; and a second fluid reservoir coupled to receive the polar fluid from the output end of the tube. The hydrophilic portion of the inner wall is configured to form an exclusion zone in fluid in the tube, the exclusion zone providing a propulsive force to drive fluid flow from the first fluid reservoir to the second fluid reservoir.

[0007] According to an embodiment, a propulsion system includes a tube having an inlet end, an output end, and an inner wall including at least a portion that is hydrophilic. A mount coupled to the tube may be configured to operatively couple to a propelled vessel. The hydrophilic portion of the inner wall is configured to form an exclusion zone in fluid in the tube, the exclusion zone providing a propulsive force to drive the propelled vessel through a polar fluid.

[0008] According to an embodiment, a method for pumping a polar fluid includes contacting a polar fluid with at least one hydrophilic surface, forming at least one exclusion zone in the polar fluid proximate to the hydrophilic surface, forming a difference in the thickness of different regions of the at least one exclusion zone, and propelling the polar fluid from a volume proximate a thick region of the at least one exclusion zone to a volume proximate a thin region of the at least one exclusion zone.

[0009] According to an embodiment, a method of mixing a fluid includes providing a body having a hydrophilic surface, providing a fluid reservoir configured to hold a polar fluid, providing a polar fluid in the fluid reservoir, and at least partially submerging the body in the polar fluid in the reservoir. The hydrophilic surface of the body forms an exclusion zone in the polar fluid in the reservoir, and the exclusion zone provides a propulsive force to drive fluid flow along the hydrophilic surface.

[0010] According to an embodiment, a body configured to drive polar fluid to flow past the body includes a body having an external surface and a hydrophilic surface formed on at least a portion of the external surface, wherein the hydrophilic surface is configured to form a proximate exclusion zone in polar fluid adjacent the body, and the exclusion zone provides a propulsive force to drive polar fluid flow substantially parallel to the surface of the body.

[0011] According to an embodiment, a method of drawing fluid into a tank includes providing a tank having a hydrophilic inner surface, providing a fluid passage through a wall of the tank, and introducing a polar fluid to the outside of the wall of the tank in the vicinity of the fluid passage. The hydrophilic surface forms an exclusion zone in polar fluid in the tank, the exclusion zone providing a propulsive force to pull the polar fluid into the tank.

BRIEF DESCRIPTION OF THE FIGURES

[0012] FIG. 1 is a diagram of a fluid flow generator, according to an embodiment.

[0013] FIG. 2A is a sectional diagram of a portion of the tube of FIG. 1, according to an embodiment.

[0014] FIG. 2B is a sectional diagram of a portion of the tube of FIG. 1 under conditions of fluid flow past the hydrophilic surface with a differential EZ characteristic, according to an embodiment.

[0015] FIG. 3 is a flow chart summarizing the fluid flow generation process used by apparatuses that operate according to principles described in conjunction with FIGS. 1, 2A, and 2B, according to an embodiment.

[0016] FIG. 4 is a diagram of a fluid propulsion system and a propelled vessel, according to an embodiment.

[0017] FIG. 5 is a diagram of an EZ fluid mixer, according to an embodiment.

[0018] FIG. 6 is a diagram of a system for drawing fluid into a tank using the EZ flow effect, according to an embodiment.

[0019] FIG. 7 is a diagram of a piston engine configured to be driven by an EZ flow effect, according to an embodiment.

[0020] FIG. 8 is a diagram of a multi-stage fluid pump based on principles disclosed herein, according to an embodiment.

[0021] FIG. 9 is a block diagram of an EZ-based power generation system, according to an embodiment.

[0022] FIG. 10 is a photograph of a positively charged hydrophilic bead in a water suspension of negatively charged microspheres.

[0023] FIG. 11 is a series of graphs showing microsphere velocity as a function of distance from the hydrophilic bead surface.

[0024] FIG. 12A is a photograph of a hydrophilic bead at the start of an experiment.

[0025] FIG. 12B is a photograph of the hydrophilic bead of FIG. 12A after 1 hour.

[0026] FIG. 12C is a close-up photograph of the hydrophilic bead of FIG. 12B showing a structure of 0.47 um microspheres attracted thereto.

[0027] FIG. 13 is a photograph showing an EZ formed between a negatively charged bead and negatively charged microspheres.

[0028] FIG. 14 is a set of graphs showing negatively charged microsphere velocity as a function of distance from the negatively charged bead surface.

[0029] FIG. 15A is a photograph of a negatively charged bead surface in a solution of negatively charged microspheres at an initial time t=0.

[0030] FIG. 15B is a photograph of the negatively charged bead surface of FIG. 15A in the suspension of negatively charged microspheres at a time t=2 hours.

[0031] FIG. 15C is a photograph of the negatively charged bead surface of FIGS. 15A, 15B in the suspension of negatively charged microspheres at a time t=5 hours.

[0032] FIG. 15D is a photograph of a negatively charged bead surface of FIGS. 15A-15C in the suspension of negatively charged microspheres at a time t=24 hours.

[0033] FIG. 16A is a photograph of a Nafion tube in a solution of microspheres just before puncture.

[0034] FIG. 16B is a photograph of the Nafion tube of FIG. 16A in the solution of microspheres just after puncture.

[0035] FIG. 17 is a graph of flow rate into the tube of FIGS. 16A, 16B as a function of time.

[0036] FIG. 18 is a graph of flow rates as a function of time into the tube of FIGS. 16A, 16B, first with a single hole and just after puncture of a second hole approximately 1 cm away.

[0037] FIG. 19A is a graph of microsphere flux into the tube of FIGS. 16A, 16B superimposed over relative EZ size inside the tube as a function of time.

[0038] FIG. 19B is a graph of microsphere flux into the tube of FIGS. 16A, 16B superimposed over relative EZ size outside the tube as a function of time.

[0039] FIG. 20 is a graph showing flow of a solution of water and microspheres into the tube of FIGS. 16A, 16B as a function of time with 0.01M NaOH solution inside tube.

[0040] FIG. 21 is a graph showing flow of a solution of water and microspheres into the tube as a function of time with 0.01 M HCl microsphere suspension inside tube.

DETAILED DESCRIPTION

[0041] In the following detailed description, reference is made to the accompanying drawings, which form a part hereof. In the drawings, similar symbols typically identify similar components, unless context dictates otherwise. Other embodiments may be used and/or other changes may be made without departing from the spirit or scope of the disclosure.

[0042] FIG. 1 is a diagram of a fluid flow generator 101 configured to pump a polar fluid between reservoirs, according to an embodiment. The fluid flow generator 101 includes a tube 102 having an inlet end 104, an output end 106, and an inner wall 108 including at least a portion that is hydrophilic. A first fluid reservoir 110 may be coupled to admit a polar fluid to the inlet end 104 of the tube 102. A second fluid reservoir 112 may be coupled to receive the polar fluid from the output end 106 of the tube 102. A fluid flow 114 from the inlet 104 to the output 106 of the tube 102 is maintained responsive to interactions between the polar fluid and the hydrophilic surface 108 of the tube 102. The fluid flow 114 may transfer a polar fluid from the first fluid reservoir 110 to the second fluid reservoir 112. Optionally, a plurality of tubes 102 may be disposed in parallel such that each is configured to receive the polar fluid from the same source first reservoir 110 and output the polar fluid to substantially the same destination second fluid reservoir 112.

[0043] A number of polar fluids were found to exhibit the flow described herein. For example, the polar fluid may include water, a polar fluid with one or more solutes, water with one or more solutes, a polar fluid with one or more suspended particle types, water with one or more suspended particle types, an alcohol, ethanol, a carboxylic acid, acetic acid, dimethyl sulfoxide, or deuterium oxide. For ease of understanding, the polar fluid will generally be referred to as water herein, but it is to be understood that other polar fluids may be substituted.

[0044] Optionally, an energy source 116 may provide energy to maintain fluid flow 114 over an extended period of time or to hasten formation of the EZ. The energy source 116 may be an explicit part of the structure of the fluid flow generator 116. Alternatively, the energy source may be inherent in the ambient environment of the fluid flow generator 116. For example, black body radiation from surrounding objects may provide energy to the tube 102 and the fluid therein.