rexresearch.com

MENZELL, Adrian, et

al.

[ Save The World Air Inc. ]

Fuel Saver Devices

[ Save The World Air Inc. ]

Fuel Saver Devices

KeelyNet : Device Increases Internal Combustion Engine Efficiency

WO2014179217 -- APPARATUS AND METHOD FOR REDUCING VISCOSITY

WO2006135963 -- DEVICE FOR SAVING FUEL AND REDUCING EMISSIONS

WO2005005817 -- Device for saving fuel and reducing emissions

WO2005045223 -- EMISSION CONTROL DEVICES

US6901917 -- Device for economy of fuel and reduction of emissions

WO2005066470 -- Inline exhaust device to improve efficiency of a catalytic converter

http://www.keelynet.com/indexapr406.htm [ 04/06/06 ]

Device Increases Internal Combustion

Engine Efficiency

A device that reduces emissions and increases fuel efficiency has passed Europe's toughest air quality standards and could be headed to the U.S. Save The World Air, Inc., has developed technology that reduces NOX and CO2 emission by creating magnetic fields that reorganizes molecules prior to combustion. The company received a U.S. patent last year and is currently distributing products in China. According to SWTA, tests showed that emissions from a motorcycle engine were cut by more than 75 percent. Perhaps this technology would be a cost-efficient way for auto manufacturers to meet California's tough emissions laws. STWA patented/patent pending devices are specifically engineered to minimize environmental pollution, to enhance fuel system performance and to increase engine efficiency. Variations of these devices can be attached to the internal combustion engines or exhaust systems in most automobiles, motorcycles, off-road vehicles, generators and other stationary implements. ZEFS devices work to enhance the atomization of the fuel by affecting the Viscosity of that fuel. The effect is achieved by the use of specific and complex magnetic flux orientations that have the ability to influence fuel at the molecular level, reducing the structure of the molecular structures with in the fuel. These devices affect the fuel atomization process by breaking down the size of the molecular structure of the fuel. Reductions have been recorded in the scale from 760 microns down to 140 microns in carburetion fuel systems and as low as 3 microns in fuel injection systems. The devices create a more efficient burn rate, thus lowering the production of CO, THC and NOX. ZEFS devices are easily fitted to the base plates of carburetors and fuel injection systems; the devices are compact and there are no moving parts. Our testing to date on both two and four stroke motorcycles, two and four stroke generators and a 1995 Mexican fuel injection VW automobiles are most encouraging. Independent tests performed in August 2004 at the Hong Kong Exhaust Emissions Laboratory (HKEEL) on a HONDA NSR 150 two-stroke motorcycle produced a 75% reduction in NOX, a 78% reduction CO and the reduction in THC emissions was even greater at 95%. Another independent test performed at HKEEL in August 2004 on a two-stroke 63cc generator engine produced a 58% reduction of THC emissions, 86% reduction of NOX and a 57% reduction of CO emissions.

http://www.savetheworldair.com [ defunct ]

Save The World Air Inc.

WO2014179217

APPARATUS AND METHOD FOR REDUCING VISCOSITY

Inventor: MENZELL ADRIAN / KOSTIC JOHN [AU]

Applicant: SAVE THE WORLD AIR INC

A fuel saving device comprising a support body (10) having at least one flow opening (15) therein and a periphery which adapts the support body (10) for positioning within a sealed environment of a fuel system of a combustion engine in a manner in which the longitudinal axis of the at least one flow opening (15) is coaxial with a fluid flow path, and a plurality of permanent magnets (11-14), the polar axes of all magnets oriented parallel to the flow path through the opening (15), the magnets (11-14) are provided in at least two stacks (16, 16'), each stack (16, 16') containing at least two magnets (11-14), the magnets (11-14) of each stack (16, 16') each have a polar axis extending in the same direction with the magnets (11- 14) of at least one stack (16) having polar axes extending in opposite direction to the other of the at least two stacks (16').

Technical Field

This invention relates to a device for saving fuel in combustion engines and reducing emissions, e.g. gaseous emissions to the atmosphere. Background Art

This invention relates particularly but not exclusively to a device for saving fuel and reducing emissions for use on internal combustion engines, e.g., normally aspirated engines and engines with fuel injectors. It will therefore be convenient to describe the invention with reference to these example applications. However, it is to be clearly understood that the invention is capable of broader application.

For example, the invention can be applied to any combustion engine and not just motor vehicle engines.

Incomplete combustion of liquid fuels increases the cost of running engines. Further unburned fuel e.g. hydrocarbons are vented to the atmosphere through the exhaust and are generally harmful to the atmosphere.

Some of the gases emitted into the atmosphere include carbon monoxide, various nitrogen oxides, and unburned hydrocarbons.

Naturally therefore any device which acted to decrease fuel consumption and thereby lower the running costs of a vehicle as well as lowering the pollution released to the atmosphere would be a major advance in the art and would be most advantageous to society generally.

International patent application No. PCT/AUOl/00585 describes a fuel saving device including a support which mounts a plurality of magnets in opposed polarities provided in a number of embodiments which enable the device to be incorporated in the fuel system of combustion engines with resulting fuel savings and a reduction in emissions.

It is generally agreed that there is strong evidence of a positive effect when carbon based liquid and gaseous fuels are magnetically influenced. It is also generally agreed that there is a possibility that the "air" (and probably specifically the O2 atoms within air) is influenced positively in terms of its ability combined with the gasoline particles.

Our tests to date have shown to our satisfaction that although gasoline can be influenced by magnetic fields arranged in particular alignments and cross alignments, the greatest influence is achieved when the air is treated either individually or in conjunction with the gasoline at the point where the air and gasoline mix. As a result of researching available data, and our own on-going practical testing observations and recordings, we believe that the fuel that combusts in an engine is not just the gasoline, but is the combination of gasoline and air. This distinction becomes important in understanding where the influence of a magnetic field may be most dominant. Any reference to fuel in this document means "the combination of gasoline and air".

The magnetic influences and/or effects that are most likely to be influencing the gasoline/air mix going into the combustion chamber of the engine include the viscosity of the fluid particles of the fuel.

Practical testing carried out in our research facility in 2002 proved that the introduction of magnetic fields with particular alignments and cross alignments, positively affects the ability of gasoline fluid particles to atomise to a greater extent, into air. The fluid particles of the gasoline/air mix became smaller and lighter.

There is no assertion as to any particular effect of magnetic influence on the gasoline prior to the point of atomisation in air. It should however be noted that Hans Dehmelt of the University of Washington, Seattle, in his 40 years of research into the basic properties of electrons showed that the electron has only four known characteristics: mass, charge, spin and magnetism. The magnetic effects seen on a daily basis, and employed in this device relate to ferromagnetic interaction. When we talk about "non-magnetic", we are actually saying non-ferromagnetic as there is no reaction with ferrite based substances. The recognition of "non-ferromagnetic forces" that are nonetheless magnetic, is a direct result of Dehmelt's work and their influences, although proven to exist, are yet to be quantified.

General laws of physics imply that the smaller the particle, the less surface tension, and the decreased weight of that particle allows for an increased "suspension" time in the air as it travels the distance through the intake manifold from the area of magnetic influence to the combustion chamber.

The fuel velocity through the intake manifold is influential in keeping fluid particles suspended in the air and this ability is enhanced if the fluid particles are smaller and lighter. The greater the amount of fluid in fine suspension on reaching the combustion chamber, the greater the fluid surface area exposed to air at the point of combustion. This has a positive effect on the rate of burn and the completeness of that burn. The result is that more power is generated from the same amount of fuel and with a more efficient burn less harmful gases are exhausted from the engine.

As the main requirement for combustion to occur in this situation is the presence of oxygen (O2), it seems logical to deduce that the most influential part of the air portion of fuel is the O2 molecule. Practical testing has been carried out in our research facility to identify the influence of magnetic fields on air before it mixes with gasoline to become "the fuel".

There is strong evidence to suggest that "air" (or more likely, specifically the O2 molecule in air) is susceptible to magnetic influence and may be the more dominant of the affected fuel components of gasoline and air.

There are devices similar to the present invention available. The devices which seem most similar are those disclosed in WO 97/25528, US 4414951 and US3762135. These devices are not the same as the present invention however and the differences between them and the present invention realise improved performance on the part of the present invention.

Summary Of The Invention

It is thus an object of the present invention to provide improvements to fuel saving devices which may at least partially overcome at least one of the abovementioned disadvantages or provide the consumer with a useful or commercial choice. hi one form, the invention resides in a fuel saving device comprising a support body having at least one flow opening therein and a periphery which adapts the support body for positioning within a sealed environment of a fuel system of a combustion engine in a manner in which the longitudinal axis of the at least one flow opening is co-axial with a fluid flow path, and a plurality of permanent magnets, the polar axes of all magnets oriented parallel to the flow path through the opening, characterised in that the magnets are provided in at least two stacks, each stack containing at least two magnets, the magnets of each stack each have a polar axis extending in the same direction with the magnets of at least one stack having polar axes extending in opposite direction to the other of the at least two stacks.

The support body of the invention is preferably a spacer, defining a passage for the fuel air mixture, which is coupled in series with the rest of the fuel line.

Preferably, there will be a pair of stacks of magnets, the stacks of magnets being on substantially opposed sides of the opening.

Suitably, the plurality of magnets of each stack will be mounted in the same plane; that is, the support body will generally be a substantially planar body. The support body is typically formed of aluminium or a similar metal.

The magnets of each stack may abut each other or may be spaced apart in the stack. Typically, at least one spacing member may be provided between magnets in a stack, the spacing member having a shape similar to that of the magnet.

The magnets can be secured to the support body by key slots of a complimentary shape. Each of the plurality of magnets is suitably keyed into the support body and each has a magnetic face which extends to and is communicable with the at least one flow opening. A portion of the magnets (and any spacing member) may form or assist with defining a sidewall of the flow opening.

The support body is suitably provided with a plurality of apertures therein to facilitate the mounting of the support body in a fuel/air line leading to a combustion chamber of an internal combustion engine.

The support body may be provided with top and bottom cover plates which secure the magnets against displacement via top and bottom surfaces of the support body. Alternatively, the magnets may be secured to the support body using an adhesive material, preferably one which is heat resistant.

There is preferably an even number of magnets keyed into the body in each stack, the poles of opposite stacks of the magnets reversed relative to each other, but the magnets in a stack having aligned polar axes.

The device, as adapted for use in association with a single-throat carburetor, will typically include a pair of stacks but there may be more than one pair of stacks provided. For example, there may be four stacks spaced substantially equidistantly about the circumference of the at least one opening in the support body, arranged at approximately 90[deg.] apart from each other. A further preferred embodiment of the device has six stacks spaced substantially equidistantly about the circumference of a substantially oval shaped central opening in the support body.

The magnets provided according to the invention may be a rare earth or neodymium iron boron magnet. Preferably, a plurality of magnets of this type are provided although alternative configurations of magnet numbers and types of magnets may be used according to the present invention. The rare earth magnets produce high strength magnetic fields. This enhances the magnetic force which is applied to the fuel droplets as they pass through the device. This enhances the breaking up or size reduction of the droplets as they pass through the device.

Naturally, the size of the magnets will influence the strength of the magnetic field generated in the fuel air passageway. In one particular form, each magnet has a cross sectional surface area in the range of 20-50mm x 20-50mm. This will suffice to produce a suitable magnetic field in a fuel air passageway having a diameter of 22 mm to 40mm, preferably about 25mm or 38mm. The depth or thickness of the magnet will typically be 10-30mm, the actual depth being influenced by the thickness of the spacer in which the magnet is received. It will be appreciated however that the size of the magnets can vary.

Brief Description Of The Drawings Aspects of the present invention will now be described with reference to the accompanying drawings in which:

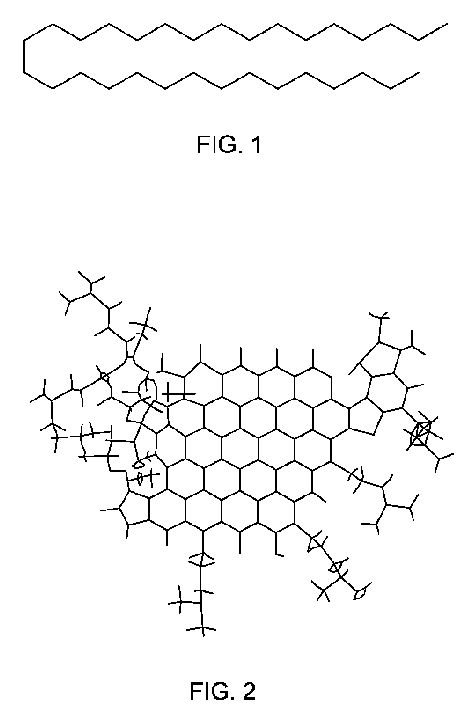

FIGURE 1 is a perspective view of a fuel saving device according to one aspect of the present invention.

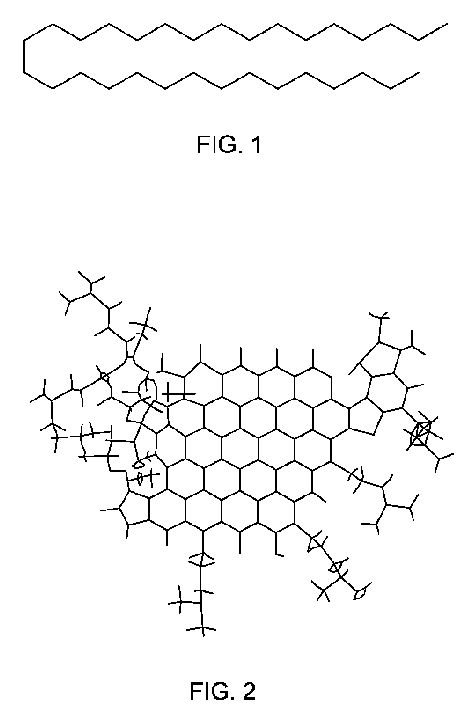

FIGURE 2 is a perspective view of the magnets of the device illustrated in Figure 1 removed from the device.

FIGURE 3 is a top view of the device illustrated in Figure 1. FIGURE 4 is a side view of the device illustrated in Figure 1 along line A-A.

FIGURE 5 is an end view of the device illustrated in Figure 1 along line B-B.

Description Of The Preferred Embodiment

With respect to Figure 1 of the drawings, the fuel saving device illustrated comprises a support body 10 which is generally hexagonal in shape and having a central aperture 15. The support body 10 supports a plurality of permanent magnets 11 (preferably 11 to 14), the support body 10 illustrated being constructed from a substantially unitary metal material and without top or bottom cover plates.

The magnets 11-14 are secured to the support body by key slots 17 of a complimentary shape. Each of the plurality of magnets 11-14 is keyed into the support body 10 and each has a face which extends to and is communicable with the central opening 15. A portion of the magnets (and any spacing member) may form or assist with defining a sidewall of the central aperture 15.

The magnets 11-14 face the central aperture 15. The polar axes of all magnets provided are oriented parallel to the flow path of fuel and air through the aperture 15 in the support body 10. The magnets 11-14 are provided in two magnet stacks 16, 16'. Each magnet stack 16, 16' contains two magnets, the magnets of each stack 16, 16' each having a polar axis extending in the same direction with the magnets of a first stack 16 having polar axes extending in opposite direction to the other stack 16'. hi this case however, the magnets extend only partially throughout the depth of the support body 10 and stop short of the bottom face of the support body 10 by a distance "S".

Such an arrangement provides the option of moving the magnetic field further away from the base of a carburetor and increasing the area of magnetic influence between the point of gasoline atomization and the point of cessation of magnetic influence.

The support body 10 is also provided with a plurality of attachment openings 18 therein to facilitate the mounting of the support body 15 in a fuel/air line leading to a combustion chamber of an internal combustion engine.

With respect to figure 2 of the drawings, the magnets of the stacks 16, 16' are illustrated removed from the support body 10. The polar axes are illustrated by designating the poles of the magnets.

Figure 3 of the drawings show a view from above the device according to the preferred embodiment with typical dimensions.

The device described has been shown to provide significant reductions in fuel consumption and significant reduction in emissions. Use of a device according to the invention generally results in a marked decrease in the level of unburnt hydrocarbons in the exhaust stream from the engine. It also leads to a decrease in the level of carbon monoxide and oxides of nitrogen in the exhaust stream from the engine. Use of the device according to the invention also results in an increase in the level of oxygen in the exhaust stream. An implication of this can be seen to be that the combustion of the hydrocarbons in the engine is more efficient resulting in a lower level of unburnt hydrocarbons in the exhaust stream and more efficient use of oxygen resulting in less oxygen being used in the combustion process.

Various experiments have been performed using the device of the invention. The following is a typical example of emission levels and fuel efficiency from such experiments, including comparison to the Euro II standard. Experiment 1

The tests were conducted in December 2005 at the Automotive

Emission Laboratory, Pollution Control Department, Ministry of Natural Resources and Environment of Thailand, and were performed jointly with S.P. Suzuki of Thailand, the authorized distributor of Suzuki products in Thailand. The tests were conducted on a used, 4-stroke motorcycle.

These certified test results were better than EURO II standards in all three of the harmful exhaust emissions by significant amounts as shown below:

THC NOx CO

EURO II Standard 1.20 g/km .30 g/km 5.50 g/km

With ZEFS Device .52 g/km .10 g/km 1.42 g/km

% Below EURO II 56% 65% 74%

In addition, during the testing, horsepower increased at all ranges, peaking at 18.8% at 50 km/h. Even more significant was the calculation by the laboratory that fuel economy increased 33% over the baseline tests. Experiment 2

This set of tests were conducted on a new Chinese-manufactured carbureted 4-stroke Suyijia SZKl 25 motorcycle, and were better than EURO3 standards for motorcycles of 150cc or less. The tests were conducted in early March

2006 at the Hong Kong Exhaust Emissions Laboratory (HKEEL) in Hong Kong, a certified laboratory of the United Kingdom 's Vehicle Certification Agency (VCA). The certified test results surpassed EURO3 standards in all three of the harmful exhaust emissions by the amounts, as shown below:

THC NOx CO

EUROS Stage Standard 0.8 g/km 0.15 g/km 2.0 g/km

With ZEFS Device 0.33 g/km 0.108 g/km 1.86 g/km

% Below EURO3 59% 28% 7%

In addition, fuel economy increased 7% over the baseline tests.

It will of course be realised that the above has been given by way of illustrative examples of the invention and that all such modifications and variations thereto as would be apparent to persons skilled in the art are deemed to fall within the broad scope and ambit of the invention. hi the present specification and claims, the word "comprising" and its derivatives including "comprises" and "comprise" include each of the stated integers but does not exclude the inclusion of one or more further integers.

Reference throughout this specification to "one embodiment" or "an embodiment" means that a particular feature, structure, or characteristic described in connection with the embodiment is included in at least one embodiment of the present invention. Thus, the appearance of the phrases "in one embodiment" or "in an embodiment" in various places throughout this specification are not necessarily all referring to the same embodiment. Furthermore, the particular features, structures, or characteristics may be combined in any suitable manner in one or more combinations.

A fuel saving device comprising a disc-like non-magnetic solid support body having at least one flow opening therein and a continuous periphery which adapts the support body for positioning within a sealed air/fuel environment of a fuel system of a combustion engine at an air/fuel mixing point within the fuel system in a manner in which the longitudinal axis of the at least one flow opening is co-axial with fluid flow paths within the air/fuel environment, a plurality of permanent magnets having opposed polar axes supported by the periphery and positioned to provide at least one magnetic field across the at least one flow opening in the support body, and at least one booster magnet associated with the at least one flow opening.

TECHNICAL FIELD

This invention relates to a device for saving fuel in combustion engines and reducing emissions, e. g. gaseous emissions to the atmosphere.

BACKGROUND ART

This invention relates particularly but not exclusively to a device for saving fuel and reducing emissions for use on internal combustion engines, e. g., normally aspirated engines and engines with fuel injectors. It will therefore be convenient to describe the invention with reference to these example applications.

However, it is to be clearly understood that the invention is capable of broader application.

For example, the invention can be applied to any combustion engine and not just motor vehicle engines.

Incomplete combustion of liquid fuels increases the cost of running engines. Further unburned fuel e. g. hydrocarbons are vented to the atmosphere through the exhaust and are generally harmful to the atmosphere.

Some of the gases emitted into the atmosphere include carbon monoxide, various nitrogen oxides, and unburned hydrocarbons.

Naturally therefore any device which acted to decrease fuel consumption and thereby lower the running costs of a vehicle as well as lowering the pollution released to the atmosphere would be a major advance in the art and would be most advantageous to society generally.

International patent application No. PCT/AU01/00585 describes a fuel saving device including a support which mounts a plurality of magnets in opposed polarities provided in a number of embodiments which enable the device to be incorporated in the fuel system of combustion engines with resulting fuel savings and a reduction in emissions.

It is generally agreed that there is strong evidence of a positive effect when carbon based liquid and gaseous fuels are magnetically influenced.

It is also generally agreed that there is a possibility that the"air" (and probably specifically the 02 atoms within air) is influenced positively in terms of its ability combine with the gasoline particles.

Our tests to date have shown to our satisfaction that although gasoline can be influenced by magnetic fields arranged in particular alignments and cross alignments, the greatest influence is achieved when the air is treated either individually or in conjunction with the gasoline at the point where the air and gasoline mix.

As a result of researching available data, and our own on-going practical testing observations and recordings, we believe that the fuel that combusts in an engine is not just the gasoline, but is the combination of gasoline and air. This distinction becomes important in understanding where the influence of a magnetic field may be most dominant. Any reference to fuel in this document means"the combination of gasoline and air".

The magnetic influences and/or effects that are most likely to be influencing the gasoline/air mix going into the combustion chamber of the engine include the viscosity of the fluid particles of the fuel.

Practical testing carried out in our research facility in 2002 proved that the introduction of magnetic fields with particular alignments and cross alignments, positively affects the ability of gasoline fluid particles to atomise to a greater extent, into air. The fluid particles of the gasoline/air mix, became smaller and lighter.

There is no assertion as to any particular effect of magnetic influence on the gasoline prior to the point of atomisation in air. It should however be noted that Hans Dehmelt of the University of Washington, Seattle, in his 40 years of research into the basic properties of electrons showed that the electron has only four known characteristics: mass, charge, spin and magnetism. The magnetic effects seen on a daily basis, and employed in this device relate to ferromagnetic interaction. When we talk about"non-magnetic", we are actually saying non-ferromagnetic as there is no reaction with ferrite based substances. The recognition of"non-ferromagnetic forces" that are none the less magnetic, is a direct result of Dehmelt's work and their influences, although proven to exist, are yet to be quantified.

General laws of physics imply that the smaller the particle, the less surface tension, and, the decreased weight of that particle allows for an increased "suspension"time in the air as it travels the distance through the intake manifold from the area of magnetic influence, to the combustion chamber.

The fuel velocity through the intake manifold is influential in keeping fluid particles suspended in the air and this ability is enhanced if the fluid particles are smaller and lighter. The greater the amount of fluid in fine suspension on reaching the combustion chamber, the greater the fluid surface area exposed to air at the point of combustion. This has a positive effect on the rate of burn and the completeness of that burn.

The result is that more power is generated from the same amount of fuel, and with a more efficient burn less harmful gases are exhausted from the engine.

As the main requirement for combustion to occur in this situation is the presence of oxygen (02), it seems logical to deduce that the most influential part of the air portion of fuel, is the 02 molecule.

Practical testing has been carried out in our research facility to identify the influence of magnetic fields on air before it mixes with gasoline to become"the fuel".

There is strong evidence to suggest that"air" (or more likely, specifically the 02 molecule in air) is susceptible to magnetic influence and may be the more dominant of the effected fuel components of gasoline and air.

The magnetic field patterns which are created by fuel saving devices such as that discussed by international patent application no. PCT/AU01/00585, are important and we conclude that multidirectional fields are more successful than orderly single line fields and that the devices may need to be arranged in different ways to best suit particular engines.

It is thus an object of the present invention to provide improvements to fuel saving devices which may at least partially overcome at least one of the abovementioned disadvantages or provide the consumer with a useful or commercial choice.

Further objects and advantages of the present invention will become apparatus from the ensuing description which is given by way of example.

In one form, the invention resides in a fuel saving device comprising a disc-like non-magnetic solid support body having at least one flow opening therein and a continuous periphery which adapts the support body for positioning within a sealed air/fuel environment of a fuel system of a combustion engine at an air/fuel mixing point within the fuel system in a manner in which the longitudinal axis of the at least one flow opening is co-axial with fluid flow paths within the air/fuel environment, a plurality of permanent magnets having opposed polar axes supported by the periphery and positioned to provide at least one magnetic field across the at least one flow opening in the support body, and at least one booster magnet associated with the at least one flow opening.

Suitably, the plurality of peripherally mounted magnets will be mounted in the same plane, that is, the disc-like non-magnetic solid support body will generally be a substantially planar body.

The booster magnet will generally be positioned in substantially the same plane as the plurality of permanent magnets.

The plurality of magnets is suitably keyed into the periphery of the body and each has a magnetic face which extends to and is communicable with the at least one flow opening.

The support body is suitably provide with a plurality of apertures therein to facilitate the mounting of the support body in a fuel/air line leading to a combustion chamber of an internal combustion engine.

The support body may be provided with top and bottom cover plates which secure the magnets against displacement via top and bottom surfaces of the support body.

There is preferably an even number of magnets keyed into the periphery of the body with the poles of opposite pairs of the magnets reversed relative to each other.

According to a most preferred embodiment, the device, as adapted for use in association with a single-throat carburetor, has four magnets spaced substantially equidistantly about the circumference of the central opening in the support body, arranged at approximately 90 apart from each other.

A further preferred embodiment of the device has six magnets spaced substantially equidistantly about the circumference of a substantially oval shaped central opening in the support body.

The booster magnet may be oriented with the polar axis of the magnet being oriented such that the negative pole of the magnet is on the outlet side of the device.

The inventors have found that in addition to defining an annular magnetic field around the central magnet, the fact that the central magnet is present places an obstruction in the flow path of the air/fuel mixture as it passes through the opening. This may result in at least radial mixing of the air/fuel mixture and will generally result in longitudinal mixing as well. The mixing characteristics of the air/fuel mixture as it passes through the opening may overcome the plug flow characteristics present in prior art devices.

Plug flow is characterised by the fact that the flow of mixture through the device is orderly with no element of fluid overtaking or mixing with any other element ahead or behind it. In a plug flow situation, the degree of treatment of the mixture varies from point to point along a flow path, with a given mixture element being treated only once as it passes through the magnetic fields caused by the device.

The present invention may promote at least radial and some longitudinal mixing of the air/fuel mixture which results in the possibility that a given mixture element pass through the magnetic fields caused by the device more than once, thus enhancing treatment.

In addition to this, prior art devices promote a convex air/fuel mixture flow profile due to the boundary layer caused by in the pipe and opening. This results in a larger amount of the mixture passing through the middle of the opening as compared to the periphery of the pipe. As the magnets of the prior art devices are located around the periphery of the opening, this resulting magnetic field is strongest or most effective closest to the magnets, that is closest to the periphery of the opening, and weakest in the centre of the opening as the field is active over the width or diameter of the opening. Therefore, in prior art devices, the majority of the air/fuel mixture is treated or affected by a weaker part of the magnetic field.

By providing the obstruction in the flow path of the air/fuel mixture as it passes through the opening of the present invention, the central magnet may disrupt the flow profile and force the fluid mixture to pass through or across the more effective portion of the magnetic field, thus enhancing treatment of the mixture. It may also have the effect of decreasing the width or diameter of the opening over which the magnetic field must span. The width of the opening may be effectively halved allowing the magnetic fields to be"shorter"and thus increase effectiveness.

Still further, the magnetic field may be increased in dimension in the longitudinal direction of the device due to the provision of the central magnet.

BRIEF DESCRIPTION OF THE DRAWINGS

Aspects of the present invention will now be described with reference to the accompanying drawings in which:

FIGURE 1 is a top perspective view of a fuel saving device according to one aspect of the present invention, and

FIGURE 2 is a top view of a fuel saving device according to another aspect of the present invention, and

FIGURES 3 and 3a are diagrammatic lines of flux created by the devices of figures 1 and 2, and

FIGURE 4 of the drawings is a plan view of a device according to a further aspect of the present invention adapted for multiple throat carburetors.

With respect to figure 1 of the drawings, the fuel saving device illustrated comprises a hexagonal shaped non-magnetic body 1 supporting a plurality of permanent magnets 2 (preferably 2 to 6), the body illustrated being constructed in two halves or having a central core and top and bottom cover plates.

The magnets 2 face a central aperture 3 and have opposed polarities as described in the abovementioned international patent application.

In this case however, the magnets extend only partially throughout the depth of the body and stop short of the top wall of the body by a distance"S".

Such an arrangement provides the option of moving the magnetic field further away from the base of a carburetor and increasing the area of magnetic influence between the point of gasoline atomization and the point of cessation of magnetic influence.

With respect to figure 2 of the drawings, the device of figure 1 is modified to include a centrally positioned magnet 5 supported by a grate (not shown) with a magnetic field running transverse to the main magnets. The magnetic field created by the additional central magnet causes an increased 3D effect.

The polarity of the central magnet 5 is negative down.

Figures 3 and 3a of the drawings show respectively the magnetic fields generated by the device of figure 1 and the device of figure 2.

With respect to figures 3 and 3a, in figure 3, there occurs a predominant plane of magnetic forces, parallel to the plane of the plurality of magnets, indicated by arrow 6 associated with magnetic lines of force which are perpendicular to the plane of the plurality of magnets, indicated by arrow 7. The direction of fuel is indicated by arrow 8. In figure 3, the central magnet, indicated by arrow 9 influences the magnetic forces to the extent that the perpendicular lines of force are increased in length.

The devices described have been shown to provide significant reductions in fuel consumption and significant reduction in emissions.

With respect to figure 4 of the drawings, a device for fitment to multiple throat carburetors comprises a body 10 constructed similarly to the devices previously described.

The body 10 is provided with mounting apertures 11 to suit a selected carburetor and is interposed between the carburetor and the air/fuel mixture of a system.

The body 10 is provided with primary and secondary passages 12.

Two magnets 13 having opposed polarities as indicated are positioned in the body facing the passages 12 at approximately ninety degree spacing.

A further magnet 13a is positioned adjacent each of the smaller passages 12a.

A mild steel plate or further magnet 14 is placed between the larger pair of passages 12b.

The device illustrated generates similar magnetic fields to that described for the previous embodiments.

The devices described have been shown to provide significant reductions in fuel consumption and significant reduction in emissions.

In this regard, a number of experiments have been conducted as a proof of concept of the invention. The results of a sample of said experiments are presented below in tabular form.

Example 1-Conducted using a 1984 Mustang V8 engine with 4 Barrel Carburetor. Engine at Idle Results

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 380 ppm 162 ppm 57

Carbon Monoxide 3. 41% 0.97% 69

Carbon Dioxide 12. 90% 14.60% (13)

NO 17 ppm 11 ppm 35

Oxygen 0. 00% 0. 04% 4

Example 2-Conducted using a 1984 Mustang V8 engine with 4 Barrel Carburetor. Engine at 1600 to 1660 rpm Results

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 103 ppm 49 ppm 52

Carbon Monoxide 2. 10% 0.20% 90

Carbon Dioxide 10. 60% 12.4% (17)

NO 58 ppm 38 ppm 34

Example 3-Conducted using a 1984 Mustang V8 engine with 4 Barrel Carburetor. Engine at 1640 to 1680 rpm Results

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 214 ppm 49 ppm 77

Carbon Monoxide 6. 08% 1.24% 79

Carbon Dioxide 8. 20% 11. 60% (41)

NO 98 ppm 31 ppm 68

Example 4-Conducted using a Volkswagen Beetle engine with Carburetor at engine Temperature of 80 C. Drive Cycle engine running at various road speeds according to IM240 test.

Results 0-20 mph

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 468 ppm 257 ppm 52

Carbon Monoxide 1. 01% 0.62% 90

Carbon Dioxide 12. 56% 12. 89% (17)

NO 345 ppm 295 ppm 34

Oxygen 1. 98% 2.15% (8)

Results 21-40 mph

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 231 ppm 192 ppm 52

Carbon Monoxide 0. 54% 0.47% 90

Carbon Dioxide 12. 97% 12. 84% (17)

NO 659 ppm 606 ppm 34

Oxygen 2. 30% 2. 31 % (0. 4)

Results 41-60 mph

Emission Constituent Value-No Value-Device Percentage

Device Fitted (Increase)/Decrease

Hydrocarbons 267 ppm 162 ppm 52

Carbon Monoxide 0. 35% 0.31% 90

Carbon Dioxide 13. 33% 13.48% (17)

NO 1465 ppm 1292 ppm 34

Oxygen 1. 60% 1.65% (3)

Where it is used above, the symbol"NO"is used in a generic sense to mean oxides of nitrogen generally as opposed to its strict sense which is nitric oxide.

As can be seen from the above examples, use of a device according to the invention generally results in a marked decrease in the level of unburnt hydrocarbons in the exhaust stream from the engine. It also leads to a decrease in the level of carbon monoxide and oxides of nitrogen in the exhaust stream from the engine. Use of the device according to the invention also results in an increase in the level of oxygen in the exhaust stream. An implication of this can be seen to be that the combustion of the hydrocarbons in the engine is more efficient resulting in a lower level of unburnt hydrocarbons in the exhaust stream and more efficient use of oxygen resulting in less oxygen being used in the combustion process.

It will of course be realised that the above has been given by way of illustrative examples of the invention and that all such modifications and variations thereto as would be apparent to persons skilled in the art are deemed to fall within the broad scope and ambit of the invention.

In the present specification and claims, the word"comprising"and its derivatives including"comprises"and"comprise"include each of the stated integers but does not exclude the inclusion of one or more further integers.

Inventor: MENZELL ADRIAN [AU] // KOSTIC JOHN

SAVE THE WORLD AIR INC

An emissions control device including an elongate body portion having a plurality of channels which are angularly orientated to each other, and each channel having at least one magnet positioned in the channel, the at least one magnet having a polar axis orientated to create magnetic fields directed at a common site adjacent to the body portion.

EMISSION CONTROL DEVICES

Technical Field

The present invention relates to emission control devices and in particular to emission control devices used in conjunction with electronically controlled fuel injection systems.

Background Art

It is now accepted that the treatment of a body of fluid with magnetic fields is capable of providing varying beneficial effects.

Magnetic devices for treating fuels have been proposed in the past and descriptions of such devices can be found in:

International Patent Application No. WO 99/23381

United States Patent No. 5558765 United States Patent No. 5161512

International Patent Application No. WO 00/31404.

Australian Patent Application No. 2001258057

Authorities throughout the world are moving to encourage efficiencies of petrol and diesel engines including non-road engines and in particular regulating to encourage manufacturers to reduce harmful emissions from engines.

Most modern motor vehicles are fitted with petrol injection systems, either mechanical or electronic.

In such a system, injectors open to spray fuel into an airstream in an inlet duct in a fuel rail. The injectors are mounted in the intake manifold so that they spray fuel directly at the intake valves. A pipe called the fuel rail supplies pressurized fuel to all of the injectors.

Fuel rails for modern injection systems are accessible and accordingly, provide a site to mount a treatment device.

It is an object of the present invention to provide a device and methodology for treating fuels via the fuel rail of a fuel injection system with a view to reducing harmful emissions.

Further objects and advantages will become apparent from the ensuing description which is given by way of example only.

Disclosure of Invention

According to the present invention, there is provided an emissions control device comprising (a) an elongate body portion having a plurality of channels which are angularly orientated to each other, and (b) each channel having at least one magnet positioned in the channel, the at least one magnet having a polar axis orientated to create magnetic fields directed at a common site adjacent to the body portion.

Each channel is most suitably oriented at approximately 120 degree intervals to each other channel. Each channel typically has an open face to allow insertion of the magnets into the channel or replacement of the magnets.

The open faces are radially spaced at approximately 120 degree intervals.

The device may include a tubular cover which houses the body portion and provides an opening common with the common site. The cover may be attachable relative to the body portion to secure the magnets provided in the various channels.

The at least one magnet mounted in a first of the channels may be a neodymium iron boron magnet. Preferably, a plurality of magnets of this type are provided although alternative configurations of magnet numbers and types of magnets may be used according to the present invention.

Magnets mounted in a second and third channels may be ferrite or neodymium iron or boron magnets. Again, a plurality of magnets of this type may be provided although alternative configurations of magnet numbers and types of magnets may be used according to the present invention. According to the most preferred embodiment of the present invention, a single bar magnet may be provided in the second and third channels.

The cover may be fabricated or moulded from aluminium tubestock.

According to the present invention, there is provided a method of treating air fuel/fuel mixtures of an engine having a fuel injection system comprising mounting a device as aforesaid coaxially with a fuel intake rail of a fuel injection system.

The device may be mounted externally of the fuel rail.

The device may be mounted within or partially within the fuel rail.

Without wishing to be limited by theory, the inventors of the present invention have found that the imposition of a magnetic field with particular alignments and/or cross alignments may affect the ability of hydrocarbon fluid particles to atomize. In particular, an increase in the effectiveness of the atomisation of the hydrocarbon fluid was realised.

The general laws of physics imply that the smaller a particle is, the lower the surface tension of that particle and the lower the weight of the particle.

Smaller particles therefore result in an increase suspension time of a particle of hydrocarbon fluid as it travels the distance through the intake manifold form the area of magnetic influence of the device according to the present invention and into the combustion chamber.

The hydrocarbon fluid velocity when injected (as well as the air velocity) through the intake manifold may be influential in keeping hydrocarbon fluid particles suspended in the air and the ability to suspend more particles for a longer period may be enhanced if the hydrocarbon fluid articles are smaller and lighter. The greater the amount of fluid in suspension on reaching the combustion chamber, the greater the hydrocarbon fluid particle surface area exposed to air at the point of combustion, thereby increasing the rate of burn, the efficiency of burn and completeness of burn. One result may be an increase in power generated per unit of hydrocarbon fluid and a decrease in noxious exhaust gases produced due to increase burn efficiency.

One way in which the magnetic field may affect the size of the hydrocarbon fluid particles upon atomisation is by affecting the viscosity of the hydrocarbon fluid. This may occur by the action of the magnetic field aligning the hydrocarbon chains in the hydrocarbon fluid.

The alignment action may be effected because the hydrocarbon chains may exhibit a degree of paramagnetism. A paramagnetic material is one whose atoms may have permanent dipole moments, but perminant no perminant magnetism exsists outside the influence of an external magnetic field. If a magnetic field is applied to such a material, the dipole moments try to line up with the magnetic field, but are

prevented from becoming perfectly aligned by their random thermal motion. Because the dipoles try to line up with the applied field, the susceptibilities of such materials are positive, but in the absence of the strong ferromagnetic effect, the susceptibilities are rather small. If on the average only a relatively small fraction of the atoms are aligned with the field (say 30% or less), then the magnetization obeys Curie's law:

where C is a constant (different for each different material), where T is the temperature in kelvins, and where Bext is the applied magnetic field. Curie's law says that if Bext is increased, the magnetization increases (the stronger magnetic field aligns more of the dipoles). It also says that if the temperature is increased, the magnetization decreases (the increased thermal agitation helps prevent alignment). Curie's law only works for samples in which only a relatively small fraction of the atoms are aligned, on the average, with the magnetic field. When the aligned fraction becomes larger, Curie's law no longer holds because it predicts that the magnetization just goes up forever with increasing applied magnetic field Beat. But this can't be true because once the dipoles are 100% aligned, further increases in the magnetization are impossible.

When this happens we say that the material is saturated, and further increases in BeXt or decreases in T will not change the magnetization very much because the atoms are about as aligned as they can get.

When a paramagnetic material is placed in a strong magnetic field, it becomes a magnet, and as long as the strong magnetic field is present, it will attract and repel other magnets in the usual way. But when the strong magnetic field is removed, the net magnetic alignment is lost as the dipoles relax back to their normal random motion.

The effects of the alignment of the hydrocarbon chains may allow the reduction in size of the hydrocarbon fluid particles when formed. (The length of time that the chains remain aligned is dependent upon several influences including but not limited to conduit surface inter-reaction, fluid density, and the degree of tortuosity of th pathway through which the particles flow, which is particularly relevent in combustion

engines.)

The effects of this may be seen from the following example using a unit scale:

If one particle of atomised hydrocarbon (calculated as a uniform sphere and identified as"A") is 12 arbitrary units in diameter, then the surface area of that particle would be 47rr2, or as the radius of this particle in 6 units, approximately 452.38 square units of surface area.

The volume of that same sphere A would be 4/37ir3 or approximately 904.8 cubic units.

If the magnetic influence has an effect of changing the packing factor of the hydrocarbon chains by 20% with an effect if a size reduction in the atomized hydrocarbon particle by 20%, then the above calculation for surface area and volume of a particle 20% smaller than 12 units in diameter or 9.6 units in diameter (Particle "B") would be as follows:

Surface area would be 289.5 square units and a volume of 463.2 cubic units.

If the total volume of all hydrocarbon atomised as it enters the system is constant, the difference in volume between particle A and Particle B requires that approximately 2 particle B's are created instead of 1 particle A (904.8/463. 2 equal 1.953 or approximately 2). If two B particles are created, then the corresponding surface area of these two B particles is 289.5 square units x 2 or 579 square units. The surface area of particle A is 452. 38 square units. Therefore, the total increase in surface area realised by providing two smaller volume particles having the same volume as a single larger particle is 126.62 square units, that is, the surface area of the smaller particles exhibit a surface area increase of approximately 28%.

The increase in surface area available for contact with the air and an increase surface area available for the combustion process, an increase in burn efficiency is realised. The increase burn efficiency may result in a lower level of emissions and more power per unit of hydrocarbon fuel.

Brief Description of the Drawings

Aspects of the present invention will now be described with reference to the accompanying drawings in which:

FIGURE 1 is an exploded perspective view of an emissions control device according to one possible embodiment of the present invention, and

FIGURE 2 is an end/sectional view of the emissions device of Figure 1 applied to the fuel rail of an injection system, and

FIGURE 3 is a diagrammatic perspective view of the device of Figure 1 applied to the fuel rail of an injector system of an engine.

Description of Preferred Embodiment

With respect to the drawings, a device according to the present invention can comprise an elongate body generally indicated by arrow 1, the body providing a plurality of channels 2 therein, each having angularly orientated open faces 3.

A plurality of magnets generally indicated by arrow 4 are positioned in the channels having polar axes as indicated which create magnetic fields directed at a common site adjacent to the body.

The open faces are radially spaced by approximately 120 degrees.

The device may include a tubular cover 5 which houses the body 1 and provides an opening 6 common with the common site.

The device is mounted on a common fuel rail 7 (see Figures 2 and 3) which defines the common site for the magnetic field.

The magnets may be separate magnets or may be in bar form.

The magnet types may vary, for example, the magnets in a first of the channels 8 may be neodymium iron boron magnets whilst magnets in channels 9 and 10 may be ferrite magnets of lesser strength.

Voids within the interiors of the cover may be filled or partially filled with a non-magnetic filler e. g. an epoxy.

Whilst the device of the present invention is primarily concerned with reducing the level of undesirable emissions from engines, it is likely that it will also reduce fuel consumption.

The magnetic field applied to a fuel line is directly applied to fuels by the magnets immediately adjacent the fuel line. It is supposed that the magnetic lines of flux from the magnets immediately adjacent the fuel line deflect and spread throughout the cross-section of the fuel line and the effect of the stronger magnet is to assist the process.

It is also supposed that an alignment of the carbon chains in the fuel in a specific way takes place. Testing has indicated that with specific magnetic field alignment, the viscosity of the liquid fuel is affected.

Examples of this testing is given in the table below, in which the test was carried out on a vehicle with an electronically controlled fuel injection system.

TEST NO 1.

Vehicle: Holden Commodore, Model VN, Year 1991.

The test was carried out at a constant 60 kph. The operating temperature of the engine was verified prior to testing as temperature can also effect the viscosity of the fluid.

The test was carried out at ambient conditions (humidity and temperature) which were recorded and remained within a 5% range throughout the test. The emissions in the gaseous exhaust were then analysed.

Base-line sets:

HEX ppm NOX ppm CO% CO2% Test 9/7 A 60 535 0.44 14.67 Test 9/7 B 53 509 0.47 14.82 BASE-LINE 56.5 522 0.45 14.745 Averaged Device on Test 9/7 C 39 519 0.28 14.55 Test 9/7 D 34 495 0.27 14.44 DEVICE 36 504 0.27 14. 495 Averaged % Improvement 36.2% 2.8% 40% 1.7% TEST NO 2.

Conditions as above with speed increase to a constant 80 KPH HEX ppm NOX ppm CO% C02% Base-line set : Test 7/10/C 114 1125 0.54 14.82

Device on 79 1056 0.36 14.68 % Improvement 30.7% 5.3% 33.3% 0.9%

The benefits of the device according to the present invention can therefore be seen from the above tests.

Inventor: MULLER JEFFREY ALAN

Applicant: SAVE THE WORLD AIR

The present invention relates to a fuel saving device (1) comprising a stationary non-magnetic supporting body (2) provided with an aperture defining a flow passage (3) for fuel-air mixture, and at least three magnets (4) each having its polar axis oriented substantially parallel to the air-fuel mixture flow way and forming a continuous magnetic field through the fuel-air mixture flow passage (3) in said supporting body (2), wherein at least two magnets (4) are located substantially opposite to each another and have their polar axes oriented in the north-south direction, wherein the axis of the at least third magnet (4) is oriented in opposite south-north direction.; The proposed fuel saving device (1) includes several embodiments of the supporting body (2) with several magnets having opposed polarities mounted thereon, and the supporting body (2) can be interposed in the fuel system of internal combustion engines with resulting fuel savings and a reduction in emissions.

Inventor: PATRICK MENZELL ADRIAN KOSTIC [US]

Applicant: SAVE THE WORLD AIR INC [US]

Inventor: BAKER PATRICK / KOSTIC JOHN

Applicant: SAVE THE WORLD AIR INC

This invention is directed to a device that can sit within, or be associated with an exhaust stream of an internal combustion vehicle and which can improve the efficiency of the catalytic converter in the exhaust stream, typically by keeping parts of the catalyst hotter than otherwise would be possible.

Background Art.

Internal combustion engines such as gasoline or petrol engines provide toxic emissions which contain carbon monoxide, nitrogen oxides and the like.

One way by which these toxic emissions can be reduced is to provide a catalytic converter in the exhaust stream. A common catalytic converter is a three-way converter that reduces the three regulated emissions - carbon monoxide, VOC's, and nitrogen oxides. The catalytic converter typically uses two different types of catalysts, being a reduction catalyst and an oxidation catalyst. The converter usually comprises a honeycomb of ceramic or metal structure which is coated with a metal catalyst which is typically platinum, palladium or rhodium.

One of the biggest shortcomings of the catalytic converters is that they only work efficiently at fairly high temperature. One simple way to keep the catalytic converter hot is to make sure that the converter is positioned upstream in the exhaust system and close to the engine. However, this is not always convenient and can result in the catalytic converter becoming too hot which will cause damage to the catalytic converter.

Thus, it is also known to preheat the catalytic converter. This is commonly done using an electric preheating element which is powered by the vehicle battery and which heats the catalytic converter to the operating temperature. During normal operation of the engine, the heat of the exhaust gases is usually sufficient to keep the catalytic converter at its operating temperature, and the preheating element can then be switched off. However, an electric preheater still requires several minutes of operation to heat the catalyst to the operating temperature. Also, the preheater can create a considerable power drain to the battery, and will not be suitable for engines that do not have a battery (such as lawnmower engines).

Another major operational problem with inline catalytic converters is that the converter temperature can drop below an operating level when the engine is idling.

For instance, if the vehicle is in heavy traffic, or is stopped by a red traffic light, the engine revolutions decrease to idling speed. This causes the temperature of the exhaust gases to quickly drop to a level where the temperature does not properly maintain the catalytic converter in its operational temperature zone.

Therefore, there would be an advantage if it were possible to provide some means which can maintain the catalytic converter in its operational temperature zone for a longer period of time than would otherwise be possible especially if the engine speed reduces (for instance is idling).

It will be clearly understood that, if a prior art publication is referred to herein, this reference does not constitute an admission that the publication forms part of the common general knowledge in the art in Australia or in any other country.

Object of the Invention.

It is an object of the invention to provide an inline exhaust device that can improve the working of a catalytic converter and which may overcome at least some of the above mentioned disadvantages or provide a useful or commercial choice.

In a broad form, the invention comprises a device to improve the working of an inline catalytic converter, the device affecting the flow of hot exhaust gasses to improve the transfer of heat from the exhaust gasses to the catalytic converter.

In this manner, there is less, or no need for a separate electric heater for the catalyst.

This now enables smaller engines [ lawnmower engines etc] to have a catalytic converter which works more efficiently, as these engines do not usually have a battery to enable an electric heater to heat the catalyst.

In a more particular form the device comprises a particular internal profile which contacts the exhaust gasses and absorbs heat from the exhaust gasses. The profile may comprise or include a plurality of recesses or cavities to facilitate increased turbulence of the gasses which may improve the heat absorption.

In another fonm, the invention resides in a device to improve the working of an inline catalytic converter, the device comprising a plurality of cavities or spaced apart members that extend at least partially into the exhaust stream, and adjacent the catalytic converter, the cavities or spaced apart members functioning to absorb heat from the exhaust stream and to keep at least part of the catalytic converter at an elevated temperature.

In this manner, the device can absorb heat from the hot exhaust gases when the engine is running normally and should the engine idle, and the exhaust gas temperature drop, the device can radiate or otherwise transmit heat to part of the catalytic converter, or warm part of the catalytic converter to maintain the converter at least partially in its more efficient operating temperature during the idling time. Of course, the device cannot indefinitely maintain the temperature of the catalytic converter, but it should be effective during stop/start traffic or ordinary periods of idling.

The device will typically be placed downstream from the catalyst. It may also be possible to place the device in front of the catalyst, but in some exhaust systems, the front portion can get quite hot and it may not be efficient to place the device in front of the catalyst. However, if the exhaust system is such that the catalyst is far enough away from the engine, it may be possible to place the device in front (upstream) of the catalyst as well as, or instead of, behind the catalyst.

The device is preferably configured to absorb heat from the exhaust stream but without unnecessarily creating a backpressure in the exhaust. A backpressure is not always advantageous as too much back pressure can reduce the engine power by between 20%-30% and can increase fuel consumption.

For this reason, it is preferred that the device comprises a plurality of spaced apart members that extend at least partially into the exhaust stream, at least some of the members being provided with an opening extending therethrough through which at least some of the exhaust gases can pass. It is preferred that the members extend substantially about the inner wall of the exhaust. Therefore, if the exhaust is substantially circular, it is preferred that the members comprise circular disks containing a central opening through which exhaust gases can pass. Of course, if the exhaust has a square, oval or rectangular cross-section, the shape of the members can vary to accommodate these configurations.

The number of spaced apart members may vary depending on the size of the exhaust, the volume of exhaust gases, etc. Typically, the device will contain between 2-20 spaced apart members and preferably between 4-10 spaced apart members.

2 0 The device may comprise a sleeve to which the spaced apart members are attached.

The sleeve may be designed to slide within the exhaust system to a position adjacent the catalyst. Alternatively, the sleeve may be designed to be part of the exhaust system and clamped to the exhaust or otherwise attached to the exhaust pipe. The sleeve may alternatively have another internal profile to improve heat transfer from the gasses to the device.

The spaced apart members (or other profile) may be spaced apart by a distance of between 3-50 millimetres and typically between 5-20 millimetres. A function of the spaced apart members is to create turbulence in the exhaust gas to cause part of the exhaust gas to swirl or be turbulent about and between the spaced apart members. It is considered that this improves the absorption of heat from the exhaust gases and into the spaced apart members. This can be due to increased resident time between the hot exhaust gas and the member caused by the turbulence or "eddy" effect which may function to cause the cooler gasses on the "outside" of the gas stream and which are in a heat exchange relationship with the device to be replaced by the hotter gasses in the "central" part of the gas flow, thereby causing the catalytic converter to heat up more quickly. This effect need not substantially increase the resident time of the gasses in the exhaust.

The spaced apart members will preferably be formed from materials which will be strong enough to survive in the hot exhaust gases while still being relatively efficient in absorbing heat from the gases. Metals such as steel are considered suitable.

However, no limitation should be placed on the invention merely by providing steel as a suitable material from which the spaced apart members can be made. The members can be made from other suitable metals, metal alloys, sintered metals, nonmetallic heat absorbing members, composite materials and the like.

The spaced apart members will typically extend from the edge of the exhaust tube into the gas flow sufficiently to efficiently absorb heat from the gas flow without unnecessarily impeding the gas flow to create an undesirable backpressure. It is considered that the spaced apart members may extend into the exhaust tube by a distance of between 10%-80% of the area. In one embodiment, this can be achieved by having the spaced apart members comprising substantially circular disks having an opening extending therethrough with the area of the disk comprising between 10% 80% of the cross-section area of the exhaust tube.

One function of the spaced apart members is to create eddies or turbulence in at least part of the gas flow inter alia to improve the ability of the members to absorb heat from the gas flow. For this reason, the profile of the members may be such to improve this effect. In one form, the spaced apart members may be substantially disk-like having parallel sidewalls. However, in another form the, or each, side wall may be profiled to improve turbulence. The profile may comprise a recess or "concavity" in the or each side wall. In another form, the members may comprise a ramped surface which may extend towards or away from the catalytic converter. Other profiles and configurations are envisaged to improve the turbulence of the gas flow.

It is considered beneficial to have a spacing gap between the catalytic converter and the first member of the device. While not wishing to be bound by theory, we believe that this gap improves the ability of the heat absorbed by the device to radiate the heat (or otherwise transmit the heat) back to the catalytic converter. The gap can comprise a "heat curtain" and can be anywhere between 5 millimetres-100 millimetres and preferably about 25 millimetres.

In another more particular form of the invention, the device may comprise a valve or iris which is operable between an open position and a closed or partially closed position, the valve being downstream from the catalytic converter and functioning to increase the resident time of the exhaust gas about the catalytic converter especially when the engine is idling.

Thus, when the engine is idling, the valve may be in a closed or partially closed position to keep the hot exhaust gases in the exhaust stream and about the catalytic converter to keep the temperature of the catalytic converter higher than would otherwise be the case if the exhaust gases were simply allowed to pass through the exhaust system unencumbered.

The method may comprise a single valve as described above or a plurality of valves. If a plurality of valves is provided, these may be in "series" in "parallel" or in any combination thereof. The valve(s) may include an iris(s) The valve may be provided downstream of the catalytic converter to throttle or choke the exhaust gases when necessary to ensure that the catalytic converter is kept at a higher temperature than would otherwise be possible. It is envisaged that the valve can be positioned at any position downstream of the catalytic converter including immediately behind the catalytic converter, or some distance away from the catalytic converter, or even external of the exhaust pipe.

It is envisaged that no particular limitation should be placed on the type of valve that may be used. Therefore, the valve may comprise a simple hinged flap valve, a slide valve, a rotating valve, a gate valve, an iris and the like.

It is preferred that the valve is operated such that it will move to a more open position or a fully open position upon an increase of the volume of exhaust gases passing through the exhaust system. For instance, it is preferred that the valve moves to a more open position when the engine revs at higher resolutions as sufficient hot gases now pass over the catalytic converter. It is preferred that the valve is operable in an automated or semi-automated manner. In a very simple form, the valve may comprise a hinged weighted valve, which moves under the influence of gravity to a closed position when the engine gas volume is low but which is pushed by the engine gas volume to an open position when the gas volume is higher. Alternatively, the valve may be spring biased to a naturally closed position and can be pushed to the open position by the volume of the engine gas. Alternatively, the valve may be operated by temperature and may move from a closed position to an open position upon an increase in the temperature. This type of valve may be called a "thermostat valve".

Alternatively, the valve may be operated by pressure differential in the exhaust stream. Other types of operating means to operate the valve may be used.

Brief Description of the Drawings.

Embodiments of the invention will be described with reference to the following drawings in which:

Figure 1 illustrates a device positioned downstream from a catalytic converter.

Figure 2 illustrates a different profile of the spaced apart members in the device.

Figure 3 illustrates yet another profile of the spaced apart members in the device.

Figure 4 illustrates a typical exhaust system.

2 5 Figure 5 illustrates an exhaust system and illustrating various places where "secondary air" can be inserted into the exhaust stream.

Figures 6-10 illustrate various embodiments of a valve used to improve the working of an inline catalyst.

Best Mode.

Referring initially to figure 4, there is illustrated a typical exhaust system that extends from the engine 10 to the tailpipe 11 and which contains an inline muffler 12, a catalytic converter 13, and a device 14 according to a first embodiment of the invention and which is mounted behind (downstream) the catalytic converter 13.

Referring to figure 1, there is illustrated a device according to an embodiment of the invention. The device 14 is positioned downstream from catalytic converter 13. Hot exhaust gases from the engine pass into the front of catalytic converter 13 at a temperature of between 2000-270' centigrade (this can of course vary). At the rear end of the catalyst is a small air gap 15 having a length of about 25 millimetres. The device 14 comprises five spaced apart members 16, each member comprising a circular disk having a central aperture 17 through which the exhaust gases can pass.

The central aperture 17 of each disk is aligned with the central aperture of each other disk to provide a central flow pathway 18 which is substantially unimpeded.

The disks are spaced apart by about 20 millimetres. As exhaust gas flows from catalyst 13 and through the aligned central apertures 17 of each disk, eddies and turbulence is provided about each disk causing exhaust gas to flow into the spacing between adjacent disks. This hot exhaust gas can then exchange heat with the respective disks causing the disks to heat up. This continues along the length of the device until the exhaust passes through the device and towards muffler 12.

Figures 2-3 illustrate different designs of the spaced apart members 16. The designs are to improve the edge effects between the gas and the member to cause turbulence and eddies to be formed between the spaced apart members.

The design does not increase the backpressure of the exhaust to an undesirable degree which can cause a reduction in engine power and increase in fuel consumption. It is considered that the aligned apertures in the disks enable exhaust gas to still flow through the device, and it is considered that having the spaced apart members provides a better heat exchange.

Tests have shown that under engine idling conditions, the temperature at the front of the catalyst is about 150' and, without the device fitted, the temperature at the rear of the catalyst is about 1000. When the device is fitted, this increases the temperature at the rear of the catalyst to about 2000.

Referring to figure 5, there is illustrated an exhaust system similar to that of figure 4, except that figure 5 illustrates various positions 20-22 where secondary air can enter into the exhaust system. For instance, at position 20, secondary air can enter the exhaust system after engine 12 but before the catalytic converter 13. At position 21, secondary air can enter into the exhaust system after the catalytic converter 13 but before muffler 12. At position 22, secondary air can enter into the exhaust system in muffler 12. At position 20, the secondary air can provide additional oxygen for assistance in proper catalytic conversion of the exhaust gases. At position 21 and position 22, the secondary air dilutes the exhaust gases to reduce the percentage of the emissions from the tailpipe.

Referring to figures 6-10, there is illustrated another embodiment of the invention where the device is a valve that can be of various configurations and types, and can be placed in various positions in the exhaust stream. The valve functions to throttle the engine gases to "bathe" the catalytic converter 13 in the hot engine gases for longer than would be possible without the valve.

Figure 6-7 show a simple hinged valve 23 which can be positioned on the end of tailpipe 11. The valve is naturally weighted to the closed position (figure 6) and is pushed to the partially open position (figure 7) by the force of exhaust gases passing through the tailpipe. Thus, on the idling conditions, the valve will be mainly closed and this will result in the exhaust gases slowing down especially about the catalytic converter 13 such that the catalytic converter can stay hotter.

Figure 8 illustrates a simple hinged valve 24 which is positioned inside part of the exhaust system and again can move between a naturally closed position and a partially opened position (shown in phantom line), again by the force of exhaust gases.

Figure 9 illustrates a valve 25 that can be pushed downwardly by the force of the exhaust gases and move between a naturally closed position by virtue of spring 26 and a pushed down open position illustrated in figure 9.

Figure 10 illustrates a turn valve 27 which can be rotated about a pivot axis 28, between an open position illustrated in figure 10 and a closed position where the valve has been rotated by 900 to block off the flow of gases. The turn valve 27 can be operated by heat which means that as the valve heats up, it moves to the open position. The valve can be heated by the exhaust gases. Alternatively, another type of thermal reed valve, or flap or disk can be used.

The valve will typically be positioned downstream from the catalytic converter to provide a degree of throttling or backpressure under low engine idling conditions to keep the hot exhaust gases about the catalytic converter for longer than would be otherwise possible if the valve was not in place.

It is envisaged that the invention will extend to a combination of a device 14 typically as illustrated in figures 1-4 and a valve typically as illustrated in figures 6-10.

The secondary air injection (see for instance figure 5) can be carried out with the valves in place or with the device 14 in place or both.

Tests carried out on the temperature on the rear of the catalytic converter using the device as illustrated in figures 1-4 show a marked increase of the temperature on the rear of the catalytic converter.

In an experiment, and using an engine containing the device illustrated in figures 1-4, the front of the catalytic converter was between 340-700 over a five-minute period, and the rear of the catalytic converter was between 70'-1400. With the same engine under a 500 watt load condition, the front of the catalytic converter was between 46 1800 over a five minute period while the rear of the catalytic converter was between 131-3240. The results show that the rear of the catalytic converter is kept quite warm due to the device re-radiating heat back to the catalytic converter.

The warming of the catalytic converter had an advantageous reduction on the emissions. In an experiment, a HONDA NSR 150cc two-stroke engine was used to test the reduction in emissions using the device is illustrated in figures 1-4.

Without the device fitted, the emissions were as follows:

Lda 0.872ULP RPM 4384 02 3.32% NO 14 ppm CO2 9.14% HC [hydrocarbons] 4902 ppm CO 2.848%

With the device fitted, the emissions over several hours were as follows:

TIME Lda RPM 02% NO ppm CO2% HC ppm CO% [Hr] 1 0.902 4559 0.00 2 13.37 1093 2.103 4 0.907 4657 0.32 2 13.51 1505 1.92 0.889 4455 0.00 2 13.28 1533 2.0 7 0.895 4311 0.23 3 13.46 1744 2.0 9 0.896 4421 0.49 3 13.27 1787 2.29 12 0.879 4717 0.00 3 13.17 1695 2.23

Thus the device functions to reduce emissions, primarily NO and hydrocarbons from an exhaust stream.

1.0 Throughout the specification and the claims (if present), unless the context requires otherwise, the term "comprise", or variations such as "comprises" or "comprising", will be understood to apply the inclusion of the stated integer or group of integers but not the exclusion of any other integer or group of integers.