rexresearch.co

Spiro Ross SPIROS

Electrolysis

Electrolysis

Improvements by the co-inventor of Yull

Brown's HHO gas generator : claims 3 forms of over-unity

http://www.bibliotecapleyades.net/ciencia/ciencia_quantum08.htm

Ross Spiros

Australian inventor and past business partner and researcher with Yul Brown (the famous Australian that put the hydrogen revolution on the map with his “Brown Gas’ technologies).

Mr. Spiros went on to refine and improve the efficiencies and commercialization of the original inventions by producing a unique technology where the cells are cost effective, efficient and can produce all transportation fuels commercially.

Ross is co-owner of Eco Global Fuels LLC, the world’s first and only producer of 100 percent renewable, alcohol-based transportation fuels, using water, sunlight and catalysis’s. Decades of research have enabled the technology to harness the power of water and sunlight for the manufacture of hydrogen in the most efficient, cost-effective and ecologically sound manner ever created.

When combined with carbon dioxide extracted from the atmosphere, this hydrogen is immediately converted into an alcohol-based liquid fuel for safe and reliable transport.

PATENTS

IMPROVEMENTS IN ELECTROLYSIS SYSTEMS AND

THE AVAILABILITY OF OVER-UNITY ENERGY

WO9528510

AU2248695

WO9528510

AU2248695

A looped energy system for the generation of excess energy available to do work is disclosed. The system comprises an electrolysis cell unit (150) receiving a supply of water to liberate separated hydrogen gas (154) and oxygen (156) by electrolysis driven by a DC voltage (152) applied across respective anodes and cathodes of the cell unit (150). A hydrogen gas receiver (158) receives and stores hydrogen gas liberated by the cell unit (150), and an oxygen gas receiver (160) receives and stores oxygen gas liberated by the cell unit (150). A gas expansion device (162) expands the stored gases to recover expansion work, and a gas combustion device (168) mixes and combusts the expanded hydrogen gas and oxygen gas to recover combusted work. A proportion of the sum of the expansion work and the combustion work sustains electrolysis of the cell unit to retain operational gas pressure in the gas receivers (158, 160) such that the energy system is self-sustaining, and there is excess energy available from the sum of energies.

Technical Field of the Invention

The present invention relates to the generation of hydrogen gas and oxygen gas from water, either as an admixture or as separated gases, by the process of electrolysis, and relates further to applications for the use of the liberated gas. Embodiments of the invention relate particularly to apparatus for the efficient generation of these gases, and to use of the gases in an internal combustion engine and an implosion pump. The invention also discloses a closed-loop energy generation system where latent molecular energy is liberated as a form of 'free energy' so the system can be self-sustaining.

Reference is made to commonly-owned International patent application No.PCT/AU94/000532, having the International filing date of 6 September 1994.

Background Art

The technique of electrolysing water in the presence of an electrolyte such as sodium hydroxide (NaOH) or potassium hydroxide (KOH) to liberate hydrogen and oxygen gas (H2, 02) is well known. The process involves applying a DC potential difference between two or more anode/cathode electrode pairs and delivering the minimum energy required to break the H-O bonds (i.e. 68.3 kcal per mole @ STP).

The gases are produced in the stoichiometric proportions for O2:H2 of 1:2 liberated respectively from the anode (+) and cathode (-).

Reference can be made to the following texts: "Modern Electrochemistry, Volume 2, John O'M. Bockris and Amulya K.N. Reddy, Plenum Publishing Corporation", "Electro-Chemical Science, J. O'M. Bockris and D.M. Drazic, Taylor and Francis Limited" and "Fuel Cells, Their Electrochemistry, J. O'M. Bockris and S. Srinivasan, McGraw-Hill Book Company".

A discussion of experimental work in relation to electrolysis processes can be obtained from "Hydrogen Energy, Part A, Hydrogen Economy Miami Energy Conference, Miami Beach, Florida, 1974, edited by T. Nejat Veziroglu, Plenum Press". The papers presented by J. O'M. Bockris on pages 371 to 379, by F.C. Jensen and F.H. Schubert on pages 425 to 439 and by John B. Pangborn and John C. Sharer on pages 499 to 508 are of particular relevance.

On a macro-scale, the amount of gas produced depends upon a number of variables, including the type and concentration of the electrolytic solution used, the anode/cathode electrode pair surface area, the electrolytic resistance (equating to ionic conductivity, which is a function of temperature and pressure), achievable current density and anode/cathode potential difference. The total energy delivered must be sufficient to disassociate the water ions to generate hydrogen and oxygen gases, yet avoid plating (oxidation/reduction) of the metallic or conductive non-metallic materials from which the electrodes are constructed.

Disclosure of the Invention

The invention discloses a looped energy system for the generation of excess energy available to do work, said system comprising: an electrolysis cell unit receiving a supply of water and for liberating separated hydrogen gas and oxygen gas by electrolysis due to a DC voltage applied across respective anodes and cathodes of said cell unit; hydrogen gas receiver means for receiving and storing hydrogen gas liberated by said cell unit; oxygen gas receiver means for receiving and storing oxygen gas liberated by said cell unit; gas expansion means for expanding said stored gases to recover expansion work; and gas combustion means for mixing and combusting said expanded hydrogen gas and oxygen gas to recover combustion work; and wherein a proportion of the sum of the expansion work and the combustion work sustains electrolysis of said cell unit to retain operational gas pressure in said hydrogen and oxygen gas receiver means such that the energy system is self-sustaining and there is excess energy available from said sum of energies.

The invention further discloses a looped energy system for the generation of excess energy available to do work, said system comprising: an electrolysis cell unit receiving a supply of water and for liberating separated hydrogen gas and oxygen gas by electrolysis due to a DC voltage applied across respective anodes and cathodes of said cell unit; hydrogen gas receiver means for receiving and storing hydrogen gas liberated by said cell unit; oxygen gas receiver means for receiving and storing oxygen gas liberated by said cell unit; gas expansion means for expanding said stored gases to recover expansion work; and fuel cell means for recovering electrical work from said expanded hydrogen gas and oxygen gas; and wherein a proportion of the sum of the expansion work and the recovered electrical work sustains electrolysis of said cell unit to retain operational gas pressure in said hydrogen and oxygen gas receiver means such that the energy system is self-sustaining and there is excess energy available from said sum of energies.

The invention further discloses a method for the generation of excess energy available to do work by the process of electrolysis, said method comprising the steps of: electrolysing water by a DC voltage to liberate separated hydrogen gas and oxygen gas; separately receiving and storing said hydrogen gas and oxygen gas in a manner to be self-pressuring; separately expanding said stores of gas to recover expansion work; combusting said expanded gases together to recover combustion work; and applying a portion of the sum of the expansion work and the combustion work as said DC voltage to retain operational gas pressures and sustain said electrolysing step, there thus being excess energy of said sum available.

The invention further discloses a method for the generation of excess energy available to do work by the process of electrolysis, said method comprising the steps of: electrolysing water by a DC voltage to liberate separated hydrogen gas and oxygen gas; separately receiving and storing said hydrogen gas and oxygen gas in aniaaner to be self-pressuring; separately expanding said stores of gas to recover expansion work; passing said expanded gases together through a fuel cell to recover electrical work; and applying a portion of the sum of the expansion work and the recovered electrical work as said DC voltage to retain operational gas pressures and sustain said electrolysing step, there thus being excess energy of said sum available.

The invention further discloses an internal combustion engine powered by hydrogen and oxygen comprising: at least one cylinder and at least one reciprocating piston within the cylinder; a hydrogen gas input port in communication with the cylinder for receiving a supply of pressurised hydrogen; an oxygen gas input port in communication with the cylinder for receiving a supply of pressurised oxygen; and an exhaust port in communication with the cylinder and wherein the engine is operable in a two-stroke manner whereby, at the top of the stroke, hydrogen gas is supplied by the respective inlet port to the cylinder driving the piston downwardly, oxygen gas then is supplied by the respective inlet port to the cylinder to drive the cylinder further downwardly, after which time self-detonation occurs and the piston moves to the bottom of the stroke and upwardly again with said exhaust port opened to exhaust water vapour resulting from the detonation.

The invention further discloses an implosion pump comprising a combustion chamber interposed, and in communication with, an upper reservoir and a lower reservoir separated by a vertical distance across which water is to be pumped, said chamber receiving admixed hydrogen and oxygen at a pressure sufficient to lift a volume of water the distance therefrom to the top reservoir, said gas in the chamber then being combusted to create a vacuum in said chamber to draw water from said lower reservoir to fill said chamber, whereupon a pumping cycle is established and can be repeated.

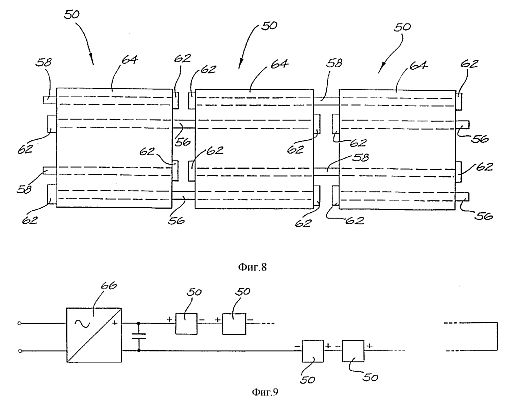

The invention further discloses a parallel stacked arrangement of cell plates for a water electrolysis unit, the cell plates alternately forming an anode and cathode of said electrolysis unit, and said arrangement including separate hydrogen gas and oxygen gas outlet port means respectively in communication with said anode cell plates and said cathode cell plates and extending longitudinally of said stacked plates, said stacked cell plates being configured in the region of said conduits to mate in a complementary manner to form said conduits such that a respective anode cell plate or cathode cell plate is insulated from the hydrogen gas conduit or the oxygen gas conduit.

Brief Description of the Drawings

Figs. 1 1a-16 of noted International application no. PCT/AU94/000532 are reproduced to aid description of the present invention, but herein denoted as Figs. la-6:

Figs. la and 1b show an embodiment of a cell plate;

Figs. 2a and 2b show a complementary cell plate to that of Figs. la and lb;

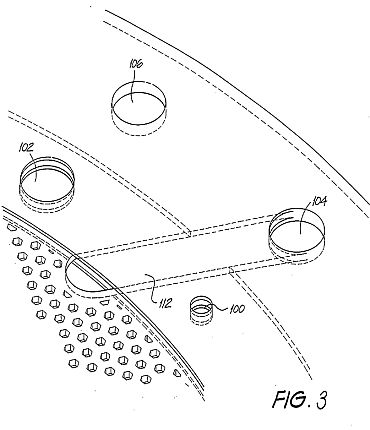

Fig. 3 shows detail of the perforations and porting of the cell plates of Figs. la, lb, 2a and 2b;

Fig. 4 shows an exploded stacked arrangement of the cell plates of Figs. la, lb, 2a and 2b;

Fig. 5a shows a schematic view of the gas separation system of Fig. 4;

Fig. 5b shows a stylised representation of Fig. 5a;

Fig. 5c shows an electrical equivalent circuit of Fig. 5a; and

Fig. 6 shows a gas collection system for use with the cell bank separation system of Figs. 4 and 5a.

The remaining drawings are:

Figs. 7a and 7b are views of a first cell plate;

Figs. 8a and 8b are views of a second cell plate;

Fig. 9 shows detail of the edge margin of the first cell plate;

Fig. 10 shows an exploded stacked arrangement of the cell plates shown in Figs. 7a and 8a;

Fig. 11 is a cross-sectional view of three of the stacked cell plates shown in

Fig. 10 in the vicinity of a gas port;

Figs. 12a and 12b respectively show detail of the first and second cell plates in the vicinity of a gas port;

Fig. 13 is a cross-sectional view of a cell unit of four stacked cell plates in the vicinity of an interconnecting shaft;

Fig. 14 shows a perspective view of a locking nut used in the arrangement of Fig. 13;

Fig. 15 shows an idealised electrolysis system;

Figs. 16-30 are graphs supporting the system of Fig. 15 and the availability of over-unity energy;

Figs. 31a to 31e show a hydrogen/oxygen gas-driven internal combustion engine; and

Figs. 32a-32c show a gas-driven implosion pump.

Detalled Description and Best Mode of Performance

The following description of Figs. la-6 is taken from PCT/AU94/000532.

Figs. la and 2a show embodiments of a first and second type of cell plate 90,98 as an end view. Figs. 1b and 2b are partial cross-sectional views along the respective mid-lines as shown. Common reference numerals have been used where appropriate. The plates 90,98 can have the function of either an anode (+) or a cathode (-), as will become apparent. Each comprises an electrode disc 92 that is perforated with hexagonally shaped holes 96. The disc 92 is made from steel or resinbonded carbon or conductive polymer material. The disc 92 is housed in a circular rim or sleeve 94. The function of the perforations 96 is to maximise the surface area of the electrode disc 92 and minimise the weight over solid constructions by 45 %.

By way of example, for a disc of diameter 280 mm, the thickness of the disc must be 1 mm in order to allow the current density (which ranges from 90 A / 2,650 cm2 - 100 A / 2,940 cm2 of the anode or cathode) to be optimal. If the diameter of the plate is increased, which consequently increases the surface area, it is necessary to increase the thickness of the plate in order to maintain uniformity of conductance for the desired current density.

The hexagonal perforations in a 1 mm disc have a distance of 2 mm between the flats, twice the thickness of the plate in order to maintain the same total surface area prior to perforation, and be 1 mm away from the next adjacent perforation to allow the current density to be optimal. A 1 mm (flat-to-flat) distance between the hexagonal perforations is required, because a smaller distance will result in thermal losses and a larger distance will add to the overall weight of the plate.

The sleeve 94 is constructed of PVC material and incorporates a number of equally spaced shaft holes 100,102. The holes are for the passage of interconnecting shafts provided in a stacked arrangement of the plates 90,98 forming the common conductor for the respective anode and cathode plates. The further two upper holes 104,106 each support a conduit respectively for the out-flow of oxygen and hydrogen gases. The further holes 108,110 at the bottom of the sleeve 94 are provided for the inlet of water and electrolyte to the respective cell plates 90,98.

Fig. 3 shows an enlarged view of a portion of the cell plate 90 shown in Fig.la. The port hole 104 is connected to the hexagonal perforations 96 within the sleeve 94 by an internal channel 112. A similar arrangement is in place for the other port hole 106, and for the water/electrolyte supply holes 108,110.

If it is the case that the hydrogen and oxygen gases liberated are to be kept separate (i.e. not to be formed as an admixture), then it is necessary to separate those gases as they are produced. In the prior art this is achieved by use of diaphragms that block the passage of gases and effectively isolate the water/electrolyte on each side of the diaphragm. Ionic transfer thus is facilitated by the ionically conductive nature of the diaphragm material (i.e. a water - diaphragm - water path). This results in an increase in the ionic resistance and hence a reduction in efficiency.

Fig. 4 shows an exploded stacked arrangement of four cell plates, being an alternative stacking of two (anode) cell plates 90 and two (cathode) cell plates 98. The two ends of the stacked arrangement of cell plates delineates a single cell unit 125.

Interposed between each adjacent cell plate 90,98 is a PTFE separation 116. Although not shown in Fig. 4, the cell unit includes separate hydrogen and oxygen gas conduits that respectively pass through the stacked arrangement of cell plates via the port holes 106,104 respectively. In a similar way, conduits are provided for the supply of water/electrolyte, respectively passing through the holes 108,110 at the bottom of the respective plates 90,98. Only two pairs of anode/cathode cell plates are shown. The number of such plates can be greatly increased per cell unit 125.

Also not shown are the interconnecting conductive shafts that electrically interconnect alternative common cell plates. The reason for having a large diameter hole in one cell plate adjacent to a smaller diameter hole in the next cell plate, is so that an interconnecting shaft will pass through the larger diameter hole, and not make an electrical connection (i.e. insulated with PVC tubing) rather only forming an electrical connection between alternate (common) cell plates.

The cell unit 125 shown in Fig. 4 arrangement is an exploded view. When fully constructed, all the elements are stacked to be in intimate contact. Mechanical fastening is achieved by use of one of two adhesives such as (a) "PUR-FECT LOK" (TM) 34-9002, which is a Urethane Reactive Hot Melt adhesive with a main'ingredient of Methylene Bispheny/Dirsocynate (MDI), and (b) "MY-T-BOND" (TM) which is a PVC solvent based adhesive. Both adhesives are Sodium Hyroxide (20% present in the electrolyte) resistant. In that case the water/electrolyte only resides within the area proscribed by the cell plate sleeve 94. Thus the only path for the inlet of water/electrolyte is by bottom channels 118,122 and the only outlet for the gases is by the top channels 112,120.In a system constructed and tested by the inventor, the thickness of the cell plates 90,98 is 1 mm (2 mm on the rim because of the PVC sleeve 94), with a diameter of 336 mm. The cell unit 125 is segmented from the next cell by an insulating PVC segmentation disc 114. A segmentation disc 114 also is placed at the beginning and end of the entire cell bank.

If there is to be no control over separation of the liberated gases, then the PTFE membranes 116 are not provided, nor is the sleeve 94 required.The PTFE membrane 116 is fibrous and has 0.2 to 1.0 micron interstices. A suitable type is type Catalogue Code J, supplied by Tokyo Roshi International Inc (Advantec).

The water/electrolyte fills the interstices and ionic current flows only via the water - there is no contribution of ionic flow through the PTFE material itself. This leads to a reduction in the resistance to ionic flow. The PTFE material also has a 'bubble point' that is a function of pressure, hence by controlling the relative pressures at either side of the PTFE separation sheets, the gases can be 'forced' through the interstices to form an admixture, or otherwise kept separate. Other advantages of this arrangement include a lesser cost of construction, improved operational efficiency and greater resistance to faults.

Fig. 5a is a stylised, and exploded, schematic view of a linear array of three series-connected cell units 125. For clarity, only six interconnecting shafts 126-131 are shown. The shafts 126-131 pass through the respective shaft holes 102,100 in the various cell plates 90,98 in the stacked arrangement. The polarity attached to each of the exposed end shafts, to which the DC supply is connected also is indicated. The shafts 126-131 do not run the full length of the three cell banks 125. The representation is similar to the arrangement shown in Figs. 7a and 8. One third the full DC source voltage appears across each anode/cathode cell plate pair 90,98.

Further, the gas conduits 132,133, respectively for hydrogen and oxygen, that pass through the port holes 104,106 in the cell plates 90,98 also are shown. In a similar way, water/electrolyte conduits 134,135, passing through the water port holes 108,110 in the cell plates also are shown.

Fig. 5b particularly shows how the relative potential difference in the middle cell bank 125 changes. That is, the plate electrode 90a now functions as a cathode (i.e.relatively more negative) to generate hydrogen, and the plate electrode 98a now functions as an anode (i.e. relatively more positive) to generate oxygen. This is the case for every alternate cell unit. The arrowheads shown in Fig. 5b indicate the electron and ionic current circuit. Fig. Sc is an electrical equivalent circuit representation of Fig. 5b, where the resistive elements represent the ionic resistance between adjacent anode/cathode plates. Thus it can be seen that the cell units are connected in series.

Because of the change of function of the cell plates 90a and 98a, the complementary gases are liberated at each, hence the respective channels 112 are connected to the opposite gas conduit 132,133. Practically, this can be achieved by the simple reversal of the cell plates 90,98.

Fig. 6 shows the three cell units 125 of Fig. 5a connected to a gas collection arrangement. The cell units 125 are located within a tank 140 that is filled with water/electrolyte to the level h indicated. The water is consumed as the electrolysis process proceeds, and replenishing supply is provided via the inlet 152. The water/electrolyte level h can be viewed via the sight glass 154. In normal operation, the different streams of hydrogen and oxygen are produced and passed from the cell units 125 to respective rising columns 142,144. That is, the pressure of electrolyte on opposed sides of the PTFE membranes 116 is equalised, thus the gases cannot admix.

The columns 142, 144 also are filled with the water/electrolyte, and as it is consumed at the electrode plates, replenishing supply of electrolyte is provided by way of circulation through the water/electrolyte conduits 134,135. The circulation is caused by entrainment by the liberated gases, and by the circulatory inducing nature of the conduits and columns.

The upper extent of the tank 140 forms two scrubbing towers 156,158, respectively for the collection of oxygen and hydrogen gases. The gases pass up a respective column 142,144, and out from the columns via openings therein at a point within the interleaved baffles 146. The point where the gases exit the columns 142,144 is

beneath the water level h, which serves to settle any turbulent flow and entrained electrolyte. The baffles 146 located above the level h scrub the gas of any entrained electrolyte, and the scrubbed gas then exits by respective gas outlet columns 148,150 and so to a gas receiver. The level h within the tank 140 can be regulated by any convenient means, including a float switch, again with the replenishing water being supplied by the inlet pipe 152.

The liberated gases will always separate from the water/electrolyte solution by virtue of the difference in densities. Because of the relative height of the respective set of baffles, and due to the density differential between the gases and the water/electrolyte, it is not possible for the liberated hydrogen and oxygen gases to mix.

The presence of the full volume of water within the tank 140 maintains the cell plates in an immersed state, and further serves to absorb the shock of any internal detonations should they occur.

In the event that a gas admixture is required, then firstly the two flow valves 136,137 respectively located in the oxygen gas outlet conduit 132 and water/electrolyte inlet port 134 are closed. This blocks the outlet path for the oxygen gas and forces the inlet water/electrolyte to pass to the inlet conduit 134 via a one-way check valve 139 and pump 138. The water/electrolyte within the tank 140 is under pressure by virtue of its depth (volume), and the pump 138 operates to increase the pressure of water/electrolyte occurring about the anode cell plates 90,98a to be at an increased pressure with respect to the water/electrolyte on the other side of the membrane 116.

This pressure differential is sufficient to cause the oxygen gas to migrate through the membrane, thus admixed oxygen and hydrogen are liberated via the gas output conduit 133 and column 144. Since there is no return path for the water/electrolyte supplied by the pump 138, the pressure about the cell plates 90,98a will increase further, and to a point where the difference is sufficient such that the water/electrolyte also can pass through the membrane 116. Typically, pressure differential in the range of 1.5 - 10 psi is required to allow passage of gas, and a pressure differential in the range of 10 - 40 psi for water/electrolyte.

While only three cell units 125 are shown, clearly any number, connected in series, can be implemented.

Embodiments of the present invention now will be described. Where applicable, like reference numerals have been used.

Figs. 7a and 7b show a first type of cell plate 190 respectively as an end view and as an enlarged cross-sectional view along line VIIb-VIIb. The cell plate 190 differs from the previous cell plate 90 shown in Figs. la and 1b in a number of important aspects. The region of the electrode disc 192 received within the sleeve 194 now is perforated. The function of these perforations is to further reduce the weight of the cell plate 190. The shaft holes 200,202 again pass through the electrode disc 192, but so too do the upper holes 204,206 through which the conduits for the out-flow of liberated hydrogen and oxygen gases pass. The bottom holes 208,210, provided for the inlet of water and electrolyte, now also are located in the region of the sleeve 194 coincident with the perforated edge margin of the electrode disc 192.The channels 212,218 respectively communicating with the port hole 204 and the supply hole 210 also are shown.

Figs. 8a and 8b show a second type of cell plate 198 as a companion to the first cell plate 190, and as the same respective views. The second cell plate 198 is somewhat similar to the cell plate 98 previously shown in Figs. 2a and 2b. The differences therebetween are the same as the respective differences between the cell plate shown in Figs. la and 1b and the one shown in Figs. 7a and 7b. The arrangement of the respective channels 220,222 with respect to the port 206 and the water supply hole 208 also are shown.

In the fabrication of the cell plates 190,198, the sleeve 94 is injection moulded from PVC plastics material formed about the edge margin of the electrode disc 192.

The injection moulding process results in the advantageous forming of interconnecting sprues forming within the perforations 196 in the region of the disc 192 held within the sleeve 194, thus firmly anchoring the sleeve 194 to the disc 192.

Fig. 9 is a view similar to Fig. 3, but for the modified porting arrangement and perforations (shown in phantom where covered by the sleeve) of the region of the disc 192 within and immediately outside of the sleeve 194.

Fig. 10 shows a cell unit 225 in the form of an exploded alternating stacking of first and second cell plates 190,198, much in the same manner as Fig. 4. Only two pairs of anode/cathode cell plates are shown, however the number of such plates can be greatly increased per cell unit 225. The membrane 216 preferably is type QR-HE silica fibre with the alternative being PTFE. Both are available from Tokyo Roshi International Inc. (Advantec) of Japan. Type QR-HE is a hydrophobic material having 0.2 to 1.0 micron interstices, and is capable of operation at temperatures up to 10000C.

The cell unit 225 can be combined with other such cell units 225 to form an interconnected cell bank in the same manner as shown in Figs. 5a, 5b and 5c.

Furthermore, the cell units can be put to use in a gas collection arrangement such as that shown in Fig. 6. Operation of the gas separation system utilising the new cell plates 190,198 is in the same manner as previously described.

Fig. 11 is an enlarged cross-sectional view of three cell plates in the vicinity of the oxygen port 204. The cell plates comprise two of the first type of plate 190 shown in Fig. 7a constituting a positive plate, and a single one of the second type of plate 198 shown in Fig. 8a representing a negative plate. The location of the respective channels 212 for each of the positive cell plates 190 is shown as a dashed representation. The respective sleeves 194 of the three cell plates are formed from moulded PVC plastics as previously described, and in the region that forms the perimeter of the port 204 have a configuration particular to whether a cell plate is positive or negative. In the present case, the positive cell plates 190 have a flanged foot 230 that, in the assembled construction, form the contiguous boundary of the gas port 204.Each foot 230 has two circumferential ribs 232 that engage corresponding circumferential grooves 234 in the sleeve 194 of the negative plate 198.

The result of this arrangement is that the exposed metal area of the negative cell plates 198 always are insulated from the flow of oxygen gas liberated from the positive cell plates 190, thus avoiding the possibility of spontaneous explosion by the mixing of the separated hydrogen and oxygen gases. This arrangement also obviates the unwanted production of either oxygen gas or hydrogen gas in the gas port.

For the case of the gas port 206 carrying the hydrogen gas, the relative arrangement of the cell plates is reversed such that a flanged footing now is formed on the sleeve 194 of the other type of cell plate 198. This represents the converse arrangement to that shown in Fig. 11.

Figs. 12a and 12b show perspective side views of adjacent cell plates, with Fig. 12a representing a positive cell plate 190 and Fig. 12b representing a negative cell plate 198. The gas port 206 thus formed is to carry hydrogen gas. The mating relationship between the flanged foot 230 and the end margin of the sleeve 194 of the positive cell plate 192 can be seen, particularly the interaction between the ribs 232 and the grooves 234.

Fig. 13 is a cross-sectional view of four cell plates formed into a stacked arrangement delimited by two segmentation plates 240, together forming a cell unit 242.

Thus there are two positive cell plates 190 and two negative cell plates 198 in alternating arrangement. The cross-section is taken in the vicinity of a shaft hole 202 through which a negative conductive shaft 244 passes. The shaft 244 therefore is in intimate contact with the electrode discs 192 of the negative cell plates 198. The electrodes discs 192 of the positive cell plates 190 do not extend to contact the shaft 244. The sleeve 194 of the alternating negative cell plates 198 again have a form of flanged foot 246, although in this case the complementarily shaped ribs and grooves are formed only on the sleeve of the negative cell plates 198, and not on the sleeve 194 of the positive cell plates 190.The segmentation plates 240 serve to delimit the stacked plates forming a single cell unit 242, with ones of the cell units 242 being stacked in a linear array to form a cell bank such as has been shown in Fig. Sa.

A threaded shaft nut 250 acts as a spacer between adjacent electrodes connecting with the shaft 244. Fig. 14 is a perspective view of the shaft nut 250 showing the thread 252 and three recesses 254 for fastening nuts, screws or the like.

In all of Figs. 11 to 13, the separation membrane material 216 is not shown, but is located in the spaces 248 between adjacent cell plates 190,198, extending to the margins of the electrode disks 192 in the vicinity of the gas ports 204,206 or the shaft holes 200,202.

An electrolysis hydrogen and oxygen gas system incorporating a gas separation system, such as has been described above, can therefore be operated to establish respective high pressure stores of gas. That is, the separated hydrogen and oxygen gases liberated by the electrolysis process are stored in separate gas receivers or pressure vessels. The pressure in each will increase with the continuing inflow of gas.

Fig. 15 shows an idealised electrolysis system, comprising an electrolysis cell 150 that receives a supply of water to be consumed. The electrolysis process is driven by a DC potential (Es) 152. The potential difference applied to the cell 150 therefore must be sufficient to electrolyse the water into hydrogen and oxygen gas dependent upon, inter alia, the water pressure PC and the back pressure of gas PB acting on the surface of the water, together with the water temperature Tc. The separate liberated hydrogen and oxygen gases, by a priming function, are pressurised to a high value by storage in respective pressure vessels 158,160, being carried by gas lines 154,156.

The pressurised store of gases then are passed to an energy conversion device that converts the flow of gas under pressure to mechanical energy (e.g. a pressure drop device 162). This mechanical energy recovered WM is available to be utilised to provide useful work. The mechanical energy WM also can be converted into electrical form, again to be available for use.

The resultant exhausted gases are passed via lines 164,166 to a combustion chamber 168. Here the gases are combusted to generate heat QR, with the waste product being water vapour. The recovered heat QR can be recycled to the electrolysis cell to assist in maintaining the advantageous operating temperature of the cell.

The previously described combustion chamber 168 can alternatively be a fuel cell. The type of fuel cell can vary from phosphoric acid fuel cells through to molten carbonate fuel cells and solid oxide cells. A fuel cell generates both heat (QR) and electrical energy (WE), and thus can supply both heat to the cell 150 or to supplement or replace the DC supply (Es) 152.

Typically, these fuel cells can be of the type LaserCellTM as developed by Dr Roger Billings, the PEM Cell as available from Ballard Power Systems Inc. Canada or the Ceramic Fuel Cell (solid oxide) as developed by Ceramic Fuel Cells Ltd. Melbourne, Australia.

It is, of course, necessary to replenish the pressurised store of gases, thus requiring the continuing consumption of electrical energy. The recovered electrical energy WE is in excess of the energy required to drive electrolysis at the elevated temperature and is used to replace the external electrical energy source 152, thereby completing the energy loop after the system is initially primed and started.

The present inventor has determined that there are some combinations of pressure and temperature where the efficiency of the electrolysis process becomes advantageous in terms of the total energy recovered, either as mechanical energy by virtue of a flow of gas at high pressure or as thermal energy by virtue of combustion (or by means of a fuel cell), with respect to the electrical energy consumed, to the extent of the recovered energy exceeding the energy required to sustain electrolysis at the operational pressure and temperature. This has been substantiated by experimentation. This notion has been termed "over-unity".

"Over-unity" systems can be categorised as broadly falling into three types of physical phenomena:

(i) An electrical device which produces 100 Watts of electrical energy as output after 10 Watts of electrical energy is input thereby providing 90 Watts of overunity (electrical) energy.

(ii) An electro-chemical device such as an electrolysis device where 10 Watts of electrical energy is input and 8 Watts is output being the thermal value of the hydrogen and oxygen gas output. During this process, 2 Watts of electrical energy converted to thermal energy is lost due to specific inefficiencies of the electrolysis system. Pressure - as the over-unity energy - is irrefutably produced during the process of hydrogen and oxygen gas generation during electrolysis.

Pressure is a product of the containment of the two separated gases. The Law of Conservation of Energy (as referenced in "Chemistry Experimental Foundations", edited by Parry, R.W.; Steiner, L.E.; Tellefsen, R.L.; Dietz, P.M. Chap. 9, pp. 199-200, Prentice-Hall, New Jersey" and "An Experimental Science", edited by Pimentel, G.C., Chap. 7, pp. 115-117, W.H. & Freeman Co. San Francisco) is in equilibrium where the 10 watts of input equals the 8 watts thermal energy output plus the 2 watts of losses. However, this Law ends at this point. The present invention utilises the apparent additional energy being the pressure which is a by-product of the electrolysis process to achieve over-unity.

(iii) An electro-chemical device which produces an excess of thermal energy after an input of electrical energy in such devices utilised in "cold fusion" e.g.10 watts of electrical energy as input and 50 watts of thermal energy as output.

The present invention represents the discovery of means by which the abovementioned second phenomenon can be embodied to result in "over-unity" and the realisation of 'free' energy. As previously noted, this is the process of liberating latent molecular energy. The following sequence of events describes the basis of the availability of over-unity energy.

In a simple two plate (anode/cathode) electrolysis cell, an applied voltage differential of 1.57 DC Volts draws 0.034 Amps per cm2 and results in the liberation of hydrogen and oxygen gas from the relevant electrode plate. The electrolyte is kept at a constant temperature of 40"C, and is open to atmospheric pressure.

The inefficiency of an electrolytic cell is due to its ionic resistance (approximately 20%), and produces a by-product of thermal energy. The resistance reduces, as does the minimum DC voltage required to drive electrolysis, as the temperature increases. The overall energy required to dissociate the bonding electrons from the water molecule also decreases as the temperature increases. In effect, thermal energy acts as a catalyst to reduce the energy requirements in the production of hydrogen and oxygen gases from the water molecule.

Improvements in efficiency are obtainable by way of a combination of thermal energy itself and the NaOH electrolyte both acting to reduce the resistance of the ionic flow of current.

Thermal 'cracking' of the water molecule is known to occur at 1 5000C, whereby the bonding electrons are dissociated and subsequently 'separate' the water molecule into its constituent elements in gaseous form. This thermal cracking then allows the thermal energy to become a consumable. Insulation can be introduced to conserve thermal energy, however there will always be some thermal energy losses.

Accordingly, thermal energy is both a catalyst and a consumable (in the sense that the thermal energy exites bonding electrons to a higher energetic state) in the electrolysis process. A net result from the foregoing process is that hydrogen is being produced from thermal energy because thermal energy reduces the overall energy requirements of the electrolysis system.

Referring to the graph titled "Flow Rate At A Given Temperature" shown in Fig. 16, it has been calculated that at a temperature of 20000C, 693 litres of hydrogen/oxygen admixed gas (2:1) will be produced. The hydrogen content of this volume is 462 litres. At an energy content of 11 BTUs per litre of hydrogen, this then gives an energy amount of 5082 BTUs (11 x 462). Using the BTU:kilowatt conversion factor of 3413:1, 5082 BTUs of the hydrogen gas equate to 1.49 kW. Compare this with lkW to produce the 693 litres of hydrogen/oxygen (including 463 litres of hydrogen). The usage of this apparatus therefore identifies that thermal energy, through the process of electrolysis, is being converted into hydrogen.These inefficiencies, i.e. increased temperature and NaOH electrolyte, reduce with temperature to a point at approximately 1000"C where the ionic resistance reduces to zero, and the volumetric amount of gases produced per kWh increases.

The lowering of DC voltage necessary to drive electrolysis by way of higher temperatures is demonstrated in the graph in Fig. 17 titled "The Effect of temperature on Cell Voltage".

The data in Figs. 16 and 17 has two sources. Cell voltages obtained from 0 C up to and including 100"C were those obtained by an electrolysis system as described hereinbefore. Cell voltages obtained from 1500C up to 2000"C are theoretical calculations presented by an acknowledged authority in this field, Prof. J. O'M. Bockris. Specifically, these findings were presented in "Hydrogen Energy, Part A, Hydrogen Economy Miami Energy Conference, Miami Beach, Florida, 1974, edited by T. Nejat Veziroglu, Plenum Press" pp. 371-379. These calculations appear on page 374.

By inspection of Fig. 17 and Fig. 18 (titled "Flow Rate of Hydrogen and Oxygen at 2:1"), it can be seen that as temperature increases in the cell, the voltage necessary to dissociate the water molecule is reduced, as is the overall energy requirement. This then results in a higher gas flow per kWh.

As constrained by the limitation of the materials within the system, the operationally acceptable temperature of the system is 1000"C. This temperature level should not, however, be considered as a restriction. This temperature is based on the limitations of the currently commercially available materials. Specifically, this system can utilise material such as compressed Silica Fibre for the sleeve around the electrolysis plate and hydrophobic Silica Fibre (part no. QR-100HE supplied by Tokyo Roshi International Inc., also known as "Advantec") for the diaphragm (as previously discussed) which separates the electrolysis disc plates.In the process of assembling the cells, the diaphragm material and sleeved electrolysis plates 190,198 are adhered to one another by using high-temperature-resistant silica adhesive (e.g. the "Aremco" product "Ceramabond 618" which has an operational tolerance specification of 1000 C).

For the above-described electrolysis cell, for the electrolyte at 10000C and utilising electrical energy at the rate of 1kWh, 167 litres of oxygen and 334 litres of hydrogen per hour will be produced.

The silica fibre diaphragm 116 previously discussed separates the oxygen and hydrogen gas streams by the mechanism of density separation, and produce a separate store of oxygen and hydrogen at pressure. Pressure from the produced gases can range from 0 to 150,000 Atmospheres. At higher pressures, density separation may not occur. In this instance, the gas molecules can be magnetically separated from the electrolyte if required.

In reference to the experiments conducted by Messrs Hamann and Linton (S.D. Hamann and M. Linton, Trans. Faraday Soc. 62,2234-2241. Specifically, page 2240), this research has proven that higher pressures can produce the same effect as higher temperatures in that the conductivity increases as temperature and/or pressure increases. At very high pressures, the water molecule at low temperatures dissociates.

The reason for this is that the bonding electron is more readily removed when under high pressure. The same phenomenon occurs when the bonding electrons are at a high temperature (e.g. 1500"C) but at low pressures.

As shown in Fig. 15, hydrogen and oxygen gases are separated into independent gas streams flowing into separate pressure vessels 158,160 capable of withstanding pressures up to 150,000 Atmospheres. Separation of the two gases thereby eliminates the possibility of detonation. It should also be noted that high pressures can facilitate the use of high temperatures within the electrolyte because the higher pressure elevates the boiling point of water.

Experimentation shows that 1 litre of water can yield 1,850 litres of hydrogen/oxygen (in a ratio of 2: 1) gas mix after discomposition, this significant differential (1:1,850) is the source of the pressure. Stripping the bonding electrons from the water molecule, which subsequently converts liquid into a gaseous state, releases energy which can be utilised as pressure when this occurs in a confined space.

A discussion of experimental work in relation to the effects of pressure in electrolysis processes can be obtained from "Hydrogen Energy, Part A, Hydrogen Economy Miami Energy Conference, Miami Beach, Florida, 1974, edited by T. Nejat Veziroglu, Plenum Press". The papers presented by F.C. Jensen and F.H. Schubert on pages 425 to 439 and by John B. Pangborn and John C. Sharer on pages 499 to 508 are of particular relevance.

Attention must be drawn to the above published material; specifically on page 434, third paragraph, where reference is made to "Fig. 7 shows the effect of pressure on cell voltage...". Fig. 7 on page 436 ("Effect of Pressure on SFWES Single Cell") indicates that if pressure is increased, then so too does the minimum DC voltage.

These quotes were provided for familiarisation purposes only and not as demonstrable and empirical fact. Experimentation by the inventor factually indicates that increased pressure (up to 2,450 psi) in fact lowers the minimum DC voltage.

This now demonstrable fact, whereby increased pressure actually lowers minimum DC voltage, is further exemplified by the findings of Messrs. Nayar, Ragunathan and Mitra in 1979 which can be referenced in their paper: "Development and operation of a high current density high pressure advanced electrolysis cell".

Nayar, M.G.; Ragunathan, P. and Mitra, S.K. International Journal of Hydrogen Energy (Pergamon Press Ltd.), 1980, Vol. 5, pp. 65-74. Their Table 2 on page 72 expressly highlights this as follows: "At a Current density (ASM) of 7,000 and at a temperature of 80"C, the table shows identical Cell voltages at both pressures of 7.6 kg/cm2 and 11.0 kg/cm2. But at Current densities of 5,000, 6,000, 8,000, 9,000 and 10,000 (at a temperature of 80"C), the Cell voltages were lower at a pressure of 11.0 kg/cm2 than at a pressure of 7.6 kg/cm2. "The present invention thus significantly improves on the apparatus employed by Mr. M.G. Nayar et al at least in the areas of cell plate materials, current density and cell configuration.

In the preferred form the electrode discs 192 are perforated mild steel, conductive polymer or perforated resin bonded carbon cell plates. The diameter of the perforated holes 196 is chosen to be twice the thickness of the plate in order to maintain the same total surface area prior to perforation. Nickel was utilised in the noted prior art system. That material has a higher electrical resistance than mild steel or carbon, providing the present invention with a lower voltage capability per cell.

The aforementioned prior art system quotes a minimum current density (after conversion from ASM to Amps per square cm.) at 0.5 Amps per cm2. The present invention operates at the ideal current density, established by experimentation, to minimise cell voltage which is .034 Amps per cm2.

When compared with the aforementioned system, an embodiment of the present invention operates more efficiently due to a current density improvement by a factor of 14.7, the utilisation of better conducting cell plate material which additionally lowers cell voltage, a lower cellivoltage of 1.49 at 800C as opposed to 1.8 volts at 800 C, and a compact and efficient cell configuration.

In order to further investigate the findings of Messrs. M.G. Nayer et al, the inventor conducted experiments utilising much higher pressures. For Nayer et al the pressures were 7.6 kg/cm2 to 11.0 kg/cm2, whereas inventor's pressures were 0 psi to 2450 psi in an hydrogen/oxygen admixture electrolysis system.

This electrolysis system was run from the secondary coil of a transformer set approximately at maximum 50 Amps and with an opencircuit voltage of 60 Volts. In addition, this electrolysis system is designed with reduced surface area in order that it can be housed in an hydraulic container for testing purposes. The reduced surface area subsequently caused the gas production efficiency to drop when compared with previous (i.e. more efficient) prototypes. The gas flow rate was observed to be approximately 90 litres per hour at 70"C in this system as opposed to 310 litres per hour at 700C obtained from previous prototypes.

All of the following data and graphs have been taken from the table shown in Fig. 19.

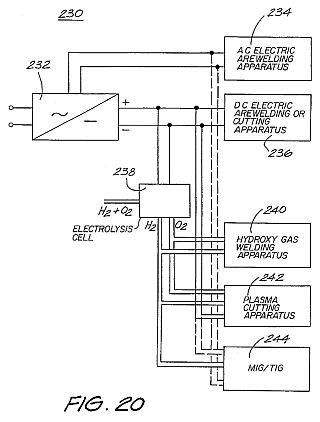

Referring to Fig. 20 (titled "Volts Per Pressure Increase"), it can be seen that at a pressure of 14.7 psi (i.e. 1 Atmosphere), the voltage measured as 38.5V and at a pressure of 2450 psi, the voltage measured as 29.4V. This confirms the findings of Nayar et al that increased pressure lowers the system's voltage. Furthermore, these experiments contradict the conclusion drawn by F.C. Jensen and F.H. Schubert ("Hydrogen Energy, Part A, Hydrogen Economy Miami Energy Conference, Miami Beach, Florida, 1974, edited by T. Nejat Veziroglu, Plenum Press", pp 425 to 439, specifically Fig. 7 on page 434) being that "... as the pressure of the water being electrolysed increases, then so too does the minimum DC Voltage".As the.inventor's experiments are current and demonstrable, the inventor now presents his findings as the current state of the art and not the previously accepted findings of Schubert and Jensen.

Referring to Fig. 21 (titled "Amps Per Pressure Increase"), it can be seen that at a pressure of 14.7 psi (i.e. 1 Atmosphere being Test Run No. 1), the current was measured as 47.2A and at a pressure of 2450 psi (Test Run No. 20), the current was measured as 63A.

Referring to Fig. 22 (titled "Kilowatts Per Pressure Increase"), examination of the power from Test Run No. 1 (1.82 kW) through to Test Run No. 20 (1.85 kW) indicates that there was no major increase in energy input required at higher pressures in order to maintain adequate gas flow.

Referring to Fig. 23 (titled "Resistance (Ohms) Per Pressure Increase"), the resistance was calculated from Test Run No. 1 (0.82 ohms) to Test Run No. 20 (0.47 ohms). This data indicates that the losses due to resistance in the electrolysis system at high pressures are negligible.

Currently accepted convention has it that dissolved hydrogen, due to high pressures within the electrolyte, would cause an increase in resistance because hydrogen and oxygen are bad conductors of ionic flow. The net result of which would be that this would decrease the production of gases.

These tests indicate that the ions find their way around the H2 and 2 molecules within the solution and that at higher pressures, density separation will always cause the gases to separate from the water and facilitate the movement of the gases from the electrolysis plates. A very descriptive analogy of this phenomenon is where the ion is about the size of a football and the gas molecules are each about the size of a football field thereby allowing the ion a large manoeuvring area in which to skirt the molecule.

Referring to Fig. 24 (titled "Pressure Differential (Increase)"), it can be seen that the hydrogen/oxygen admixture caused a significant pressure increase on each successive test run from Test Run No. 1 to Test Run No. 11. Test Runs thereafter indicated that the hydrogen/oxygen admixture within the electrolyte solution imploded at the point of conception (being on the surface of the plate).

Referring again to the table of Fig. 19, it can be noted the time taken from the initial temperature to the final temperature in Test Run No. 12 was approximately half the time taken in Test Run No. 10. The halved elapsed time (from 40"C to 700C) was due to the higher pressure causing the hydrogen/oxygen admixture to detonate which subsequently imploded within the system thereby releasing thermal energy.

Referring to the table shown in Fig. 25 (titled "Flow Rate Analysis Per Pressure Increase"), these findings were brought about from flow rate tests up to 200 psi and data from Fig. 24. These findings result in the data of Fig. 25 concerning gas flow rate per pressure increase. Referring to Fig. 25, it can be seen that at a pressure of 14.7 psi (1 Atmosphere) a gas production rate of 88 litres per kWh is being achieved. At 1890 psi, the system produces 100 litres per kWh. These findings point to the conclusion that higher pressures do not affect the gas production rate of the system, the gas production rate remains constant between pressures of 14.7 psi (1Atmosphere) and 1890 psi.

Inferring from all of the foregoing data, increased pressure will not adversely affect cell performance (gas production rate) in separation systems where hydrogen and oxygen gases are produced separately, nor as a combined admixture. Therefore, in an enclosed electrolysis system embodying the invention, the pressure can be allowed to build up to a predetermined level and remain at this level through continuous (ondemand) replenishment. This pressure is the over-unity energy because it has been obtained during the normal course of electrolysis operation without additional energy input.

This over-unity energy (i.e. the produced pressure) can be utilised to maintain the requisite electrical energy supply to the electrolysis system as well as provide useful work.

The following formulae and subsequent data do not take into account the apparent efficiencies gained by pressure increase in this electrolysis system such as the gained efficiency factors highlighted by the previously quoted Hamann and Linton research. Accordingly, the over-unity energy should therefore be considered as conservative claims and that such claimed over-unity energy would in fact occur at much lower pressures.

This over-unity energy can be formalised by way of utilising a pressure formula as follows: E = (P - PO) V which is the energy (E) in Joules per second that can be extracted from a volume (V) which is cubic meters of gas per second at a pressure (P) measured in Pascals and where P0 is the ambient pressure (i.e. 1 Atmosphere).

In order to formulate total available over-unity energy, we will first use the above formula but will not take into account efficiency losses. The formula is based on a flow rate of 500 litres per kWh at 10000C. When the gases are produced in the electrolysis system, they are allowed to self-compress up to 150,000 Atmospheres which will then produce a volume (V) of 5.07 x 10-8 m3/sec.

Work [Joules/sec] = ((150-1) x 108) 5.07 x 10-8 m3/sec = 760.4 Watts

The graphs in Figs. 27-29 (Over-Unity in Watt-Hours) indicate over-unity energy available excluding efficiency losses. However, in a normal work environment, inefficiencies are encountered as energy is converted from one form to another.

The results of these calculations will indicate the amount of surplus- over-unity energy after the electrolysis system has been supplied with its required 1 kWh to maintain its operation of producing the 500 Iph of hydrogen and oxygen (separately in a ratio of 2:1).

The following calculations utilise the abovestated formula including the efficiency factor. The losses which we will incorporate will be 10% loss due to the energy conversion device (converting pressure to mechanical energy, which is represented by device 162 in Fig. 15) and 5% loss due to the DC generator We providing a total of 650 Watt-Hours which results from the pressurised gases.

Returning to the 1 kWh, which is required for electrolysis operation, this 1 kWh is converted (during electrolysis) to hydrogen and oxygen. The 1 kWh of hydrogen and oxygen is fed into a fuel cell. After conversion to electrical energy in the fuel cell, we are left with 585 Watt-Hours due to a 65 % efficiency factor in the fuel cell (35 % thermal losses are fed back into electrolysis unit 150 via Qr in Fig. 15)

Fig. 30 graphically indicates the total over-unity energy available combining a fuel cell with the pressure in this electrolysis system in a range from 0 kAtmospheres to 150 kAtmospheres. The data in Fig. 30 has been compiled utilising the previously quoted formulae where the Watt-Hours findings are based on incorporating the 1 kWh required to drive the electrolysis system, taking into account all inefficiencies in the idealised electrolysis system (complete the loop) and then adding the output energy from the pressurised electrolysis system with the output of the fuel cell. This graph thereby indicates the energy break-even point (at approximately 66 k Atmospheres) where the idealised electrolysis system becomes self-sustaining.

In order to scale up this system for practical applications, such as power stations that will produce 50 MW of available electrical energy (as an example), the required input energy to the electrolysis system will be 170 MW (which is continually looped).

The stores of high pressure gases can be used with a hydrogen/oxygen internal combustion engine, as shown in Figs. 31a to 31e. The stores of high pressure gases can be used with either forms of combustion engines having an expansion stroke, including turbines, rotary, wankel and orbital engines. One cylinder of an internal combustion engine is represented, however it is usually, but not necessarily always the case, that there will be other cylinders in the engine offset from each other in the timing of their stroke. The cylinder 320 houses a piston head 322 and crank 324, with the lower end of the crank 324 being connected with a shaft 326. The piston head 322 has conventional rings 328 sealing the periphery of the piston head 322 to the bore of the cylinder 320.

A chamber 330, located above the top of the piston head 322, receives a supply of regulated separated hydrogen gas and oxygen gas via respective inlet ports 332,334.

There is also an exhaust port 336 venting gas from the chamber 330.

The engine's operational cycle commences as shown in Fig. 31a, with the injection of pressurised hydrogen gas, typically at a pressure of 5,000 psi to 30,000 psi, sourced from a reservoir of that gas (not shown). The oxygen gas port 334 is closed at this stage, as is the exhaust port 336. Therefore, as shown in Fig. 31b, the pressure of gas forces the piston head 322 downward, thus driving the shaft 326. The stroke is shown as distance "A".

At this point, the oxygen inlet 334 is opened to a flow of pressurised oxygen, again typically at a pressure of 5000 psi to 30,000 psi, the volumetric flow rate being one half of the hydrogen already injected, so that the hydrogen and oxygen gas within the chamber 330 are the proportion 2:1.

Conventional expectations when injecting a gas into a confined space (e.g. such as a closed cylinder) are that gases will have a cooling effect on itself and subsequently its immediate environment (e.g. cooling systems/refrigeration). This is not the case with hydrogen. The inverse applies where hydrogen, as it is being injected, heats itself up and subsequently heats up its immediate surroundings. This effect, being the inverse of other gases, adds to the efficiency of the overall energy equation when producing over-unity energy.

As shown in Fig. 31c, the piston head 322 has moved a further stroke, shown as distance "B", at which time there is self-detonation of the hydrogen and oxygen mixture.

The hydrogen and oxygen inlets 332,334 are closed at this point, as is the exhaust 336.

As shown in Fig. 31d, the piston head is driven further downwardly by an additional stroke, shown as distance "C", to an overall stroke represented by distance "D". The added piston displacement occurs by virtue of the detonation.

As shown in Fig. 31e, the exhaust port 336 is now opened, and by virtue of the kinetic energy of the shaft 326 (or due to the action of others of the pistons connected with the shaft), the piston head 322 is driven upwardly, thus exhausting the waste steam by the exhaust port 336 until such time as the situation of Fig. 31e is achieved so that the cycle can repeat.

A particular advantage of an internal combustion motor constructed in accordance with the arrangement shown in Figs. 3 1a to 3 1e is that no compression stroke is required, and neither is an ignition system required to ignite the working gases, rather the pressurised gases spontaneously combust when provided in the correction proportion and under conditions of high pressure.

Useful mechanical energy can be extracted from the internal combustion engine, and be utilised to do work. Clearly the supply of pressurised gas must be replenished by the electrolysis process in order to allow the mechanical work to continue to be done. Nevertheless, the inventor believes that it should be possible to power a vehicle with an internal combustion engine of the type described in Figs. 31a to 31 e, with that vehicle having a store of the gases generated by the electrolysis process, and still be possible to undertake regular length journeys with the vehicle carrying a supply of the gases in pressure vessels (somewhat in a similar way to, and the size of, petrol tanks in conventional internal combustion engines).

When applying over-unity energy in the form of pressurised hydrogen and oxygen gases to this internal combustion engine for the purpose of providing acceptable ranging (i.e. distance travelled), pressurised stored gases as mentioned above may be necessary to overcome the problem of mass inertia (e.g. stop-start driving). Inclusion of the stored pressurised gases also facilitates the ranging (i.e. distance travelled) of the vehicle.

Over-unity energy (as claimed in this submission) for an average sized passenger vehicle will be supplied at a continual rate of between 20 kW and 40 kW. In the case of an over-unity energy supplied vehicle, a supply of water (e.g. similar to a petrol tank in function) must be carried in the vehicle.

Clearly electrical energy is consumed in generating the gases. However it is also claimed by the inventor that an over-unity energy system can provide the requisite energy thereby overcoming the problem of the consumption of fossil fuels either in conventional internal combustion engines or in the generation of the electricity to drive the electrolysis process by coal, oil or natural gas generators.

Experimentation by the inventor shows that if 1,850 litres of hydrogen/oxygen gas mix (in a ratio of 2:1) is detonated, the resultant product is 1 litre of water and 1,850 litres of vacuum if the thermal value of the hydrogen and oxygen gas mix is dissipated. At atmospheric pressure, 1 litre of admixed hydrogen/oxygen (2:1) contains 11 BTUs of thermal energy. Upon detonation, this amount of heat is readily dissipated at a rate measured in microseconds which subsequently causes an implosion (inverse differential of 1,850:1). Tests conducted by the inventor at 3 atmospheres (hydrogen/oxygen gas at a pressure of 50 psi) have proven that complete implosion does not occur. However, even if the implosion container is heated (or becomes heated) to 400C, total implosion will still occur.

This now available function of idiosyncratic implosion can be utilised by a pump taking advantage of this action. Such a pump necessarily requires an electrolysis gas system such as that described above, and particularly shown in Fig. 6.

Figs. 32a-32c show the use of implosion and its cycles in a pumping device 400. The pump 400 is initially primed from a water inlet 406. The water inlet 406 then is closed-off and the hydrogen/oxygen gas inlet 408 is opened.

As shown in Fig. 32b, the admixed hydrogen/oxygen gas forces the water upward through the one-way check valve 410 and outlet tube 412 into the top reservoir 414. The one-way check valves 410,416 will not allow the water to drop back into the cylinder 404 or the first reservoir 402. This force equates to lifting the water over a distance. The gas inlet valve 408 then is closed, and the spark plug 418 detonates the gas mixture which causes an implosion (vacuum). Atmospheric pressure forces the water in reservoir 402 up through tube 420.

Fig. 32c shows the water having been transferred into the pump cylinder 404 by the previous action. The implosion therefore is able to 'lift' the water from the bottom reservoir 402 over a distance which is approximately the length of tube 420.

The lifting capacity of the implosion pump is therefore approximately the total of the two distances mentioned. This completes the pumping cycle, which can then be repeated after the reservoir 402 has been refilled.

Significant advantages of this pump are that it does not have any diaphragms, impellers nor pistons thereby essentially not having any moving parts (other than solenoids and one-way check valves). As such, the pump is significantly maintenancefree when compared to current pump technology.

It is envisaged that this pump with the obvious foregoing positive attributes and advantages in pumping fluids, semi-fluids and gases can replace all currently known general pumps and vacuum pumps with significant benefits to the end-user of this pump.

Electrolysis systems

US5843292

US5843292

Also published as: WO9507373 // US5997283 // SG52487 // PL313328

A cell arrangement for the electrolysis of water to liberate hydrogen and oxygen gases is described. A cell unit (125) has a stacked arrangement of segmentation disks

(114), a first type of (anode) cell plates (90), a second type of (cathode) cell plates (98) and separation membranes (116). Interconnecting conductive shafts (126-131) pass through holes (100, 102) of the cell plates (90,98) to have selective electrical interconnection therewith. Water and electrolyte are supplied by inlet ports (108, 110) to immerse the cell plates (90, 98). The membranes (116) normally isolate adjacent cathode and anode plates (90, 98) from the mixing of liberated oxygen and hydrogen gases while allowing ionic current to flow. By selective adjustment of the water/electrolyte pressure differential on the respective sides of the separation membranes (116), the admixture of the liberated gases can be produced. The liberated gases discharge through outlet ports (104,106).

A cell arrangement for the electrolysis of water to liberate hydrogen and oxygen gases is described. A cell unit (125) has a stacked arrangement of segmentation disks (114), a first type of (anode) cell plates (90), a second type of (cathode) cell plates (98) and separation membranes (116). Interconnecting conductive shafts (126-131) pass through holes (100, 102) of the cell plates (90,98) to have selective electrical interconnection therewith. Water and electrolyte are supplied by inlet ports (108, 110) to immerse the cell plates (90, 98). The membranes (116) normally isolate adjacent cathode and anode plates (90, 98) from the mixing of liberated oxygen and hydrogen gases while allowing ionic current to flow. By selective adjustment of the water/electrolyte pressure differential on the respective sides of the separation membranes (116), the admixture of the liberated gases can be produced. The liberated gases discharge through outlet ports (104,106).

TECHNICAL FIELD OF THE INVENTION

The present invention relates to the generation of hydrogen gas and oxygen gas from water, either as an admixture or as separated gases, by the process of electrolysis, and relates further to applications for the use of the liberated gas. Embodiments of the invention particularly relate to an apparatus for the efficient generation of these gases, and to the use of the gases as a thermal source in atomic welding or cutting, and in gaseous waste disposal.

BACKGROUND ART

The technique of electrolysing water in the presence of an electrolyte such as sodium hydroxide (NaOH) or potassium hydroxide (KOH) to liberate hydrogen and oxygen gas (H2, O2) is well known. The process involves applying a DC potential difference between two or more anode/cathode electrode pairs and delivering the minimum energy required to break the H--O bonds (i.e. 68.3 kcal per mole @STP). The gases are produced in the stoichiometric proportions for O2 :H2 of 1:2 liberated respectively from the anode (+) and cathode (-).

Reference can be made to the following texts: "Modern Electrochemistry, Volume 2, by John O'M. Bockris and Amulya K. N. Reddy, (Plenum Publishing Corporation)", "Electro-Chemical Science," by J. O'M. Bockris and D. M. Drazic, (Taylor and Francis Limited) and "Fuel Cells, Their Electrochemistry," by J. O'M. Bockris and S. Srinivasan, (McGraw-Hill Book Company).

A discussion of experimental work in relation to electrolysis processes can be obtained from "Hydrogen Energy, Part A, Hydrogen Economy Miami Energy Conference," Miami Beach, Fla., 1974, edited by T. Nejat Veziroglu, Plenum Press. The papers presented by J. O'M. Bockris on pages 371 to 379, by F. C. Jensen and F. H. Schubert on pages 425 to 439 and by John B. Pangborn and John C. Sharer on pages 499 to 508 are of particular relevance.

On a macro-scale, the amount of gas produced depends upon a number of variables, including the type and concentration of the electrolytic solution used, the anode/cathode electrode pair surface area, the electrolytic resistance (equating to ionic conductivity, which is a function of temperature), the achievable current density and anode/cathode potential difference. The total energy delivered must be sufficient to disassociate the water ions to generate hydrogen and oxygen gases, yet avoid plating (oxidation/reduction) of the metallic or conductive non-metallic materials from which the electrodes are constructed.

Reference also is made to prior art Australian Patent No. 487062 to Yull Brown, that discloses an electrolysis cell arrangement to produce hydrogen and oxygen on demand, together with a safety device preventing the generation of excess pressure of the liberated gases. FIG. 2 of the Brown patent shows a number of electrodes (20a,20b) in a series electrical arrangement between two terminals (22), across which a voltage is applied. The cell (20) produces a gas volumetric flow rate output, and if that output is insufficient for a particular application, then a larger number of individual cell units must be provided which are all electrically connected in series.

The end result is a large structure to be supported.

It is also not possible to produce high gas flow rates (of the order of 10,000 liters per hour) on demand from the prior art apparatus without the use of expensive and complicated equipment, and even then the equipment suffers from low efficiencies in the conversion of electrical energy to generate the hydrogen and oxygen gases. Thus, the large scale commercial implementation of such apparatus is not economically viable.

Admixed hydrogen and oxygen gases (or hydroxy gas) are used as a thermal source when burnt in a stream, for example, in furnaces. Hydrogen alone is used for atomic cutting and often for atomic welding, although the device described in the Brown patent performed atomic welding with admixed hydrogen and oxygen. Recent industry practice clearly exemplifies that the presence of oxygen in a plasma arc causes severe oxidation of the tungsten electrodes.

One of the problems experienced in implementing these applications is the need to incorporate electrical switchgear to transform main supply voltages to a level suitable for a bank of electrolysis cells (i.e. by step-down transformers). The resulting completed arrangement is electrically inefficient and cumbersome, and also can be expensive if precise voltage and current regulation (hence gas flow regulation) is required.

Combusted hydrogen and oxygen gases mixed into a single stream burn at a very high temperature, typically of the order of 6000 DEG C. Hydrogen/oxygen welding sets are generally known to comprise of a welding tip or hand piece connected by a dual gas hose to separate supplies of oxygen and hydrogen.

There are four other common types of welding apparatus and techniques in use. These are oxy-acetylene welding, electric arc welding, MIG (metal-inert-gas)/TIG (tungsten-inert-gas) systems and plasma cutting.

It is estimated that more than 100,000 oxy-acetylene sets are used in Australia. Of those, approximately 70% are used primarily for cutting metals, with the remainder being used as a heat source, for fusion welding of sheet metal, brazing, silver soldering and the like. Typically, oxy-acetylene sets can weld thicknesses of metal between 0.5 mm to 2 mm. Further, thicknesses up to 140 mm can be cut, but only where the steel contains a high percentage of iron. The reason for this is that the iron and the oxygen are required to support the oxidation process which induces the cutting effect. The acetylene gas provides the initial temperature to start the oxidation reaction, being typically 850 DEG C. Oxy-acetylene sets require a bottled supply of both acetylene and oxygen gas. Hence, the bottles must be bought or rented, then continually maintained and refilled with use.

Electric arc welding is a method used for welding metals of greater than 1.5 mm in thickness. The principle of operation is that a hand piece is supplied with a consumable electrode, and the work piece forms the other electrode. An AC or DC potential difference is created between the electrodes, thus causing an arc to be struck when the hand piece is brought into proximity of the work piece. The arc can be used to fuse or weld metal pieces together.

MIG systems are based around a continuous wire feed system. In one known arrangement, the consumable wire is shrouded by argon gas (or a plasma) which typically is provided from a bottled supply. TIG systems, on the other hand, require the filler wire to be hand-fed into the weld pool. MIG/TIG systems can weld metals from between 1 mm to 20 mm in thickness. These metals, typically include stainless steel, aluminium, mild steel and the like. Reference can be made to a text "The Science and Practice of Welding, Volume 2, A. C. Davies, Cambridge University Press" with respect to a plasma MIG processes.

Plasma cutting is a method of cutting by introducing compressed air (comprising predominantly nitrogen) to a DC electric arc, thereby producing very high temperatures (about 15,000 DEG C.) and so stripping electrons from the nitrogen nucleus to form a high temperature plasma. This plasma can be utilized to cut ferrous and non-ferrous materials such as mild steel, stainless steel, copper, brass and aluminium. Available plasma cutters can cut up to a 25 mm thickness and have the advantage of not requiring bottled gas, but rather utilize free air. Reference can be made to the text "Gas Shielded Arc Welding," by N. J. Henthome and R. W. Chadwick, (Newnes Technical Books.) with respect to plasma cutting.

As can be seen from the discussion of the prior art, no one unit or system has the capability of performing all welding and cutting functions, and typically, one of the systems already described would be chosen over another for any particular job. This then requires that metal workers or other metal trade industry manufacturers must purchase and maintain a number of different types of welding units in order to have the capability to handle any job on demand. The costs associated with the purchase of replacement bottled gas also are very high.

DISCLOSURE OF THE INVENTION

It is a preferred object of the present invention to provide an arrangement whereby hydrogen and oxygen gases can be produced by electrolysis in a manner that avoids one or more of the foregoing disadvantages. In that sense, the electrolysis apparatus is compact and offers greater efficiencies than the prior art for comparative gas flow rates.

It is a further preferred object of the invention to provide an improved structure for an electrolysis cell for use in the generation of hydrogen and oxygen gas. The electrolysis cell can be used in hydrogen/oxygen welding or hydrogen plasma cutting. Other applications may relate to industrial processes where a combustible source of fuel is required, such as incinerators, and to the incineration of intractable wastes.

It is a yet further preferred object to provide an electrolysis cell arrangement that allows the selective separation or admixture of hydrogen and oxygen gas into individual gas streams.

The present invention further preferably is directed to provision of a unitary welding unit which can provide all the welding or cutting requirements of a user. Advantageously, no bottled supply of hydrogen or oxygen is required. A bottled supply of any other gas also required is not. For example, argon is not required in shrouded MIG/TIG applications.

It is a yet further preferred object of the invention to provide a flashback arrester for a hydrogen/oxygen welding or hydrogen plasma cutting tip.

Therefore, the invention discloses a cell arrangement for the electrolysis of water to liberate hydrogen and oxygen gases, the arrangement comprising:

a plurality of anode-forming electrodes in a stacked relation, each anode electrode comprising a flat plate through which passes one or more common first conductive interconnecting members; and

a plurality of cathode-forming electrodes in a stacked relation, each cathode electrode comprising a flat plate through which passes one or more common second conductive interconnecting members;

and wherein the anode electrodes and the cathode electrodes are interleaved.

The invention further discloses a cell arrangement for the electrolysis of water to liberate hydrogen and oxygen gases, the arrangement comprising:

a plurality of anode-forming electrodes interconnected by one or more first common conductive members to be electrically in parallel, the anode electrodes being interleaved with a plurality of cathode forming electrodes interconnected by one or more second conductive members to be electrically in parallel, the anode electrodes and cathode electrodes forming a cell unit; and a plurality of the cell units being electrically connected in series.

The invention further discloses a cell arrangement for the electrolysis of water to liberate separated or admixed hydrogen and oxygen gases, the arrangement comprising:

a plurality of anode-forming electrodes arranged in a stacked relation, each anode electrode comprising a flat plate through which passes one or more first conductive interconnecting members;

a plurality of cathode-forming electrodes arranged in a spaced linear stacked relation, each cathode electrode comprising a flat plate through which passes one or more second conducting interconnecting members; wherein the anode electrodes and the cathode electrodes are interleaved; and