rexresearch.com

Maxwell WHISSON

Air Well

Max-Air

http://www.waterunlimited.com.au/

General Enquires can be fowarded to WATER

UNLIMITED.

Postal: PO Box 695

West Perth WA 6872

Australia

Em Telephone: +61 8 9381 2177

Fax +61 8 9486 4944

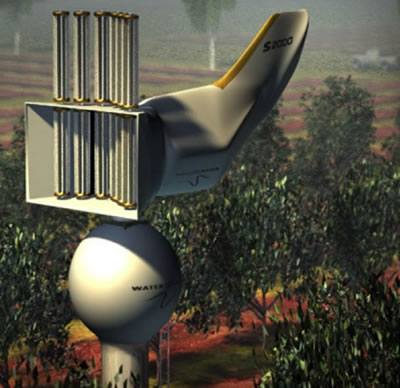

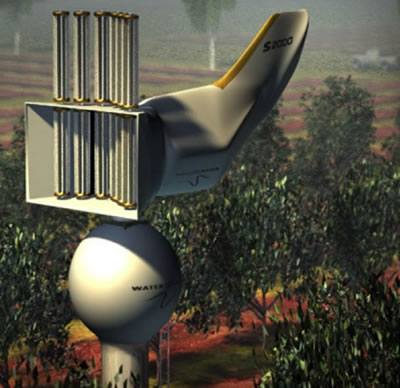

Introducing the Max Water

Water UN Limited was incorporated to acquire the

technology and intellectual property associated with water from

ambient air technology, also known as Ďthe Max Water', from

world renowned Perth based inventor Dr Max Whisson.

This breakthrough technology has the potential to

produce water from air using a turbine containing refrigerants.

If successful, this technology will be capable of supplying

commercial quantities of water for a wide variety of uses

powered by wind energy alone.

If successful the technology developed by Dr Max

Whisson may represent the most important breakthrough in water

production in recent years. The commercialisation of Max Water

may be by license, direct sales, distributor networks or a

combination of these. Under any marketing strategy a percentage

of units produced will be donated via appropriate charitable

organizations to supply water to areas of extreme poverty in

developing economies.

Our company mission is to now build the first

complete prototype and hopefully prove the concept.

Video : http://www.waterunlimited.com.au/video.html

Learn more about the Max Water : This

short presentation outlines how the Max Water may use only wind

power to cool the air and achieve condensation of the contained

water. It contains drawings, research and other relevant

statistical information. DOWNLOAD PDF (2.8 MB):

http://www.waterunlimited.com.au/images/presentation/WaterUNlimited-MAY.pdf

QuickTime Movie :

http://www.waterunlimited.com.au/images/presentation/WaterUNlimited-MAY-big.mov

YouTube :

http://www.youtube.com/watch?v=Gf0krn99Y20

http://www.abc.net.au/science/news/stories/2007/1860729.htm

ABC Science Online

( Friday, 2 March 2007 )

Making Water Out of Thin Air

Anna Salleh

Could a wind turbine that sucks water out of the

air supply enough water for the whole world?

A wind-driven device could provide an unlimited

water supply by harvesting water from the air, says its

Australian inventor.

But critics are asking if it's too good to be

true.

Dr Max Whisson, a retired medical specialist

turned inventor, says he has designed a highly efficient wind

turbine that can run a refrigeration system to cool air and

condense moisture from it.

"The wind carries in the water and [provides] the

power required to separate that water from the wind," says

Whisson, who is based in Perth.

He says there is a huge amount of water in the

atmosphere that is replaced every few hours. This means the

whole world could just use water from the air without disrupting

the environment.

Whisson says the system would even harvest

significant amounts of water in areas with low humidity.

He says a 4 metre square device could extract an

average 7500 litres of water a day.

In his design, moisture-laden air enters the

system and is cooled by a drop in pressure behind the wind

turbine blades, says Whisson.

The air then flows into a chamber containing

refrigerated metal plates covered by a non-wettable surface that

causes water droplets to run off immediately into a collection

point.

Could it work?

Full technical details of the design are not

available but at least one mechanical engineer is sceptical.

"I have found in general that inventors tend to

enormously overstate the capacities of their devices. They just

have a very rosy outlook on what their devices will do," says

mechanical engineer Professor John Reizes, an adjunct professor

at the University of New South Wales.

"It's not until you've made one that you discover

all the problems."

Reizes, who specialises in heat transfer, says he

is sceptical because of the huge amount of energy that is needed

to condense water.

Whisson says he is well aware that a large amount

of energy is required to do the job.

"It's like boiling a kettle in reverse," he says.

But he is confident his wind turbine, still

subject to patent applications and yet to be independently

tested, is efficient enough.

"The wind turbine is a surprisingly good

development. I'm surprised because it performs so well," says

Whisson.

And he says the power generating part of the wind

turbine can simply be increased to collect the wind power

required for the condensation process.

"We've got unlimited power," he says.

But Reizes says wind turbines are so far only

about 30% efficient at best and the energy arriving at them is

very diffuse, requiring large devices to collect the energy.

"It may be a fantastic idea on paper and it looks

as if it could work," he says.

"However, the thing may have to be so big to drive

this device that it becomes impractical."

Drawing moisture from air

One thing seems more certain. If the system does

work, it is unlikely to backfire on the environment, says Dr

Michael Coughlan, of Australia's Bureau of Meteorology.

He says the amount of water that humans would use

is trivial compared with the amount available in the atmosphere.

"If you can tap into it, then go for it, because

you would do little to upset the hydrological cycle," says

Coughlan.

http://www.alternate-energy-sources.com/Whisson-windmill.html

The Whisson Windmill - Water From Air,

Why Not?

...Dr Whisson himself describes his Whisson

Windmill as follows: "The essential principle is that more wind

is used for power than for water supply. In other words, the

area of power turbines is greater than the area of turbines

leading to water harvest. This is all made much easier by the

invention of a new kind of wind turbine or 'windmill'. The

amount of water available in the air is for all forseeable

practical purposes unlimited. The bottom 1 kilometre (in the

atmosphere) alone contains about 1.000,000,000,000,000 litres of

water and that is turned over every few hours. The "Whisson

Windmill" or Max Water From Air device will make it possible to

get adequate water anywhere at any time, drought or no drought."

http://www.abc.net.au/austory/specials/windmills/default.htm

Windmills of Your Mind

PROGRAM TRANSCRIPT: Monday, 21 May , 2007

JAMES O'LOUGHLIN: Hello, I'm James O'Loughlin from "The New

Inventors".

Australia has a long tradition of innovation, from the Hills

Hoist to the black box flight recorder, and our home grown

ideas have often found international markets.

Well, Perth inventor Max Whisson believes he may have come up

with a solution to the world's water problems and he has some

influential supporters. This is Max Whisson's story.

MAX WHISSON: The state of the world at the moment is, I

think, the most dangerous in the evolution of Homo sapiens,

for two main reasons. Power is almost entirely in the hands of

those who gained power by exercising commercial advantage, and

at the same time the ability of modern technology to destroy

the world is unprecedented. The destruction of vast ecosystems

is happening as we speak: forests being destroyed, catchment

areas being destroyed, rivers being destroyed. We are a highly

developed species, can fly to the moon and do all sorts of

clever things, and we destroy the rivers all over the planet.

I think itís utterly absurd, outrageous. Grassroots action is

the only hope to get a healthy world community.

PROFESSOR ROGER DAWKINS, SCIENCE CENTRE DIRECTOR: I know that

some people think that Max is a crackpot but heís a very

engaging one and heís certainly a very productive one.

MARCUS WHISSON, SON: He can be a bit of a handful, heís an

eccentric old bugger, heíd probably say that himself.

PHILLIP ADAMS, FRIEND: I think Max is a reincarnation of an

ancient Roman, the Romans were wonderful at water.

MAX WHISSON: It took me a little while to realise that the

expanding population of the world cannot rely on surface water

which accumulates from rain. We have to find unlimited sources

of water and the sea seemed to me to be the obvious source of

vast quantities of water. Seventy-one per cent of the Earthís

surface at an average depth of four or five kilometres, and I

thought, how can you purify that water without fossil fuels or

big machines or high technology? And sunlight seemed to be the

obvious way. I came up with the idea of the Water Road in

about 2002 in a sort of Eureka moment. Most places in need of

water are far inland and it would seem so logical to just run

the sea water inland over a long distance, producing pure

water as it goes. The Water Road is a very simple design. Itís

just a series of parallel black pipes, preferably to a width

of about 10 metres, covered in a transparent cover such as

perspex or polycarbonate, and maybe a thousand kilometres

long. The sea water heats to 70 or 80 degrees, by my

calculation, in about three to four days, heated by the sun,

and at intervals the sea water is run into big swimming pools

that I call evaporation ponds. The hot, wet air in the

evaporation ponds is ducted up to a hilltop where it just

condenses in a special condensation shed. So youíve got pure

water produced at a high point and that greatly assists the

distribution to irrigation or to households along the way. A

pipeline of that size would produce about 200,000 litres per

kilometre per day. The salt from the returning sea water goes

back to the sea where itís diluted within minutes to normal

sea water. But it could be sent to a salt manufacturer.

COLIN BARBOUTIS, BUSINESS PARTNER: When Max first mentioned

the Water Road to me, I thought, this could be an answer for

the water problem that weíre going to have in Perth in the

very near future. Maxís mind works very differently to most

people. And Max told me this himself, he said, ďColin all my

life, Iíve seen things differently to most people.Ē He said,

ďYou see a glass of water on the table, I see a mathematical

calculation for a vessel that holds liquid.Ē

ANNEMARIE WHISSON, WIFE: When he comes to invention heís

very, very obsessive and quite stubborn, but in a good way.

MAX WHISSON: I graduated as a doctor in '55. I met Annemarie

whilst I was working on cancer research in London.

ANNEMARIE WHISSON: I trained as a medical technologist in

Switzerland and I was his research assistant. Oh goodness me,

after two weeks, I just fell in love with this man and, and

after a while, you know, I could see, he said he liked me too

and so we had a little bit lunch together or coffee and, you

know from then on it started, you know, I was just completely

besotted with him.

MAX WHISSON: Annemarie and I have two sons and there are four

sons from my first marriage.

ALEX WHISSON, SON: I think in many ways my mumís sacrificed

her own life to support my dadís inventions and his scientific

research work. If it wasnít for my mum, my dad would be a

disorganised brain in the ether somewhere. I mean she actually

roots him in the earth, she actually grounds him in reality

and heíd be completely lost without her.

MARCUS WHISSON, SON: He is an eccentric, the quintessential

nutty professor. For a long time I know in the 1980s he had a

fairly healthy obsession with solar power from cooling

someoneís head with a solar-powered hat to allowing a bicycle

to be used not by pedal power but by solar power.

MAX WHISSON: I worked for many years as a haematologist at

the Red Cross Blood Bank in Western Australia.

PHILLIP ADAMS, FRIEND: By the late '80s the magnitude of the

AIDS epidemic was becoming well known and I was concerned

about my daughter, the doctor, getting needle stick injuries

where she was working in an ER hospital in New York. And I was

expressing these concerns to Max, who miraculously was working

on a retractable needle.

To any project he examines Max brings a very fresh

intelligence and so he looked at the needle again and again

and he then came up with a Mark II, a completely different way

of solving the issue involving a sleeve rather than a

retreating needle.

PROFESSOR ROGER DAWKINS, SCIENCE CENTRE DIRECTOR: It was 1982

in the early days of HIV that I really got to know Max

Whisson. He does have some weird and wonderful ideas, thereís

no doubt about it.

The Needlesleeve seems to be a very good idea and it seems to

work very well. Iíd like to see it in use.

Max has always been very limited by funds. The country really

needs to support people like Max without pressing them to

early commercialisation because there are hazards in early

commercialisation and many a good project has really been

destroyed by the commercial partners.

ALEX WHISSON, SON: There was a very nasty and prolonged court

case involving my dadís Needlesleeve invention which basically

involved some of his former business associates laying claim

to his inventions. And even though he won that case actually

on three separate occasions, it has left him a bit bitter.

PHILLIP ADAMS, FRIEND: The saddest thing for Max is that his

needle, his wonderful hypodermic that prevents needlestick

injury, isnít being manufactured to this day because of the

problems heís had in an out of courts. Great shame.

ANNEMARIE WHISSON, WIFE: I think Max is actually a

renaissance man. Heís so interested in so many things. Heís

interested in physics, biology, cancer, politics nature,

birds. He loves reading poetry and he writes poetry himself

and short stories. He plays the violin in the Fremantle

Symphony Orchestra. He enjoys it immensely. Even when heís

very, very tired he always goes to rehearsal.

MAX WHISSON: For the last nine years Annemarie and I have

lived in separate places. I think at a certain stage of life

there is some sense in having a wife down the road. There were

quite a lot of conflicts.

ALEX WHISSON, SON: My dad was always a workaholic and heíd

often go on extended trips to haematology conferences, medical

conferences, and never invite my mother on those trips. She

felt excluded, I think, from more and more aspects of his

life. And as well, truth be told, he had a wandering eye for

other women. My dadís inventions have cost a fortune in

patents and thatís led to financial difficulties for the

family, which has been tough, especially on my mum.

MARCUS WHISSON, SON: It has taken enormous emotional toll and

it can be up and down with my parentsí relationship, but at

the end of the day theyíre most in love and really support one

another.

ANNEMARIE WHISSON, WIFE: We see each other every day. He

actually has got less difficult now. I think it makes all

sense now in hindsight. í94, í95 he started to get sometimes

quite aggressive, verbally, and short-tempered and then it

developed even in a kind of paranoia as well. I was really

very puzzled about it and I thought, what is going on? And

sometimes you know he accused us of things which was

completely irrational which he never had done before. And

Marcus just said, ďI think dad is going senile.Ē

ALEX WHISSON, SON: Strange things started happening with my

dadís brain. Heíd be able to read the start of a paragraph but

not the end of it. He couldnít distinguish left from right,

heíd get lost driving from Subiaco to Nedlands on a route that

heíd travelled a thousand times before.

ANNEMARIE WHISSON, WIFE: And then again we said, ďPlease go

to the doctor. We canít do anything.Ē And he said very

aggressively, ďI donít need your advice.Ē

MARCUS WHISSON, SON: It was August the 17th 2000, the day

after my motherís birthday. It was a blessing in disguise for

him. My father was involved in an accident where he hit a

parked ute and he was given a scan and they found a tumour the

size of my fist, a huge tumour in the back of his head,

pressing against his visual cortex.

ALEX WHISSON, SON: And suddenly it was like a revelation for

all of us because we all realised sort of what had been

happening with his brain over these past few years.

MARCUS WHISSON, SON: It was a benign tumour but they realised

that they had to operate immediately because there was every

chance that it would break through his skull.

MAX WHISSON: An incredibly, I tell you, extraordinarily

skilful set of surgeons, got this whole thing out intact. And

my whole brain kind of went, "Ah, now I can work again." It

was quite amazing.

ALEX WHISSON, SON: The amount of energy my dad has is

phenomenal. Heís 76 now, he still works probably 12, 14 hours

a day. I have tremendous admiration for my dadís inventions.

Itís never just something trivial. It's the fact that theyíre

inventions that are all geared towards actually improving

human welfare, improving the standards of life, the conditions

of life. Itís never something like, I donít know, a faster car

or something that is just economically viable.

MAX WHISSON: I suppose itís occurred to me a little bit that

I havenít got much time to do all the things that I really

want to do. Do I feel like an old man in a hurry? Yeah. My

grandfather was an irrigation controller in the little town of

Dingee, just not far from Bendigo in Victoria. So that I

suppose gave me an interest in water.

(Outdoors, standing near a dried up lake)

This was quite a lovely lake, a little lake, and I used to

visit it quite a lot, lots of birds came here, walk around and

see these beautiful things. Itís really tragic to see it like

this. You canít look at this without being dreadfully upset,

especially knowing that itís not just a one off and itís not

really accidental. Itís because weíve not taken care of these

things. The water table has gone down so that the lake is

worse because of that because everyoneís sucking up water to

keep their lawns healthy. The bores have gone down deeper in

Perth as in almost every city in the world.

I donít really know where I get my ideas but I do read widely

in scientific books and in things like "New Scientist". I do

look very carefully at what has gone before. Iím not an expert

on anything, but I throw things around and I sometimes kind of

turn ideas upside down and you suddenly find youíve got a

really interesting answer thatís been staring people in the

face for centuries, you know? After working on the Water Road

for some time, I did some calculations which showed that

thereís heaps of water in the air. And so I began to think,

why bother with the sea water? So why not just collect water

from the air and you can collect the water anywhere, in any

small community or out in the desert or on the coast, wherever

you want.

PHILLIP ADAMS, FRIEND: The water thatís in the air goes up

for about a hundred miles, constantly replenished by

evaporation from the ocean. Water is constantly extracted from

the air in the form of dew. The technology of extracting it is

known. The American army, for example, uses great thundering

diesel machines to pull it out of the air, but thatís not very

appropriate technology for a world suffering climate change.

Max thinks, no, no, no, I can use the air to produce the power

to produce the water.

MAX WHISSON: The key to the process is to refrigerate the air

as quickly as possible so that water separates from the air

and condenses as drops which will run down into a collection

tank.

The best place to remove heat quickly is as the air hits a

windmill. Now existing windmills did not work out at all well

so I invented a new one and Iíve arranged to have it

refrigerated so that as soon as the wind hits that windmill it

gets cooled.

PHILLIP ADAMS, FRIEND: The astonishing thing is if you even

breathe near one of Maxís windmills, the windmill starts

spinning furiously. And the theory is, the more air you can

pass through that windmill, the more air is available for

cooling and for dispensing the water within it. So itís a very

elegant, very simple but tricky idea.

MAX WHISSON: There was a point where I had a bit of a hitch.

I could achieve fairly rapid condensation of water on a cold

plate but it would just stick as little droplets and not run

off the plate quickly so that water could be collected. And

then I came across this little chap, the little beetle called

Stenocara. Itís quite amazing how creatures over millions of

years evolve clever techniques which are ahead of us.

COLIN BARBOUTIS, BUSINESS PARTNER: I was at Maxís house one

day, and Max said, "Well, if I tell you, youíre going to think

Iím completely mad." And we had the discussion about the

little African beetle that pops out of the sand in the early

morning, does a headstand, faces his tummy into the breeze,

sits there most of the day and a little droplet of water

collects on the fibres on his tummy, runs down his nose and

into his mouth and heís back into his burrow. So, heís self

sufficient in water. And he said, ďSee, I told you youíd think

I was mad.Ē And I said, ďWell I actually donít know that

youíre mad, tell me a little bit more.Ē And he went into more

detail about how heíd been thinking about this for a little

while and that it was do-able. He said, "Often the simplest

things in this world are the hardest to invent."

MAX WHISSON: Observing nature has taught me a lot. Now I have

a surface on the plates which is very like the surface on this

little beetle, the water touches the plates and just runs

quickly off. And so the little beetle has helped a great deal

and Iíd like to thank him.

COLIN BARBOUTIS, BUSINESS PARTNER: I believe it will take us

another 12 months to fully develop this unit, to test it, to

see if the working prototypes do work. I guess Max is a bit of

a crackpot but then again, you'd have to be to come up with

some of these wonderful inventions. Iíve put my money on that

one out there. I think this water project is something that's

very unique. I absolutely believe in Maxís abilities and have

blind faith that he can do this and he'll get it right. I may

be wrong but thatís my thought.

PHILLIP ADAMS, FRIEND: Iím a great enthusiast for the theory

of the windmill, and I write a newspaper column about my old

friendís bright new idea. And in all my born days in over 50

years of writing columns, rarely seen a response like it - a

couple of thousand, a couple of thousand rapturous emails,

some sceptical, but mostly thrilled to the back teeth, from

every nook and cranny on the planet. From the Middle East,

from Venezuela, from Russia, from India, everyone thinks this

is it.

SEAN BLOCKSIDGE, WINE COMPANY MANAGER: Sustainable farmingís

something that weíre looking at more and more. Itís an

imperative, particularly as a wine business. Certainly we do

have some fairly good, consistent rainfall but weíre certainly

seeing decreases. Weíve looked at the more traditional sources

of water in the past. One thing Margaret River doesnít have a

shortage of is wind and certainly Max Whissonís invention is

something worth investigating. Weíre also regenerating large

tracts of land around the estate and we donít necessarily have

the capacity to irrigate re-vegetation projects, so to be able

to put one of these windmills out there and have it producing

water would be fantastic.

PHILLIP ADAMS, FRIEND: Iíve got a feeling there are many Max

Whissons around. At the moment of course heís tilting at his

windmills, a bit like Don Quixote, because governments are

remarkably uninterested, but everyone else is.

MAX WHISSON: The question whether the Water Road idea is now

redundant because of the Water Windmill is one that several

people have asked. I see the Water Road as a much more

practical national or large-scale water producing system.

PHILLIP ADAMS, FRIEND: And provided Max can live another 10

years and work out a few little minor details, itís going to

be fantastic. A freeway, not just a Water Road, a freeway of

fresh water - wouldnít that be fantastic? And Max wouldnít

even want to charge toll, so it would be a freeway not a

tollway.

ANNEMARIE WHISSON, WIFE: I think I would quite like to live

with Max again and I think he probably would like to live with

me. I still love him. Itís just, itís a different love, after,

my goodness, forty years. You know, we were incredibly

passionately in love but itís, it has become a very

comfortable love.

MAX WHISSON: Certainly I feel bad that I havenít provided a

secure life. I suppose, yeah, I probably havenít been a

perfect husband or father. But I think itís important to

follow your geist, your spirit, what you think youíre good at.

APPARATUS AND METHOD FOR COOLING OF AIR

US2007204633

AU2005274673 // CN101014817 //

BRPI0515188

Abstract -- A wind turbine apparatus for cooling of air

having a wind turbine axially connected to a refrigeration

compressor arranged to compress refrigerant, at least one tube

for conducting compressed refrigerant centrifugally outwards, a

construction for causing the compressed refrigerant to lose

pressure so as to cool fades of the wind turbine, and a conduit

for returning spent refrigerant centripetally to the compressor.

Correspondence Name and Address: BACHMAN & LAPOINTE,

P.C.-- 900 CHAPEL STREET -- SUITE 1201, NEW

HAVEN CT 06510 US

U.S. Current Class: 62/93; 62/401; 62/404; 62/426; 62/498

U.S. Class at Publication: 062/093; 062/404; 062/426;

062/401; 062/498

Intern'l Class: F25D 17/06 20060101 F25D017/06; F25D 9/00

20060101 F25D009/00;

Description

FIELD OF THE INVENTION

[0001] The present invention relates to an

apparatus and method for cooling air.

SUMMARY OF THE INVENTION

[0002] In accordance with one aspect of the

present invention there is provided a wind turbine apparatus for

cooling of air characterised by comprising a wind turbine

axially connected to a refrigeration compressor arranged to

compress refrigerant, means for conducting compressed

refrigerant centrifugally outwards, means for causing the

compressed refrigerant to lose pressure so as to cool blades of

the wind turbine, and means for returning spent refrigerant

centripetally to the compressor.

[0003] In accordance with a further aspect of the

present invention there is provided a method of condensing water

from ambient air, which comprises driving, by means of ambient

wind, a wind turbine apparatus in accordance with the present

invention mounted in a duct by ambient wind so as to cause

blades of the wind turbine to be cooled and to thereby cool

ambient wind air passing through the duct and the wind turbine,

and causing water vapour in the ambient wind air to condense to

form liquid water, and collecting the liquid water.

[0004] In accordance with a yet further aspect of

the present invention there is provided a wind turbine having at

least one blade mounted to a compressor housing mounted on a

shaft for axial rotation relative to the shaft, and means for

conducting compressed refrigerant outward centrifugally and

means for returning the refrigerant centripetally through the or

each blade with loss of pressure and change of phase from liquid

to gas so as to cool the or each blade.

DESCRIPTION OF THE DRAWINGS

[0005] The present invention will now be

described, by way of example, with reference to the accompanying

drawings, in which:

[0006] FIG. 1 is a schematic plan view of

a wind turbine of the present invention showing a single turbine

blade;

[0007] FIG. 2 is a further schematic plan

view similar to FIG. 1 showing a plurality of turbine blades;

[0008] FIG. 3 is a schematic side

elevation of a first embodiment of an apparatus to convey air in

accordance with the present invention;

[0009]

FIG. 4 is a view similar to FIG. 3 showing a

second embodiment of an apparatus of the present invention;

[0010] FIG. 5 is a side elevation of a

third embodiment of an apparatus of the present invention;

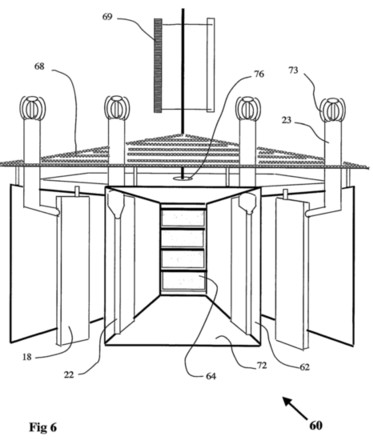

[0011] FIG. 6 is a plan view of a further

embodiment of a wind turbine of the present invention as used in

the third embodiment of apparatus illustrated in FIG. 5;

[0012] FIG. 7 is a side elevation of a

fourth embodiment of an apparatus of the present invention;

[0013] FIG. 8 is a plan view of a yet

further embodiment of a wind turbine of the present invention

used in the fourth embodiment of apparatus illustrated in FIG.

7;

[0014] FIG. 9 is a schematic side

elevation of a compressor used in the air cooling apparatus of

the present invention;

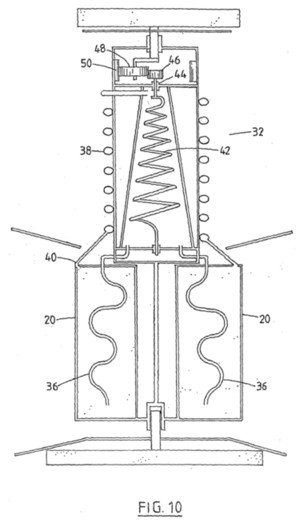

[0015] FIG. 10 is a schematic

side-elevation of a further embodiment of a compressor used in

the air cooling apparatus of the present invention;

[0016] FIGS. 11a, b, c and d are various

views of the compressor of FIG. 10;

[0017] FIG. 12 is a schematic side

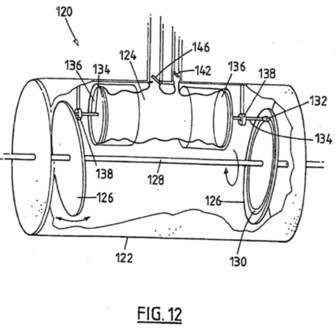

elevation of a yet further embodiment of a compressor used in

the air cooling apparatus of the present invention;

[0018] FIG. 13 is a view similar to FIG. 3

showing a fifth embodiment of an apparatus of the present

invention;

[0019] FIGS. 14A, 14B and 14C show

schematically a scroll refrigerant compressor useful in the

present invention in various positions;

[0020] FIG. 15A is a plan view of an

alternative form of scroll compressor useful in the present

invention; and

[0021] FIG. 15B is a side view of the

scroll compressor of FIG. 15A.

DESCRIPTION OF THE INVENTION

[0022] In FIG. 1 of the accompanying drawings,

there is shown a wind turbine apparatus 10 comprising a central

shaft 12 having a compressor 13 comprising a housing 14 mounted

thereabout. The compressor housing 14 is arranged to rotate

axially relative to the shaft 12. Further, a plurality of

turbine blades 16 (only one of which is shown) are mounted to

the compressor housing 14. As shown, a tube 18 extends outwardly

from the housing 14 to a peripheral cooling coil 20. A

convoluted pipe 22 extends from the cooling coil 20 back to the

housing 14. There is a constriction 23 at a part in the pipe 22

adjacent the cooling coil 20.

[0023] In use, the turbine blade 16 is caused to

rotate axially about the shaft 12 by the kinetic energy of

ambient wind air. Rotation of the blade 16 causes rotation of

the compressor housing 14 and refrigerant in the compressor

housing 14 to be compressed so as to undergo a phase change from

gas to liquid. The compressed liquid refrigerant flows outwardly

driven by the compressor and assisted by centrifugal force along

the tube 18 to the cooling coil 20 which acts as a manifold.

[0024] As shown, the refrigerant has to travel

almost in a complete circle to reach the pipe 22. This enables

the compressed refrigerant to be cooled during its residence in

the cooling coil 20.

[0025] The refrigerant leaves the cooling coil 20

through the constriction 23 which leads into the pipe 22. At

this point the refrigerant undergoes a rapid loss of pressure

and thus evaporates back to the gaseous phase and causes the

blade 16 to be cooled. The spent refrigerant then passes

centripetally back to the housing 14 on a low pressure line of

the compressor 13.

[0026] The cooling of the blade 16 causes ambient

wind air to be cooled which has useful effects as will be

described.

[0027] In FIG. 2, there is shown an apparatus 30

similar to that in FIG. 1. In FIG. 2 there can be seen a

plurality of turbine blades 16, a plurality of tubes 18, a

cooling coil 20 and a plurality of pipes 22. In this embodiment,

the compressed refrigerant passes along the tubes 18 to the

cooling coil 20. From the cooling coil 20 the compressed

refrigerant passes through a plurality of short tubes 28 to an

inner manifold 26. From the inner manifold 26 the compressed

refrigerant passes through the constrictions 23 into the tubes

22 as described hereinabove. Thus the compressed refrigerant

does not enter the tubes 22 directly and therefore is cooled by

its residence in the cooling coil 20 and the tubes 28 and the

inner manifold 26.

[0028] In FIG. 3, there is shown an apparatus 40

which comprises a wind turbine 10. There is also shown a

respective inner manifold 26 adjacent an outer end of each blade

16. The compressed liquid refrigerant passes initially from the

cooling coil 20 to each inner manifold 26 through short tubes

28. The refrigerant then passes through constrictions 23 into

the pipes 22 as described hereinabove.

[0029] Further, there is shown in FIG. 3, a wind

collecting duct 42 and an outlet condensation chamber 44. The

duct 42 includes an outer wide portion 46 and an inner

relatively narrow portion 48. The combination of the wide

portion 46 and the narrow portion 48 increases air velocity in

the duct 42.

[0030] Ambient wind air blowing in the direction

of an arrow 50 flows through the wind turbine 10 so as to cause

the latter to rotate such that the blades 16 are cooled. This

causes the air temperature to fall below the condensation point

or dew point and water vapour to condense from the ambient air

to form liquid water. This is enhanced by the presence of

baffles 52 which impede the flow of air and induce liquid water

to collect thereon. The liquid water flows from the baffles 52

onto a sloping floor portion 54 from which the liquid water

flows into a collection trough 56. The cooled air from which

water has been removed is exhausted through an upper outlet 58.

As can be seen in FIG. 3, the coil 20 is located externally of

the duct 42 so that heat lost from the compressed refrigerant is

dispersed into the ambient air rather than inside the duct 42.

[0031] In FIG. 4, there is shown an apparatus 60

similar to that in FIG. 3, except that an inlet 62 is lowermost

and is provided with flaps 64. In this case, the flaps 64 are

only opened, as shown, on the windward side of the apparatus 60.

Wind air flows upwardly through the turbine 10 and then through

a condensation chamber 66 to exhaust through a top vent 68. Once

again liquid water collects on baffles 52 and then flows along a

sloping floor 54 to collect in a trough 56.

[0032] In FIG. 5, there is shown an apparatus 70

similar to that in FIG. 4, except that the exhaust vent 68 is

provided with an additional wind turbine 72 to reduce pressure

in the exhaust vent 68 and enhance removal of exhaust air. Power

obtained from the wind turbine is available for any useful

purpose.

[0033] In FIG. 6, there is shown a wind turbine 10

having wind guides 62 with flaps 64 between adjacent pairs of

wind guides 62. The flaps 64 are arranged to be opened as shown

by the wider oblong shape when the flaps face in the direction

of the ambient wind.

[0034] In FIG. 7, there is shown an alternative

form of the apparatus of the present invention

[0035] In this Figure there is shown an apparatus

80 having a funnel 82 at an intermediate level and a downwardly

directed deviation device 84. The device 84 is arranged to pivot

about a substantially vertical axis so as to orientate itself,

in use, into a position which is most effective in directing the

ambient wind air through a wind turbine 10. Cooled air can then

enter a condensation chamber 86 below the wind turbine 10 and

deposit moisture on baffles 88. The deposited moisture can then

flow into a collection trough 90. The cooled air depleted of

moisture can then pass upwardly to an upper vent 92.

[0036] In FIG. 8, there is shown a wind turbine 10

similar to that shown in FIG. 7. As shown, the device 84 faces

the incoming ambient wind. The wind air is directed into the

wind turbine 10.

[0037] In FIG. 9, there is shown a preferred form

of compressor 90 of the present invention. The compressor 90 has

a central rotating cylindrical hub or housing 92 on which is

mounted the blades 16 and refrigerant carrying tubes of the wind

turbine 10 as described herein. The compressor 90 includes

compressor blades 94 mounted on a drive shaft 96. The blades 94

are arranged to be driven at high speed by a gear train 98

fitted to an inner wall of the hub 92. Used refrigerant

returning centripetally to the compressor 90 as described above

is recompressed and sent out centrifugally as described above.

[0038] In FIG. 10 there is shown an alternative

form of compressor 100 mounted within a cylindrical hub or

housing 102. In this embodiment refrigerant is displaced by a

roller 104 mounted eccentrically on a shaft 106 relative to a

main shaft 108 of the compressor 100.

[0039] As shown in FIGS. 11a, 11b, 11c and 11d,

the compressor 100 operates as follows. The compressor 100

comprises a central shaft 101 having an eccentric 102 mounted

thereon. A rotatable housing 103 is mounted about the eccentric

102. A tube 104 leads away from the housing 103 and a pipe 105

leads into the housing 103. A spring biased vane 106 extends

through a wall of the housing 103 and contacts an outer surface

of the eccentric 102. Rotation of the housing 103 causes

refrigerant contained therein to be compressed and exited

through the tube 104. Similarly, used refrigerant returns to the

housing 103 through the pipe 105. This is facilitated by the

vane 106 which is spring biased into engagement with the outer

surface of the eccentric 102.

[0040] In FIG. 12 there is shown a further

alternative form of compressor 120 mounted within a cylindrical

hub 122. In this embodiment refrigerant is contained in an

elastic chamber 124. The chamber 124 is alternately contracted

and expanded. This is done by eccentric discs 126 fixedly

mounted on a central shaft 128. Each disc 126 has a circular

channel 130 formed on an inner side thereof A slidable bearing

132 is mounted in each channel 130. A respective rod 134 extends

from each bearing 132 to a respective end plate 136 of the

chamber 124. Each rod 134 is constrained by a circular guide

member 138.

[0041] In use, a hub 122 rotates axially about the

shaft 128 and the chamber 124 rotates with the hub 122. This

movement causes the bearings 132 to slide in the channels 130

and the rods 134 to reciprocate correspondingly in the guide

member 138. In this way the chamber 124 is expanded and

retracted so alternately compressing and driving out compressed

refrigerant through a one way valve 140 and allowing ingress of

used refrigerant through a one way valve 142.

[0042] In FIG. 13, there is shown a wind turbine

apparatus 130 which is similar to that shown in FIGS. 4 and 5.

In this embodiment, wind funnels 132 are arranged to direct

ambient wind air over a water surface 134. The water may be

brackish or fresh water. The wind air then passes upwardly

through an upright tube 136 (or a sloping duct on a hillside) to

pass through a wind turbine 10 and thence a condensation chamber

138 having baffles 52 and a sloping floor 54 from which water

flows into a collection trough 56. Exhaust air is vented through

an outlet 58. Absolute humidity of air entering the apparatus

130 increases and the density of the air is therefore lowered.

Thus, flow of air due to the wind is augmented by convection as

the wet air rises to the wind turbine 10.

[0043] It is also envisaged that the refrigeration

compressor used in the apparatus of the present inventions could

be in the form of a scroll compressor.

[0044] This embodiment of the present invention is

illustrated in FIGS. 14A, 14B and 14C of the accompanying

drawings.

[0045] In FIG. 14 there is shown a scroll

compressor 150 having a housing 151 having mounted therein a

circular plate 152. Further, an internal ring gear 154 mounted

on a wind turbine axial shaft (not shown) extends around the

internal periphery of the housing 151. Turbine blades 16 are

mounted to the housing 151 and cause wind to effect axial

rotation of the housing 151 on a fixed shaft (not shown).

[0046] The housing 151 is rotated, in use, by

rotation of blades of a wind turbine as described hereinabove.

[0047] As indicated above, the scroll compressor

150 is mounted on a bearing on the fixed axial shaft (not

shown). One scroll 156 is attached to the housing 151 whilst

another 158 is driven by three planetary gears 160 mounted on

the housing 151 disposed at the apex of an equilateral triangle.

The gears 160 are driven by the ring gear 154. The scroll 158

maybe described as a wobbling scroll.

[0048] The gears 160 are asymmetrically connected

to the plate 152 by means of respective pivotal connections 162.

In use the housing 151 is axially rotated by the wind turbine.

This causes the planetary gears to be turned by engagement with

the fixed ring gear 154. This causes the ring gear 154 to rotate

and thereby cause rotation of the planetary gears 160. Rotation

of the planetary gears 160 causes the plate 152 to move in a

wobbling motion which causes the scroll 158 to move

correspondingly.

[0049] As shown in FIGS. 14A to 14C this causes

gaps between the two scrolls 156 and 158 to be alternately

opened up and closed in a progressive manner. This action leads

to compression of refrigerant vapour contained between the

scrolls such that the vapour is subjected to increased pressure

and is converted-to liquid form.

[0050] As described hereinabove, the compressed

liquid refrigerant is thus urged outwardly of the compressor

housing 151 through a tube (not shown) by centrifugal-force.

Further, as described hereinabove, the spent refrigerant returns

through pipes (not shown) to the interior of housing 151 where

it enters the gap between the scrolls 156 and 158.

[0051] In FIGS. 15A and 15B there is shown an

alternative arrangement of scroll compressor 180 useful in the

present invention compared to the scroll compressor of FIG. 14.

Like reference numerals denote like parts. It should be noted in

FIG. 15A that only the scroll 158 is shown.

[0052] In this embodiment there is a central shaft

182 having mounted thereon a housing 184. The housing is mounted

on a bearing on the shaft 182. The shaft 182 may or may not be

continuous. A central gear wheel 186 is fixedly mounted about

the shaft 182. The gear wheel 186 is connected to three

planetary gears 188.

[0053] Further, as can be seen in FIG. 15B one

scroll 156 is fixed to the housing 184 by any suitable means

such as an end plate (not shown). The other scroll 158 is

mounted on an end plate 190 and is connected to the planetary

gears 188 through eccentric pins 192.

[0054] The shaft 182 and the gear wheel 186 are

fixed in position. The housing 184 is arranged to rotate about

the shaft 182 as described hereinabove. The planetary gears 188

engage with the gear wheel 186 and are thereby caused to rotate

as the housing 184 rotates. This rotation of the planetary gears

188 causes the scroll 158 to move on the plates 190 by means of

the pins 192 such that the scroll 158 undergoes a wobbly motion

as described hereinabove.

[0055] Modifications and variations as would be

apparent to a skilled addressee are deemed to be within the

scope of the present invention.

http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=EP1907637&F=0

GUST WATER TRAP APPARATUS

EP1907637

2008-04-09

Also published as: WO2007009184 (A1) // EP1907637 (A0) //

AU2006272459

http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=WO2007098534&F=0

APPARATUS FOR PURIFICATION OF WATER

WO2007098534

2007-09-07

Apparatus for purification or water having an evaporation

chamber (3), a roof (5) and a condensation chamber (8) and wind

air inlet means (14, 15). The evaporation chamber (3) contains a

body of impure water (2) and the roof (5) can transmit solar

radiation. The solar radiation heats the impure water, increases

evaporation and wind air from the wind air inlet (14, 15) moves

the water laden air into the condensation chamber (8) where

water condenses.

CROSS-AXIS WIND TURBINE ENERGY CONVERTER

WO2007068054

2007-06-21

The invention relates to a wind energy converter apparatus (10)

which comprises an incoming wind guide (12), a cross-axis wind

turbine (18), a wind containing region (16) and a wind outlet

(24). Preferably, means is provided for cooling the wind air to

enhance precipitation of moisture from the wind air in the

apparatus.

Apparatus and method for cooling of air

AU2005274673

CN101014817